Preparation method of nitrogen-doped graphene coated SiC nanoparticle lithium ion battery negative electrode material

A technology of nitrogen-doped graphene and lithium-ion batteries, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem that the shape and size cannot fundamentally change the slow kinetic process of electrode materials, and the lithium-ion battery rate Reduced performance and cycle life, etc., to achieve the effect of simple preparation steps and good electrolyte wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. The equipment required for the preparation of nitrogen-doped graphene-coated SiC nanoparticles

[0030] Single temperature zone horizontal high temperature tube furnace and corundum boat.

[0031] 2. Reagents required for the preparation of nitrogen-doped graphene-coated SiC nanoparticles

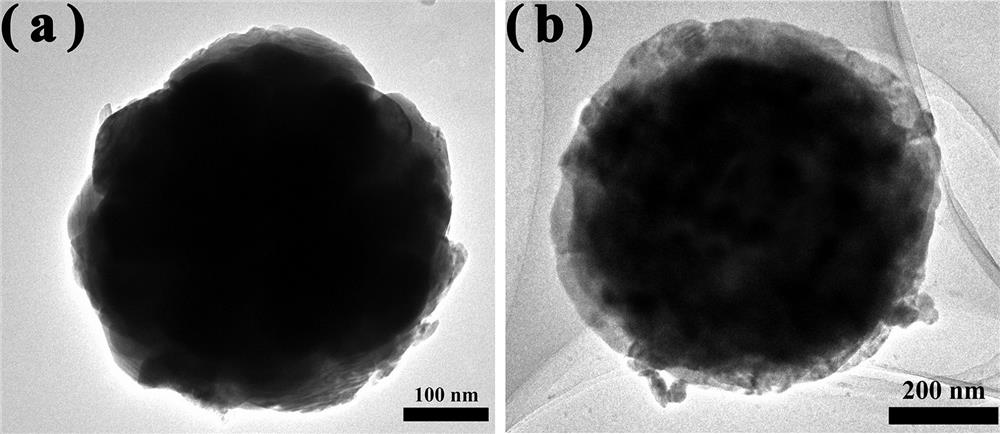

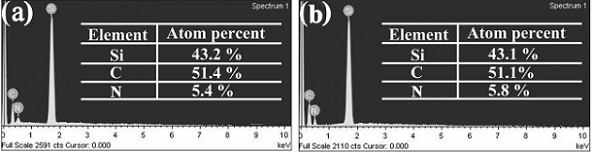

[0032] SiC nanoparticles with a diameter of 100–300 nm and ammonia gas.

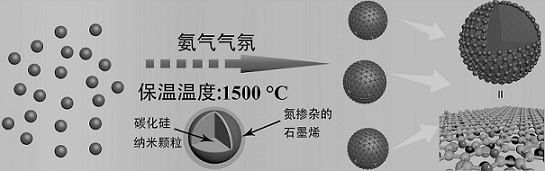

[0033] 3. Preparation process of nitrogen-doped graphene-coated SiC nanoparticles

[0034] In an ammonia atmosphere, the SiC nanoparticles are heated for a predetermined time, and cooled to obtain nitrogen-doped graphene-coated SiC nanoparticles.

[0035] Preferably, the preparation method of nitrogen-doped graphene-coated SiC nanoparticles comprises the steps of:

[0036] S1. Weigh a certain mass of SiC nanoparticles and place them in a container, and place the container containing a certain mass of SiC nanoparticles in a heating system;

[0037] S2. Evacuate the air in the heating system, and then feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com