High-strength polyimide nano fiber porous membrane, and preparation method and application thereof

A technology of polyimide and nanofibers, applied in textiles and papermaking, heating/cooling fabrics, non-woven fabrics, etc., can solve the problem of poor heat resistance of polyimide porous membrane, low mechanical properties of porous membrane, mechanical Low strength and other problems, to achieve the effect of improving mechanical properties, excellent thermal stability, and reducing thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

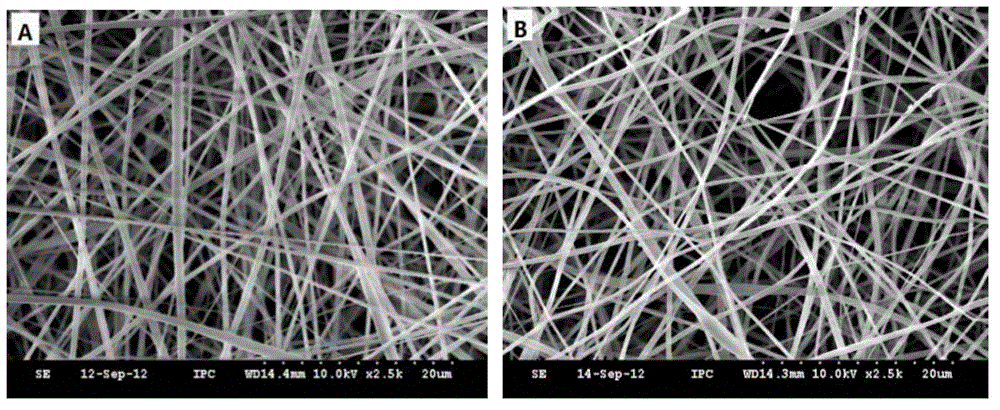

Image

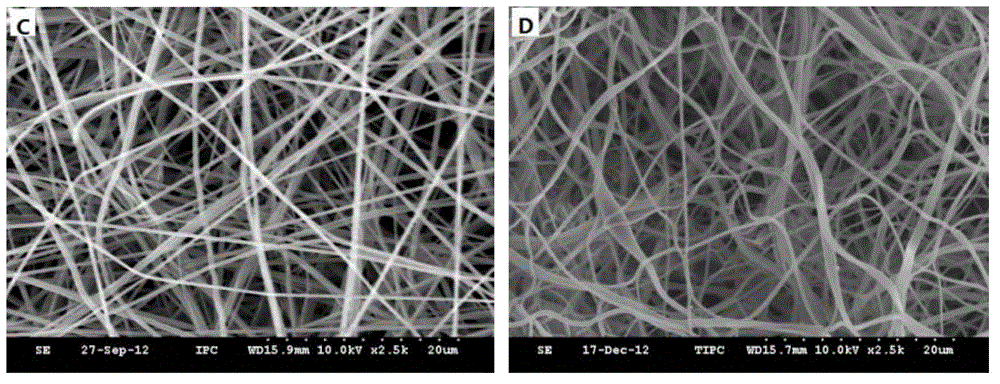

Examples

Embodiment 1

[0042] Synthesis of polyamic acid solution: according to the molar ratio of BTDA:ODA:DAPBI=10:10:0, first take a certain amount of 4,4'-diaminodiphenyl ether (ODA) and dissolve it in DMAc to make the total solid The content is 20%, and then mechanically stir it under the protection of nitrogen to dissolve it, and then add equimolar benzophenone tetra-acid dianhydride (BTDA) in batches, and make it continue to react for 5 hours under the nitrogen atmosphere below 25°C to obtain viscous thick polyamic acid solution. The polyamic acid solution was sealed and placed in a refrigerator for use, and its viscosity was measured to be 6.0 Pa·s after 24 hours.

[0043] Preparation of polyimide nanofiber porous membrane: The above polyamic acid solution was subjected to an electrospinning process in a high-voltage electric field of 100 kv / m, and the polyamic acid fiber porous membrane was received by a stainless steel roller. The obtained fibrous porous membrane was thermally imidized in...

Embodiment 2

[0046] The synthesis of polyamic acid solution: carry out by BTDA:ODA:DAPBI=10:4:6 molar ratio, at first adding ODA and DAPBI two kinds of diamine monomers that the molar ratio is 4:6 in the metered DMAc, make the total The solid content is 15%, and then mechanically stirred under the protection of nitrogen, and then BTDA equal to the total amount of the two diamines is added in batches, and the reaction is continued for 5 hours below 25°C in a nitrogen atmosphere to obtain a viscous polyamide acid solution. Seal the polyamic acid solution and place it in the refrigerator for use. After 24 hours, its viscosity was measured to be 4.4 Pa·s.

[0047] Preparation of the polyimide nanofiber porous membrane: the above polyamic acid solution was subjected to an electrospinning process in a high-voltage electric field of 80 kv / m, and the polyamic acid fiber porous membrane was received by a stainless steel roller. The obtained polyamic acid fiber porous membrane is subjected to therm...

Embodiment 3

[0050] The synthesis of polyamic acid solution: carry out by BTDA:ODA:DAPBI=10:6:4 molar ratio, at first adding ODA and DAPBI two kinds of diamine monomers that the molar ratio is 6:4 in the metered DMAc, make the total The solid content is 15%, and then mechanically stirred under the protection of nitrogen, and then BTDA equal to the total amount of the two diamines is added in batches, and the reaction is continued for 5 hours below 25°C in a nitrogen atmosphere to obtain a viscous polyamide acid solution. The polyamic acid solution was sealed and placed in a refrigerator for use, and its viscosity was measured to be 4.1 Pa·s after 24 hours.

[0051] Preparation of the polyimide nanofiber porous membrane: the above polyamic acid solution was subjected to an electrospinning process in a high-voltage electric field of 80 kv / m, and the polyamic acid fiber porous membrane was received by a stainless steel roller. The obtained polyamic acid fiber porous membrane is thermally imi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com