Hydrophilic single-layer porous membrane as well as preparation method and application thereof

A porous membrane and hydrophilic technology, applied in the field of functional material preparation, can solve problems such as complex preparation and adjustment process, instability, easy layering mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]A method for preparing a hydrophilic single-layer porous membrane with an asymmetric pore size, the method specifically includes the following steps:

[0040] (1) Mix the macromolecule with the surfactant and the solvent in the ratio of (1~3):(1~2):(1~6), wherein the surfactant is preferably PVP (polyvinylpyrrolidone), CTAB (hexadecyl Alkyltrimethylammonium bromide) or SDS (sodium dodecyl sulfate), the solvent is preferably DMAC (dimethylacetamide) or THF (tetrahydrofuran), stirring at (50°C-100°C) for 3-24h, A homogeneous polymer solution was obtained.

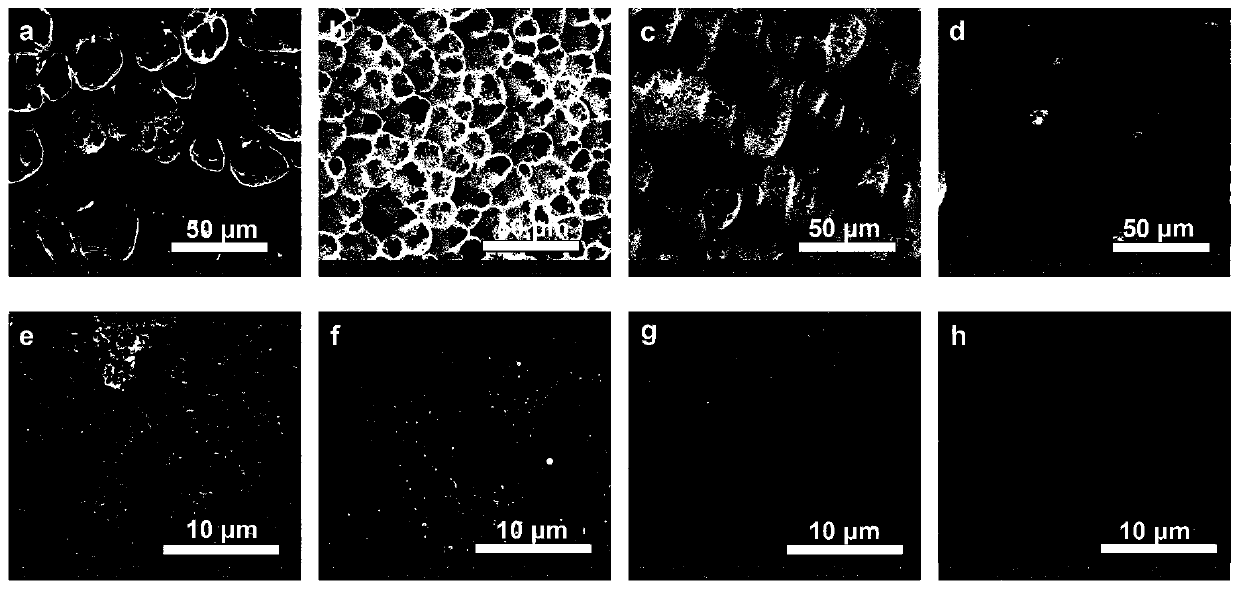

[0041] (2) Scrape the film with different thicknesses (1 μm to 200 μm) on a clean glass plate with a scraper, and immediately immerse the glass slices with polymer films of different thicknesses in different phase inversion solvents. The phase inversion solvents are preferably methanol, ethanol, Propanol, water, toluene, acetone, sodium chloride solution and mixed solvents mixed in different proportions, etc. For exam...

Embodiment 1

[0047] Preparation method and permeability performance of a kind of hydrophilic monolayer porous membrane

[0048] (1) Preparation of casting solution: Stir and mix polysulfone polymer particles, PVP and DMF at a ratio of 3:1:6 to obtain polysulfone casting solution;

[0049] (2) Scraping film: use a scraper to scrape and coat the polysulfone casting solution prepared in step (1) on a glass plate, and control the thickness of the scraping film by adjusting the height of the scraper to obtain a polysulfone film of 100 μm;

[0050] (3) Preparation of a hydrophilic single-layer porous membrane: a glass plate loaded with polysulfone is immersed in a phase inversion solvent for a predetermined time, followed by ultrasonic cleaning and drying to obtain a hydrophilic single-layer polysulfone porous membrane.

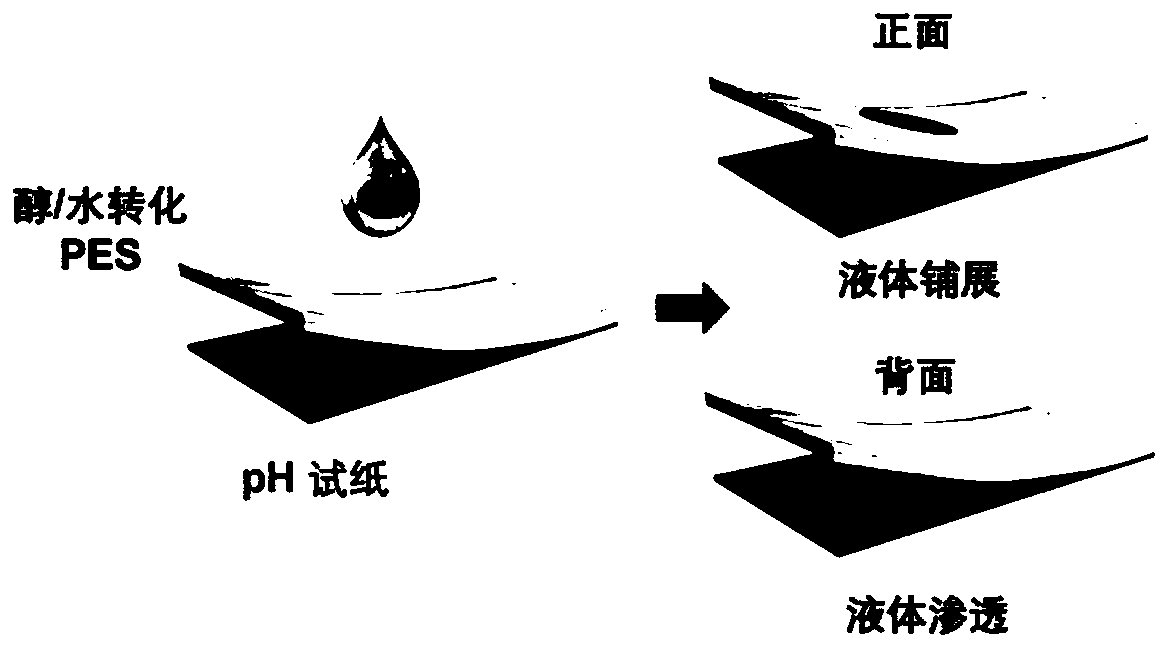

[0051] (4) By studying the permeability of water droplets, the permeability of both sides can be obtained.

Embodiment 2

[0053] Preparation method and permeability performance of a kind of hydrophilic monolayer porous membrane

[0054] (1) Preparation of casting solution: Stir and mix polyethersulfone polymer particles, PVP and DMF at a ratio of 3:1:6 to obtain polyethersulfone casting solution;

[0055] (2) Scraping film: use a scraper to scrape the polyethersulfone membrane solution prepared in step (1) on a glass plate, and control the thickness of the scraping film by adjusting the height of the scraper to obtain a series of polystyrene films with different thicknesses ;

[0056] (3) Preparation of a hydrophilic single-layer porous membrane: the glass plate carrying the polyethersulfone membrane is immersed in a phase inversion solvent for a predetermined time, followed by ultrasonic cleaning and drying to obtain a hydrophilic single-layer polyethersulfone porous membrane.

[0057] (4) Through the study of the permeability of its water droplets, different permeability properties can be obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com