Non-medical nano-film filtering mask

A nano-membrane and nano-membrane layer technology, applied in the field of non-medical masks, can solve the problems of low reliability and durability of melt-blown cloth filter masks, poor protection effect, etc., achieve better filtering effect, and improve reliability and durability. , the effect of effective protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

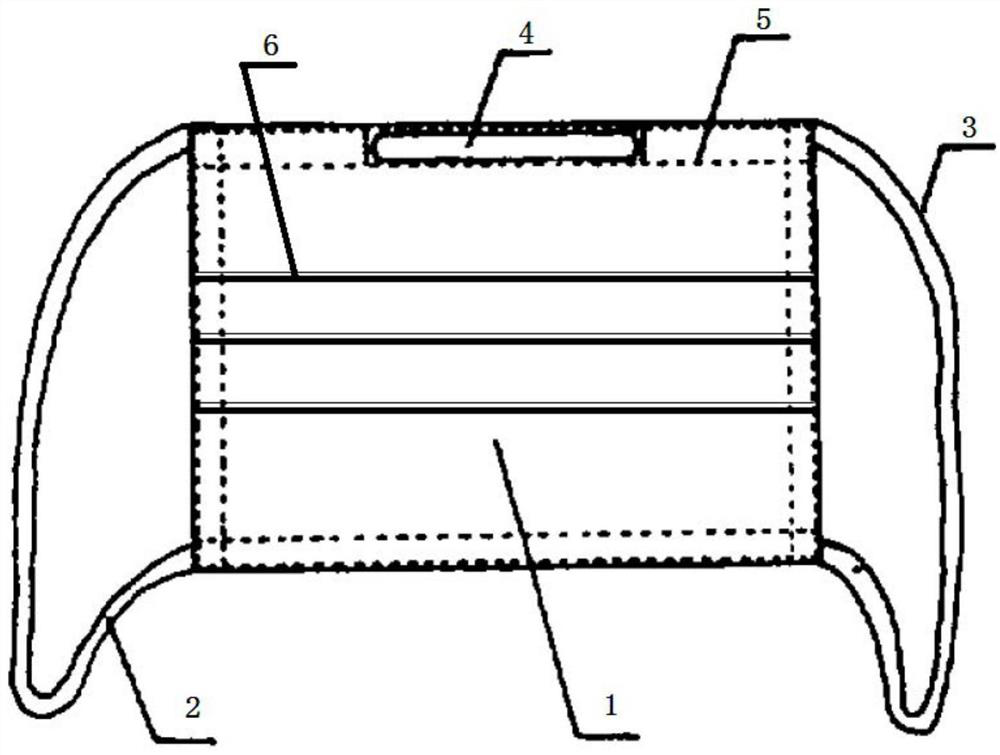

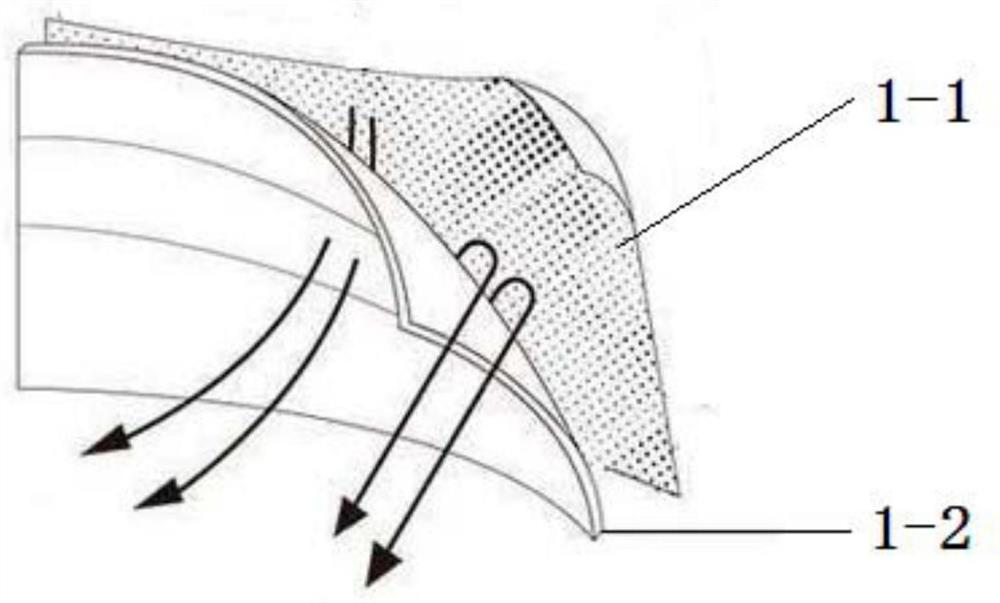

[0014] Combine below figure 1 and figure 2 Illustrate the present embodiment, it comprises mouth mask body 1, left ear strap 2 and right ear strap 3, mouth mask body 1 is made up of nano film layer 1-1, outer layer nonwoven fabric 1-2 and inner layer nonwoven fabric, The nano film layer 1-1 is attached to the outer surface of the outer non-woven fabric 1-2, and the thickness of the nano film layer 1-1 is 0.2mm. The outer layer non-woven fabric 1-2 and the inner layer non-woven fabric are fixed as a whole by punching line 5.

[0015] The nano-membrane layer is a PTFE membrane, and the PTFE membrane has a fibrillar microporous structure with a porosity of more than 85%, 1.4 billion micropores per square centimeter, and a pore diameter range of 0.02 μm-15 μm.

[0016] PTFE membrane technology has been used in clothing membranes, air filtration membranes, air purification membranes and other fields, but it has not yet been applied to the field of mask manufacturing. The fabric...

specific Embodiment approach 2

[0018] Combine below figure 1 Illustrate this embodiment, this embodiment will be further described to embodiment one, and it also comprises sticking nose bridge plastic strip 4, and described nose sticking plastic strip 4 is arranged on the mouth mask between outer layer nonwoven fabric 1-2 and inner layer nonwoven fabric On the upper edge of the body 1. The nose bridge plastic strip 4 is to make the mask body 1 stick to the nose more, so as to avoid air leakage from here.

[0019] Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Combine below figure 1 Describe the present embodiment, this embodiment will further describe the first embodiment, the mask body 1 is provided with a plurality of overlapping folds 6 . Increase the use area of mask body 1.

[0022] Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com