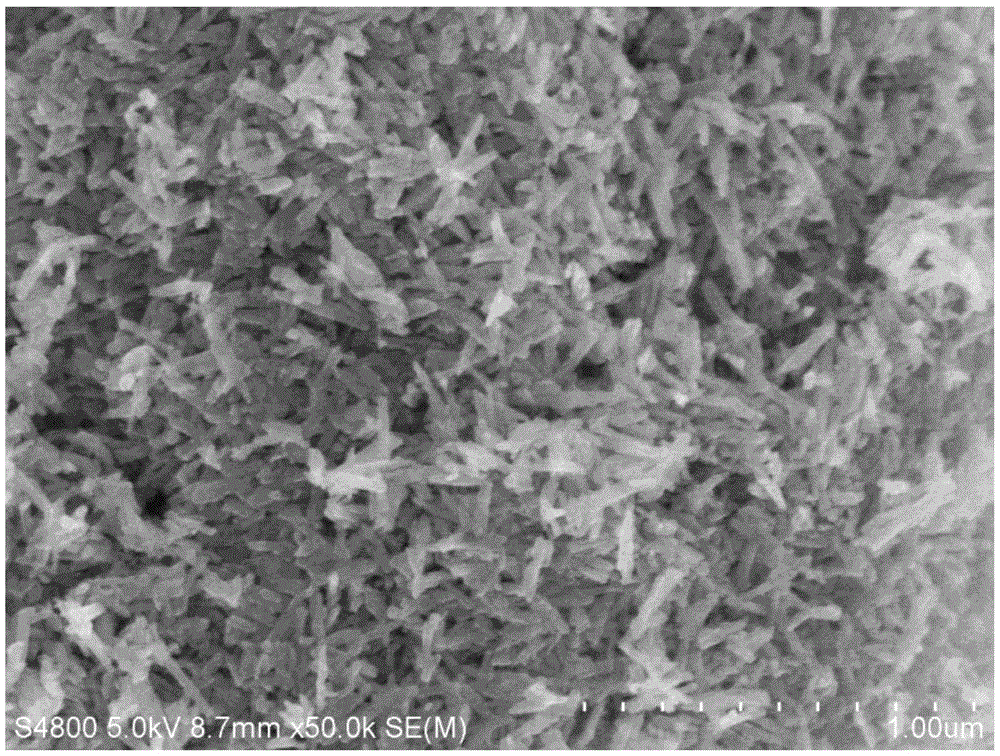

Nanorod-like low-temperature denitration catalyst and preparation method thereof

A nano-rod-shaped, low-temperature denitration technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of high cost, pollution caused by production and use, and difficult disposal of waste catalysts. To achieve the effect of improving activity, uniform distribution, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A nanorod-shaped low-temperature denitration catalyst, the preparation method of which comprises the following steps:

[0033] 1) After mixing tetra-n-butyl titanate, absolute ethanol, glacial acetic acid and ethyl acetoacetate evenly, add template agent (the molar ratio of hexadecyltrimethylammonium bromide and polyethylene glycol 600 is 1: 0.3), stir evenly to get TiO 2 Sol, wherein the molar ratio of tetrabutyl titanate, absolute ethanol, glacial acetic acid, ethyl acetoacetate and templating agent is 1:3:0.5:0.3:0.5;

[0034] 2) Dissolve manganese acetate hydrate in distilled water to prepare manganese acetate solution, wherein the molar ratio of manganese acetate tetra-n-butyl titanate is 0.35:1, the concentration of manganese acetate solution is 0.5mol / L, manganese acetate and tetrabutyl titanate The molar ratio of the Mn element and the Ti element introduced by the ester is 0.3; under stirring conditions, the manganese acetate solution will be dripped into the T...

Embodiment 2

[0042] A nanorod-shaped low-temperature denitration catalyst, the preparation method of which comprises the following steps:

[0043] 1) After mixing tetra-n-butyl titanate, absolute ethanol, glacial acetic acid and ethyl acetoacetate evenly, add template agent (the molar ratio of hexadecyltrimethylammonium bromide and polyethylene glycol 600 is 1: 0.4), stir evenly to get TiO 2 Sol, wherein the molar ratio of tetrabutyl titanate, absolute ethanol, glacial acetic acid, ethyl acetoacetate and templating agent is 1:3.5:0.6:0.4:1.0;

[0044] 2) Dissolve manganese acetate hydrate in distilled water to prepare manganese acetate solution, wherein the molar ratio of manganese acetate to tetra-n-butyl titanate is 0.4:1, the concentration of manganese acetate solution is 0.5mol / L, manganese acetate and tetra-n-butyl titanate The molar ratio of the Mn element and the Ti element introduced by butyl ester respectively is 0.4; 2 In the sol, the dropping speed is 2 seconds / drop, and the s...

Embodiment 3

[0051] A nanorod-shaped low-temperature denitration catalyst, the preparation method of which comprises the following steps:

[0052] 1) After mixing tetra-n-butyl titanate, absolute ethanol, glacial acetic acid and ethyl acetoacetate evenly, add template agent (the molar ratio of hexadecyltrimethylammonium bromide and polyethylene glycol 600 is 1: 0.5), stir evenly to get TiO 2 Sol, wherein the molar ratio of tetrabutyl titanate, absolute ethanol, glacial acetic acid and ethyl acetoacetate and templating agent is 1:4:0.7:0.5:1.5;

[0053] 2) Dissolve manganese acetate hydrate in distilled water to prepare manganese acetate solution, wherein the molar ratio of manganese acetate to tetra-n-butyl titanate is 0.45:1, the concentration of manganese acetate solution is 0.5mol / L, manganese acetate and tetra-n-butyl titanate The molar ratio of Mn element and Ti element that butyl ester introduces respectively is 0.5; Under agitation condition, will drop by constant pressure dropping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com