Patents

Literature

91results about How to "Good electrolyte wettability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

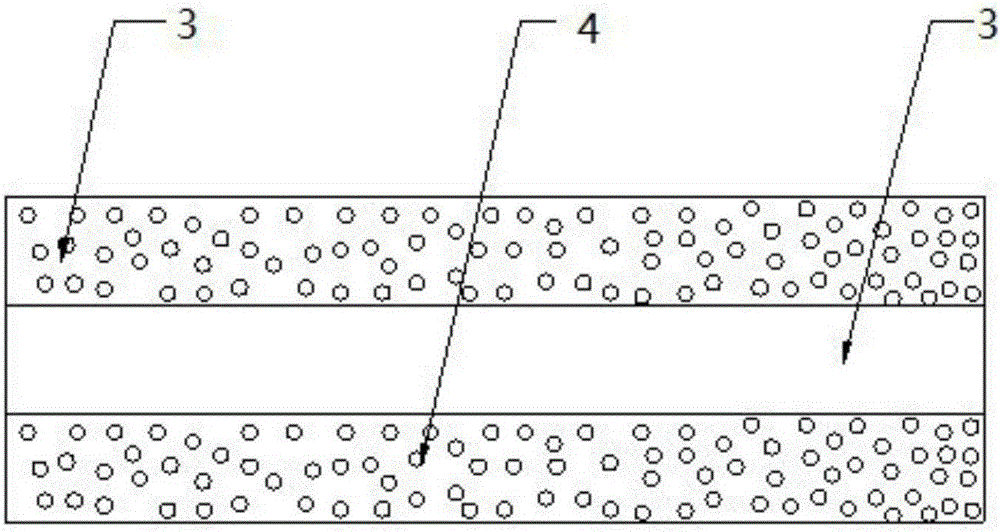

Ceramic diaphragm for lithium ion battery and preparation method of ceramic diaphragm

InactiveCN105514328AImproved cycle life and rate performanceImprove bindingCell component detailsSolventCeramic particle

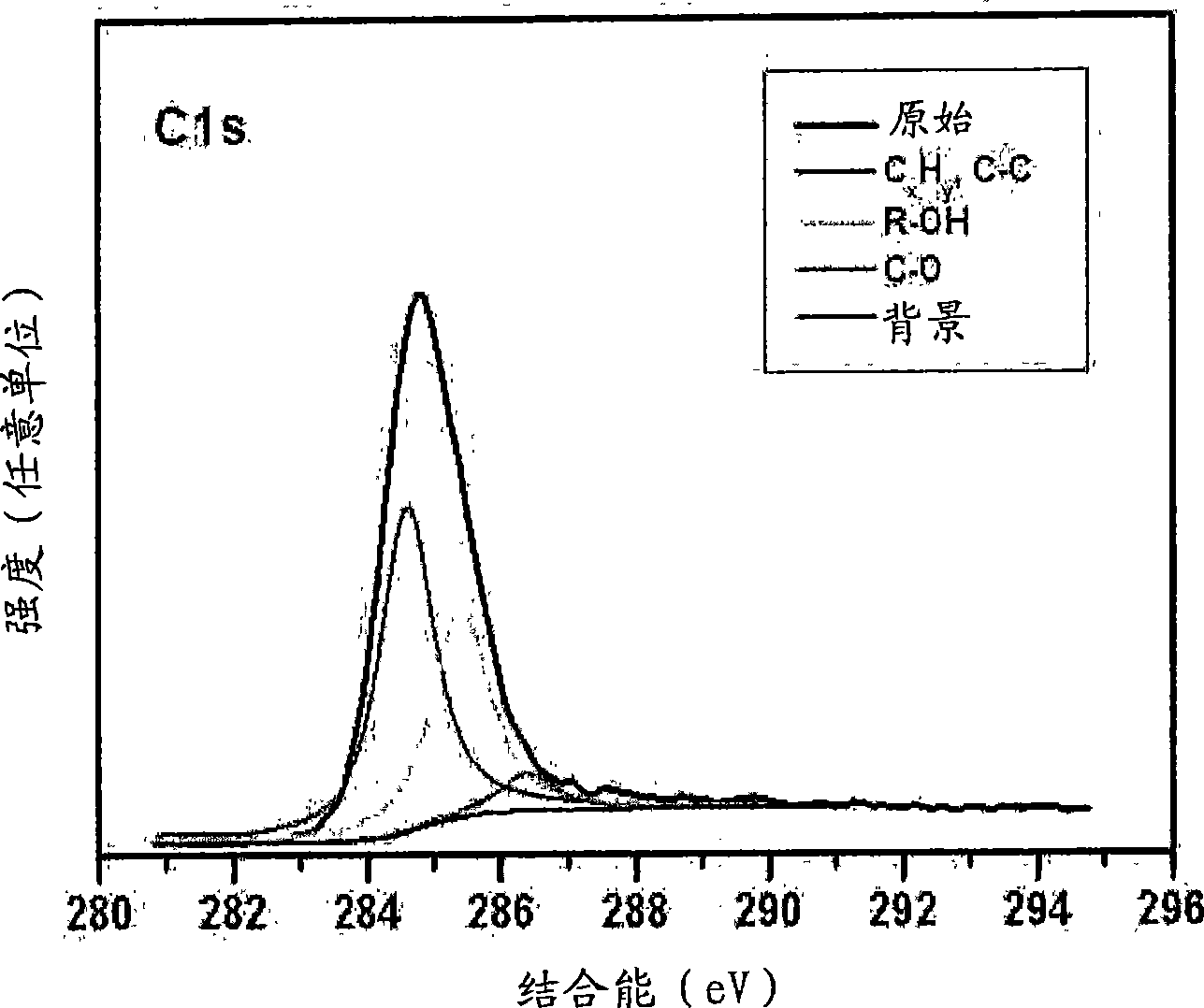

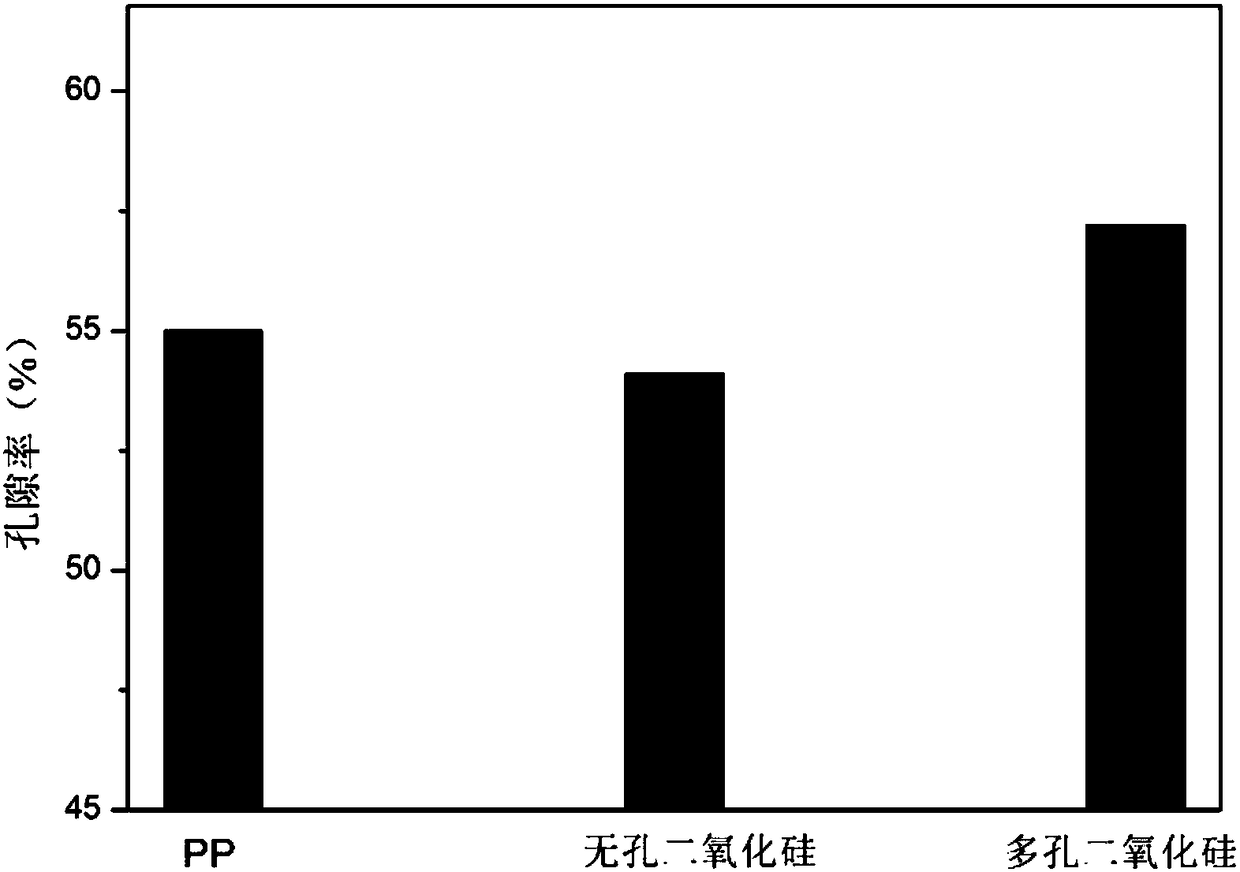

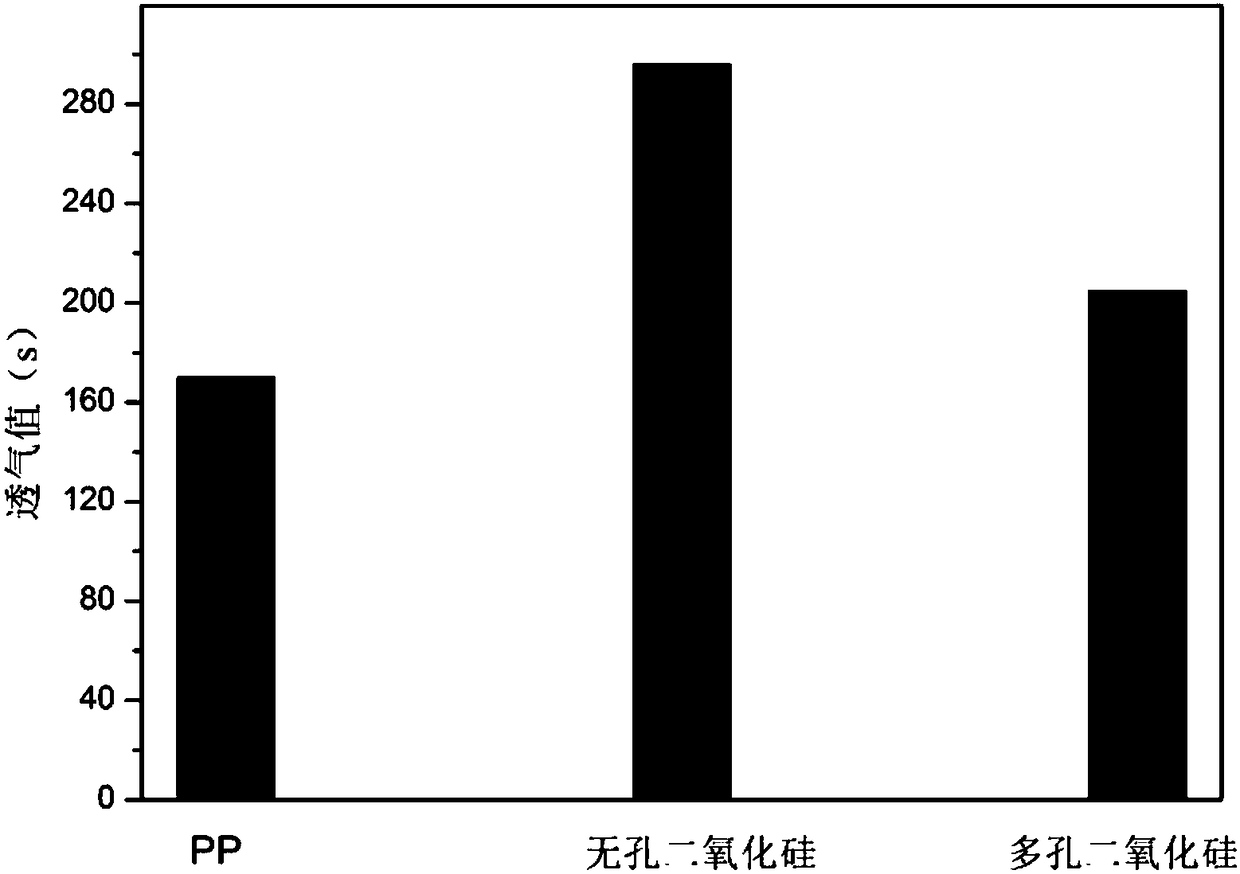

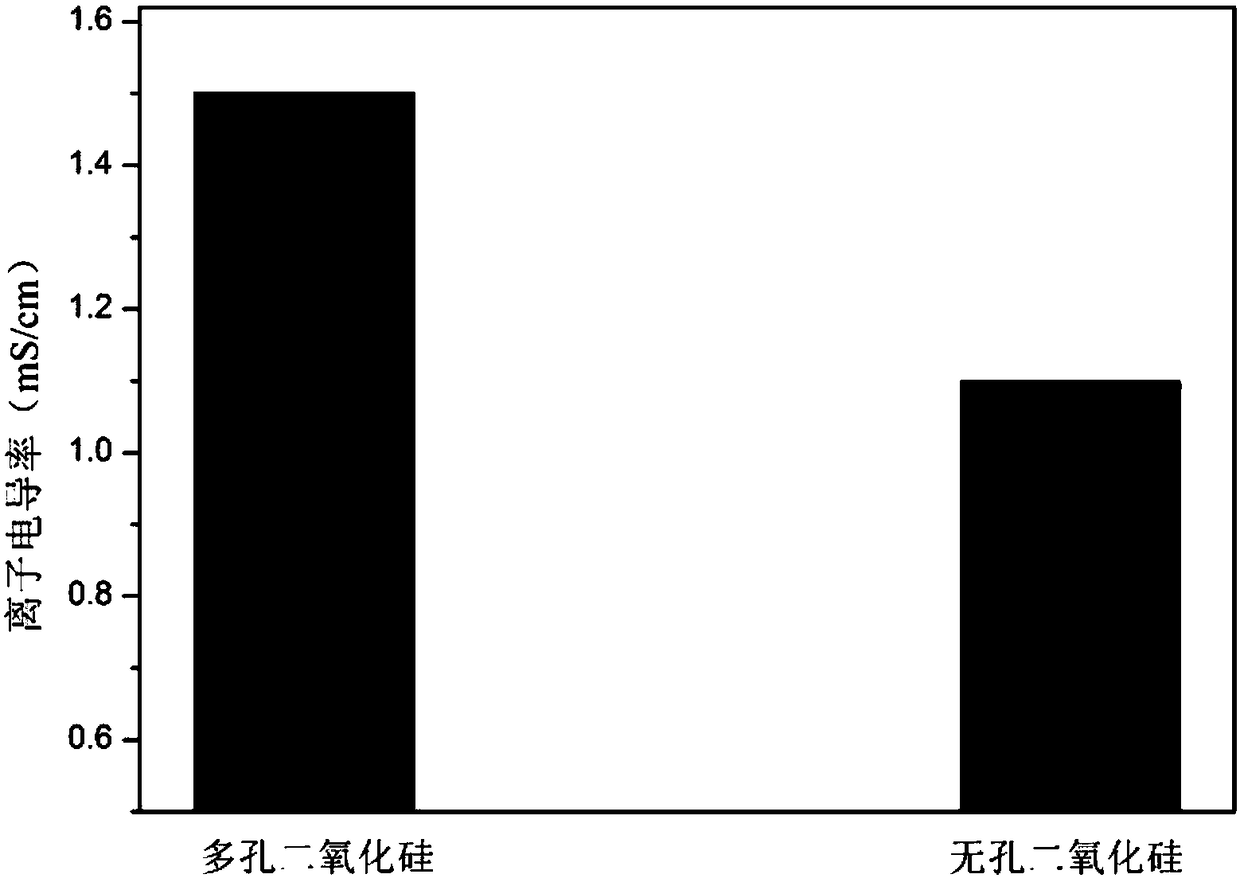

The invention discloses a ceramic diaphragm for a lithium ion battery. The ceramic diaphragm comprises a diaphragm base material and a ceramic coating on the surface of the diaphragm base material, wherein ceramic particles having a porous structure and a high specific surface area are selected for the ceramic coating. A preparation method includes the following steps of firstly, evenly mixing ceramic particles, binder and solvent to obtain coating slurry; secondly, evenly coating the surface of the diaphragm base material with the coating slurry, and conducting drying to form the ceramic diaphragm. Quite strong binding force exists between the porous ceramic powder and the binder, and the powder falling phenomenon is effectively avoided; meanwhile, the ceramic diaphragm has high electrolyte wettability and quite strong liquid absorption capacity, the cycle life and rate capability of the lithium ion battery are increased, and excellent electrochemical performance is achieved; in addition, under the same thickness, the mass of the porous ceramic coating is far lower than that of an ordinary ceramic coating, and the energy density of the battery is improved.

Owner:TIANNENG SAFT ENERGY JOINT CO

Novel ceramic coating polyolefin composite film and preparation method thereof

ActiveCN103811702AReduced service lifeExtended service lifeSecondary cellsCell component detailsSolventPolyolefin

The invention relates to a novel ceramic coating polyolefin composite film which comprises a polyolefin substrate with micro pores, wherein one side or both sides of the polyolefin substrate is / are compounded with ceramic coating(s); the ceramic coating comprises porous ceramic particles, an inorganic filler and an adhesive. The invention also relates to a method for preparing the novel ceramic coating polyolefin composite film. The method comprises the following steps: a, dissolving the adhesive in a solvent, thereby preparing an adhesive solution; b, adding the porous ceramic particles and the functional inorganic filler into the adhesion solution prepared in the step a, and performing dispersing treatment, thereby preparing coating slurry; and c, coating one or two surfaces of the polyolefin substrate with the coating slurry prepared in the step b, and drying and curing to prepare the product. The novel functional composite film has high liquid absorption and retention performance, has the functions of reducing harmful gases inside a battery, improving the performance of the battery and prolonging the service life of the battery, and has the safety characteristics of low closed pore temperature, high melting temperature and low hot-shrinkage rate.

Owner:河南惠强新能源材料科技股份有限公司

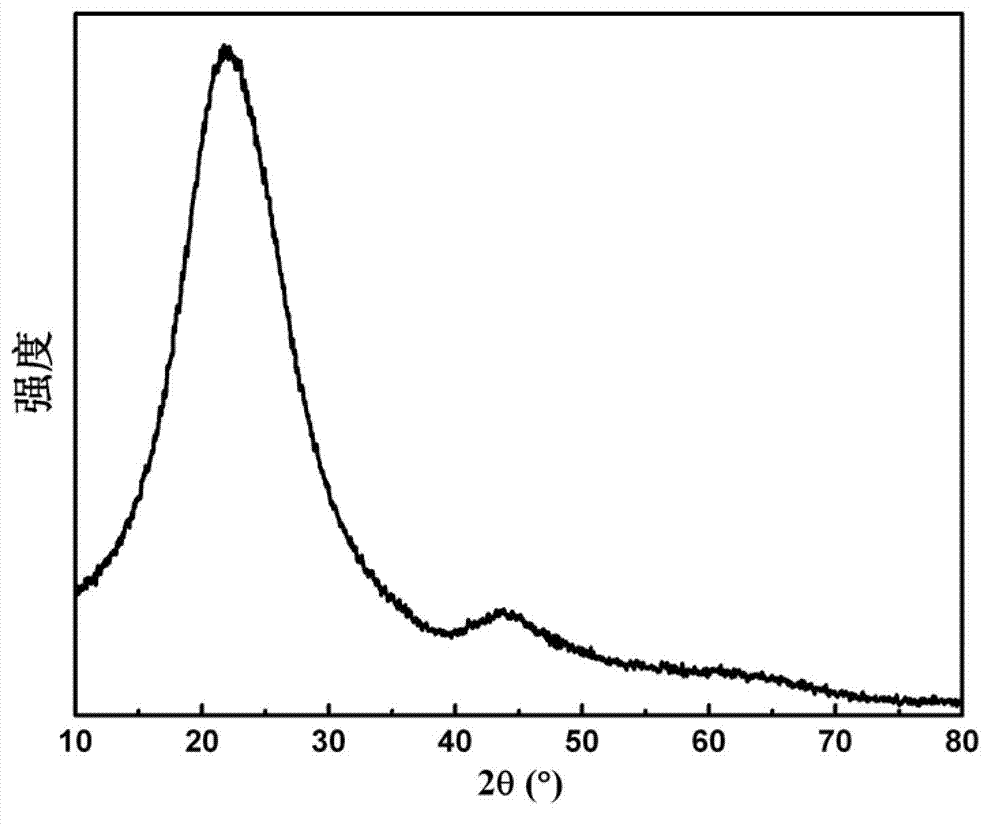

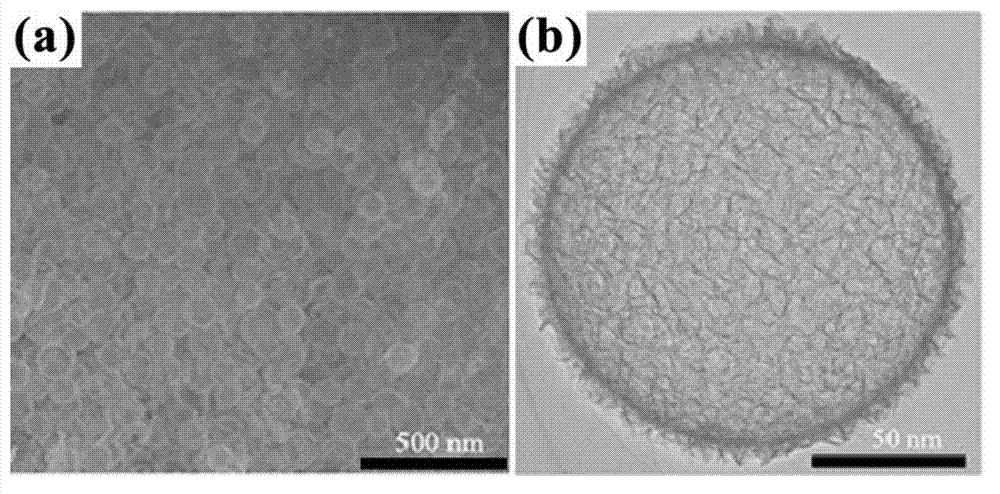

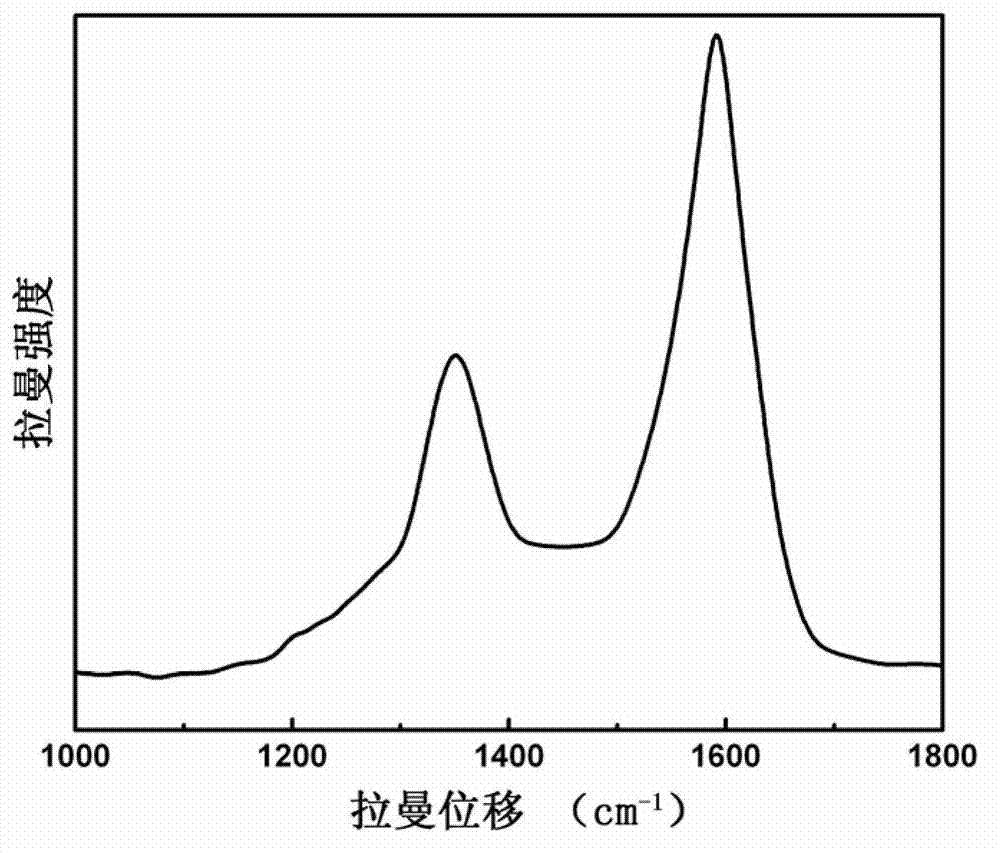

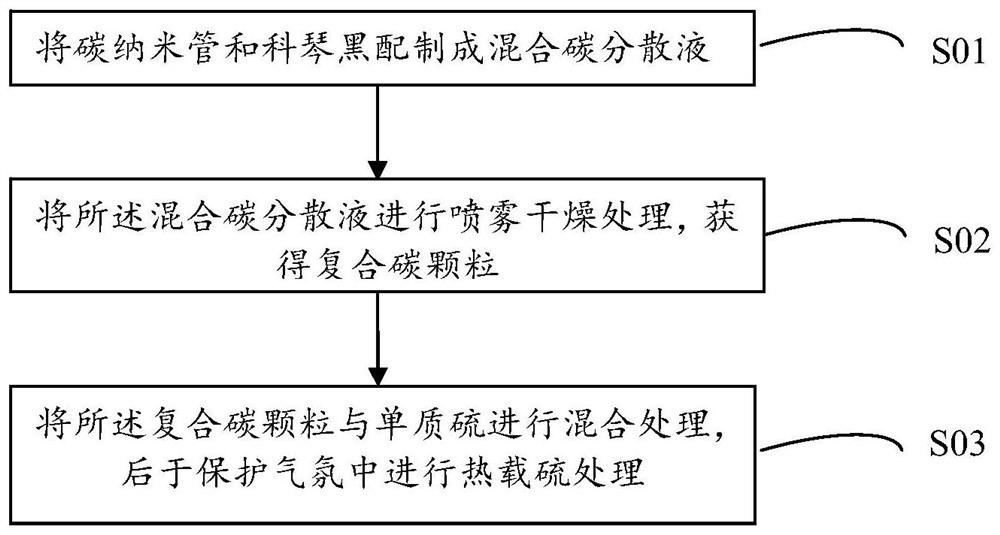

Carbon-sulfur composite material used for positive pole of lithium-sulfur battery and preparation method of material

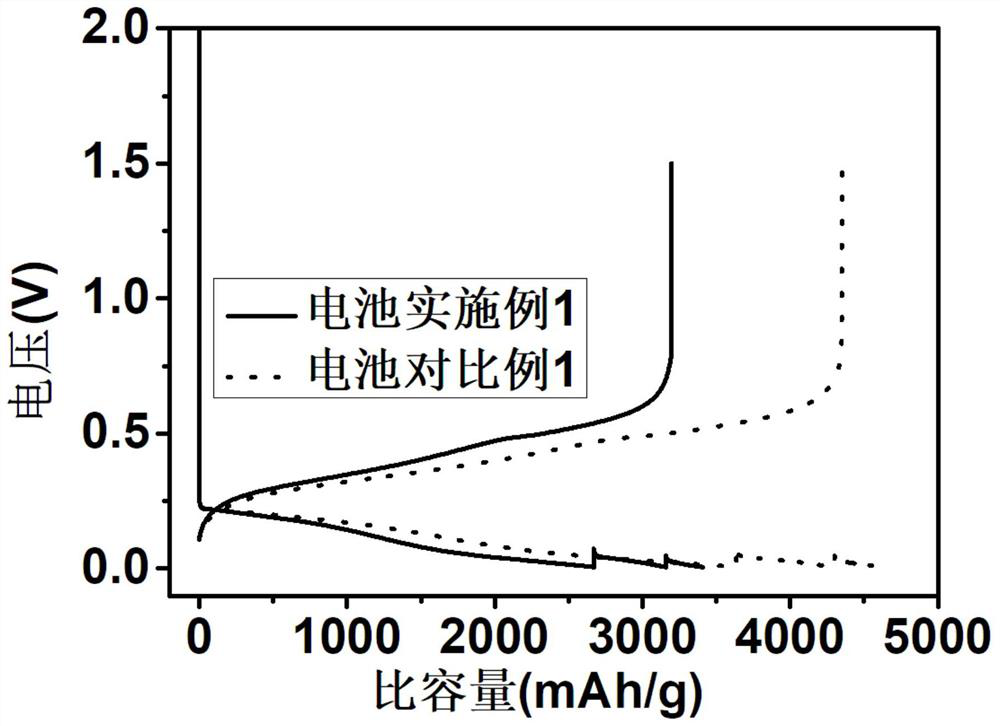

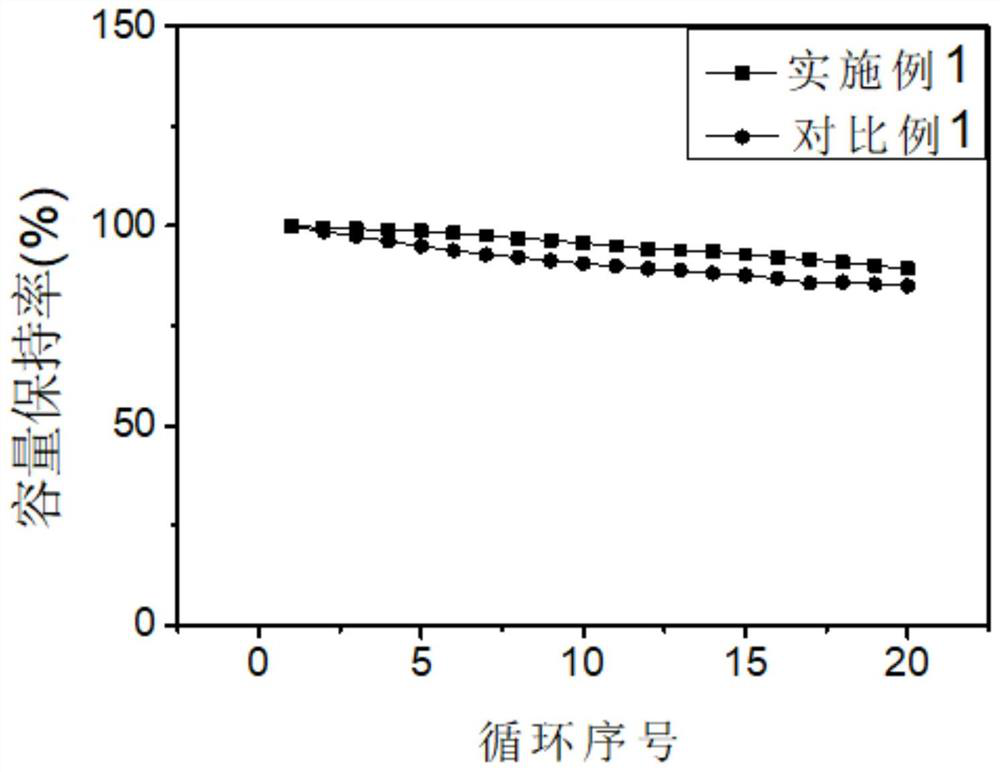

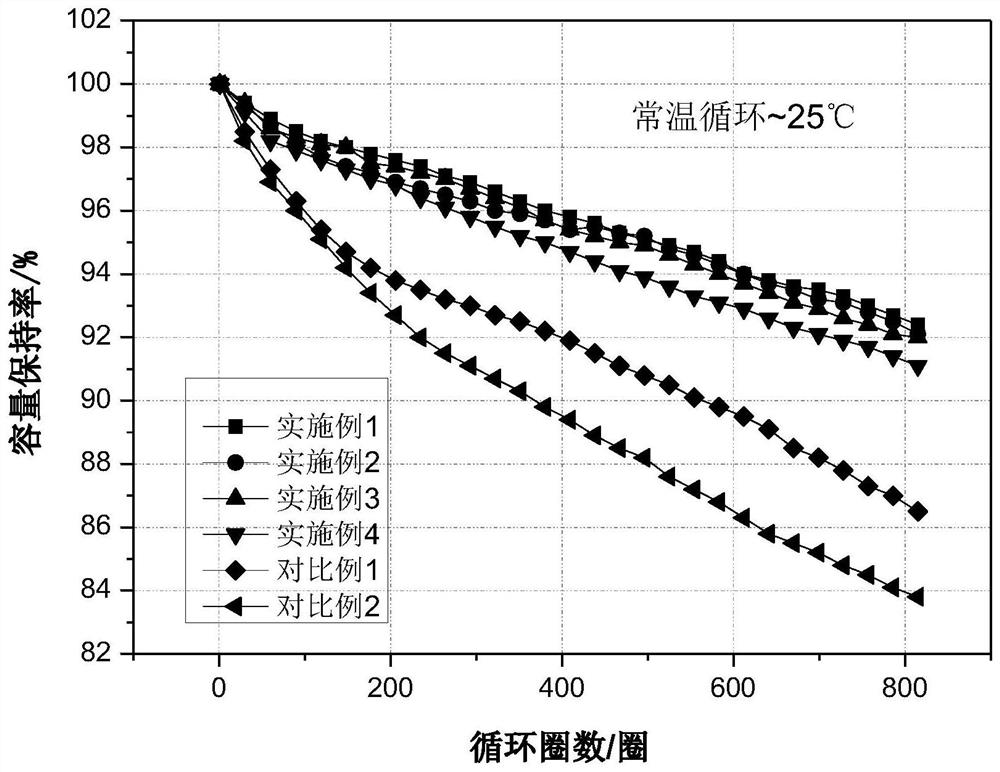

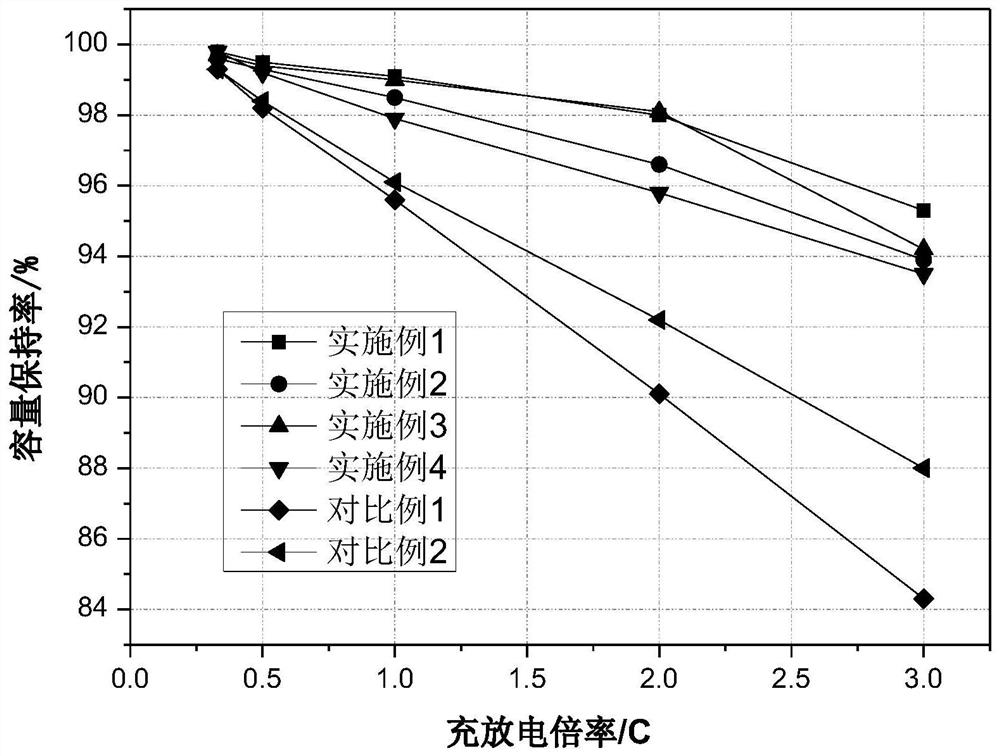

ActiveCN102969487AUniform structureInhibition of lithium polysulfide dissolutionCell electrodesStored energySulfur

The invention relates to a carbon-sulfur composite material used for a positive pole of a lithium-sulfur battery. The carbon-sulfur composite material is characterized in that elemental sulfur is filled in a multi-hole hollow carbon ball which is synthesized through a simple template method, and the elemental sulfur is injected into the multi-hole hollow carbon ball by adopting a fusion diffused method; the carbon-sulfur composite material is used for preparing a positive pole material of a high-performance lithium-sulfur battery cell, the positive pole is composed of the carbon-sulfur composite material, a binding agent and an electric conduction agent, and polytetrafluoroethylene or polyvinylidene fluoride is used as the binding agent; and the electric conduction agent is a mixture of one or more than two of carbon nanometer fibre, electric conduction graphite, acetylene black and Super p in any proportion. The carbon-sulfur composite material provided by the invention has the advantages that compared with the reportorial lithium-sulfur secondary battery, the preparation method of the anode material is simple, the large specific capacity is 1450 Ahg-1, the coulomb efficiency is high and is greater than 99.0%, the cycle performance is good, the initial capacity is kept 93.6% after circulating for 50 weeks and the like, and the carbon-sulfur composite material is expected to be applied to the next generation large-scale stored energy batteries.

Owner:NANKAI UNIV

Microporous polyethylene film with improved strength, permeability and surface energy

InactiveCN101436651AGood orientationReduce contentCell component detailsFlat articlesPorosityPolymer science

Owner:SK ENERGY CO LTD (KR)

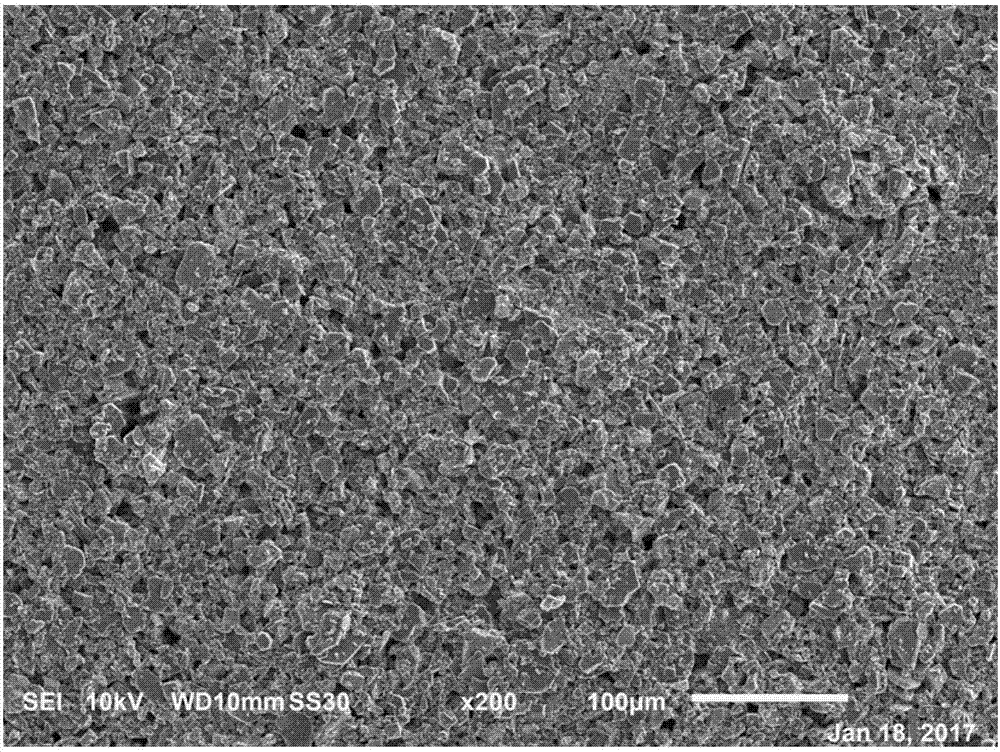

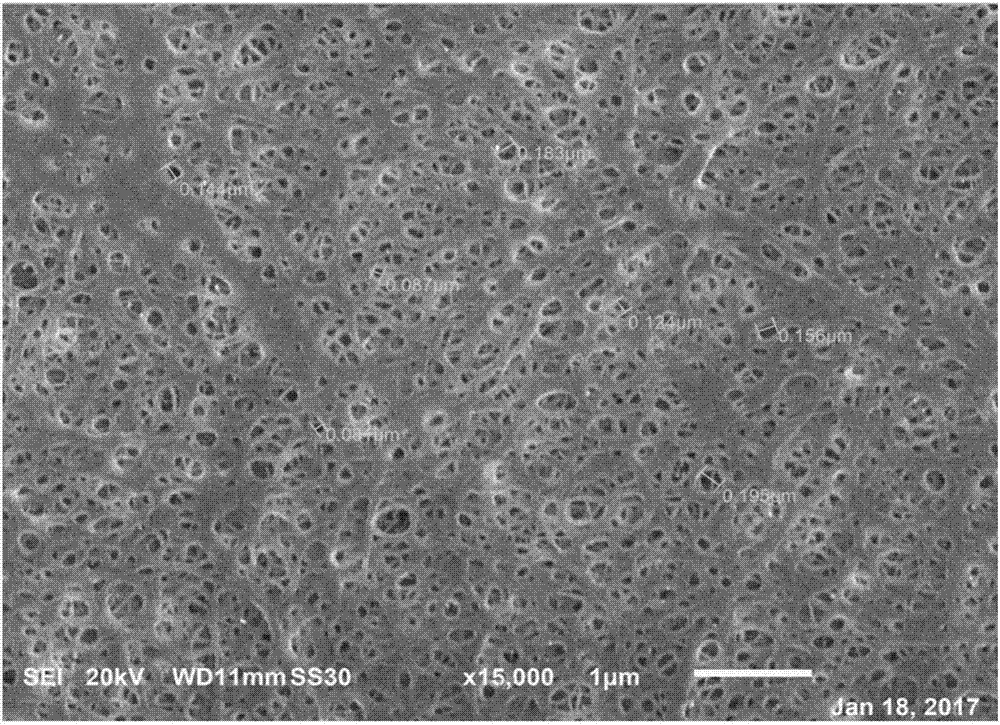

Nanoparticle coated lithium ion battery diaphragm and preparation method thereof

InactiveCN108336279AGuaranteed ion mobility performanceFacilitate deliveryCell component detailsHigh rateFree diffusion

The application discloses a nanoparticle coated lithium ion battery diaphragm and a preparation method thereof. The nanoparticle coated lithium ion battery diaphragm comprises a basal membrane and nanoparticles coated on at least one surface of the basal membrane, wherein the nanoparticles have porous structures, and at least a part of channels penetrate the surface of the nanoparticles. The nanoparticle coated lithium ion battery diaphragm employs the nanoparticles with the porous structures to prepare a coating, the nanoparticles with the porous structures have developed channel structures,lithium ions can diffuse in gaps between nanoparticles, and lithium ions can freely diffuse in the internal channels in the porous structures of the nanoparticles, in order to improve porosity of thediaphragm with the nanoparticle coating, and improve wettability of diaphragm electrolyte. The nanoparticle coated lithium ion battery diaphragm keeps heat resistance of the traditional diaphragms with nanoparticle coatings, and at the same time improves conductivity of lithium ions, so that batteries have high rate performance and long circulation performance.

Owner:武汉中兴创新材料技术有限公司

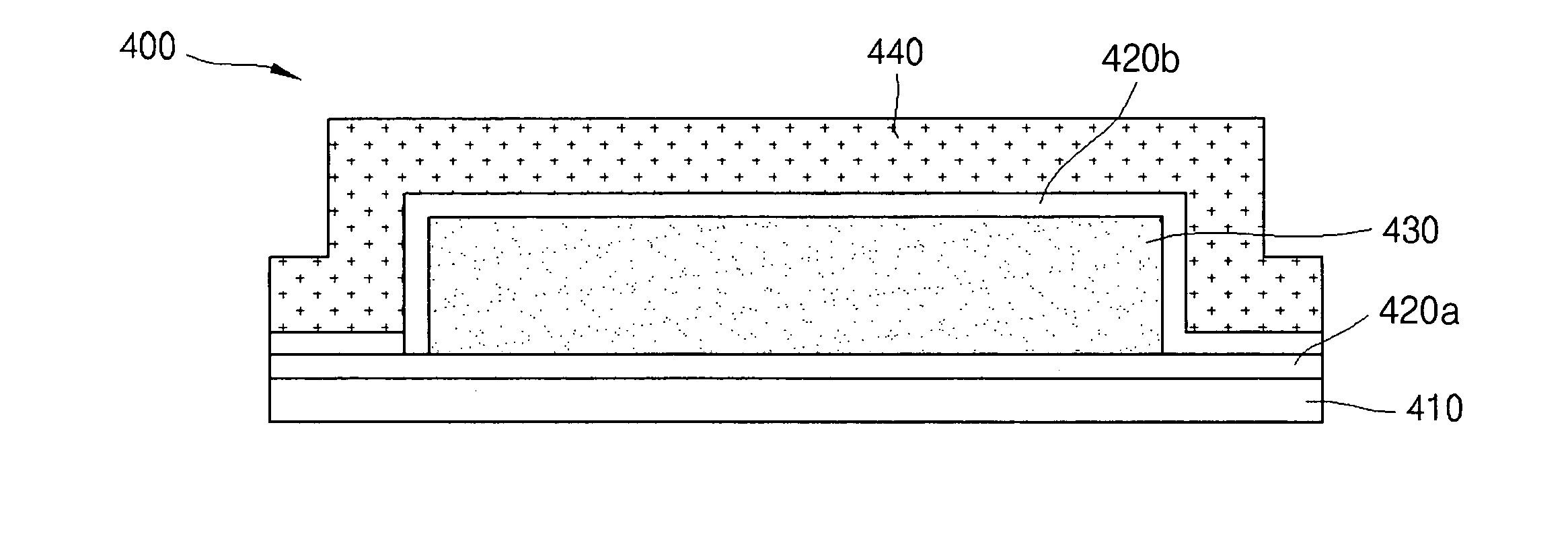

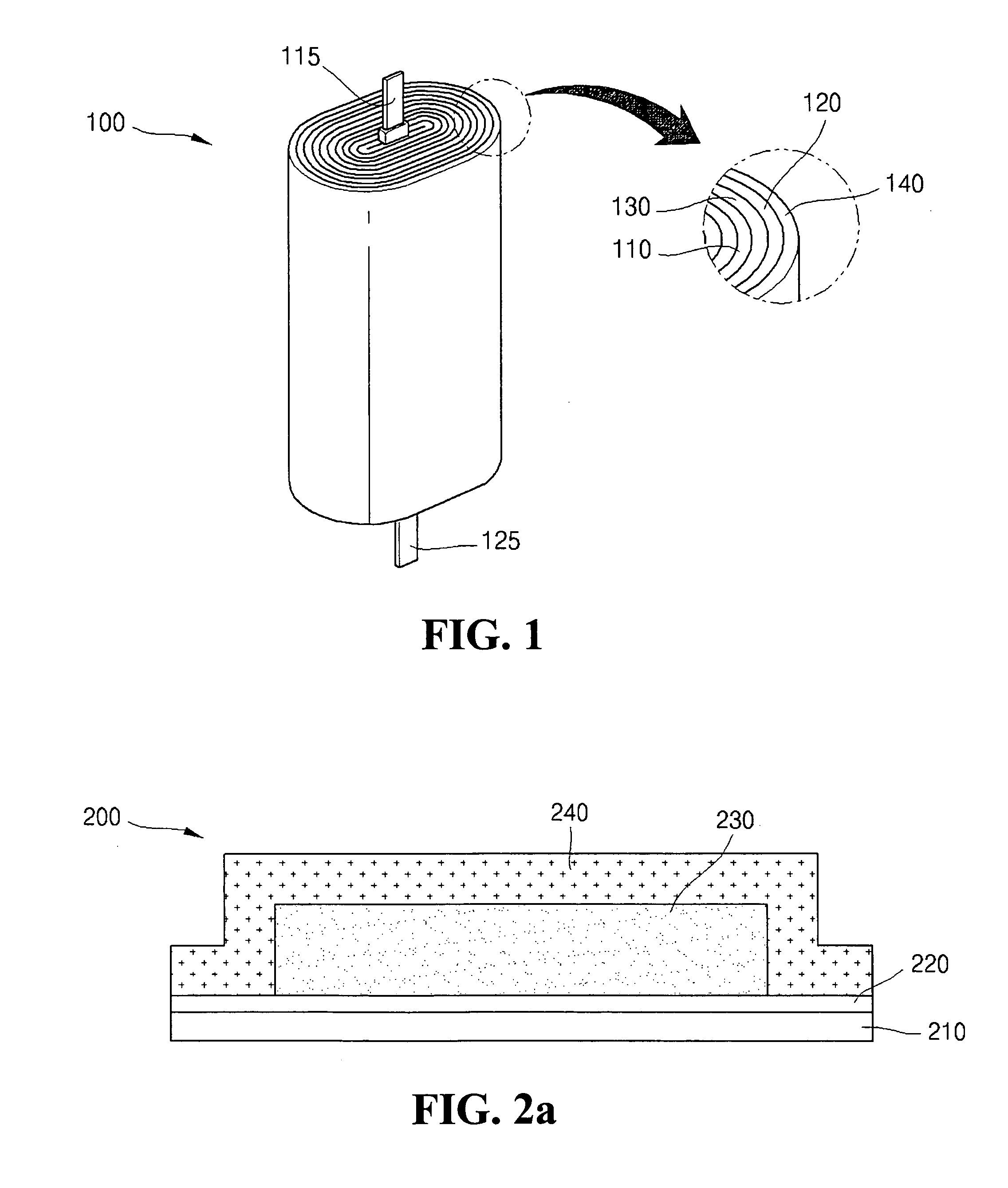

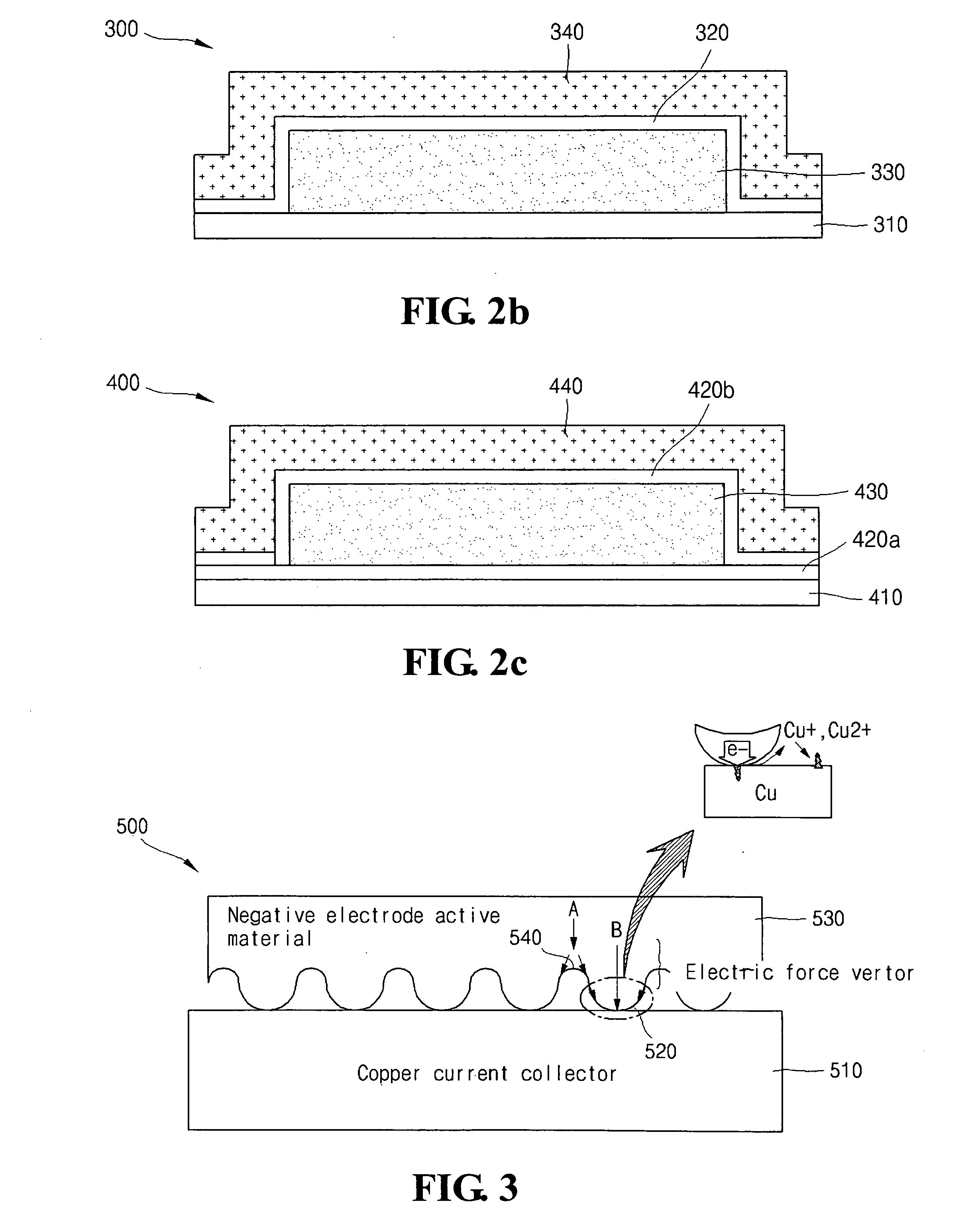

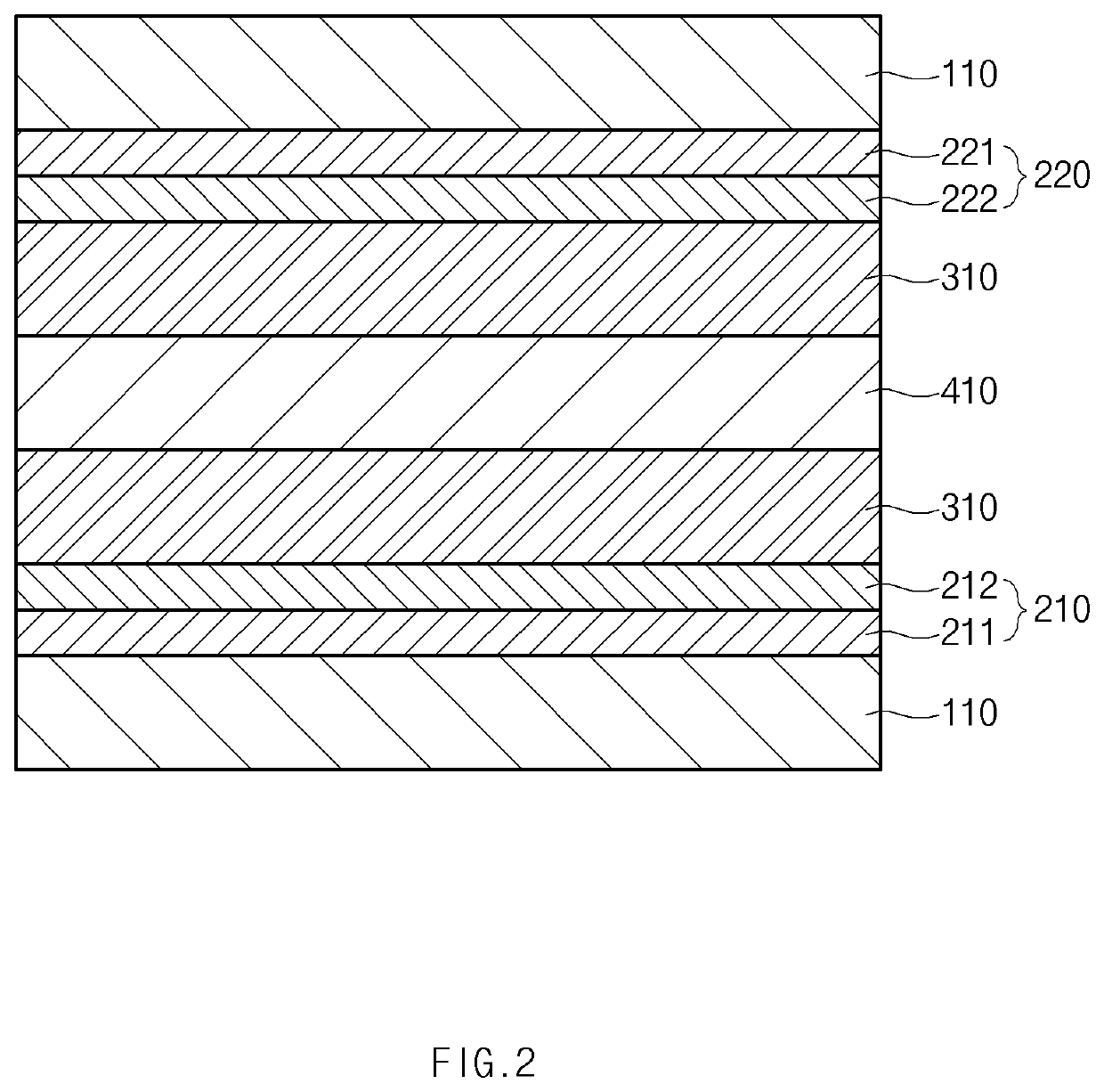

Electrode including Si-containing material layer and porous film, and lithium battery employing the same

InactiveUS20070020524A1Good ohmic contactImprove adhesionElectrode carriers/collectorsNegative electrodesSchottky barrierOhmic contact

An electrode which has a Si-containing material layer and a porous film, and a lithium battery employing the same. In the electrode, the Si-containing material layer is applied on an electrode current collector and / or an electrode active material to protect the surface of the electrode current collector from oxidation. Also, the applied Si-containing material layer enhances the adhesion between the electrode current collector and the electrode active material to improve cycle life characteristics. Also, it increases the adhesion between the electrode active material and the porous film to reduce resistance, and to improve ohmic contacts and to lower the Shottkey barrier. In addition, the electrode includes the porous film functioning as a separator, and thus can provide a battery which is safe under conditions of overcharge and heat exposure without needing an additional separator.

Owner:SAMSUNG SDI CO LTD

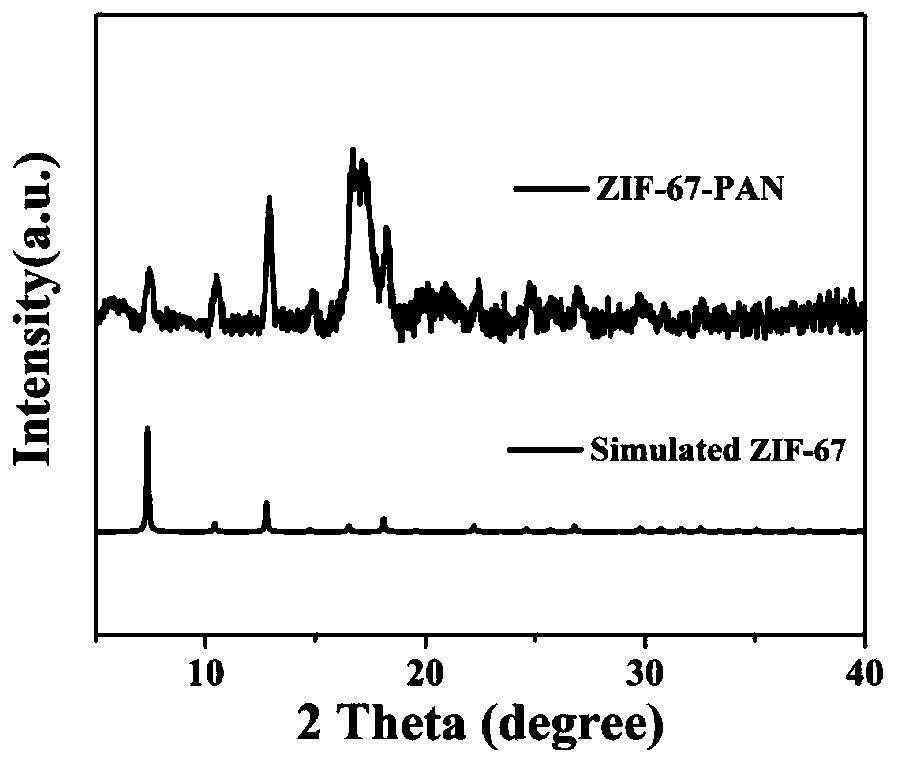

Metal organic framework-modified polymer film and preparation method and application thereof

ActiveCN110295498AImprove electrochemical performanceGood electrolyte wettability and thermal stabilityFibre typesCell component detailsElectrospinningPolymer thin films

The invention relates to a method of preparing a metal organic framework-modified polymer film based on electrostatic spinning. The method is characterized in that various metal organic frameworks areapplied to modify the surface of polymer nano fibers prepared by electrostatic spinning, and allowing the metal organic frameworks to grow in situ on the surface of the polymer nano fibers to form acomplete composite structure, wherein the polymer film is 80-200 mu m in thickness and the metal organic frameworks are 50-100 nm in particle size. The method of the invention has the advantages thata polyacrylonitrile-based nano fiber film has good electrolyte wetting property and thermal stability; the metal organic frameworks on the surface of the nano fibers can adsorb polysulfides effectively and inhibit aero effect of a lithium-sulfur battery; these features enable the cycle stability and rate performance of the lithium-sulfur battery to be improved when the film is applied to lithium-sulfur battery diaphragms; the method is simple, low in production cost and suitable for large-scale production.

Owner:WUHAN UNIV OF TECH

Diaphragm for lithium ion battery and preparation method thereof

ActiveCN103187549AUniform thicknessUniform pore sizeSynthetic resin layered productsCell component detailsPolymer scienceFunctional monomer

The present invention relates to a microporous membrane material, particularly relates to diaphragm for lithium ion batteries and a preparation method thereof, and belongs to the technical field of membrane. The diaphragm is a composite microporous membrane prepared from a polyolefin intermediate layer and fluorine-containing polymer outer layers of the same thickness on both sides by melt extrusion, biaxial stretching and heat setting processes, wherein the polyolefin layer is a polyvinyl layer, a polypropylene layer or a composite layer of polyethylene and polypropylene, the fluorine-containing polymer outer layer is a melt-processable modified vinyl fluorine resin layer which is copolymerized by vinyl fluoride, ethylene and fluorine-containing functional monomer, the thickness of the composite microporous membrane is 5-30 microns, the fluorine-containing polymer outer layer at one side is 1-10 microns, the pore diameter is of 0.01-0.1 microns, and the porosity is of 50-80%. The diaphragm prepared by the invention is uniform in thickness and pore size, stable in dimension, excellent in mechanical property and chemical stability, good in electrolyte wettability and electrode adhesion, simple in preparation process and easy to implement.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Composite separator and application thereof in lithium ion battery

InactiveCN107093693AGood electrolyte wettabilityImprove ionic conductivityCell seperators/membranes/diaphragms/spacersSecondary cellsPhosphateThermal stability

The invention discloses a composite separator for a lithium ion battery. The composite separator comprises a microporous base membrane and a ceramic layer coating one or two sides of the microporous base membrane, wherein lithium-containing phosphate is the main ingredient of ceramic powder in the ceramic layer. The composite separator can be used for effectively improving the electrolyte wettability, ionic conductivity, thermal stability and machinability of a membrane. A lithium ion battery containing the composite separator can be used as a driving power supply of a mobile phone, a laptop computer or an electric automobile.

Owner:南通中航泛能新材料有限公司

Environment-friendly high-performance ceramic coating lithium ion battery diaphragm and preparation method thereof

ActiveCN104638220AGuaranteed adhesionIncrease capacityCell seperators/membranes/diaphragms/spacersPolyolefinCeramic coating

The invention discloses an environment-friendly high-performance ceramic coating lithium ion battery diaphragm and a preparation method thereof. The environment-friendly high-performance ceramic coating lithium battery diaphragm comprises a polyolefin matrix microporous membrane and a ceramic coating which is composited on the upper surface or on the upper surface and the lower surface of the polyolefin matrix microporous membrane; the overall thickness of the environment-friendly high-performance ceramic coating lithium battery diaphragm is 8 to 40 micrometers; the thickness of the ceramic coating is 2 to 5 micrometers; the porosity of the polyolefin matrix microporous membrane is 42 to 52 percent, the aperture of the polyolefin matrix microporous membrane is 0.15 to 1.5 micrometers, and the axial cross section of each hole in the polyolefin matrix microporous membrane is in a wavy shape. A lithium ion battery prepared by adopting the environment-friendly high-performance ceramic coating lithium ion battery diaphragm is relatively good in safety, and the problems of dropping and no temperature resistance of an existing lithium battery diaphragm ceramic coating and the safety problem caused by the diaphragm of a lithium ion battery can be effectively solved; the lithium ion battery diaphragm provided by the invention is high in porosity and good in electrolyte wetting property, mechanical property and temperature resistance and also has high-temperature turn-off performance.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

Ceramic separator and lithium ion battery

PendingCN107195837AImprove liquid absorption capacityLarge specific surface areaCell component detailsSecondary cells servicing/maintenanceSolventLithium-ion battery

The invention provides a ceramic separator. The ceramic separator comprises a separator substrate, wherein ceramic paste is coated on a surface of at least one side of the separator substrate, a protection layer is formed on a surface of the separator substrate after the ceramic paste is dried, the ceramic paste is formed by mixing ceramic powder with mass percent of 20-70%, a flame retardant with mass percent of 20-70%, a binding agent with mass percent of 5-30% and a solvent, and the ceramic powder is of a hollow spherical or hollow pipe structure. The safety of a lithium ion battery employing the ceramic separator can be improved.

Owner:OPTIMUM BATTERY CO LTD

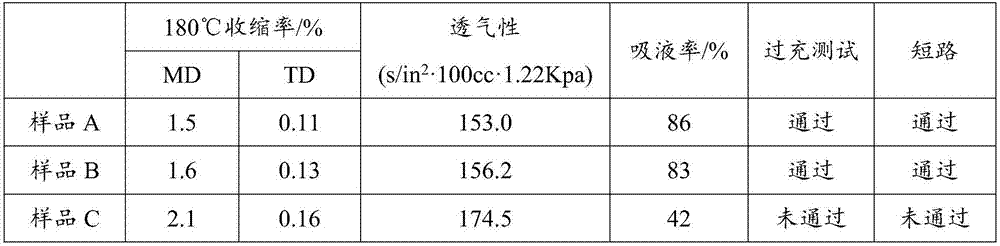

Lithium ion battery separator with low thermal shrinkage rate and preparation method therefor

InactiveCN105185939ASmall capacity attenuationLow heat shrinkageCell component detailsSecondary cells servicing/maintenanceCelluloseCarbamate

The invention belongs to the production field of lithium batteries, in particular to a lithium ion battery separator with low thermal shrinkage rate and a preparation method therefor. The surface of the lithium ion battery separator with the low thermal shrinkage rate is uniformly coated with a cellulose layer; and a porous membrane base material is any one of a PE single-layer membrane, a PP single-layer membrane or a PP / PF / PP three-layer co-extruding membrane. The preparation method provided by the invention is as follows: cellulose dissolving, mixing the cellulose, strong alkali, urea and water at a proper proportion to obtain a cellulose carbamate solution; cellulose coating, coating the solution on the surface of the porous membrane base material and drying; and cellulose regenerating, immersing the porous membrane base material which is coated with the cellulose into a sulfuric acid solution at a certain concentration to regenerate, and drying. The lithium ion battery separator and the preparation method therefor have the beneficial effects that: the coating layer is in tight contact with the porous membrane base material without falling easily; the thermal shrinkage rate of the diaphragm is greatly reduced; the lithium ion battery separator is higher in electrolyte wettability; the capacity fading of the battery can be effectively reduced; and the cellulose of waste batteries can be dissolved and reused, so that the lithium ion battery separator is energy-saving and environment-friendly.

Owner:HUIQIANG WUHAN NEW ENERGY MATERIAL TECH

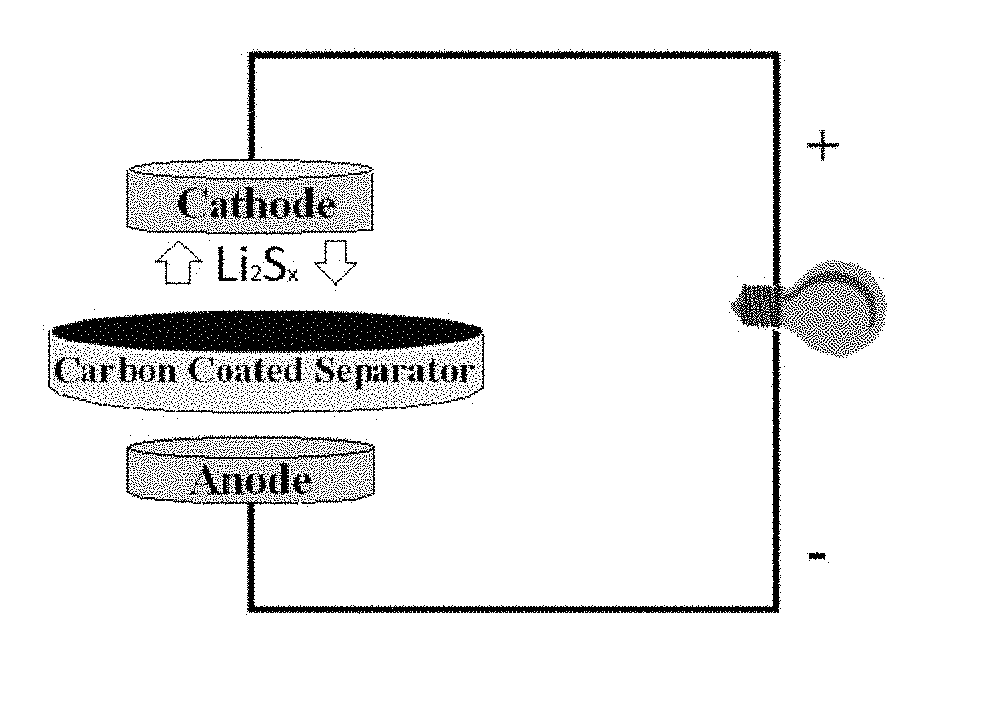

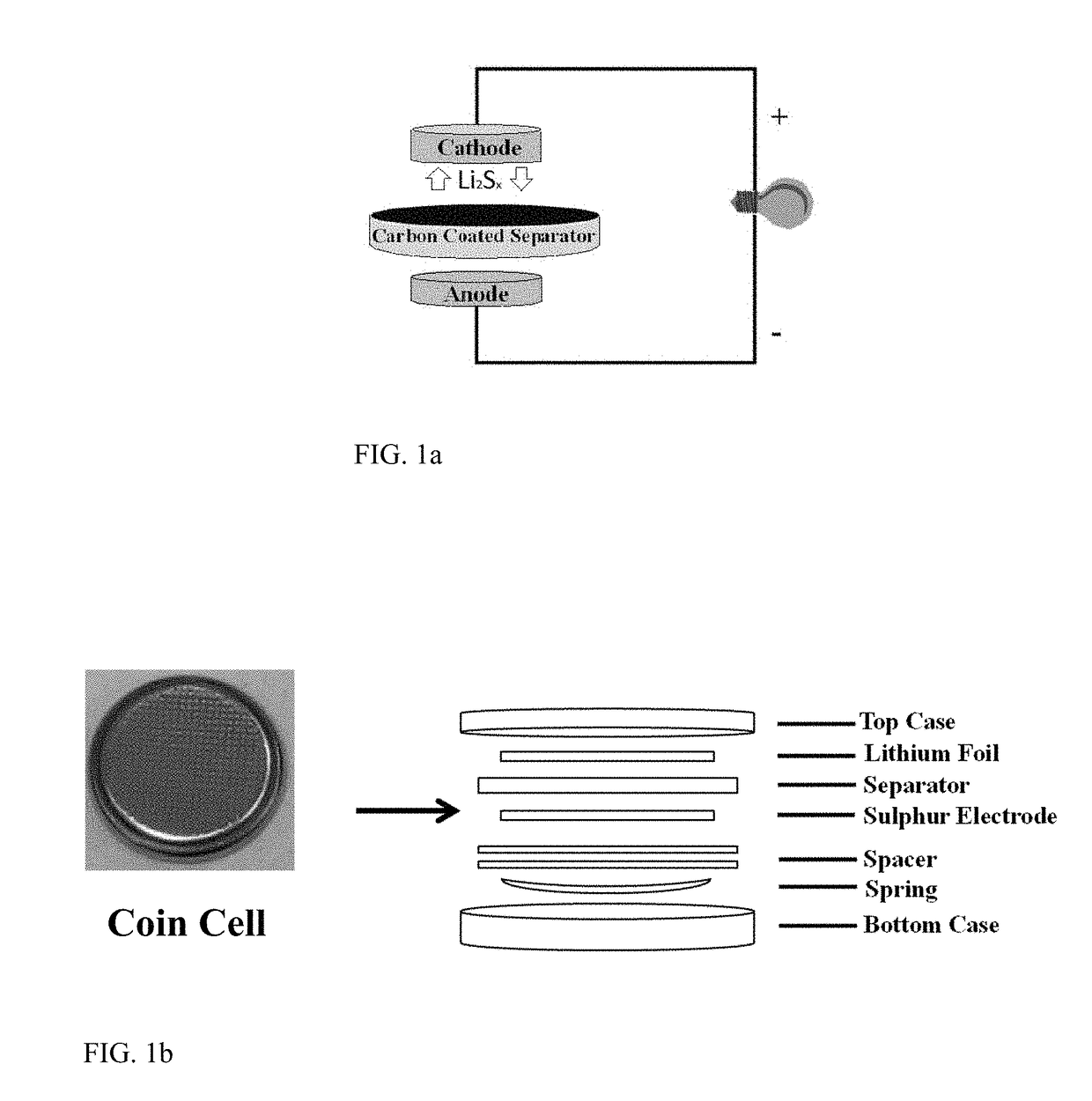

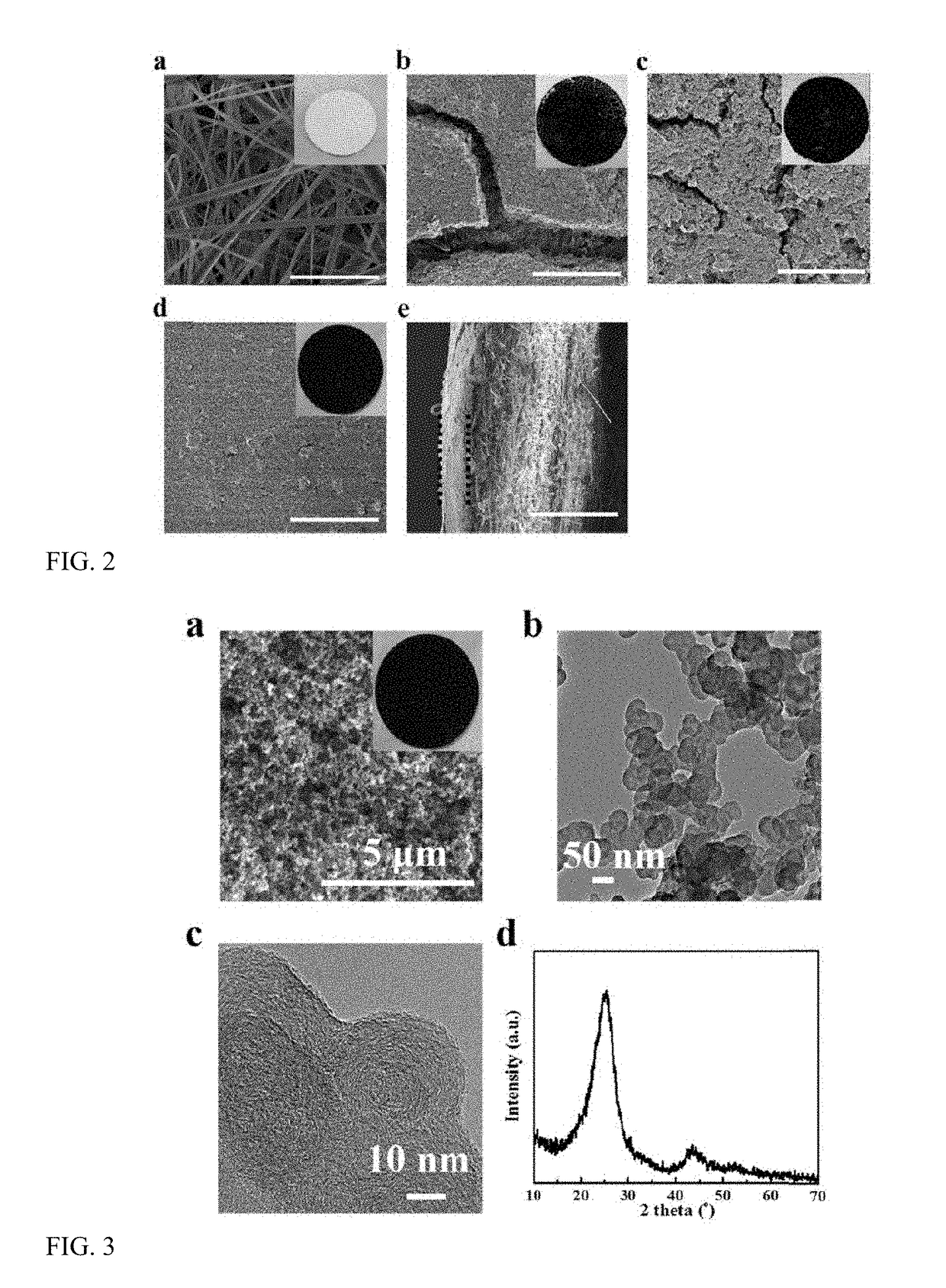

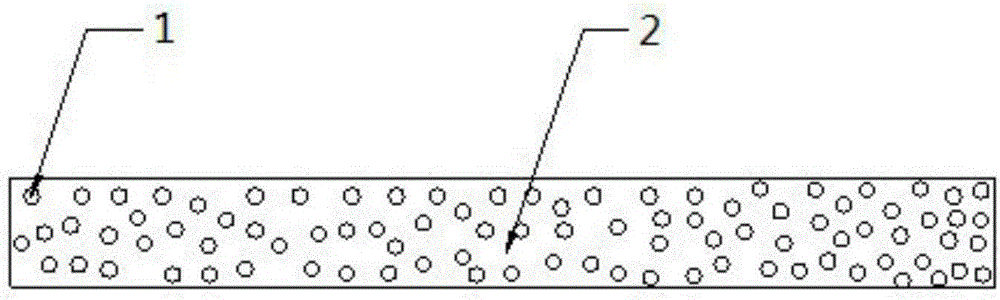

Li-S Battery with Carbon Coated Separator

ActiveUS20180287121A1Inhibit migrationHigh porosityCell electrodesFinal product manufactureCarbon coatedBattery cell

A Li—S battery cell comprising a Sulphur-containing cathode, a Lithium-containing anode, a separator in between the cathode and anode with an electrolyte on both sides of the separator filling interspaces between the anode and the cathode. The separator contains electrically conducting carbon and prevents polysulphide intermediates from migrating from the Sulphur-containing cathode to the Lithium anode.

Owner:NORTH CAROLINA STATE UNIV +1

Safe high-performance lithium-ion battery membrane

ActiveCN105185936ASolve the problem of not having self-closing holesFix security issuesCell seperators/membranes/diaphragms/spacersSecondary cellsPolyolefinElectrical battery

The invention discloses a safe high-performance lithium-ion battery membrane, which comprises a polyolefin microporous membrane and nano metal hydroxide coatings which are compounded on the upper surface and / or the lower surface of the polyolefin microporous membrane, or comprises an ultrahigh molecular weight polyethylene (UHMWPE) / high-density polyethylene (HDPE) / nano metal hydroxide microporous membrane, or comprises the UHMWPE / HDPE / nano metal hydroxide microporous membrane and nano metal hydroxide coatings which are compounded on the upper surface and / or the lower surface of the UHMWPE / HDPE / nano metal hydroxide microporous membrane. The three safe high-performance lithium-ion battery membranes disclosed by the invention have double safety guarantees of high-temperature self-closing holes and flame retardation; and the safety problem that an existing UHMWPE lithium-ion battery membrane does not have the self-closing holes or the flame retardant property is solved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

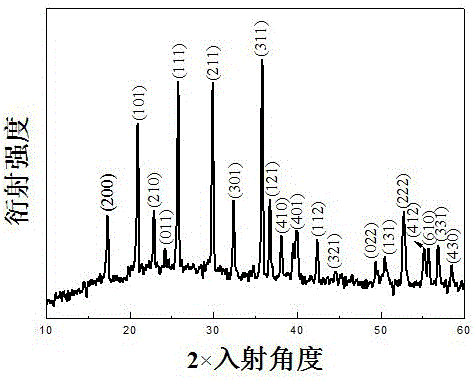

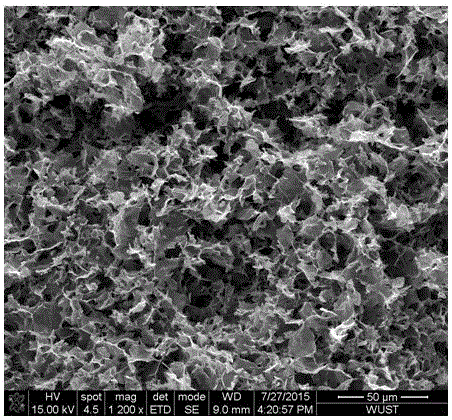

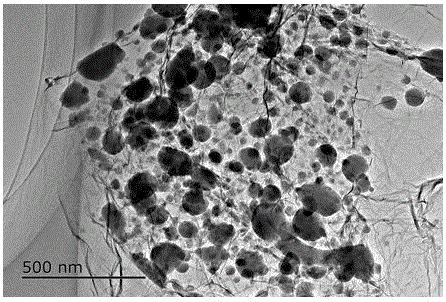

Graphene aerogel loaded lithium iron phosphate porous composite material and preparation method thereof

ActiveCN106025241AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsHigh ratePhosphate

The invention relates to a graphene aerogel loaded lithium iron phosphate porous composite material and a preparation method thereof. The technical scheme of the invention is as follows: the preparation method comprises the steps: adding a graphene oxide into deionized water, and carrying out stirring so as to obtain a solution I with the concentration of 2kg / m<3> to 5kg / m<3>; adding a ferric salt into the solution I in accordance with that the mass ratio of the ferric salt to the graphene oxide is 1: (0.03 to 0.3), and carrying out stirring so as to obtain a solution II; adding phosphate and a lithium salt into the solution II in accordance with that the mass ratio of the ferric salt to the phosphate to the lithium salt is 1: 1: 2, carrying out stirring, carrying out a hydrothermal reaction in a reactor, carrying out washing, carrying out freezing, and carrying out drying in a vacuum freeze drier; carrying out heat preservation for 4 to 10 hours in a tube type furnace in a protective atmosphere at the temperature of 550 DEG C to 850 DEG C, and carrying out furnace cooling, thereby preparing the graphene aerogel loaded lithium iron phosphate porous composite material. According to the graphene aerogel loaded lithium iron phosphate porous composite material and the preparation method thereof, the operation is convenient, industrial production is facilitated, the prepared product is adjustable in pore structure and particle size of lithium iron phosphate loaded on the surface of graphene, and the structural stability, cycle performance and high rate capability are excellent.

Owner:WUHAN UNIV OF SCI & TECH

Fiber meshed modified lithium sulfur battery diaphragm and preparation method and application thereof

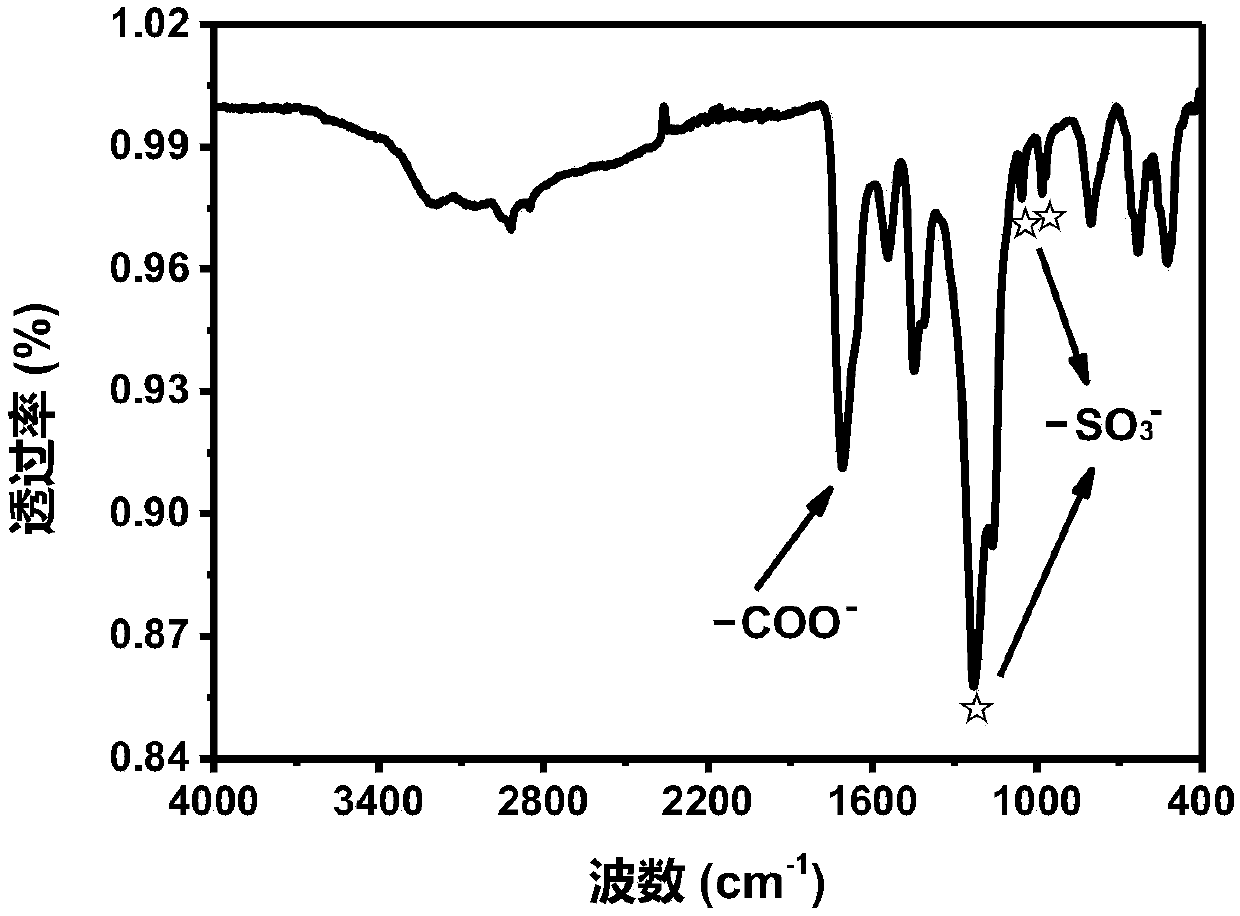

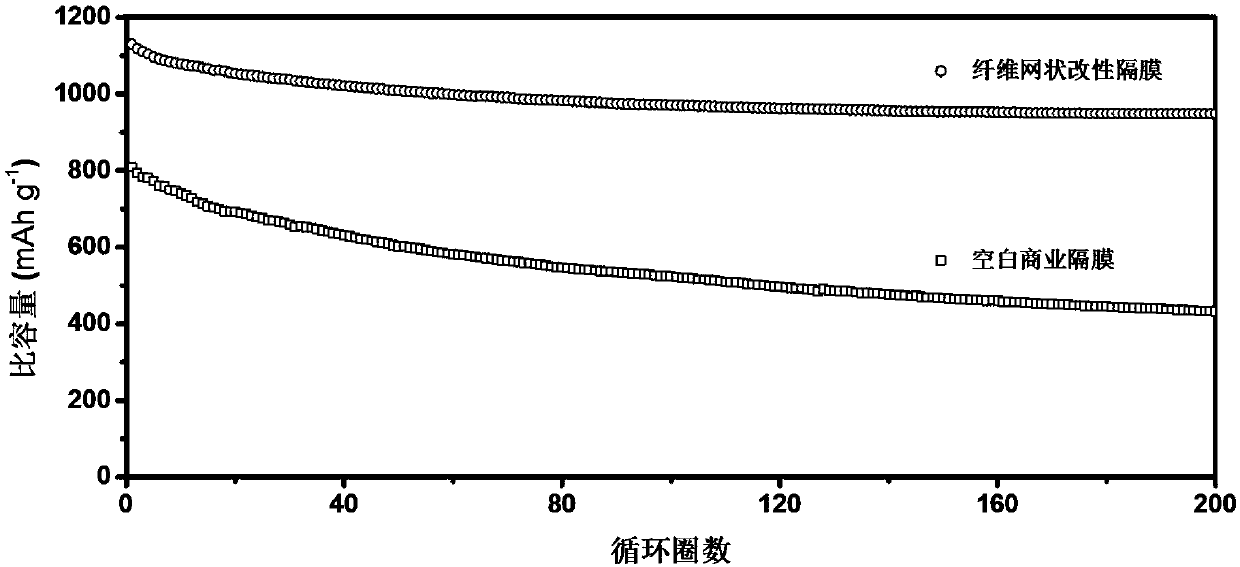

ActiveCN109638205AEasy to passStop passingSecondary cellsLiquid/gas/vapor removalElectrical batteryLithium–sulfur battery

The invention belongs to the technical field of lithium sulfur battery diaphragms, in particular to a fiber meshed modified lithium sulfur battery diaphragm and a preparation method thereof. The fibermeshed modified lithium sulfur battery diaphragm is obtained by arranging a Nafion / polyacrylic acid fiber layer on a commercial diaphragm and carrying out heat treatment and lithium treatment sequentially. The fiber meshed modified lithium sulfur battery diaphragm prepared in the invention has good electrolyte wettability, small impedance and the ability of fast lithium ion conduction, and can prevent the shuttle of polysulfides. Therefore, excellent electrochemical performance is achieved in the application to lithium-sulfur batteries, the capacity attenuation of lithium-sulfur batteries isinhibited, and the service life of batteries is prolonged. In addition, the electro-spinning technology used in the preparation process is simple, the degree of automation and the production efficiency are high, and the diaphragm is easy to scale up and produce.

Owner:河南景创新能源科技有限公司 +1

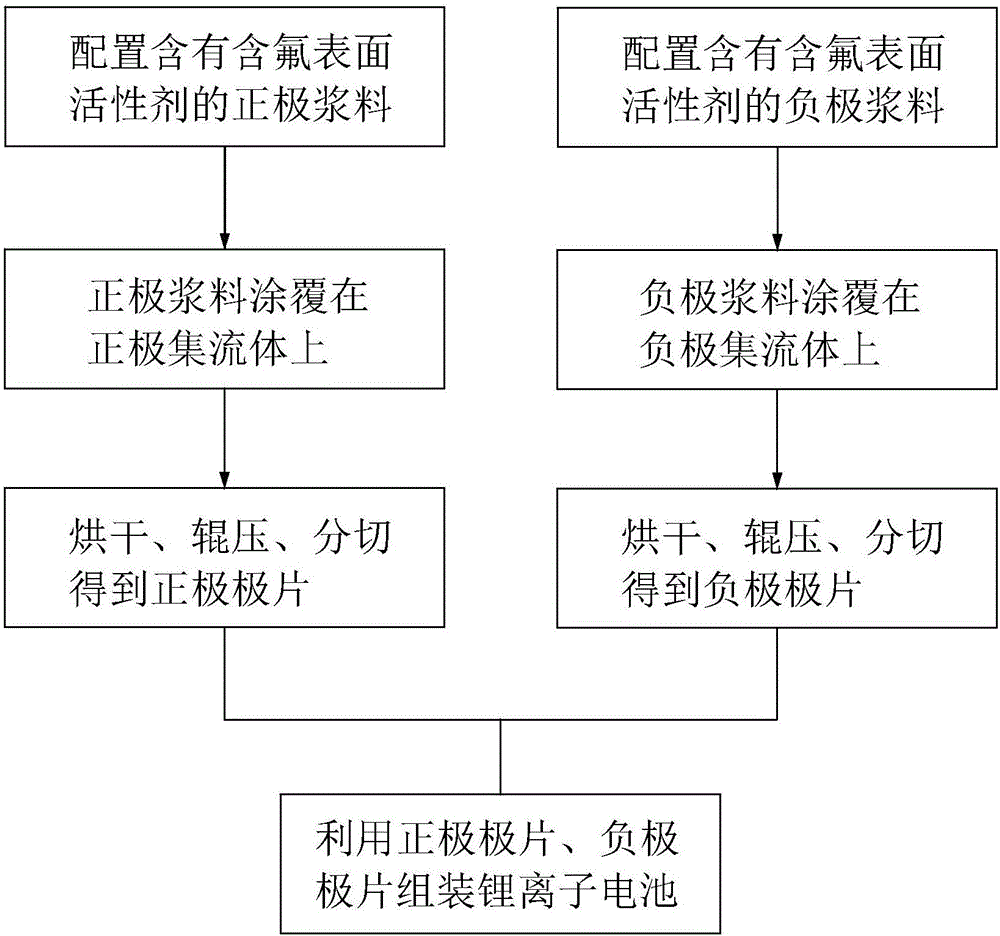

Preparation method for lithium ion battery

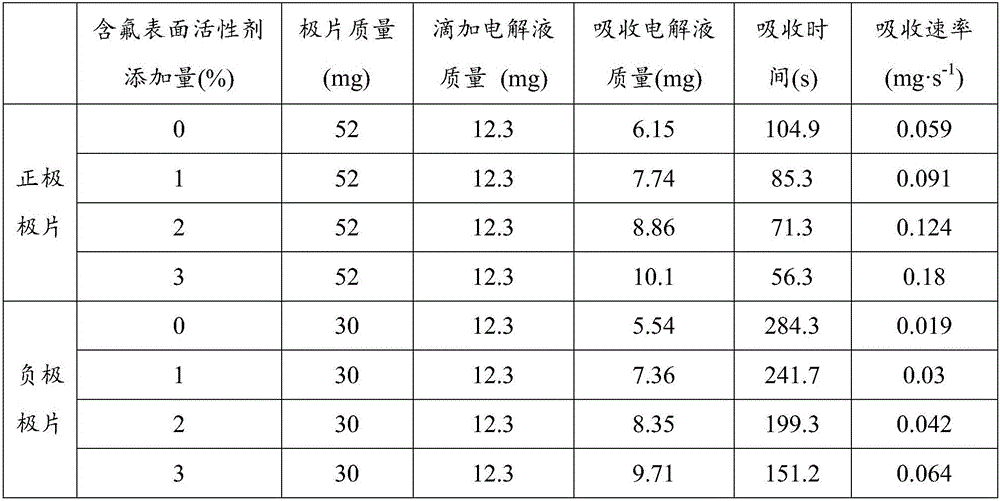

InactiveCN106785064AShorten the injection timeImprove electrolyte wettabilityFinal product manufactureElectrolyte accumulators manufactureMass ratioSolvent

The invention provides a preparation method for a lithium ion battery. The method comprises the following steps: 1) mixing an anode active material, a conductive agent, a binder and a fluorine-containing surfactant at a mass ratio of (80%-97%): (1%-10%): (1%-10%): (0.5%-10%) with a dissolvent, preparing the mixture into an anode sizing agent; coating the anode sizing agent onto an anode current collector, drying, rolling and slitting, thereby obtaining an anode pole piece; 2) mixing a cathode active material, a conductive agent, a binder and a fluorine-containing surfactant at a mass ratio of (80%-97%): (1%-10%): (1%-10%): (0.5%-10%) with a dissolvent, preparing the mixture into a cathode sizing agent; coating the cathode sizing agent onto a cathode current collector, drying, rolling and slitting, thereby obtaining a cathode pole piece; and 3) utilizing the anode pole piece, the cathode pole piece, the diaphragm and the electrolyte to assemble the lithium ion battery.

Owner:OPTIMUM BATTERY CO LTD

Composite separator and preparation method thereof

ActiveCN109817865AHigh porosityPorosity, improved heat resistance in the improved separatorLi-accumulatorsCell component detailsPorosityPolyolefin

The invention relates to a composite separator and a preparation method thereof. The lithium battery composite separator is formed by compounding a polyolefin microporous membrane and one or two high-temperature-resistant non-woven fabric layers, wherein the thickness of the composite separator is 6-40[mu]m, the surface density is 5-35g / m<2>, the porosity is 35-50%, the liquid absorption rate is greater than 150%, the thermal shrinkage rate at 130 DEG C is less than 0.5%, and the ionic conductivity is (1.0-5.0)*10<-3>S / cm. The composite separator disclosed by the invention has the advantages that the is fast; the lithium battery composite diaphragm has the characteristics of fast electrolyte infiltration, high liquid absorption rate, low thermal shrinkage rate, good mechanical property andthe like, the compatibility of the separator and an electrolyte is improved, the safety and the service life of a lithium battery are improved, and the prepared composite separator also adapts to thetechnological requirements of mechanical assembly of a battery production line and has a relatively wide application field.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

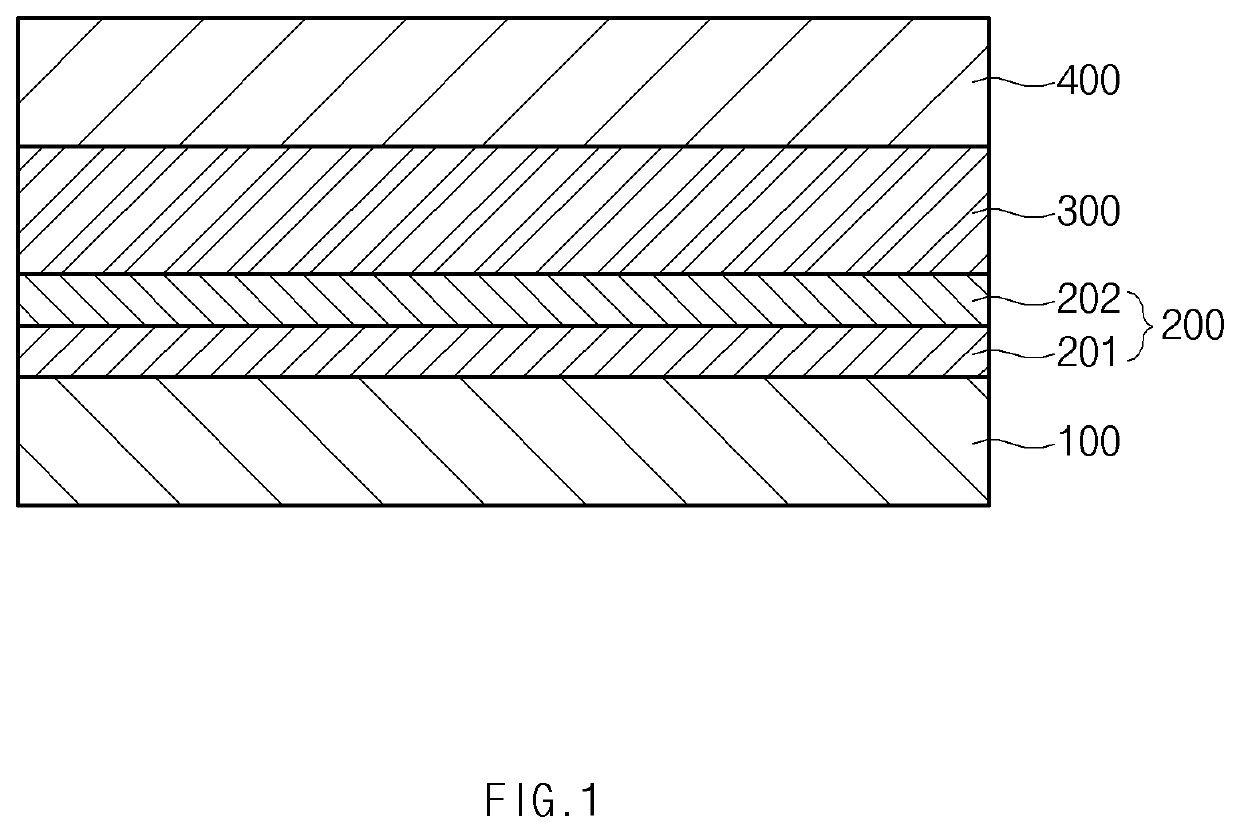

Current collector, pole sheet and electrochemical device

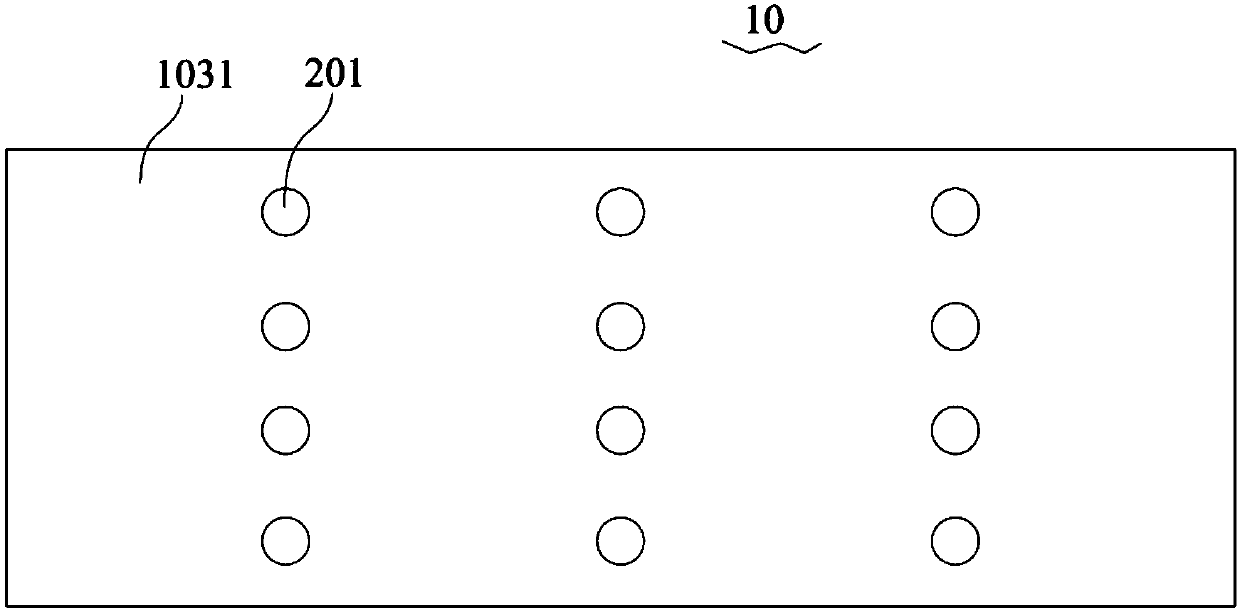

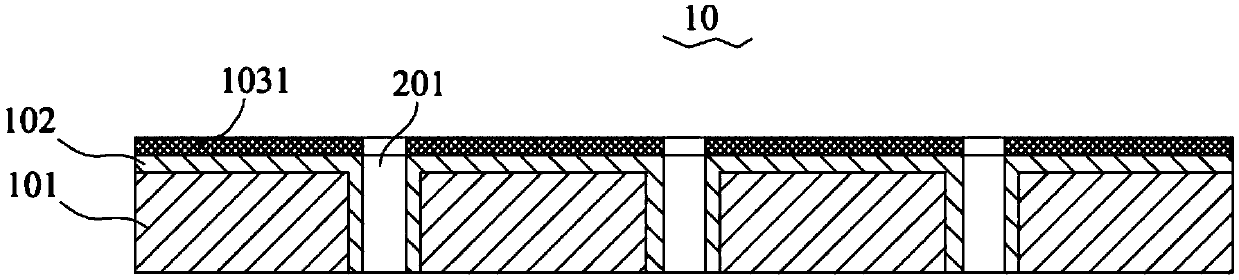

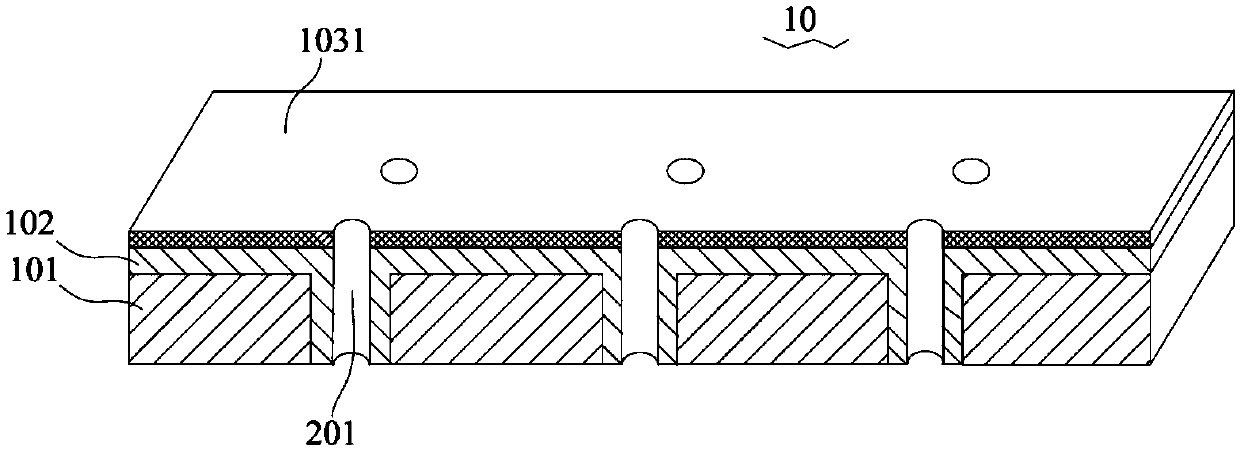

ActiveCN110661000AHigh mechanical strengthImprove securityElectrode carriers/collectorsSecondary cellsElectrolytic agentElectrical resistance and conductance

The application belongs to the field of batteries and relates to a current collector. The current collector includes an insulating layer and a conducting layer, wherein the conductive layer is positioned on at least one surface of the insulating layer; the current collector further comprises a first protective layer arranged on a surface, far away from the insulating layer, of the conducting layer; a plurality of holes penetrating through the insulating layer, the conducting layer and the first protective layer are formed in the current collector; and the first protective layer is a metal oxide protective layer. According to the current collector provided by the invention, short-circuit resistance during a short circuit under the abnormal condition of a battery can be improved, so that heat generated the short circuit can be greatly reduced, and therefore, the safety performance of the battery is improved; the mechanical strength of the conductive layer can be improved through the protective layer; the working stability of the current collector is improved; the service life of the current collector is prolonged; the plurality of holes penetrating through the insulating layer and the conductive layer can facilitate the passage of electrolyte, and therefore, the wettability of the electrolyte can be improved, and the electrochemical performance of the battery and the weight energy density of the battery can be improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Full-ceramic lithium ion battery diaphragm and preparation method thereof

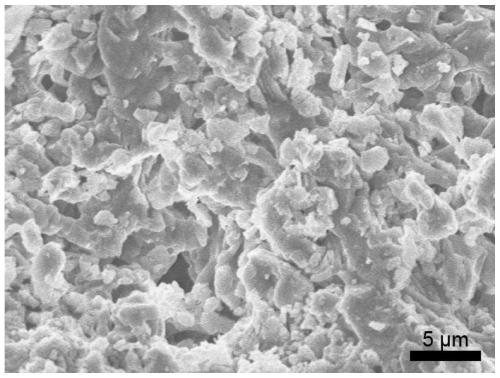

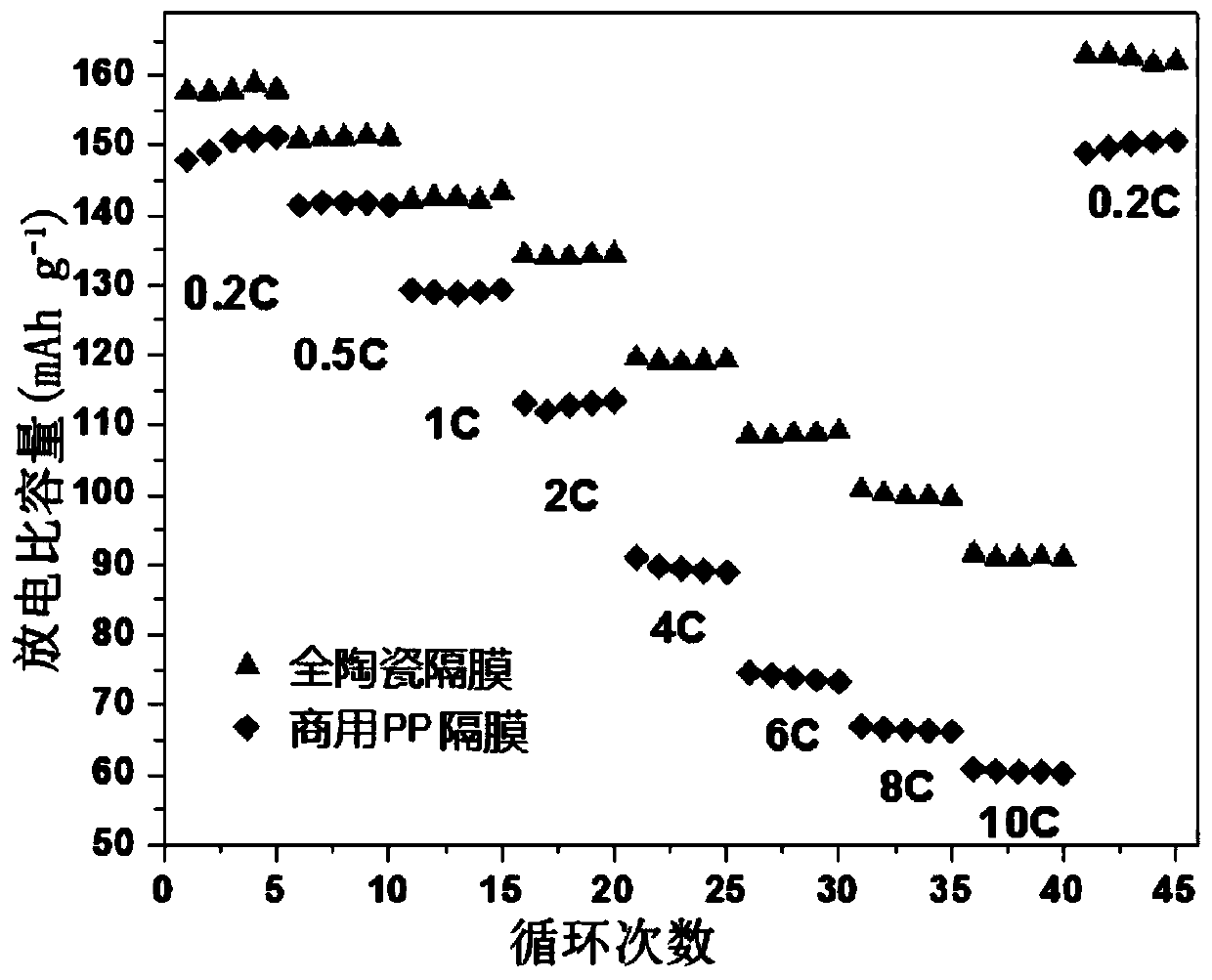

ActiveCN111477818AEasy transferImprove mass transfer efficiencySecondary cellsCell component detailsLithium hydroxidePhysical chemistry

The invention relates to a full-ceramic lithium ion battery diaphragm and a preparation method thereof, and belongs to the field of diaphragm materials. According to the method, diatomite is used as amain raw material, lithium hydroxide is matched, a small amount of rare earth elements are doped, an organic binder is used for molding, and the full-ceramic lithium ion battery diaphragm taking silicon dioxide and lithium silicate as main components is formed after high-temperature calcination. The diaphragm is excellent in thermal stability, and the safety problem that a traditional lithium ionbattery diaphragm shrinks and deforms due to heating to cause short circuit and fire in a battery is thoroughly solved. Meanwhile, the diaphragm has the characteristics of good electrolyte affinity,high porosity and large liquid absorption capacity, the mass transfer efficiency of lithium ions in the battery is effectively promoted, and the capacity retention ratio of the battery during high-current charging and discharging and long-time operation is improved.

Owner:JILIN UNIV

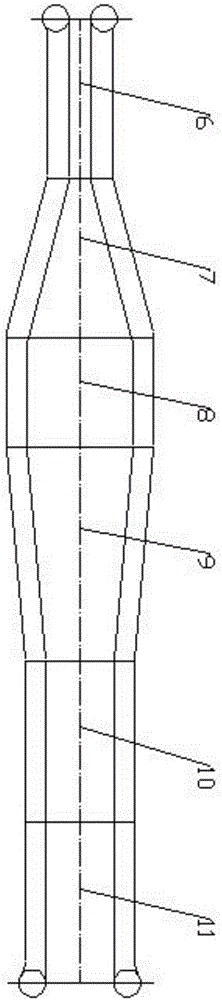

Parallel pre-formation module composed of low-cost high-space-utilization lithium ion battery

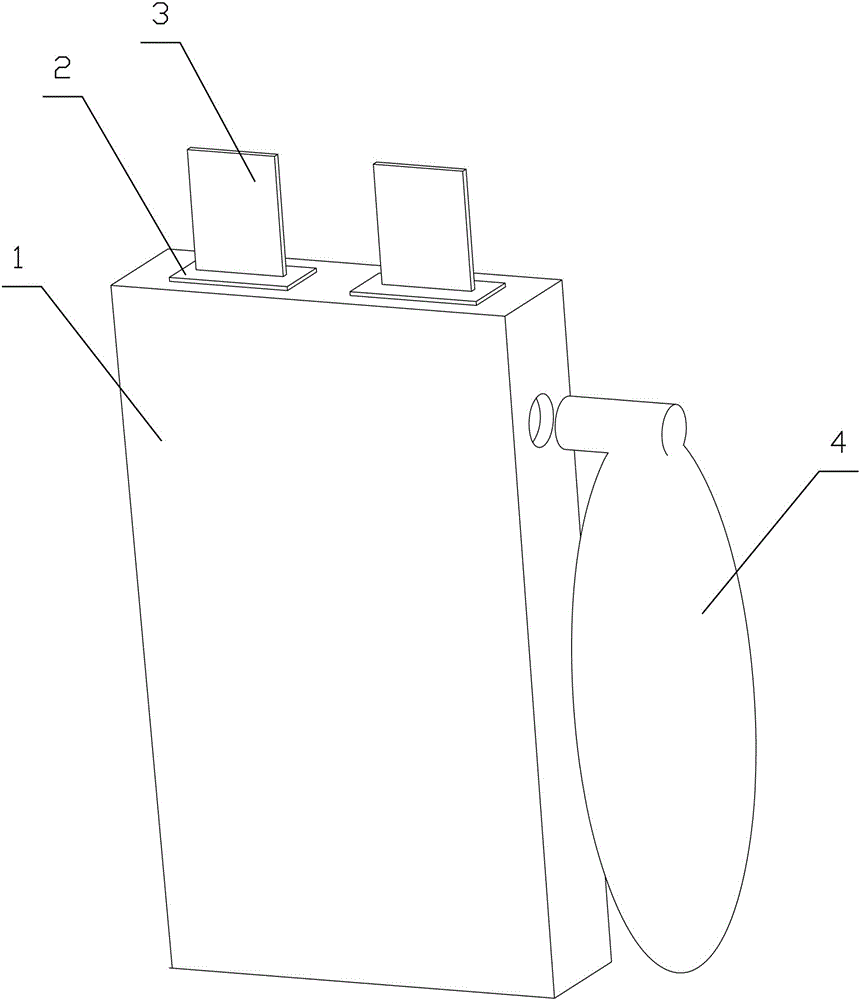

PendingCN106252713AReduce the risk factorReduce exhaust stepsCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrical batteryMicrometer

A parallel pre-formation module composed of a low-cost high-space-utilization lithium ion battery is characterized in that a rolled cell is arranged in an aluminum shell by means of rolling, tabs are led out of the same side of the rolled cell, the top of the aluminum shell is provided with two openings, aluminum-plastic film is welded to the openings and is provided with holes which the tabs run through, the aluminum shell is fitted with a balloon, the side of the aluminum shell is provided with a side opening which is connected with a balloon connection hole, a diaphragm includes a microporous PET (polyethylene terephthalate) thin film and a layer of multi-pore material, straight micropores arranged along the thickness are distributed in the microporous PET thin film, the layer of multi-pore material is applied to the microporous PET thin film to form double-layer stacked meshed microporous structure, and the layer of multi-pore material has a porosity of 10-90% and is less than 2 micrometers in pore size. The microporous PET thin film is 2-50 micrometers in thickness, and cells are connected in parallel through a clamp and are subjected to parallel pre-formation.

Owner:SHANDONG FOREVER NEW ENERGY +2

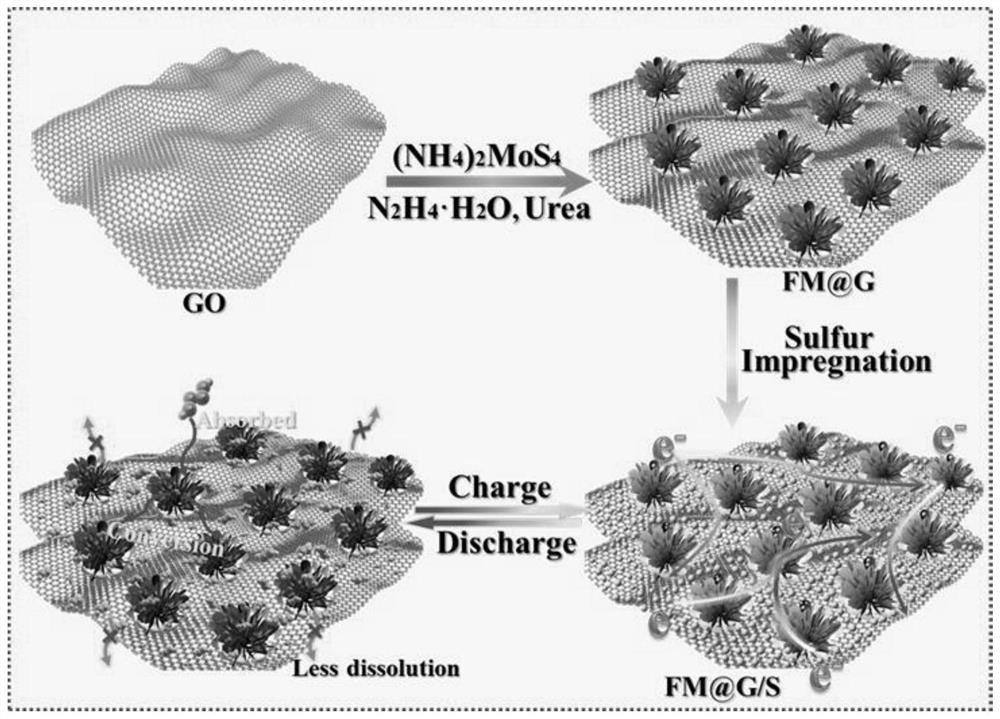

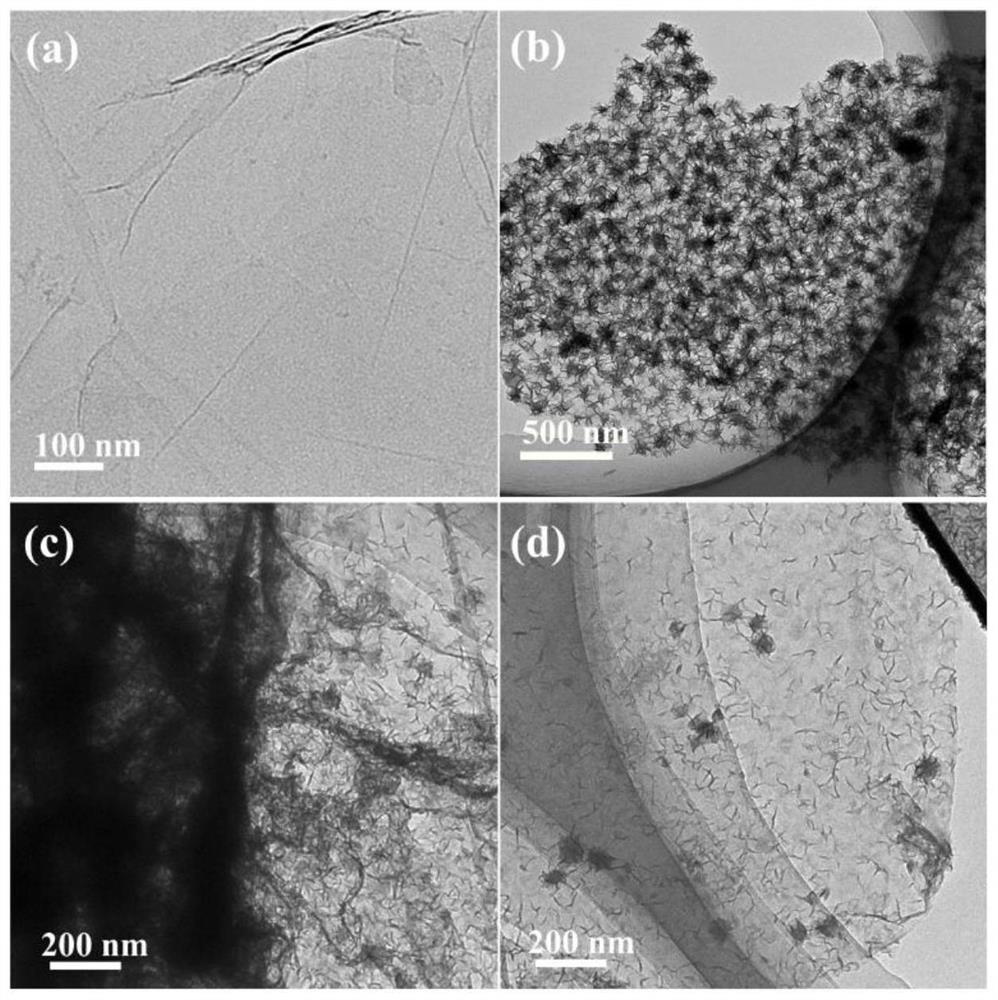

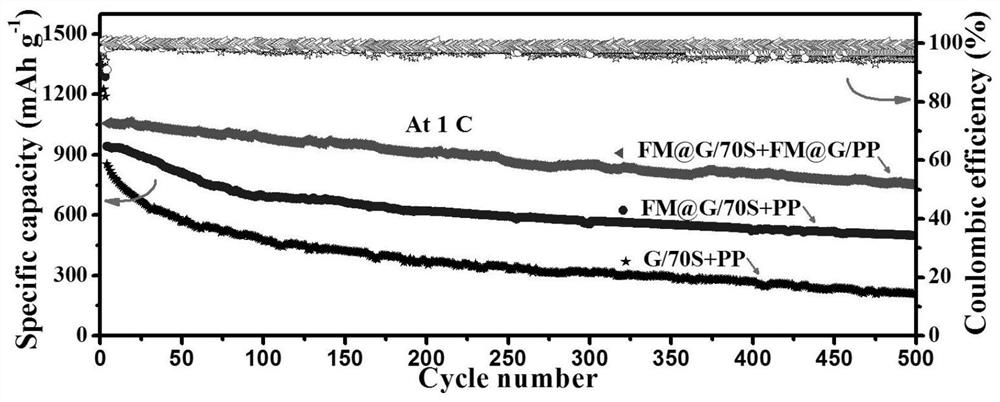

Preparation method and application of graphene-loaded high-conductivity molybdenum sulfide nanoflower material

ActiveCN112421045AIncrease sulfur loadImprove Coulombic efficiencyMaterial nanotechnologyPositive electrodesHigh energyLithium sulfur

The invention relates to a preparation method of a high-conductivity composite material (FM-coating G) with molybdenum sulfide nanoflowers uniformly loaded on graphene and system modification of the high-conductivity composite material for a lithium-sulfur battery. The preparation method comprises the following steps: dispersing a certain amount of graphene oxide in a DMF solution, adding a certain amount of ammonium tetrathiomolybdate and urea into the dispersion liquid, carrying out ultrasonic treatment, adding a hydrazine hydrate solution, stirring the obtained mixed solution, carrying outuniform ultrasonic treatment, and carrying out a solvothermal reaction to prepare the FM-coating G composite material. An FM-coating G / S positive electrode material is prepared from the quantitative FM-coating G and elemental sulfur through a hot melt diffusion method. The FM-coating G ethanol dispersion liquid is filtered to a PP diaphragm under vacuum, thereby obtaining the FM-coating G-PP modified diaphragm. The obtained material has an efficient synergistic effect when being applied to a positive electrode and a diaphragm of a lithium-sulfur battery, and the adsorption / catalysis capabilityon polysulfide is enhanced, so that the battery has excellent cycle performance and high energy density.

Owner:FUJIAN NORMAL UNIV

A kind of novel ceramic coated polyolefin composite film and preparation method thereof

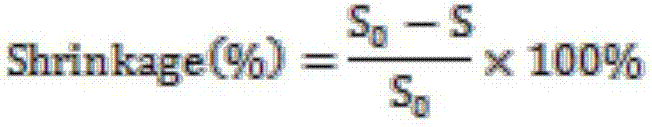

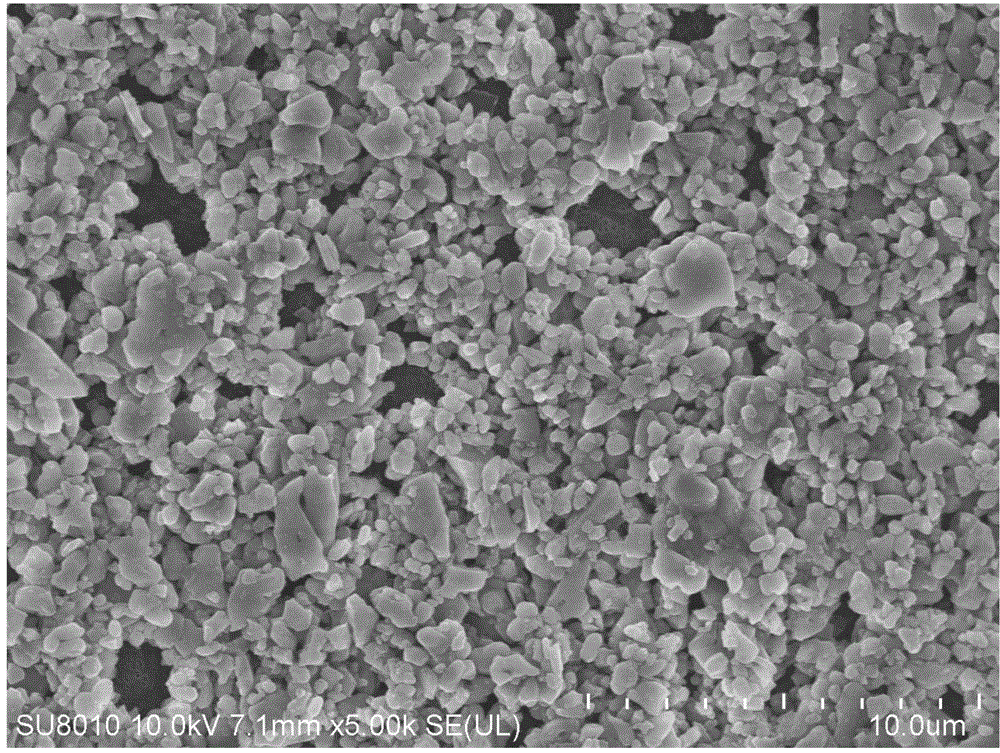

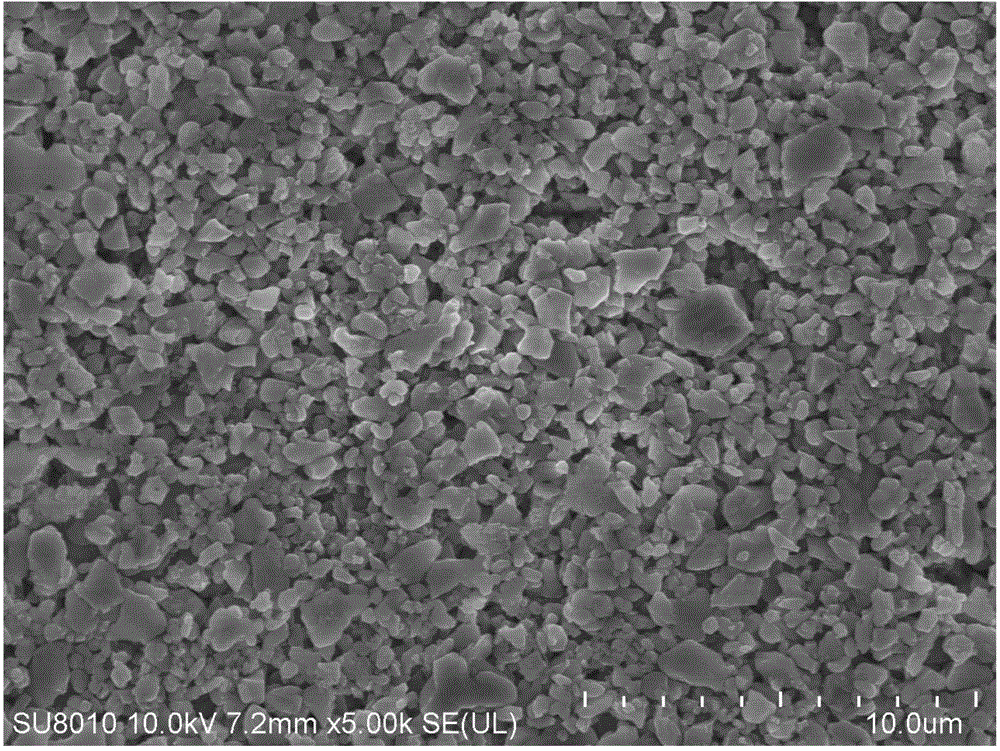

ActiveCN103811702BReduced service lifeExtended service lifeSecondary cellsCell component detailsPolymer sciencePolyolefin

The invention relates to a new type of ceramic-coated polyolefin composite membrane, which includes a microporous polyolefin base. One or both sides of the polyolefin base are compounded with a ceramic coating. The ceramic coating includes: porous ceramic particles, inorganic Fillers and binders. The invention also relates to a method for preparing a new ceramic-coated polyolefin composite film, which includes the following steps: a. Dissolving the binder in a solvent to prepare a binder solution; b. Adding porous ceramic particles and functional inorganic fillers into the into the binder solution prepared in step a, and then perform dispersion treatment to obtain a coating slurry; c. The coating slurry prepared in step b is coated on one or both surfaces of the polyolefin substrate, and then dried and solidified to obtain a product. The new functional composite film of the present invention has good liquid absorption and liquid retention properties and the function of reducing harmful gases inside the battery, improving battery performance and service life. It also has low closed cell temperature, high melting temperature and small thermal shrinkage rate. and other safety features.

Owner:河南惠强新能源材料科技股份有限公司

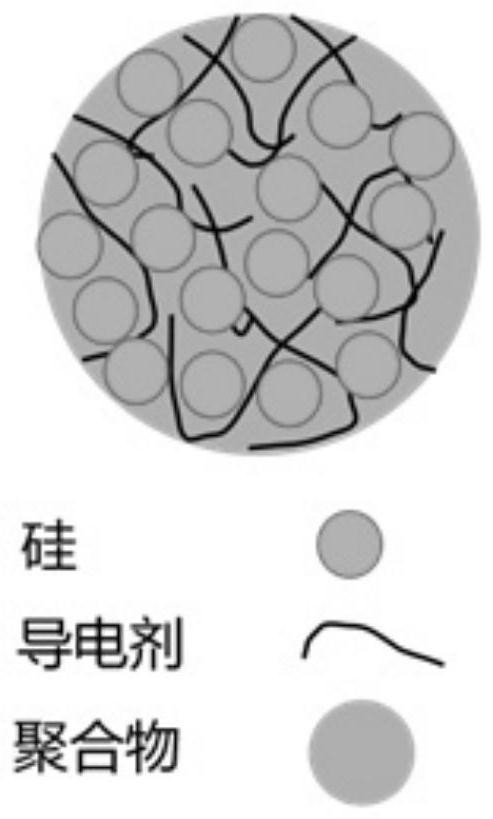

Composite nano-silicon negative electrode and preparation and application thereof

InactiveCN111883760AExcellent performanceImprove stabilityCell electrodesSecondary cellsLithium electrodePolymer

The invention discloses a composite nano-silicon negative electrode material and preparation and application thereof, and belongs to the technical field of lithium ion batteries. The composite nano-silicon negative electrode material comprises nano-silicon, a three-dimensional electron conduction skeleton and a polymer, and the nano silicon is uniformly dispersed in the three-dimensional electronconduction skeleton and the polymer. The basic principle of the composite negative electrode material is that the nano-silicon, the three-dimensional electron conduction skeleton and the polymer are uniformly mixed and dispersed, then the composite three-dimensional nano-silicon negative electrode material is obtained by methods of granulation, drying and the like, the nano-silicon, the polymer and the three-dimensional electron conduction skeleton are uniformly distributed, and the three-dimensional electron conduction skeleton and the polymer have the properties of absorbing electrolyte andmaintaining an ion channel, so that excellent ion conductivity and electron conductivity of the composite nano silicon negative electrode material during working in a lithium ion battery are ensured.

Owner:黄杰

Composite conductive agent and preparation method thereof, and lithium ion battery

ActiveCN112038637AHigh magnificationImprove cycle performanceMaterial nanotechnologyCell electrodesAcid etchingCarbon nanotube

The invention discloses a composite conductive agent and a preparation method thereof, and a lithium ion battery, belonging to the technical field of lithium ion batteries. The composite conductive agent is prepared by growing a metal organic framework 2-methylimidazole zinc salt on the surface of an initial conductive agent, and then carrying out high-temperature carbonization and acid etching toobtain the composite conductive agent surface-coated with porous amorphous carbon, wherein the initial conductive agent is composed of a granular conductive agent and a linear conductive agent. According to the invention, the granular conductive agent is anchored on the linear conductive agent, namely a carbon nanotube, and the dispersing capacity of the carbon nanotube is improved through sterichindrance repulsion; in positive electrode slurry and negative electrode slurry, the granular conductive agent fills in gaps among active material particles, and the linear conductive agent is used for remote overlapping with the granular conductive agent to form a dot-line three-dimensional net-shaped conductive network, so the contact performance of the conductive agents and an active materialis improved, electron transmission efficiency is improved, and the probability of insufficient contact caused by expansion of active substances in the charging and discharging processes is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

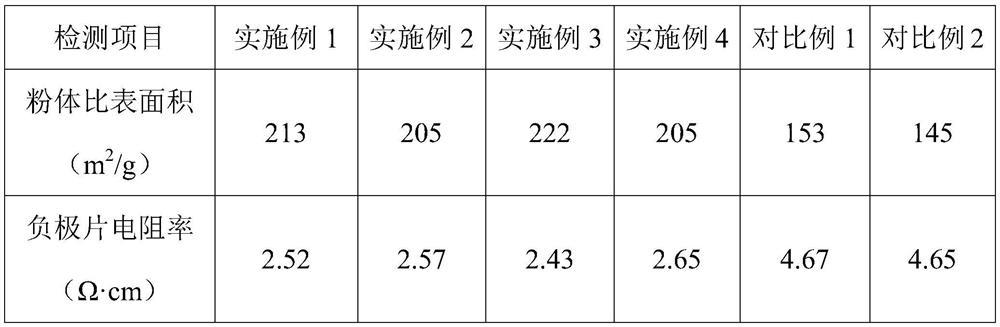

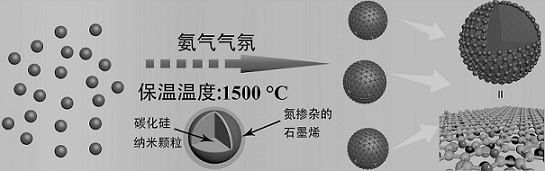

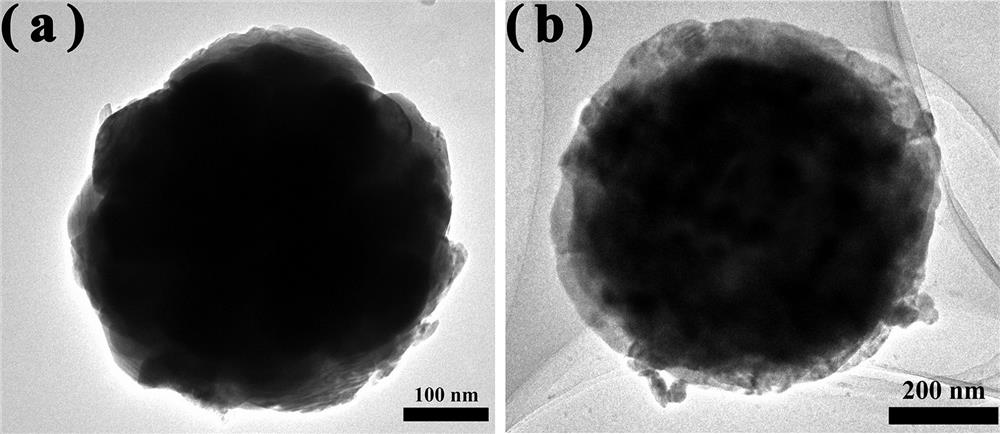

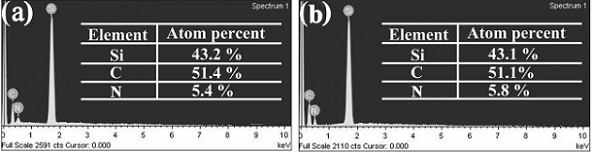

Preparation method of nitrogen-doped graphene coated SiC nanoparticle lithium ion battery negative electrode material

InactiveCN112054185AGood electrolyte wettabilitySimple preparation stepsSecondary cellsNegative electrodesDoped grapheneNanoparticle

The invention provides a preparation method of a nitrogen-doped graphene coated SiC nanoparticle lithium ion battery negative electrode material. The method comprises the following steps: in an ammonia atmosphere, heating SiC nanoparticles to a predetermined time, and cooling to obtain nitrogen-doped graphene coated SiC nanoparticles. The prepared nitrogen-doped graphene coated SiC nanoparticles can significantly improve the electrochemical performance of the lithium ion battery.

Owner:DONGGUAN UNIV OF TECH

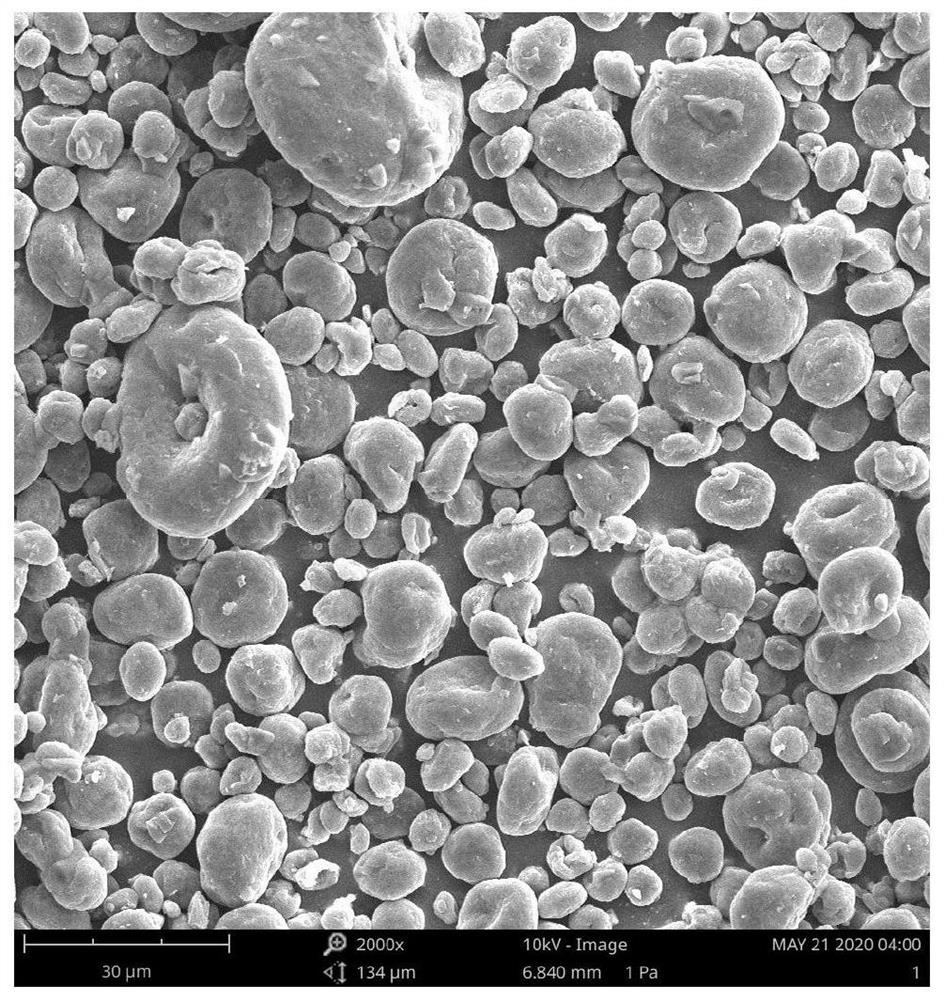

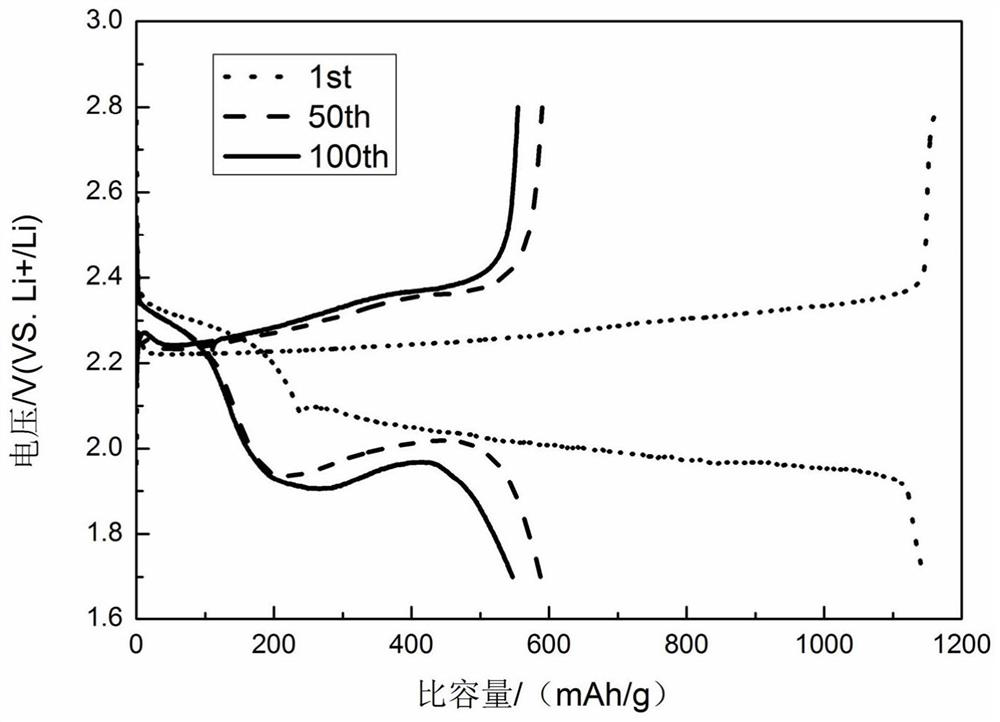

Lithium-sulfur battery cathode material, preparation method thereof and lithium-sulfur battery

InactiveCN112216839AIncrease energy densityImprove cycle stabilityPositive electrodesLi-accumulatorsElectrical batteryLithium–sulfur battery

The invention discloses a positive electrode material of a lithium-sulfur battery, a preparation method of the positive electrode material and the lithium-sulfur battery. The lithium-sulfur battery positive electrode material comprises a composite carbon particle body, the composite carbon particle body is spherical and has a three-dimensional porous structure, the composite carbon particle body comprises carbon nanotubes and Ketjen black, and the carbon nanotubes and the Ketjen black are mixed and distributed; and elemental sulfur is at least deposited on the surface of the composite carbon particle body and the pore surface of the three-dimensional porous structure. The active layer of the positive electrode of the lithium-sulfur battery contains the positive electrode material of the lithium-sulfur battery. According to the lithium-sulfur battery positive electrode material disclosed by the invention, the composite carbon particle body formed by the carbon nanotubes / Ketjen black isa spherical and porous sulfur-loaded skeleton, so that the sulfur loading capacity is high, the energy density is high, the shuttle effect caused by polysulfide is low, and the cycling stability is good. A pole piece formed by the positive electrode material of the lithium-sulfur battery and the lithium-sulfur battery are high in energy density, good in electrolyte wettability and excellent in cycle performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

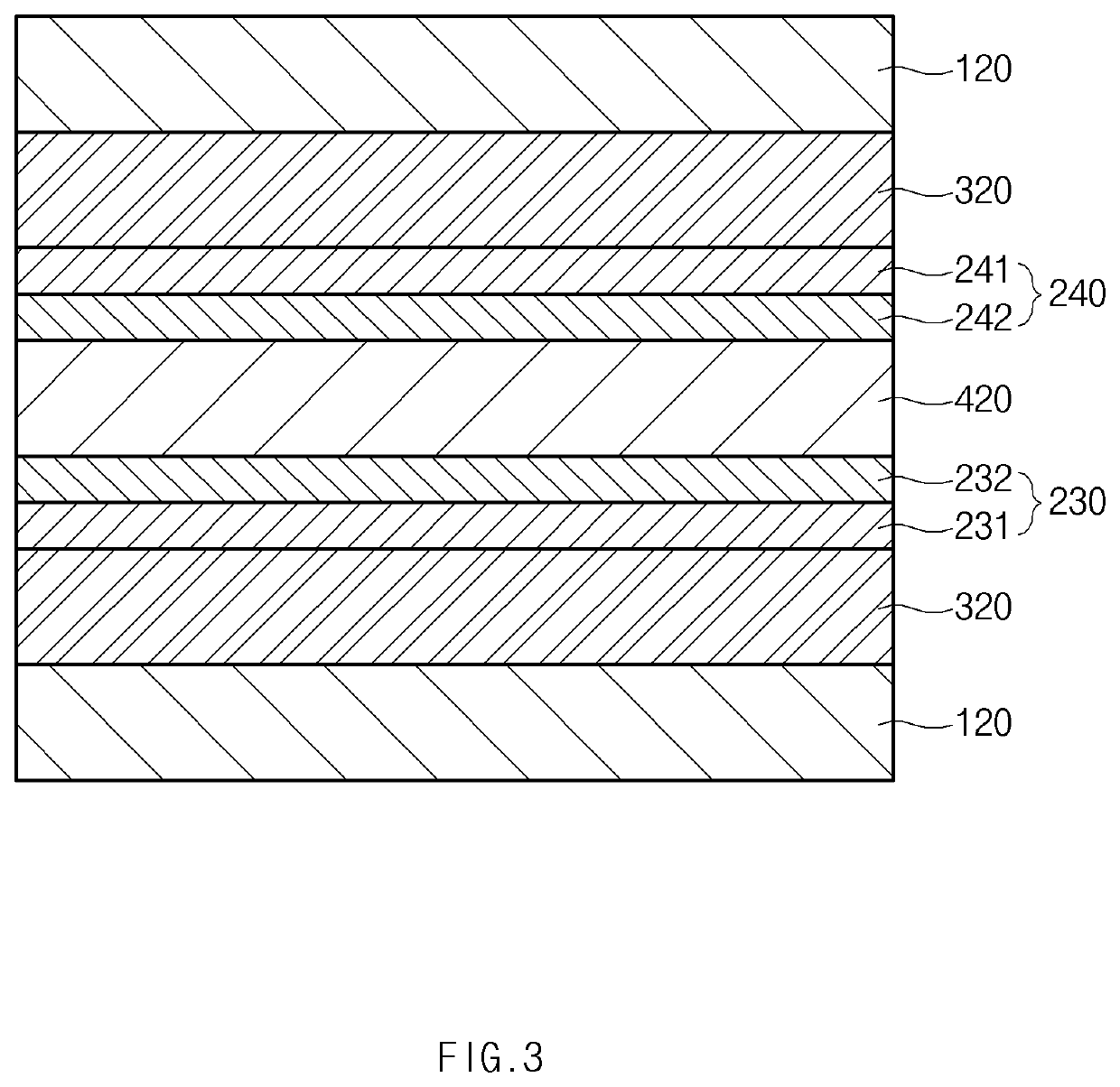

Electrode Assembly, Method of Manufacturing the Same and Secondary Battery Including the Same

ActiveUS20200067049A1Reduce riskGood electrolyte wettabilityFinal product manufactureSecondary cellsBattery cellMaterials science

The present invention provides an electrode assembly, which includes a first electrode, an adhesive layer disposed on the first electrode and including a host layer comprising a host and a guest layer comprising a guest, a separator disposed on the adhesive layer, and a second electrode disposed on the separator, a method of manufacturing the same, and a secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

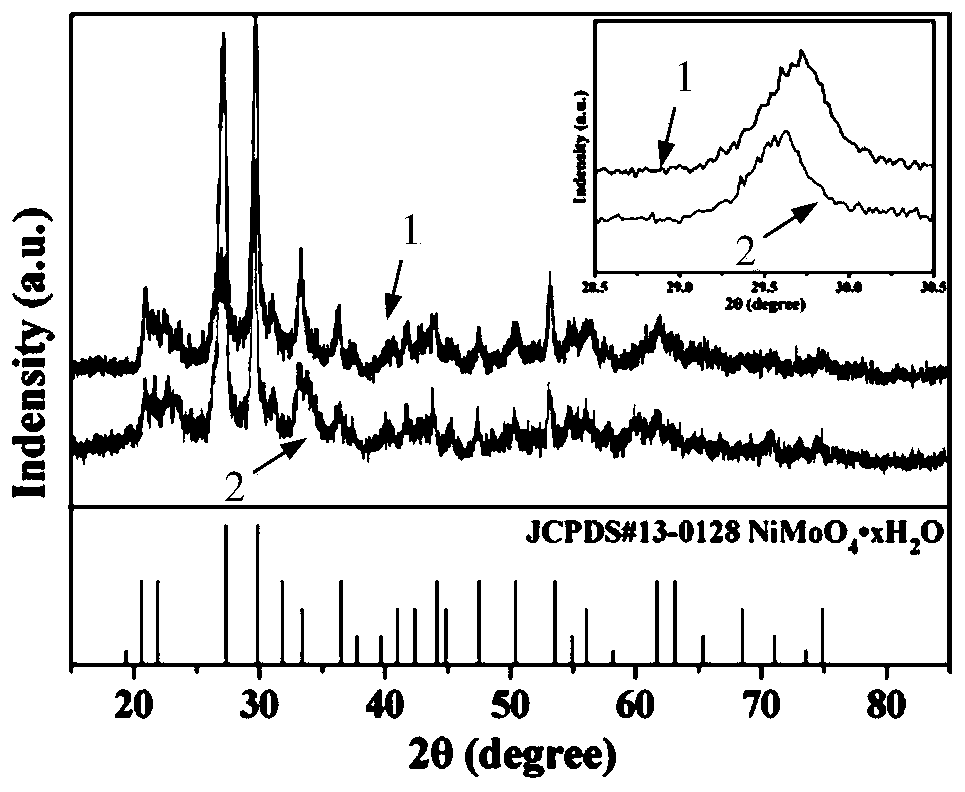

Composite material with oxide @ sulfide core-shell structure as well as preparation method and application of composite material

ActiveCN110033951AIncrease profitRealize one-step controlHybrid capacitor electrodesHybrid/EDL manufactureVulcanizationCore shell

The invention provides a composite material with an oxide @ sulfide core-shell structure as well as a preparation method and application of the composite material. A NiMoS4 nanosheet layer is attachedto the surface of a NiMoO4 nanorod to form a NiMoO4 nanorod@ NiMoS4 nanosheet composite material which takes the NiMoO4 nanorod as a core and takes the NiMoS4 nanosheet as a shell. The preparation method comprises the steps of carrying out vulcanization modification on the NiMoO4 nanorod and a sulfur source through a hydrothermal method to obtain the NiMoO4 nanorod@ NiMoS4 nanosheet composite material. According to the method, through the combination of oxide and sulfide, the synergistic effect of the oxide and the sulfide is exerted, so that the electrode material with higher performance isobtained.

Owner:SHANDONG UNIV

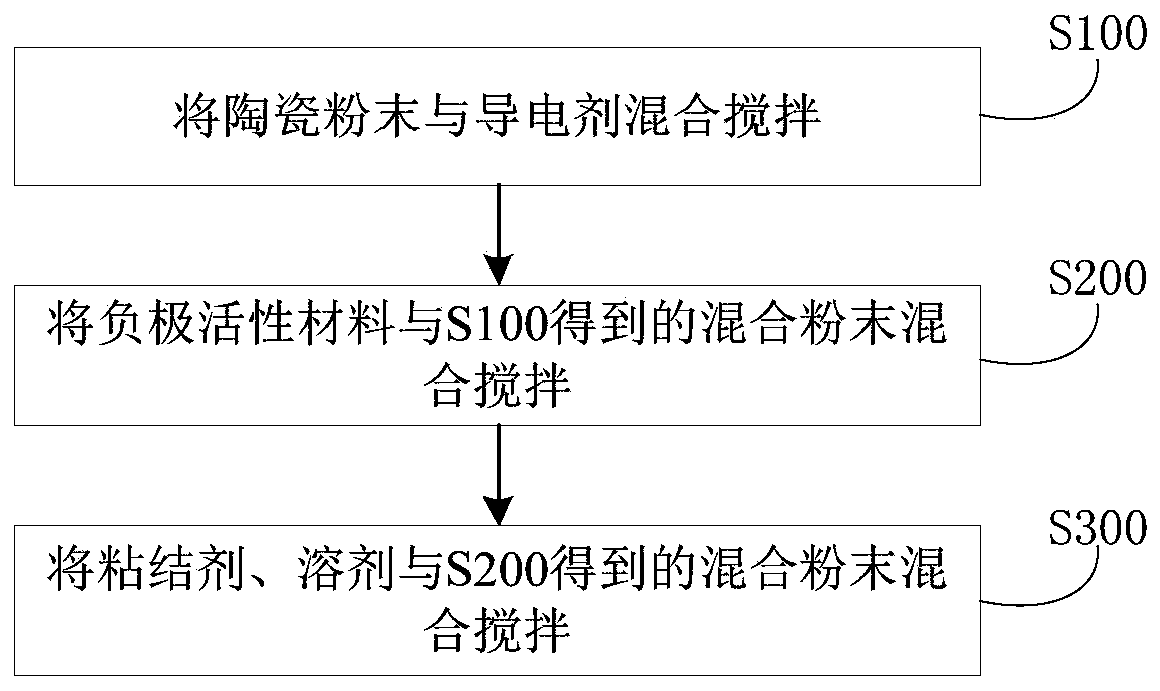

Anode slurry and preparation method thereof, and application of anode slurry

InactiveCN110190283AImprove liquid retention capacityShorten the soaking timeNegative electrodesSecondary cellsMetallurgySlurry

The invention discloses anode slurry and a preparation method thereof, and application of anode slurry. The anode slurry contains ceramic powder, a conductive agent, an anode active material, a binderand a solvent. Because the anode slurry contains ceramic powder, the conductive agent, the anode active material, the binder and the solvent, the high-compaction anode piece prepared by the anode slurry has high liquid absorption and retention, high electrolyte wettability and capability of reducing the soaking time of the high-energy battery electrolyte. Furthermore, the ceramic powder has low cost and low price, so that the cost of the anode slurry is relatively low.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com