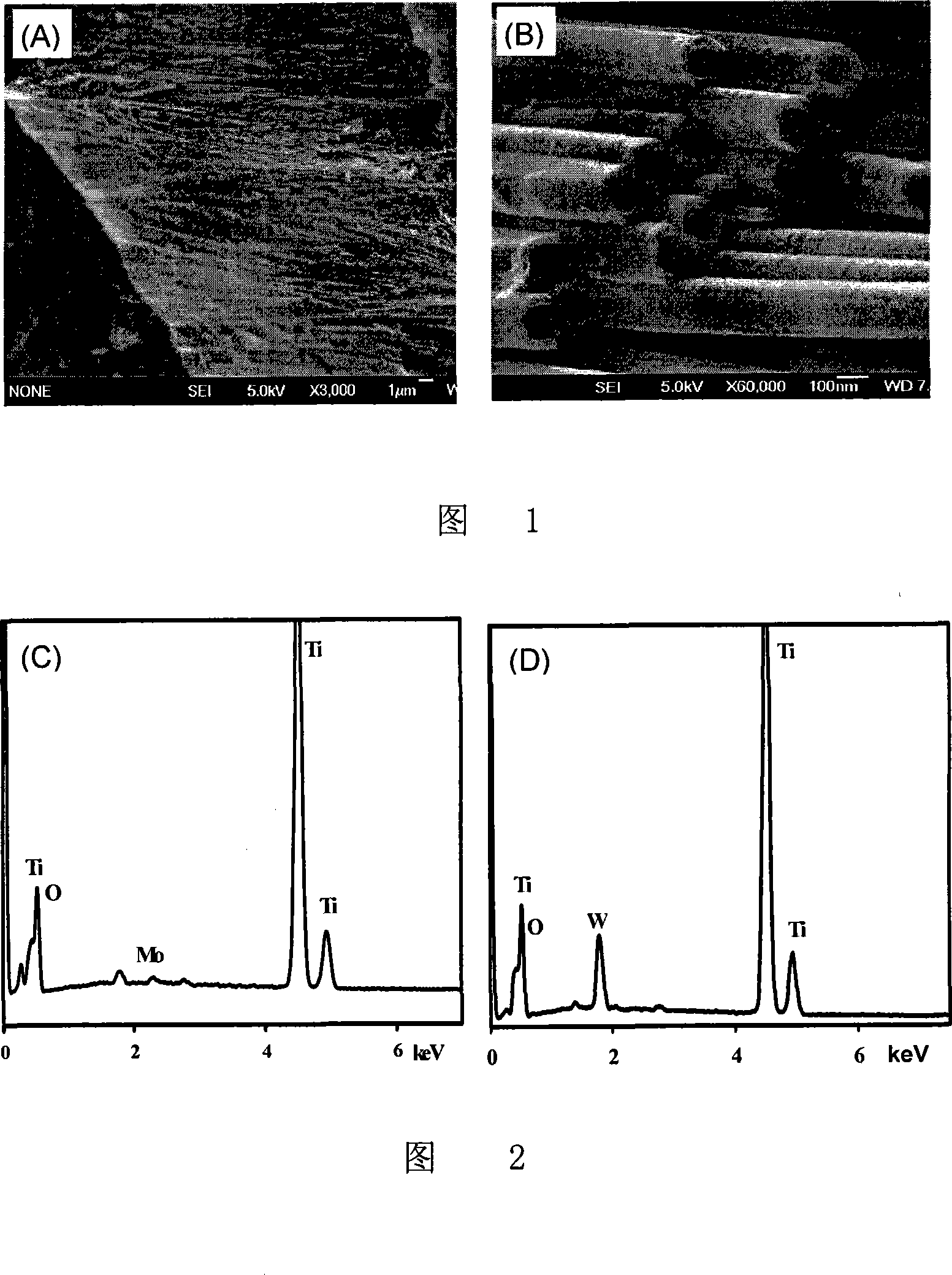

Method for producing titanium dioxide nano tube array with molybdenum tungsten doped anodizing method

An anodic oxidation method, nanotube array technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrolytic coating, etc., can solve the problems of only absorption, insufficient specific surface area, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Grinding the surface of the base material, cleaning it for later use;

[0020] (2) Preparation of organic electrolyte:

[0021] Measure 1.47mL of 40% hydrofluoric acid (HF) solution by mass, mix it evenly with 28.53mL of anhydrous dimethyl sulfoxide (DMSO), and prepare a DMSO solution with 2% by mass of HF ;

[0022] (3) Preparation of titanium oxide nanotube arrays: use a titanium sheet (0.3*1.8cm) with a purity of more than 99.9% as an anode, and a platinum sheet (0.5*1cm) as a cathode, and electrolyze it for 24 hours under a DC voltage of 60V to produce Nanotubes with a length of 35 microns were obtained;

[0023] (4) Preparation of titanium dioxide nanotube arrays doped with tungsten and molybdenum:

[0024] (a). Dissolve 1g of tungsten powder or molybdenum powder in 15mL of 30% H 2 o 2 , stirred in ice bath for 10h, to obtain WO 3 or MoO 3 with O 2 2- It is the clear solution of chelating agent, then add 15mL absolute ethanol solution to the above clea...

Embodiment 2

[0028] (1) Grinding the surface of the base material, cleaning it for later use;

[0029] (2) Preparation of organic electrolyte:

[0030] (a). Measure 2.21mL of 40% hydrofluoric acid (HF) solution by mass, mix it with 27.79mL of anhydrous dimethyl sulfoxide (DMSO), and prepare 3% by mass of HF % DMSO solution;

[0031] (3) Preparation of titanium oxide nanotube arrays: use a titanium sheet (0.3*1.8cm) with a purity of more than 99.9% as an anode, and a platinum sheet (0.5*1cm) as a cathode, and electrolyze it for 24 hours under a DC voltage of 40V to produce Nanotubes with a length of 8 microns were obtained.

[0032] (4) Preparation of titanium dioxide nanotube arrays doped with tungsten and molybdenum:

[0033] (a). Dissolve 1g of tungsten powder or molybdenum powder in 15mL of 30% H 2 o 2 , stirred in ice bath for 10h, to obtain WO 3 or MoO 3 with O 2 2- It is the clear solution of chelating agent, then add 15mL absolute ethanol solution to the above clear solutio...

Embodiment 3

[0037] (1) Grinding the surface of the base material, cleaning it for later use;

[0038] (2) Preparation of organic electrolyte:

[0039] (a). Measure 0.375mL of 40% hydrofluoric acid (HF) solution by mass, mix it with 29.625mL of anhydrous dimethyl sulfoxide (DMSO), and prepare 0.5% by mass of HF % DMSO solution;

[0040] (3) Preparation of titanium oxide nanotube arrays: use a titanium sheet (0.3*1.8cm) with a purity of more than 99.9% as an anode, and a platinum sheet (0.5*1cm) as a cathode, and electrolyze it for 12 hours under a DC voltage of 30V to produce nanotubes with a length of 2 microns.

[0041] (4) Preparation of titanium dioxide nanotube arrays doped with tungsten and molybdenum:

[0042] (a). Dissolve 1g of tungsten powder or molybdenum powder in 15mL of 30% H 2 o 2 , stirred in ice bath for 10h, to obtain WO 3 or MoO 3 with O 2 2- It is the clear solution of chelating agent, then add 15mL absolute ethanol solution to the above clear solution;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com