Unsaturated acetate catalyst and preparation method thereof

A catalyst and unsaturated technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low activity and selectivity of unsaturated acetate, and achieve improved selectivity and good technical effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

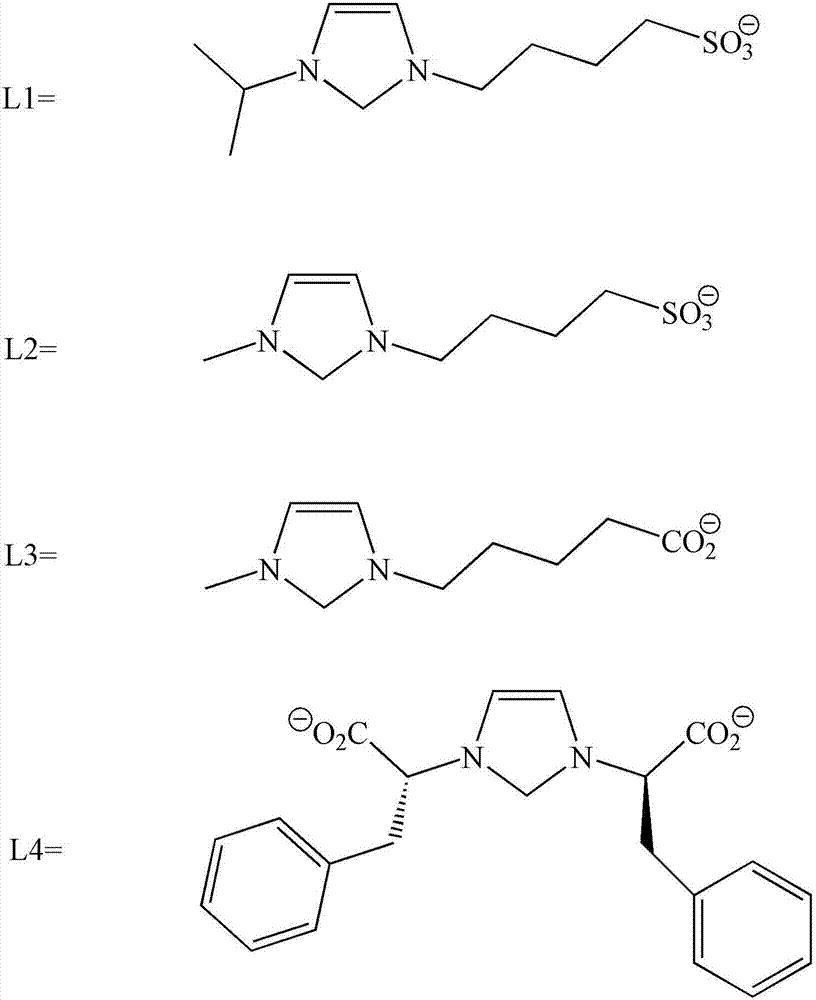

Image

Examples

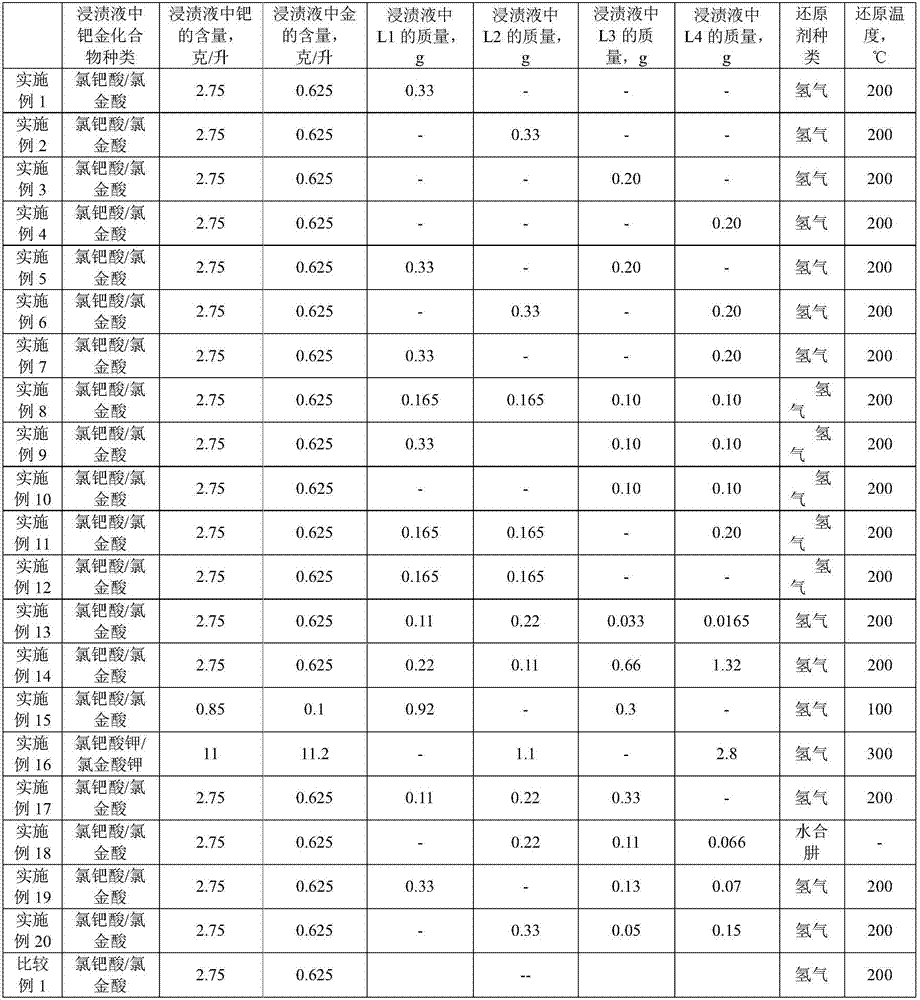

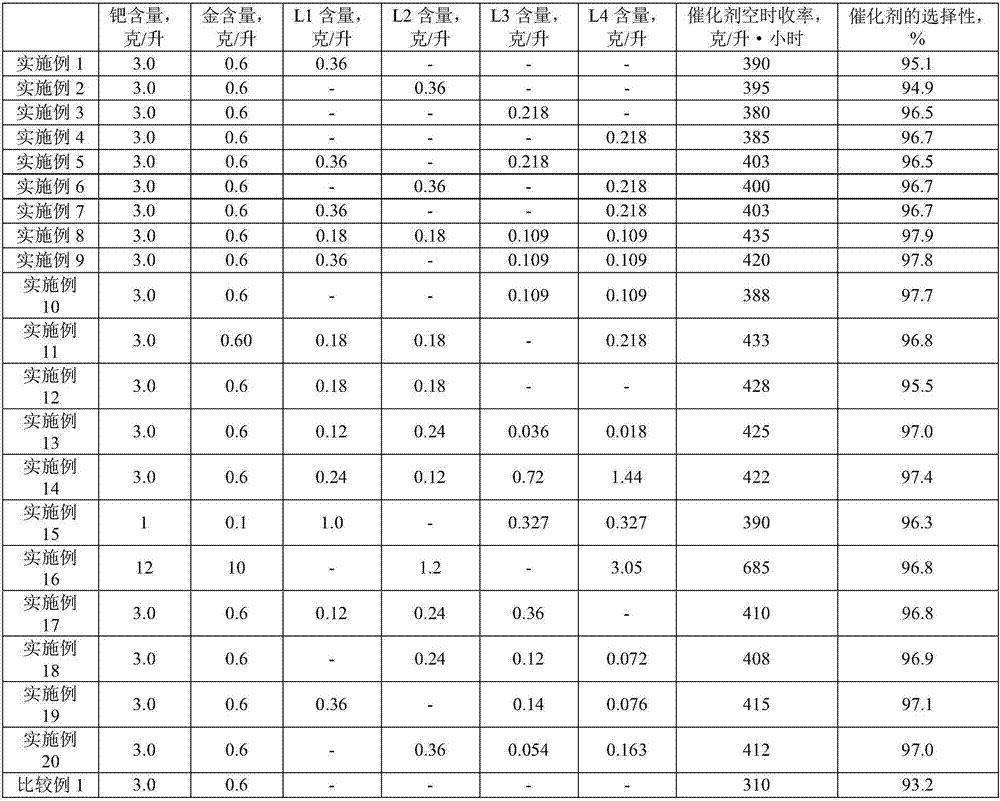

Embodiment 1

[0030] (1) Catalyst preparation

[0031] Step (a): get the solution 1200ml that contains chloropalladic acid and chloroauric acid, wherein the content of palladium in the solution is 2.75 grams per liter, and the content of gold is 0.625 grams per liter, adding a volume of 1100ml and a diameter of 5.0mm spherical silica carrier to obtain catalyst precursor I;

[0032] Step (b): 27.5g of sodium silicate nonahydrate was formulated into 100ml of aqueous solution and added to catalyst precursor I, mixed uniformly, left standing for 24hr, and then dried at 80°C for 8hr to prepare catalyst precursor II;

[0033] Step (c): reducing the catalyst precursor II in a hydrogen atmosphere, the hydrogen flow rate is 0.2ml / min, the pressure is 0.5MPa, and the reduction temperature is 200°C to obtain the catalyst precursor III;

[0034] Step (d): take 1200ml of potassium acetate aqueous solution, wherein the content of potassium acetate is 27.5 g / L, and add L1 with a mass of 0.33 g to the abo...

Embodiment 2

[0049] (1) Catalyst preparation

[0050] Step (a): get the solution 1200ml that contains chloropalladic acid and chloroauric acid, wherein the content of palladium in the solution is 2.75 grams per liter, and the content of gold is 0.625 grams per liter, adding a volume of 1100ml and a diameter of 5.0mm spherical silica carrier to obtain catalyst precursor I;

[0051] Step (b): 27.5g of sodium silicate nonahydrate was formulated into 100ml of aqueous solution and added to catalyst precursor I, mixed uniformly, left standing for 24hr, and then dried at 80°C for 8hr to prepare catalyst precursor II;

[0052] Step (c): reducing the catalyst precursor II in a hydrogen atmosphere, the hydrogen flow rate is 0.2ml / min, the pressure is 0.5MPa, and the reduction temperature is 200°C to obtain the catalyst precursor III;

[0053] Step (d): take 1200ml potassium acetate aqueous solution, wherein potassium acetate content is 27.5 grams / liter, add the L2 that quality is 0.33g in above-men...

Embodiment 3

[0056] (1) Catalyst preparation

[0057] Step (a): get the solution 1200ml that contains chloropalladic acid and chloroauric acid, wherein the content of palladium in the solution is 2.75 grams per liter, and the content of gold is 0.625 grams per liter, adding a volume of 1100ml and a diameter of 5.0mm spherical silica carrier to obtain catalyst precursor I;

[0058] Step (b): 27.5g of sodium silicate nonahydrate was formulated into 100ml of aqueous solution and added to catalyst precursor I, mixed uniformly, left standing for 24hr, and then dried at 80°C for 8hr to prepare catalyst precursor II;

[0059] Step (c): reducing the catalyst precursor II in a hydrogen atmosphere, the hydrogen flow rate is 0.2ml / min, the pressure is 0.5MPa, and the reduction temperature is 200°C to obtain the catalyst precursor III;

[0060] Step (d): take 1200ml of potassium acetate aqueous solution, wherein the content of potassium acetate is 27.5 g / L, and add L3 with a mass of 0.20 g to the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com