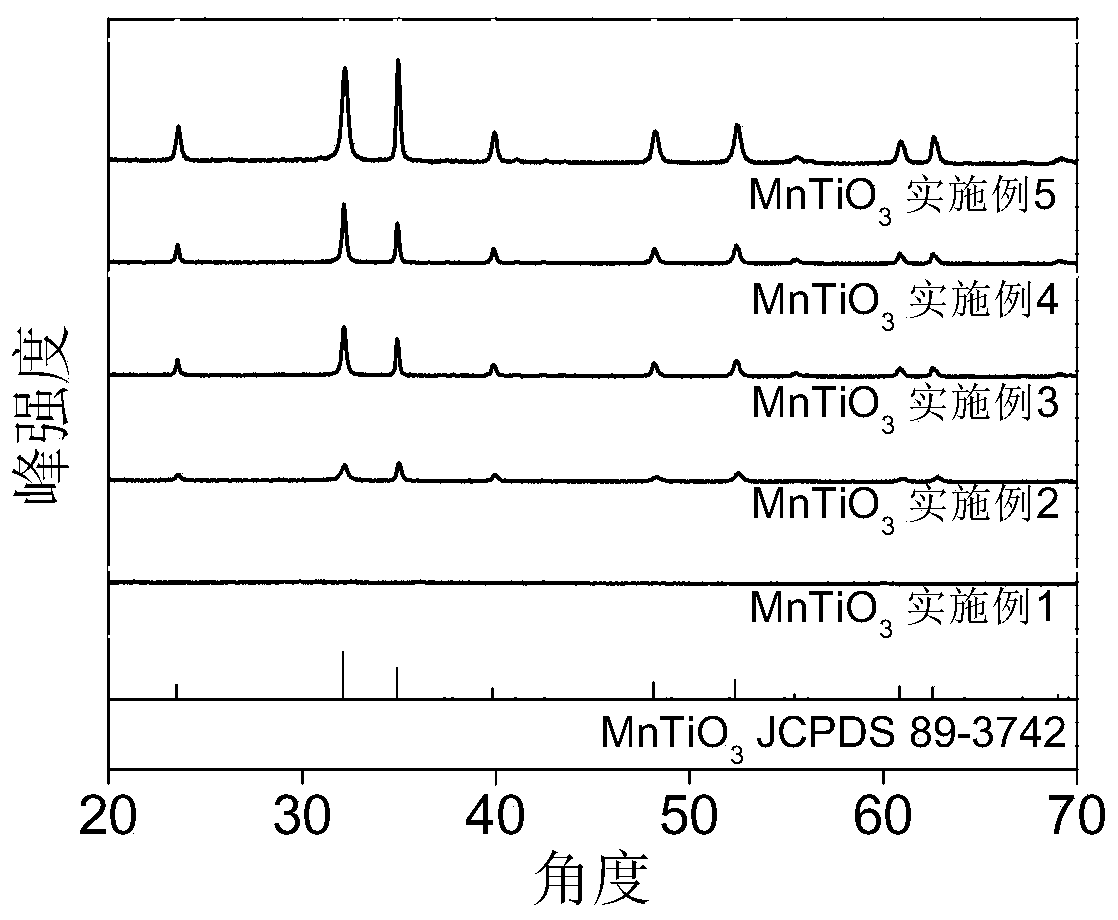

A kind of preparation method and application of manganese titanate nano sheet material

A technology of manganese titanate nano and sheet materials, which is applied in the direction of nanotechnology, chemical instruments and methods, manganese compounds, etc., can solve the problems of few surface active sites and large particle size of manganese titanate, and achieve rich surface active centers and particles And the effect of uniform particle size and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: the preparation method of manganese titanate nano sheet material of this embodiment comprises the following steps:

[0037] 1. Dissolving manganese salt and titanium salt in deionized water to obtain manganese salt and titanium salt solution;

[0038] Two, organic base is then dissolved in the manganese salt and titanium salt solution that step one obtains, as shape control agent;

[0039] 3. Dissolving caustic alkali in deionized water to form a caustic alkali solution, and then adding the caustic alkali solution to the manganese salt and titanium salt solutions to react to form manganese and titanium hydroxide precursors;

[0040] 4. Transfer the manganese-titanium hydroxide precursor obtained in step 3 into a hydrothermal kettle, and heat at 100-220°C for 5-15 hours to obtain manganese titanate nanosheet materials with different shapes;

[0041] 5. After washing and drying the manganese titanate nanosheet material, the finished product is ob...

specific Embodiment approach 2

[0043] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the titanium salt tetrabutyl titanate, isopropyl titanate, titanium oxysulfate, hexafluorotitanic acid, potassium fluorotitanate, fluorine The concentration of titanium in ammonium titanate, tetraethyl titanate, titanium tetrachloride, titanium sulfate, titanium trichloride or potassium titanium oxalate, manganese salt and titanium salt solution is 5mmol / L-20mmol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentration of titanium in the manganese salt and titanium salt solutions is 10 mmol / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com