Preparation method of manganese monoxide/nitrogen-doped reduced graphene oxide composite electrode material

A graphene composite, manganese monoxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity and structural instability, and achieve improved conductivity, increased active sites, and improved electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) adding manganese acetate tetrahydrate and urea into water respectively with magnetic stirring to make them uniformly mixed to prepare a mixed solution with a mass fraction of manganese acetate of 3.5% and a mass fraction of urea of 4.6%;

[0024] 2) Take 30mg of graphene oxide and add it to 30ml of mixed solution, under stirring, with ultrasonic power of 60W, ultrasonically disperse for 2h to obtain a mixture;

[0025] 3) Transfer the mixture obtained in step 2) to a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 120° C. for 12 hours;

[0026] 4) After filtering the hydrothermal reaction product obtained in step 3), it is washed alternately with deionized water, absolute ethanol and acetone, and then dried;

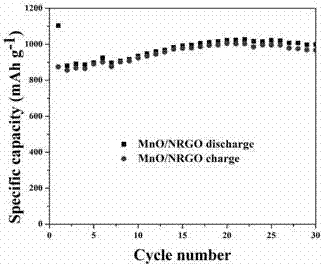

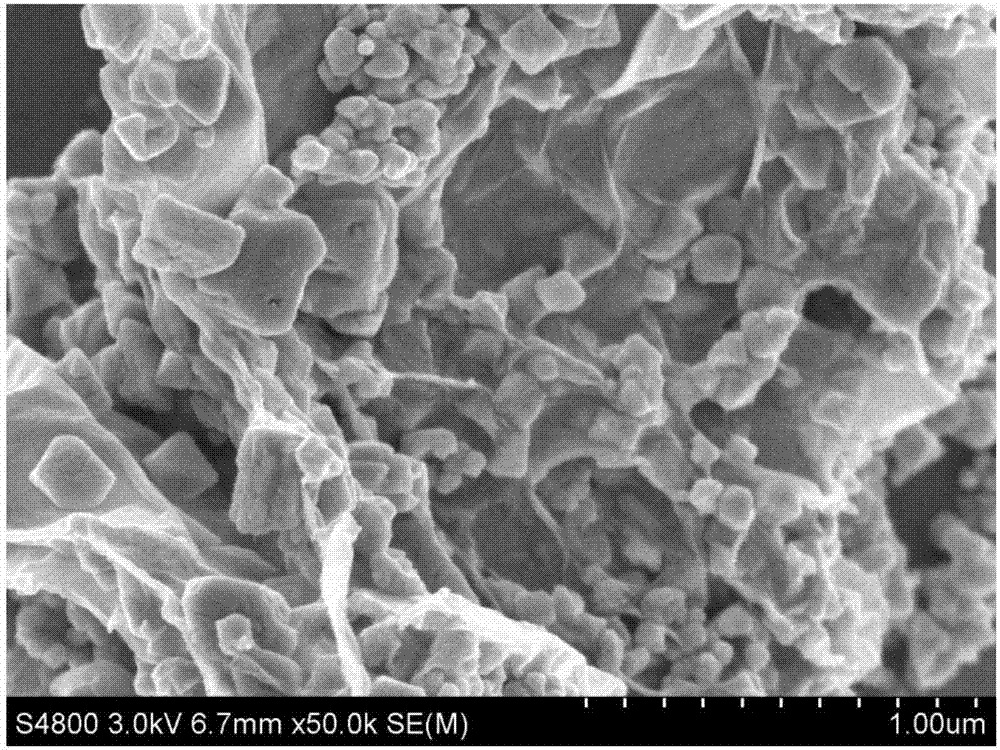

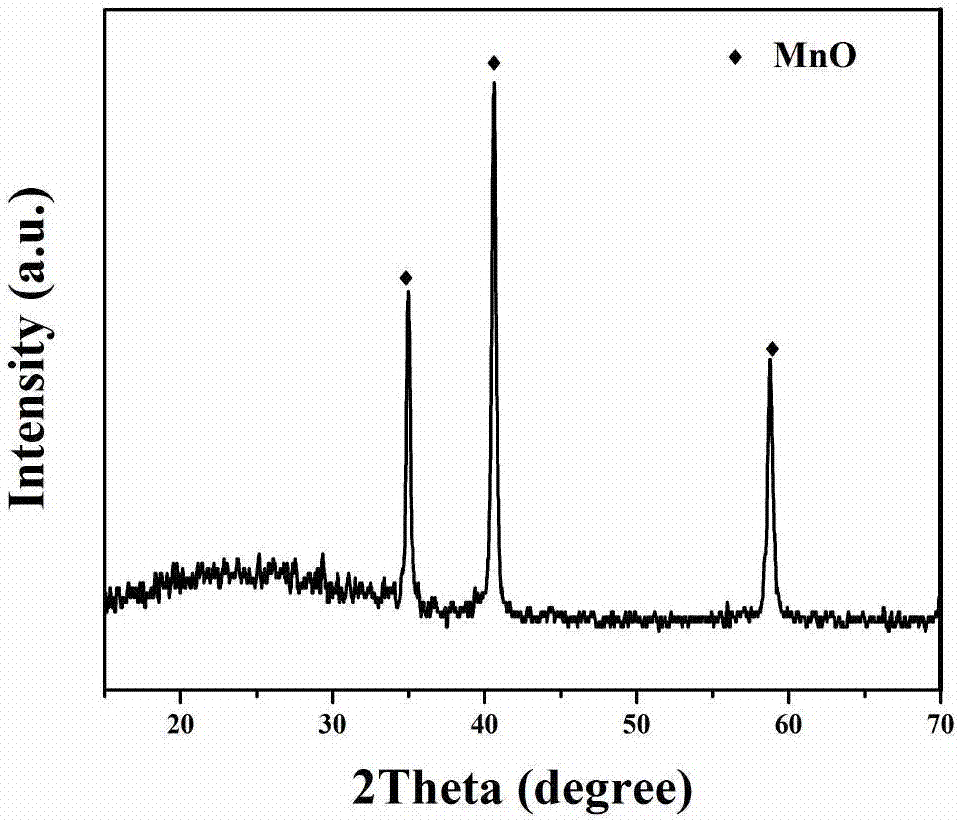

[0027] 5) The product obtained in step 4) was heat-treated at 400°C for 5h in an argon atmosphere to obtain a solid form of manganese monoxide / nitrogen doped reduction with a particle size of 100nm on which granular MnO was loaded on a...

Embodiment 2

[0032] 1) adding manganese acetate tetrahydrate and urea into water respectively with magnetic stirring to make them evenly mixed to prepare a mixed solution with a mass fraction of manganese acetate of 4.5% and a mass fraction of urea of 4.0%;

[0033] 2) Take 70mg of graphene oxide and add it to 50ml of the mixed solution, under stirring, with ultrasonic power of 70W, ultrasonically disperse for 3h to obtain a mixture;

[0034] 3) Transfer the mixture obtained in step 2) to a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 120° C. for 6 hours;

[0035] 4) After filtering the hydrothermal reaction product obtained in step 3), it is washed alternately with deionized water, absolute ethanol and acetone, and then dried;

[0036] 5) The product obtained in step 4) was heat-treated at 400°C for 4h in an argon atmosphere to obtain a solid shape of granular MnO supported on a graphene sheet, with a particle size of 100nm manganese monoxide / nitrogen doped re...

Embodiment 3

[0038] 1) adding manganese acetate tetrahydrate and urea into water respectively with magnetic stirring to make them evenly mixed to prepare a mixed solution with a mass fraction of manganese acetate of 5.0% and a mass fraction of urea of 3.5%;

[0039] 2) Take 50mg of graphene oxide and add it to 60ml of mixed solution, under stirring, with ultrasonic power of 80W, ultrasonically disperse for 2h to obtain a mixture;

[0040] 3) Transfer the mixture obtained in step 2) to a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 150° C. for 10 h;

[0041]4) After filtering the hydrothermal reaction product obtained in step 3), it is washed alternately with deionized water, absolute ethanol and acetone, and then dried;

[0042] 5) The product obtained in step 4) was heat-treated at 500°C for 3h in an argon atmosphere to obtain a solid form of manganese monoxide / nitrogen doped reduction with a particle size of 100nm on a graphene sheet in the form of granular M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com