Method for synthesizing nano silicon dioxide modified PVDF (polyvinylidene fluoride) hydrophobic microporous membrane in situ

A nano-silica, in-situ synthesis technology, applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of reduced membrane flux, poor dispersion, easy to block membrane pores, etc., to improve the microstructure, improve Dispersibility, effect of increasing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

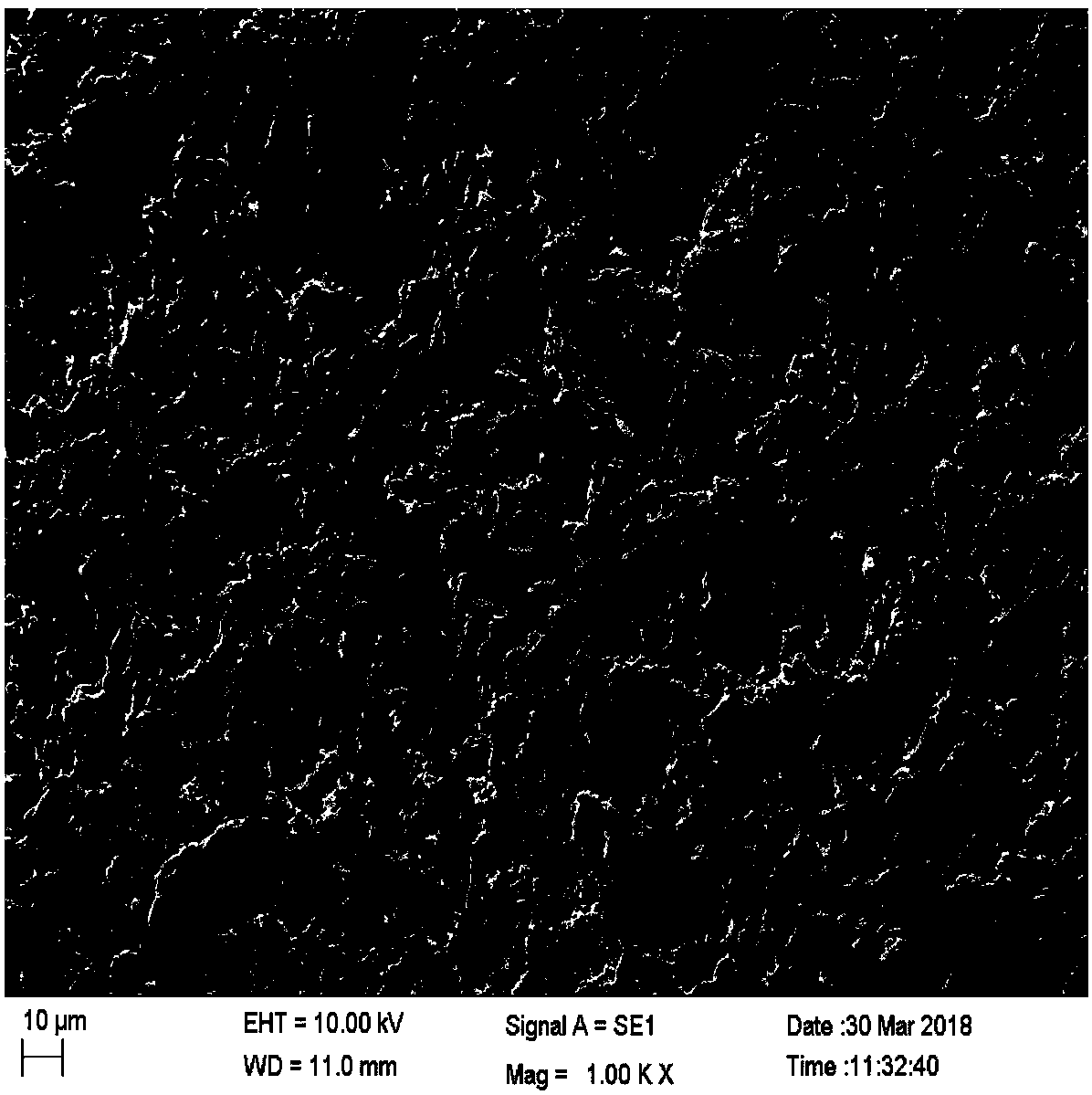

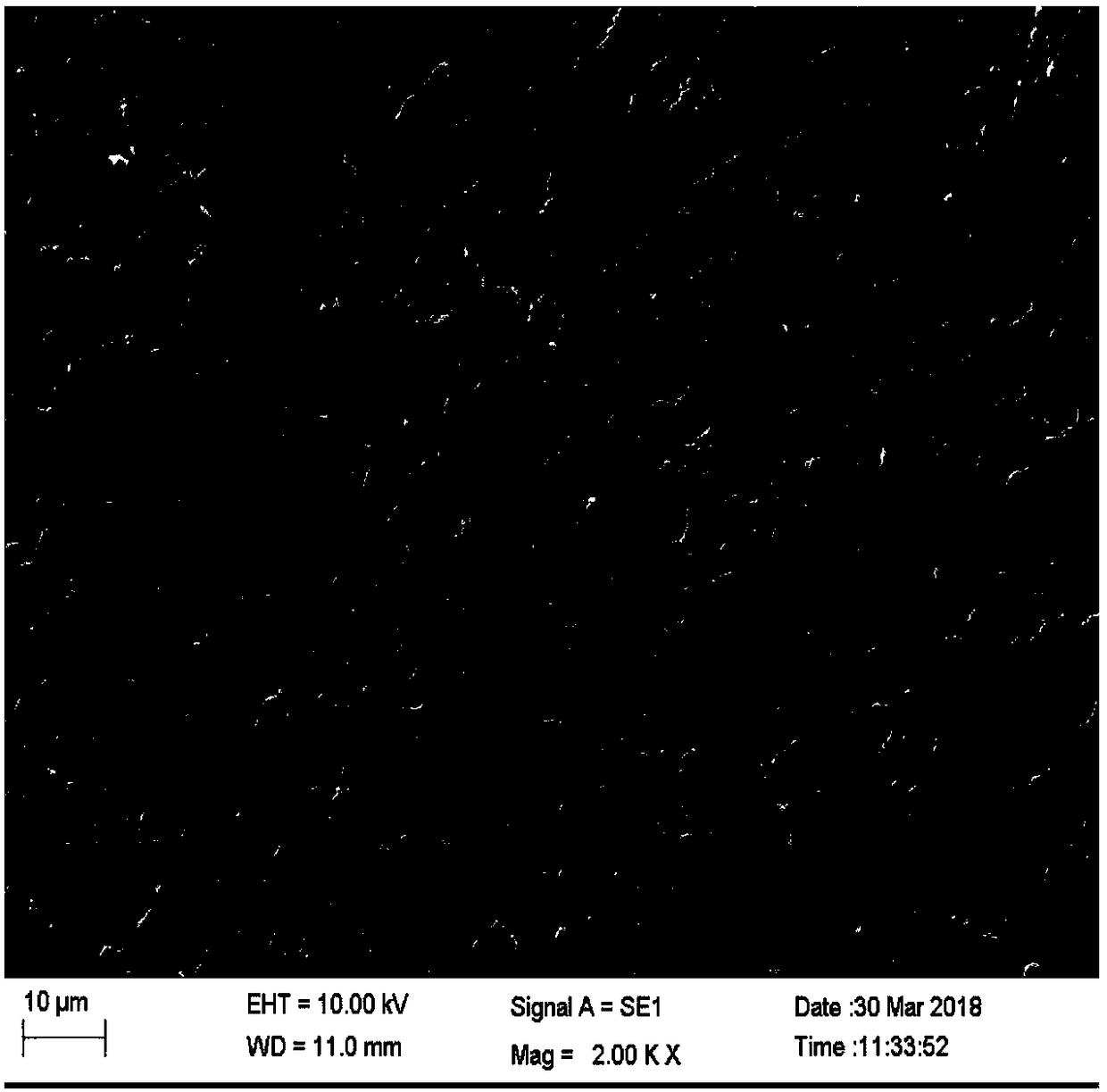

Image

Examples

Embodiment 1

[0049] A method for in-situ synthesis of nano silicon dioxide modified PVDF hydrophobic microporous membrane, comprising the following steps:

[0050] (1) Preparation of PVDF solution: PVDF powder is mixed with dispersing solvent I, stirred uniformly to obtain PVDF solution; the mass ratio of the PVDF powder and dispersing solvent I is 3:17; the dispersing solvent I is N, N- Dimethylacetamide; the stirring speed is 400r / min, the temperature is 52°C, and the stirring time is 1.1h;

[0051] (2) Prepare a solution containing nano-silica: add absolute ethanol, hydrochloric acid, water to the magnetic stirring container, magnetically stir and mix evenly, then quickly drop the ethanol solution that is dissolved with ethyl orthosilicate, after the dropwise addition is completed Under the condition of 25°C, the in-situ synthesis reaction was carried out for 4h to obtain a solution containing nano silicon dioxide; the volume ratio of tetraethyl orthosilicate, water, hydrochloric acid a...

Embodiment 2

[0056] A method for in-situ synthesis of nano silicon dioxide modified PVDF hydrophobic microporous membrane, comprising the following steps:

[0057] (1) Preparation of PVDF solution: PVDF powder is mixed with dispersing solvent I, and stirred evenly to obtain PVDF solution; the mass ratio of the PVDF powder and dispersing solvent I is 3:25; the dispersing solvent I is N, N- Dimethylformamide; the stirring speed is 600r / min, the temperature is 60°C, and the stirring time is 3h;

[0058] (2) Prepare a solution containing nano-silica: add absolute ethanol, hydrochloric acid, water to the magnetic stirring container, magnetically stir and mix evenly, then quickly drop the ethanol solution that is dissolved with ethyl orthosilicate, after the dropwise addition is completed Carry out the in-situ synthesis reaction at 58° C. for 10 h to obtain a solution containing nano-silica; the volume ratio of tetraethyl orthosilicate, water, hydrochloric acid and absolute ethanol is 1:10:1:1; ...

Embodiment 3

[0063] A method for in-situ synthesis of nano silicon dioxide modified PVDF hydrophobic microporous membrane, comprising the following steps:

[0064] (1) Preparation of PVDF solution: PVDF powder is mixed with dispersing solvent I and stirred evenly to obtain PVDF solution; the mass ratio of the PVDF powder and dispersing solvent I is 3:21; the dispersing solvent I is N-methyl Pyrrolidone; the stirring speed is 510r / min, the temperature is 55°C, and the stirring time is 2h;

[0065] (2) Prepare a solution containing nano-silica: add absolute ethanol, hydrochloric acid, water to the magnetic stirring container, magnetically stir and mix evenly, then quickly drop the ethanol solution that is dissolved with ethyl orthosilicate, after the dropwise addition is completed Under the conditions of 43° C., the in-situ synthesis reaction was carried out for 7 hours to obtain a solution containing nano silicon dioxide; the volume ratio of tetraethyl orthosilicate, water, hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com