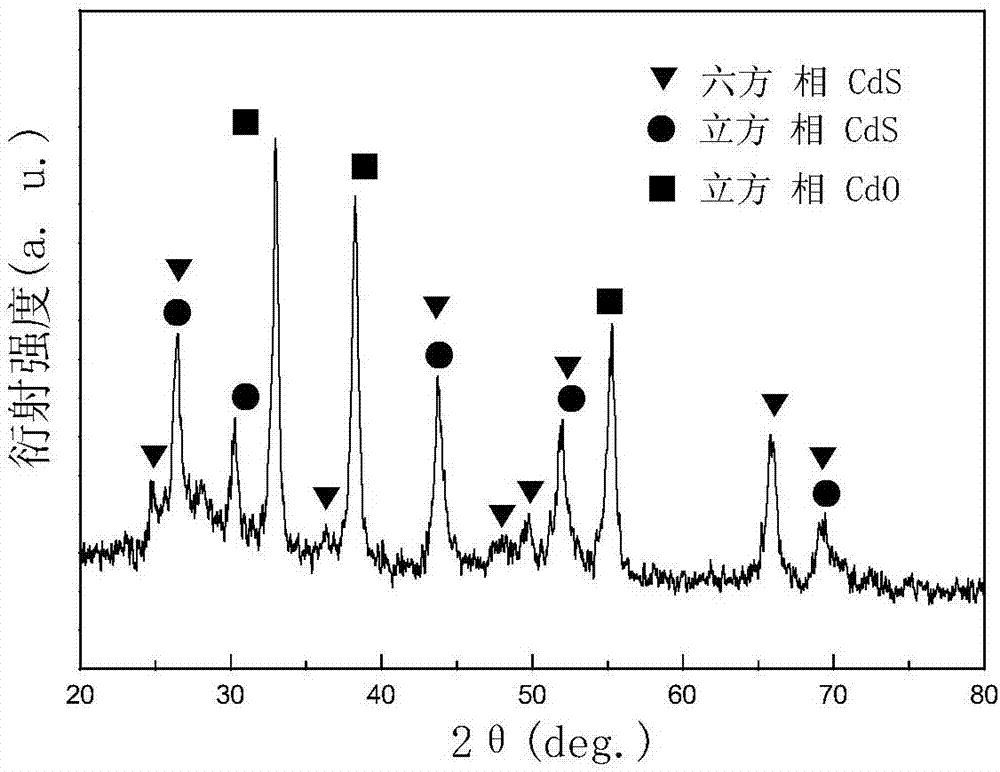

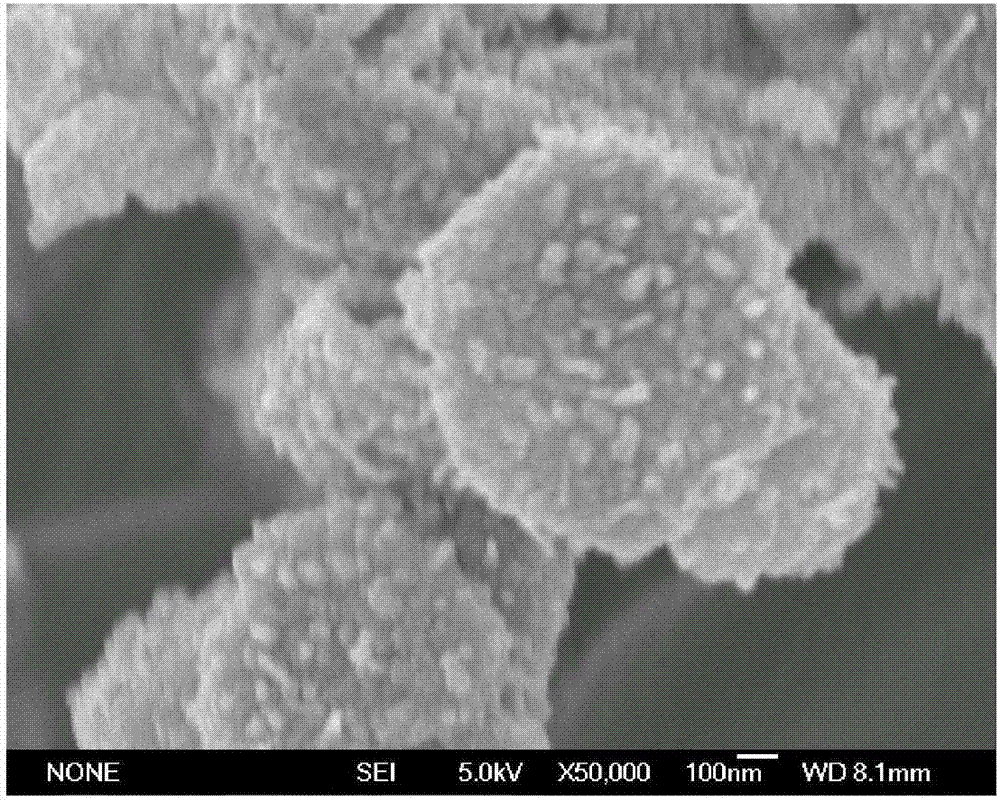

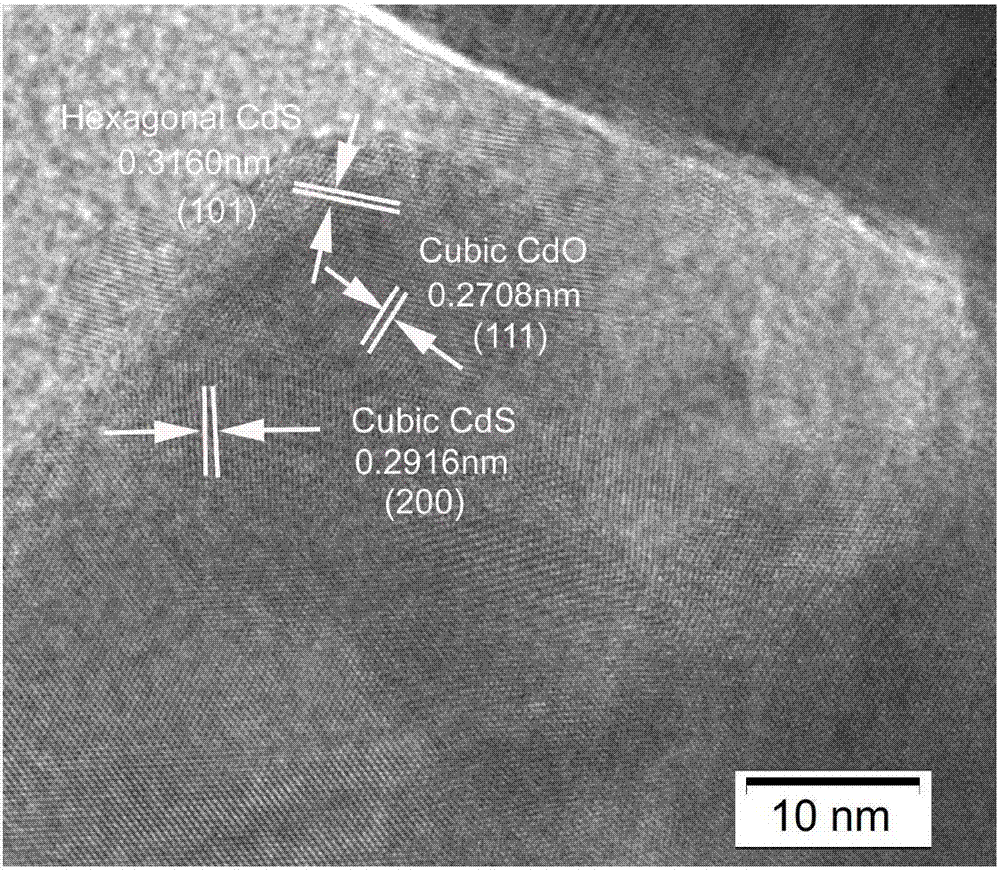

Method for simply preparing hexagonal CdO/CdS heterojunction nano composite material

A nanocomposite material and heterojunction technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Technical scheme of the present invention is as follows:

[0010] A preparation method of a hexagonal CdO / CdS heterojunction nanocomposite material, comprising the steps of:

[0011] (1) Cadmium nitrate is dissolved in dehydrated alcohol to form cadmium nitrate ethanol solution; Lithium hydroxide is dissolved in secondary distilled water to form lithium hydroxide solution; The mol ratio of described cadmium nitrate and lithium hydroxide is 1 : 2.4~2.6, under the condition of stirring, lithium hydroxide solution is added dropwise in the cadmium nitrate ethanol solution to form a uniform mixed solution, continue to stir for 50~60min, then stand still at 26~29°C for 5~6h, Transfer to a reaction kettle and react at 180-200°C for 10-12 hours; the obtained product is washed and dried to obtain a cadmium hydroxide precursor; the prepared cadmium hydroxide precursor is placed in a muffle furnace, Roasting at 300°C for 1.5-2 hours to obtain nano-cadmium oxide;

[0012] (2) Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com