Carboxylated porous polystyrene microspheres and preparation method thereof

A porous polystyrene and carboxylation technology, applied in the field of polymer microspheres, can solve the problems of unsatisfactory swelling effect, uneven distribution of functional groups, uneven size of microspheres, etc., and achieves good mechanical properties, uniform size, Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

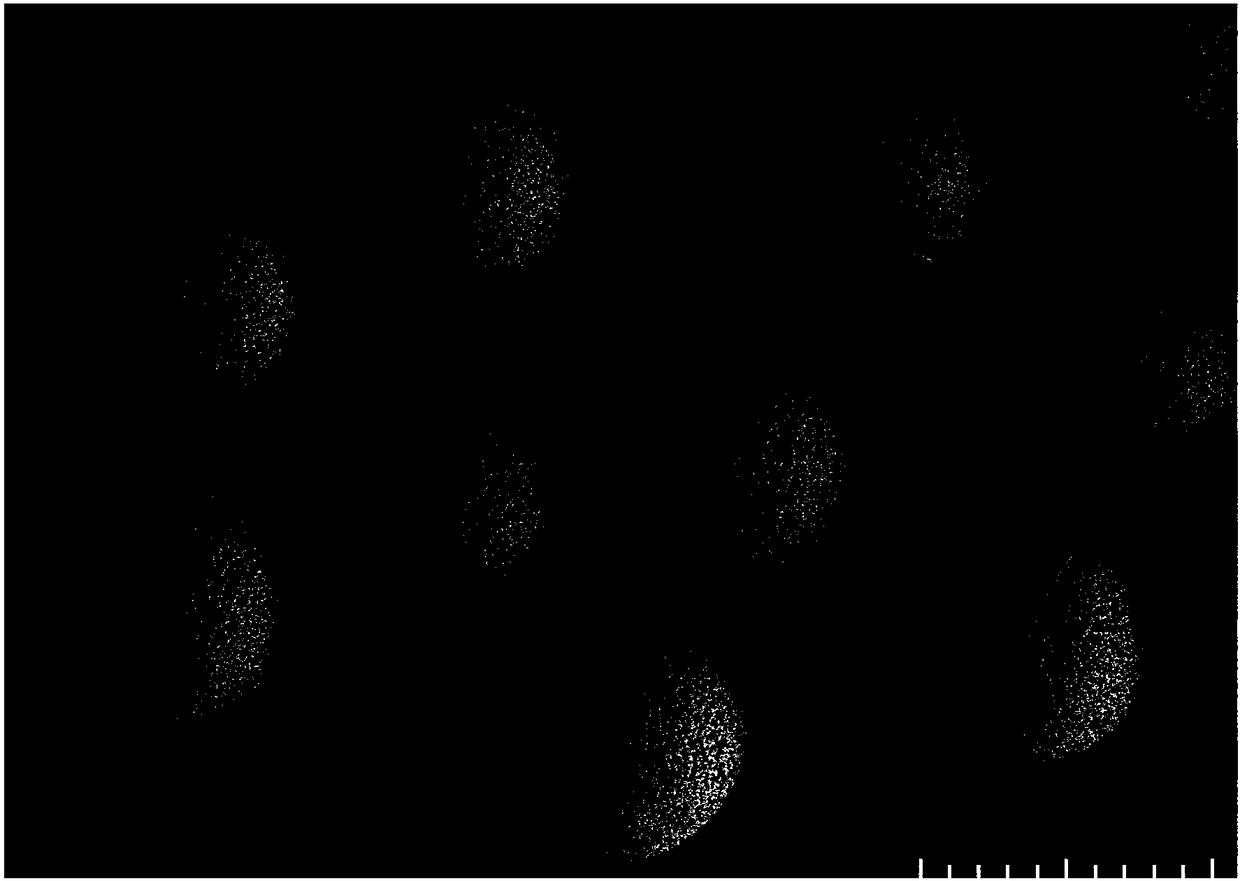

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing carboxylated porous polystyrene microspheres, including:

[0044] 1) Take 2mL polystyrene seed microsphere solution (mass volume fraction 5% (w / v), solvent 0.25wt% SDS solution) and ultrasonically disperse it in 25mL sodium dodecyl sulfate SDS aqueous solution, take 128 μL cyclohexane ultrasonic Emulsified and dispersed in 15mL SDS aqueous solution, and added dropwise to the above dispersed seed microsphere solution, mixed with magnetic stirring and swelled at temperature T=30°C for 6h;

[0045] 2) Dissolve 0.1g of dibenzoyl peroxide BPO in 11mL of styrene, add 9.5mL of ethylene glycol dimethacrylate EGDMA, 0.5mL of methacrylic acid MAA, and 11.5mL of toluene in sequence, mix well and then add In the reaction system obtained in step 1), add 80 mL of SDS aqueous solution to it, and continue to swell for 10 h at a temperature T=30° C.;

[0046]3) Add 2 g of PVP, 400 μL of methylene blue aqueous solution, and 80 mL of ultrap...

Embodiment 2

[0050] This embodiment provides a kind of preparation method of carboxylated porous polystyrene microspheres, comprising:

[0051] 1) Get 2mL divinylbenzene cross-linked polystyrene microsphere solution (5% by mass volume fraction (w / v), solvent 0.25wt% SDS solution) and ultrasonically disperse in 25mL sodium dodecyl sulfate SDS aqueous solution, take 128 μL of cyclohexane was ultrasonically emulsified and dispersed in 15 mL of SDS aqueous solution, and added dropwise to the above dispersed seed microsphere solution, mixed with magnetic stirring and swelled at temperature T=30°C for 6 hours;

[0052] 2) Dissolve 0.1g of dibenzoyl peroxide BPO in 11mL of styrene, add 9.5mL of ethylene glycol dimethacrylate EGDMA, 0.5mL of methacrylic acid MAA, and 11.5mL of toluene in sequence, mix well and then add In the reaction system obtained in step 1), add 80 mL of SDS aqueous solution to it, and continue to swell for 10 h at a temperature T=30° C.;

[0053] 3) Add 2 g of PVP, 400 μL of...

Embodiment 3

[0057] This embodiment provides a kind of preparation method of carboxylated porous polystyrene microspheres, comprising:

[0058] 1) Take 2mL polystyrene seed microsphere solution (mass volume fraction 5% (w / v), solvent 0.25wt% SDS solution) and ultrasonically disperse it in 25mL sodium dodecyl sulfate SDS aqueous solution, take 128 μL cyclohexane ultrasonic Emulsified and dispersed in 15mL SDS aqueous solution, and added dropwise to the above dispersed seed microsphere solution, mixed with magnetic stirring and swelled at temperature T=40°C for 3h;

[0059] 2) Dissolve 0.1g of dibenzoyl peroxide BPO in 11mL of styrene, add 9.5mL of ethylene glycol dimethacrylate EGDMA, 0.5mL of methacrylic acid MAA, and 11.5mL of toluene in sequence, mix well and then add In the reaction system obtained in step 1), add 80 mL of SDS aqueous solution to it, and continue to swell for 20 h at a temperature T=40° C.;

[0060] 3) Add 2 g of PVP, 400 μL of methylene blue aqueous solution, and 80 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com