Composite separator and application thereof in lithium ion battery

A lithium-ion battery and composite diaphragm technology, applied in the field of electrochemistry, can solve the problems of no ion conductivity, low processability, and high hardness of the composite diaphragm, achieve high electrolyte wettability, and improve the effect of capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

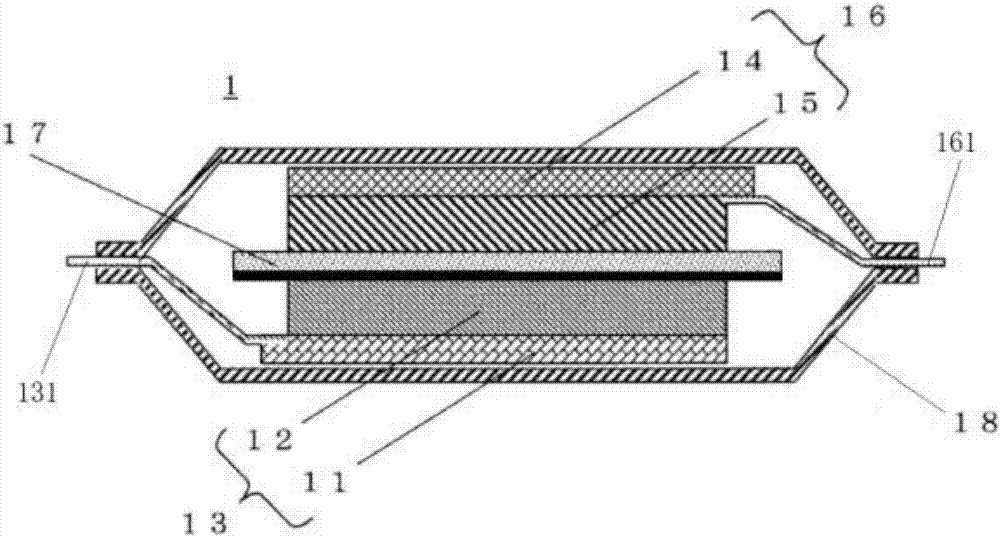

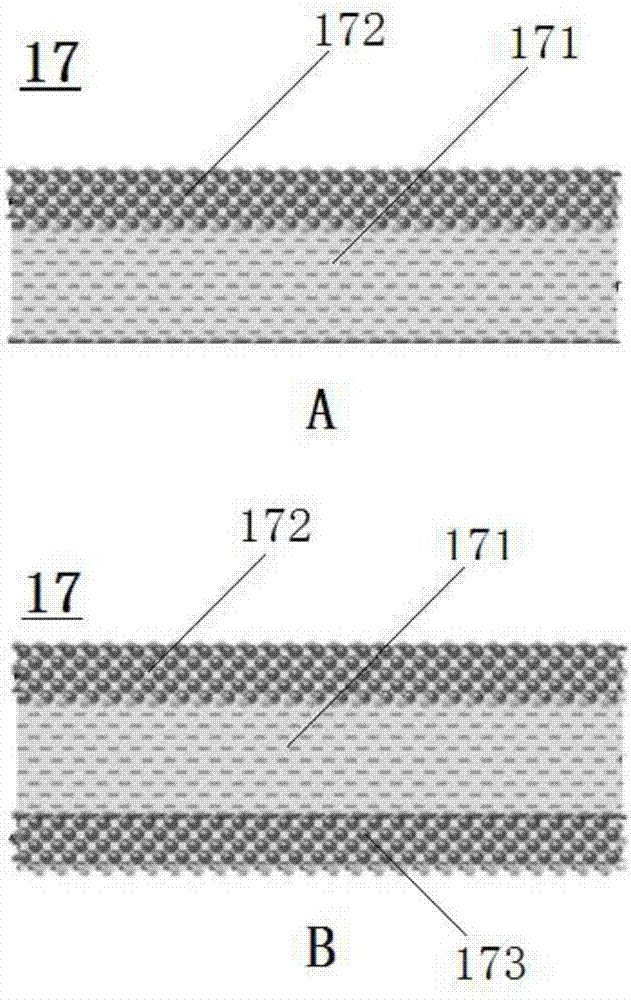

[0083] Preparation of Composite Diaphragm 17:

[0084] Put commercially available lithium phosphate, sodium carboxymethylcellulose (CMC) and styrene-butadiene rubber (SBR) into deionized water and acetone (3:1, v : In 10 mL of the mixed solution of v), ball mill the obtained slurry overnight, ultrasonically disperse the mixed slurry for 20 minutes, and evenly coat the obtained slurry on one side of a common commercially available 16 μm PE diaphragm 171 with a silk stick. Preheat with an electric heating plate at 60°C, wait for most of the solvent to volatilize, put it in a vacuum oven and dry at 60°C overnight to completely remove the solvent, and obtain a lithium phosphate-coated single-sided composite separator 17, in which the thickness of the lithium phosphate layer is about 4 μm.

[0085] Preparation of lithium-ion battery 1:

[0086] Fabrication of electrodes: Firstly, the positive electrode 13 is fabricated. In 94 parts by mass of lithium manganate (LiMn 2 o 4), mix...

Embodiment 2

[0091] Magnetron Sputtering of Nitrogen-Containing Lithium Phosphate Li under Nitrogen Atmosphere 3.3 PO 3.9 N 0.17 (LiPON) compounds. Put the synthetic nitrogen-containing lithium phosphate and sodium carboxymethylcellulose (CMC) and styrene-butadiene rubber (SBR) into deionized water and ethanol (3:1, v : In 10 mL of the mixed solution of v), a nitrogen-containing lithium phosphate-coated single-sided composite separator 17 and a battery 1 with a nitrogen-containing lithium phosphate layer thickness of 4 μm were prepared in the same manner as in Example 1.

Embodiment 3

[0093] A lithium phosphate-coated single-sided composite separator 17 having a lithium phosphate layer thickness of 2 μm was prepared in the same manner as in Example 1, and a lithium ion battery 1 using the separator 17 was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com