Lithium-sulfur battery cathode material, preparation method thereof and lithium-sulfur battery

A technology for lithium-sulfur batteries and positive electrode materials, which is applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., and can solve the problems of poor electrolyte wettability, unsatisfactory cycle performance, and low sulfur loading of pole pieces. Achieve the effects of inhibiting the shuttle effect, improving cycle stability, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

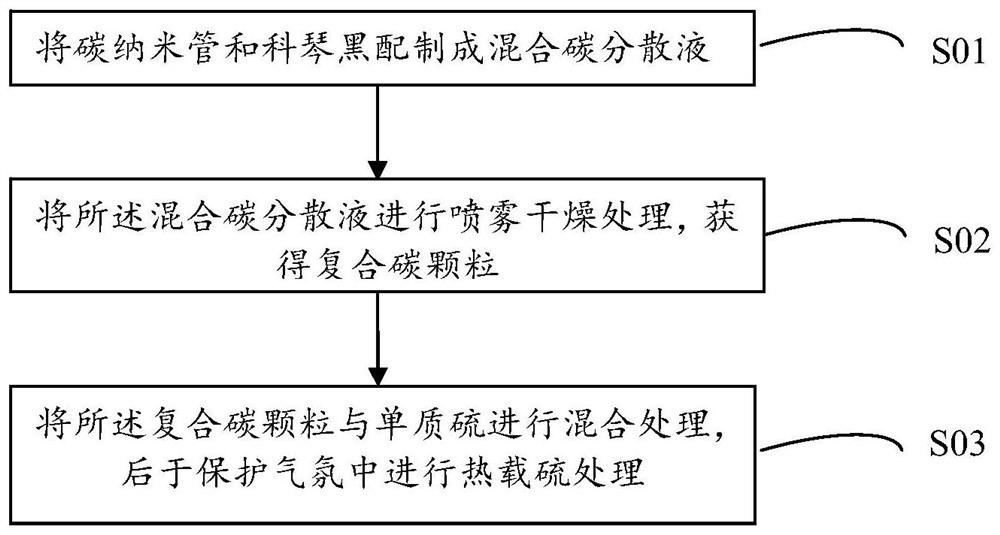

[0036] Correspondingly, based on the anode material of the lithium-sulfur battery described above, the embodiment of the present invention also provides a preparation method of the anode material of the lithium-sulfur battery. The process flow of the preparation method of the lithium-sulfur battery positive electrode material is as follows: figure 1 As shown, it includes the following steps:

[0037] S01: carbon nanotubes and ketjen black are prepared into a mixed carbon dispersion;

[0038] S02: Spray drying the mixed carbon dispersion to obtain composite carbon particles;

[0039] S03: Mixing the composite carbon particles with elemental sulfur, and then performing heat-carrying sulfur treatment in a protective atmosphere.

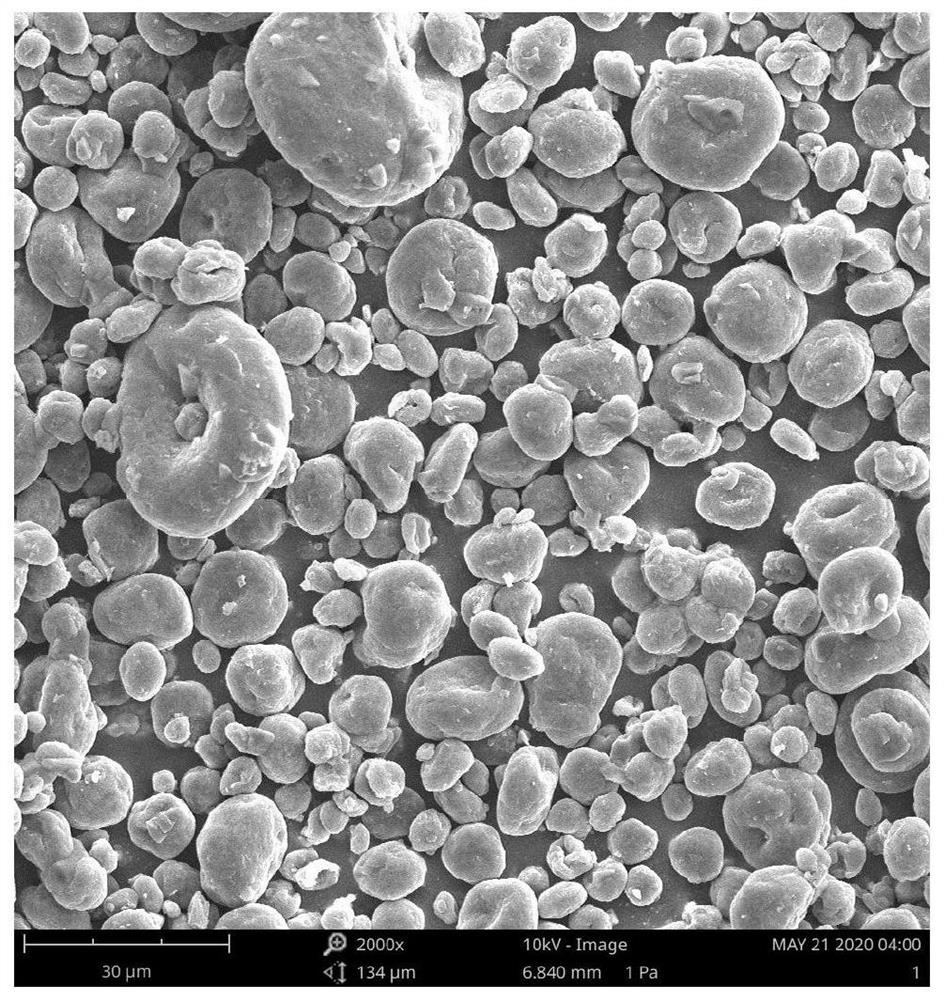

[0040] In this way, the preparation method of the positive electrode material of the lithium-sulfur battery in the embodiment of the present invention prepares the composite carbon particle body with a three-dimensional porous structure and spherical s...

Embodiment 11

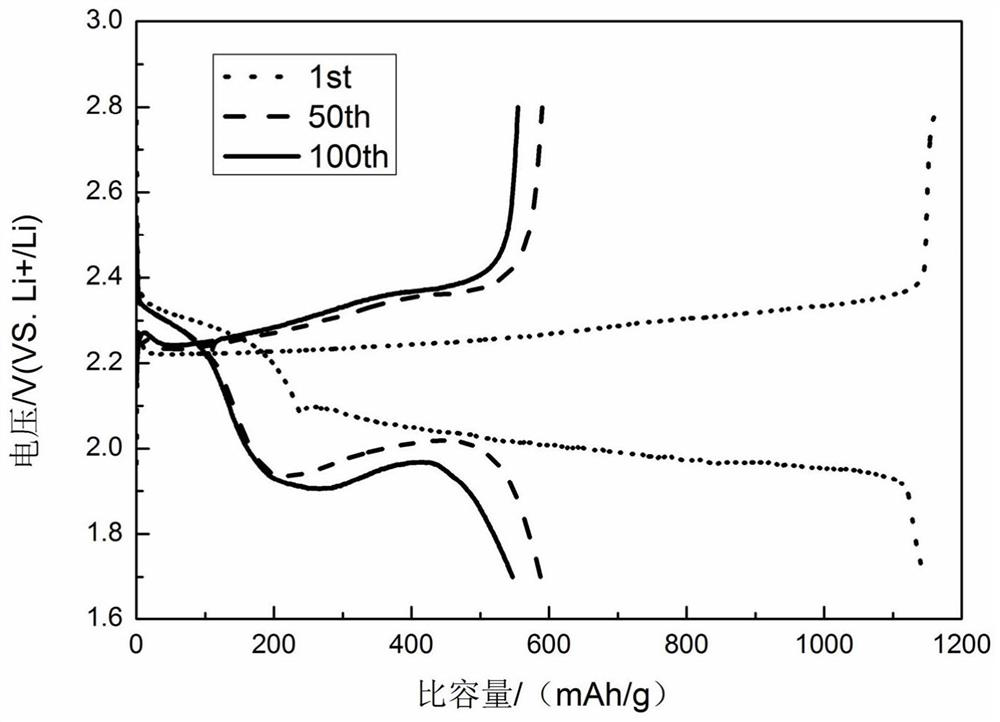

[0060] This embodiment provides a lithium-sulfur battery cathode material and a preparation method thereof. The positive electrode material of the lithium-sulfur battery includes a carbon nanotube with a mass ratio of 1:1: Ketjen black, which is spherical and has a three-dimensional porous composite carbon particle body, and at least on the surface of the composite carbon particle body and the Elemental sulfur is deposited on the pore surface of the three-dimensional porous structure.

[0061] The preparation method of the lithium-sulfur battery cathode material comprises the following steps:

[0062] S1: Using water as a solvent, prepare a carbon nanotube solution with a mass fraction of 2.5%, and prepare a Ketjen Black dispersion with a mass fraction of 2.5%, wherein the diameter of the carbon nanotube used is 10nm, and the specific surface of Ketjen Black is 1450m 2 / g; carbon nanotube dispersion liquid, Ketjen black dispersion liquid are mixed, wherein mass ratio carbon na...

Embodiment 12

[0067] This embodiment provides a lithium-sulfur battery cathode material and a preparation method thereof. The positive electrode material of the lithium-sulfur battery includes a carbon nanotube with a mass ratio of 1:1: Ketjen black, which is spherical and has a three-dimensional porous composite carbon particle body, and at least on the surface of the composite carbon particle body and the Elemental sulfur is deposited on the pore surface of the three-dimensional porous structure.

[0068] The preparation method of the lithium-sulfur battery cathode material comprises the following steps:

[0069] S1: Using water as a solvent, prepare a carbon nanotube solution with a mass fraction of 5%, and prepare a Ketjen Black dispersion with a mass fraction of 5%, wherein the diameter of the carbon nanotube used is 10nm, and the specific surface of Ketjen Black is 1450m 2 / g; carbon nanotube dispersion liquid, Ketjen black dispersion liquid are mixed, wherein mass ratio carbon nanot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com