Magnetic porous bentonite chitosan composite microsphere and preparation method thereof

A technology of composite microspheres and bentonite, applied in chemical instruments and methods, radioactive purification, alkali metal compounds, etc., can solve the problems of complex preparation process, long operation time, and difficult control, and achieve large adsorption capacity and easy solid-liquid separation , the effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

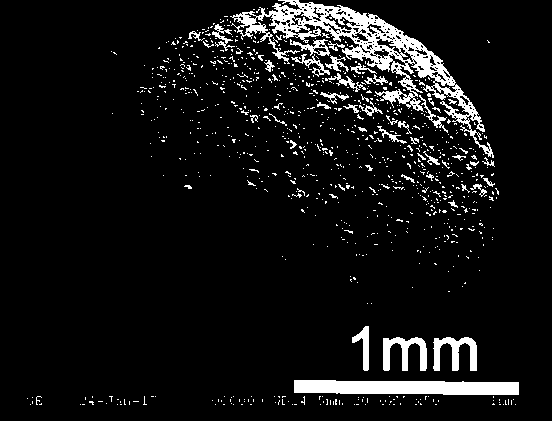

Image

Examples

Embodiment 1

[0049] A magnetic porous bentonite-chitosan composite microsphere, comprising the following raw materials in parts by weight: 1 part of bentonite, 1 part of acetic acid, 1 part of chitosan, 1 part of ferric chloride hexahydrate, and 1 part of ferrous chloride tetrahydrate 1 part, 10 parts of sodium hydroxide, 5 parts of sodium citrate and 200 parts of water.

Embodiment 2

[0051] A magnetic porous bentonite-chitosan composite microsphere, comprising the following raw materials in parts by weight: 5 parts of bentonite, 3 parts of acetic acid, 3 parts of chitosan, 3 parts of ferric chloride hexahydrate, and ferrous chloride tetrahydrate 2 parts, 12 parts of sodium hydroxide, 8 parts of sodium citrate and 220 parts of water.

Embodiment 3

[0053] A magnetic porous bentonite-chitosan composite microsphere, comprising the following raw materials in parts by weight: 10 parts of bentonite, 5 parts of acetic acid, 3 parts of chitosan, 6 parts of ferric chloride hexahydrate, and ferrous chloride tetrahydrate 3 parts, 15 parts of sodium hydroxide, 10 parts of sodium citrate and 250 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com