Composite material with oxide @ sulfide core-shell structure as well as preparation method and application of composite material

A composite material, core-shell structure technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as low electrical conductivity, and achieve the effects of high material utilization, excellent electrochemical performance, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

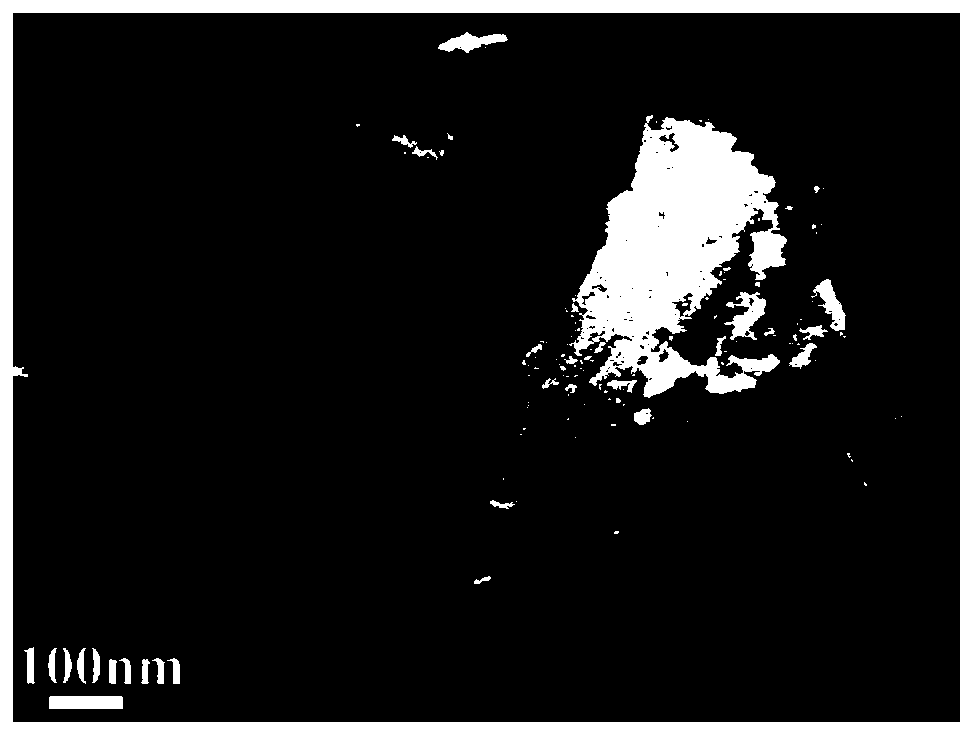

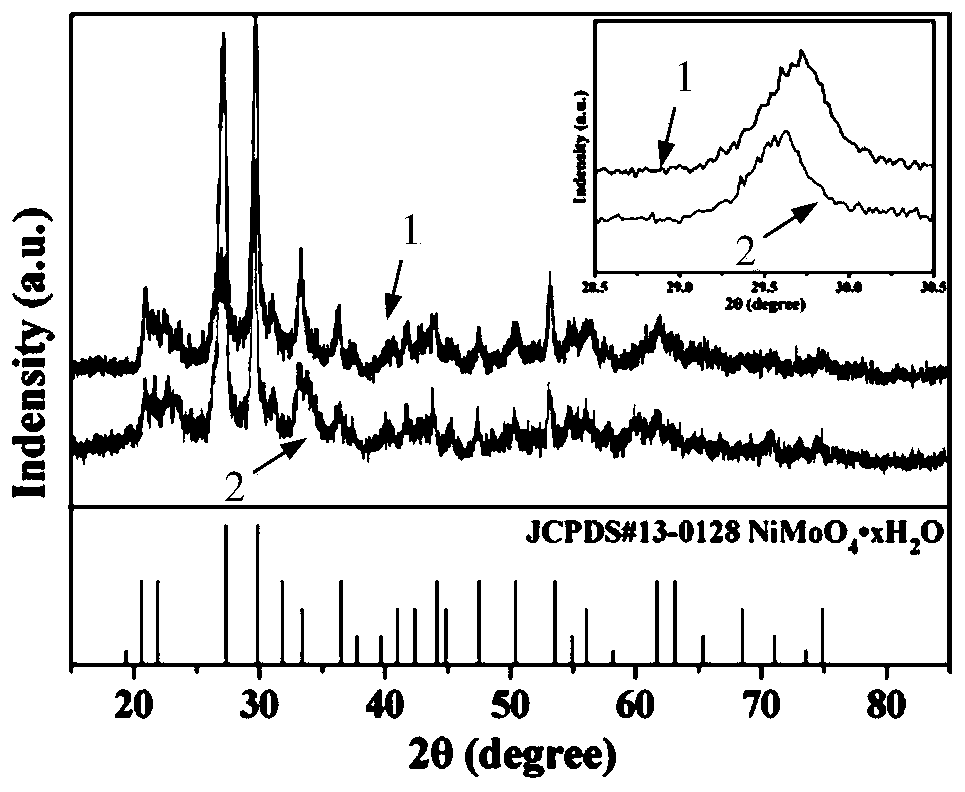

[0066] 1. Core-shell structure NiMoO 4 Nanorod @NiMoS 4 Preparation of nanosheet composites

[0067] Preparation steps:

[0068] 2mmol Ni(NO 3 ) 2 ·6H 2 O and 2 mmol Na 2 MoO 4 2H 2 O was dissolved in 60mL deionized water, stirred evenly for 30 minutes, then transferred to a 100mL reactor, and reacted at a constant temperature of 150°C for 5 hours, and NiMoO was obtained after washing and drying. 4 nanorod material.

[0069] 0.06mol Na 2 S·9H 2 O was dissolved in 60 mL of deionized water, stirred and NiMoO 4 The nanorod materials were poured into a hydrothermal reactor (100mL) and kept at 120°C for 8 hours to obtain the core-shell structure NiMoO 4 Nanorod @NiMoS 4 nanosheet composites.

[0070] 2. Preparation of asymmetric supercapacitors

[0071] NiMoO with core-shell structure 4 Nanorod @NiMoS 4The nanosheet composite material is used as the active material, and the active material, acetylene black, and PVDF adhesive are mixed in a mass ratio of 8:1:1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com