Environment-friendly high-performance ceramic coating lithium ion battery diaphragm and preparation method thereof

A lithium battery diaphragm and ceramic coating technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of weak interface bonding and easy peeling off of the coating, and achieve high capacity and fast charging and discharging functions, which are not easy to Shedding, good use of the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

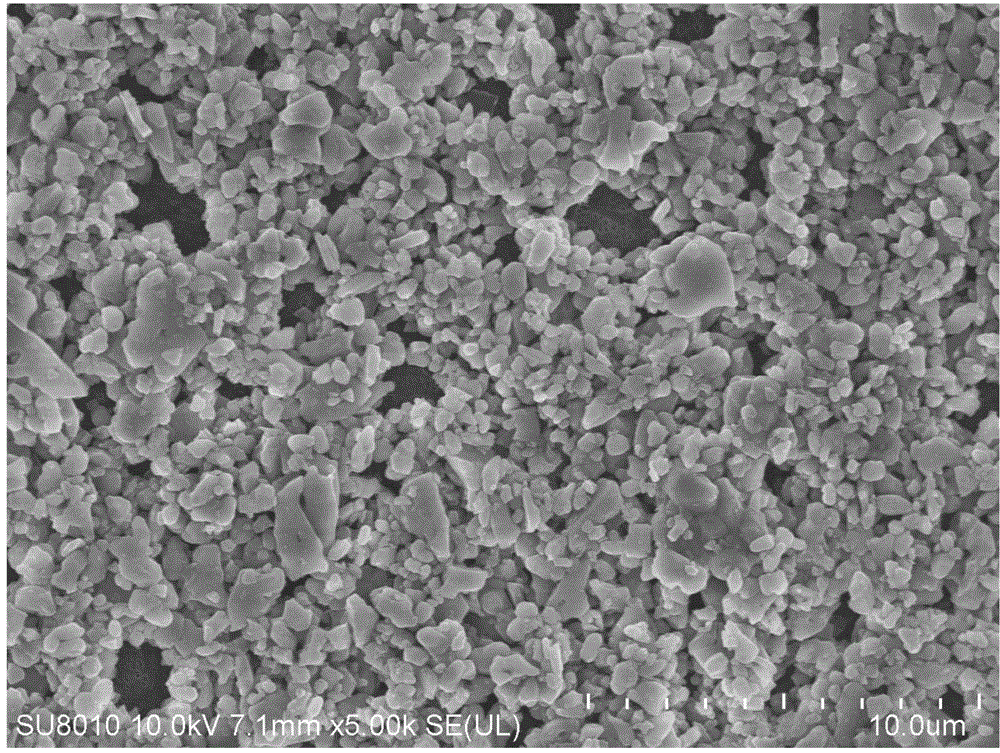

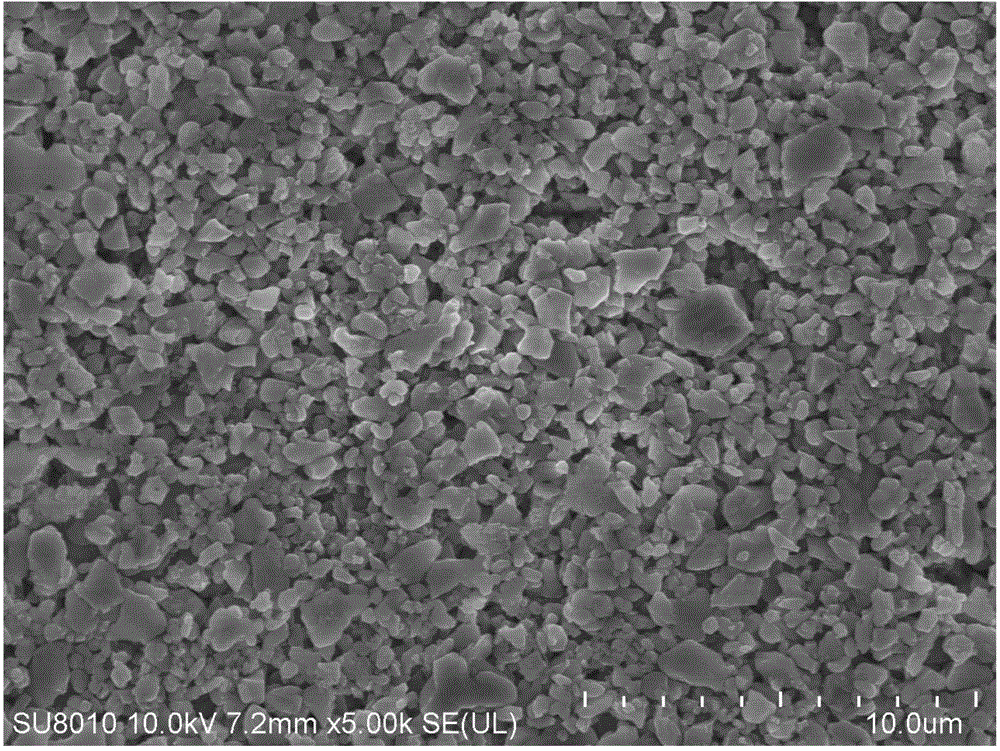

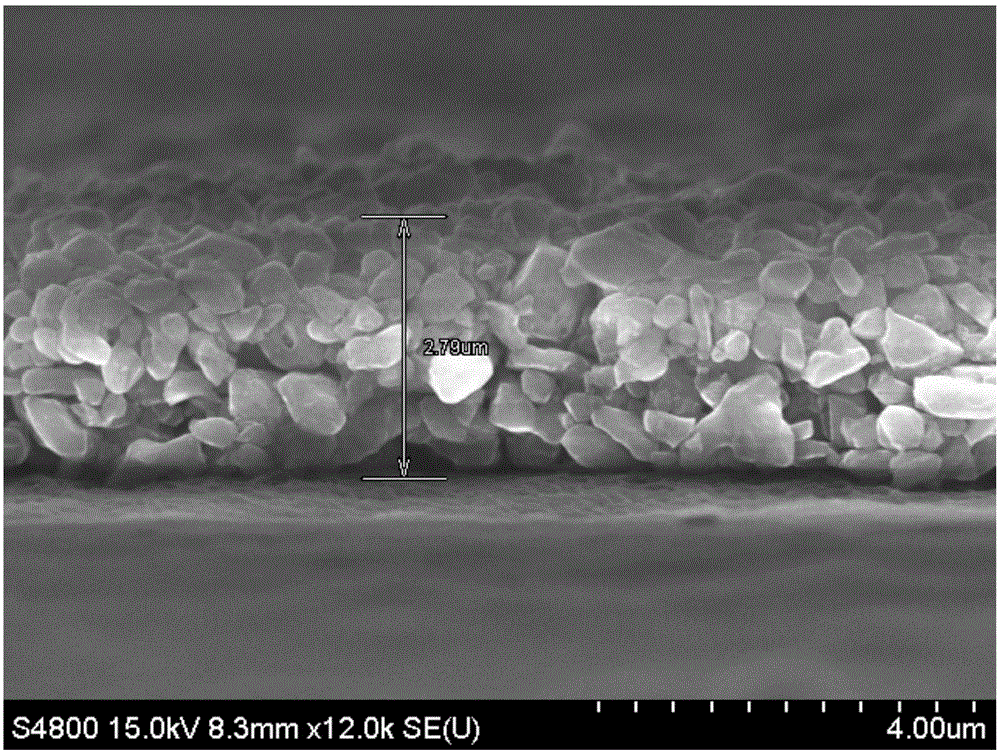

[0045] The green high-performance ceramic-coated lithium battery separator includes a polyolefin-based microporous membrane and a ceramic coating compounded on the upper surface of the polyolefin-based microporous membrane; the total thickness of the green high-performance ceramic-coated lithium battery separator is 11 μm; the ceramic coating The thickness of the layer is 2 μm; the porosity of the polyolefin matrix microporous membrane is 42%, the pore diameter is 0.48 μm, and the axial section of the pores on the polyolefin matrix microporous membrane is wavy.

[0046] The specific preparation of the green high-performance ceramic-coated lithium battery separator is as follows:

[0047] (1) Weigh 9g of Shanghai Youdao Auba Chemical Co., Ltd., the model is American Dow POLYOX WSR301 polyethylene oxide, add it to 100mL deionized water at 65°C, stir for 20 minutes to obtain a homogeneous solution, and then cool to room temperature; ( 2) Then take 0.5g of ethyl acrylate of Shangh...

Embodiment 2

[0049] The green high-performance ceramic-coated lithium battery separator includes a polyolefin-based microporous membrane and a ceramic coating compounded on the upper surface of the polyolefin-based microporous membrane; the total thickness of the green high-performance ceramic-coated lithium battery separator is 151 μm; the ceramic coating The thickness of the layer is 3 μm; the porosity of the polyolefin matrix microporous membrane is 45%, the pore diameter is 0.455 μm, and the axial section of the pores on the polyolefin matrix microporous membrane is wavy.

[0050] The specific preparation of the green high-performance ceramic-coated lithium battery separator is as follows:

[0051] (1) Weigh 10g of polyvinyl alcohol (average molecular weight 22,000) produced in Japan by Jinan Yida Chemical Trading Co., Ltd., add it to 100mL deionized water at 80°C, stir for 30 minutes to obtain a homogeneous solution, and then cool to room temperature; ( 2) Next, take 1g of methyl acry...

Embodiment 3

[0053] The green high-performance ceramic-coated lithium battery separator includes a polyolefin-based microporous membrane and a ceramic coating compounded on the upper surface of the polyolefin-based microporous membrane; the total thickness of the green high-performance ceramic-coated lithium battery separator is 18 μm; the ceramic coating The thickness of the layer is 2 μm; the porosity of the polyolefin matrix microporous membrane is 48%, the pore diameter is 0.40 μm, and the axial section of the pores on the polyolefin matrix microporous membrane is wavy.

[0054] The specific preparation of the green high-performance ceramic-coated lithium battery separator is as follows:

[0055] (1) Weigh 12g of Hangzhou Zhuoli Chemical Co., Ltd. model 515# melamine formaldehyde resin into 100mL deionized water at 90°C, stir for 30 minutes to obtain a homogeneous solution, and then cool to room temperature; (2) Then take 1.5g Shandong Add methyl acrylate with CAS No. 96-33-3 from Cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com