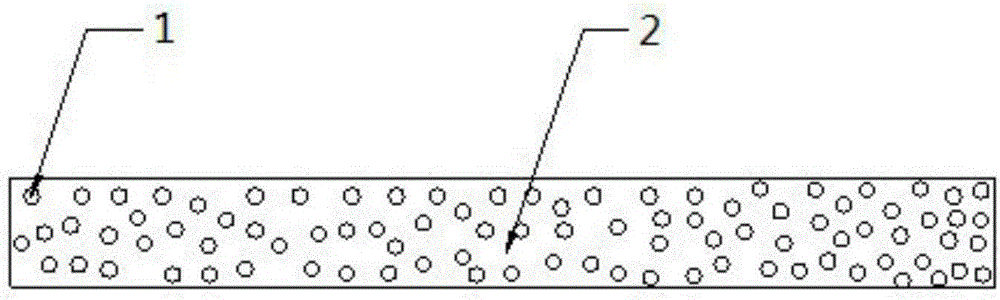

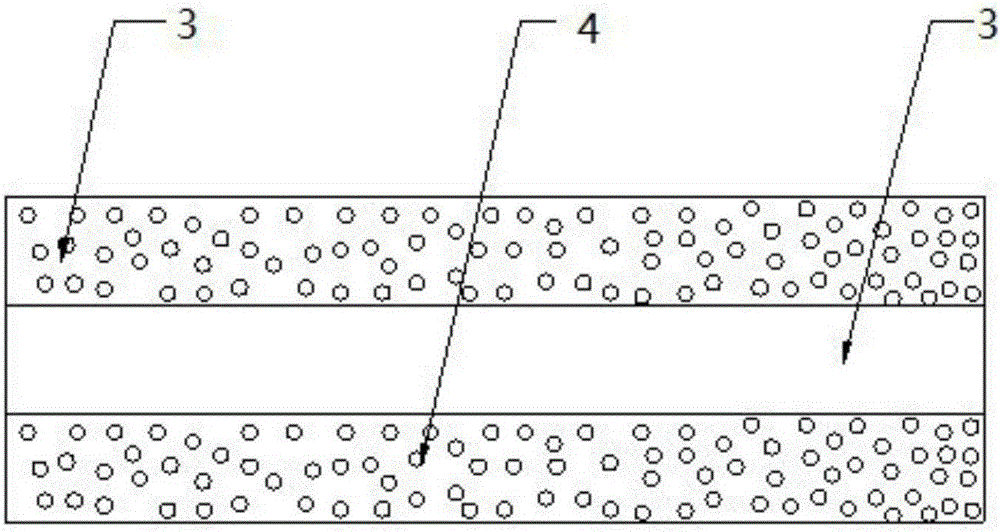

Safe high-performance lithium-ion battery membrane

A lithium-ion battery, high-performance technology, applied in the direction of secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve problems such as explosion, combustion, and post-deformation lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

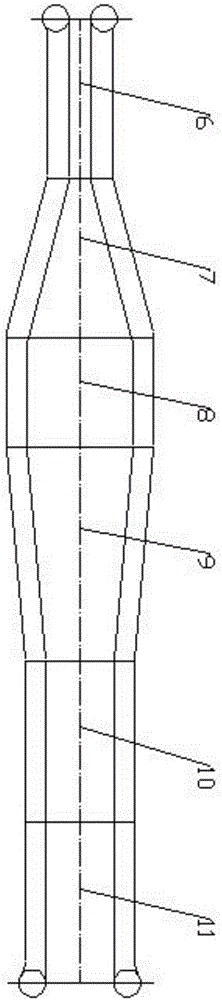

Method used

Image

Examples

Embodiment 1

[0049] Weigh 50kg of environmentally friendly paraffin oil of Suzhou Saipahan Special Oil Products Co., Ltd. product model SPH-400#, add a sonochemical mixer equipped with ultrasonic grinding, emulsification, dispersion and focusing (product of Hangzhou Success Ultrasonic Equipment Co., Ltd., product model: YP ) and the heating system of Zhongshi (Shanghai) Machinery Co., Ltd. product model ZHDS-22 double-shaft high-speed disperser, stirring slowly (stirring speed 60rpm) and heating to 160 ℃ at the same time; Weigh Jing Tianwei Chemical Co., Ltd. Antioxidant Add 0.04kg of 1010 model product, slowly add (adding time 15 minutes) into the paraffin oil in the above-mentioned dispersing equipment, turn on the ultrasonic equipment, 20Hz, 1000w, stirring speed 80rpm, stirring time 40 minutes; Weigh Shandong Zhenhua Industrial Co., Ltd. 0.006kg of hexametaphosphoric acid nano-dispersant with a molecular weight of 611.77 was slowly added to the above mixed solution, the addition time wa...

Embodiment 2

[0054]Weigh 50kg of environmentally friendly paraffin oil of Suzhou Saipahan Special Oil Products Co., Ltd. product model SPH-400#, add a sonochemical mixer equipped with ultrasonic grinding, emulsification, dispersion and focusing (product of Hangzhou Success Ultrasonic Equipment Co., Ltd., product model: YP ) and the heating system of Zhongshi (Shanghai) Machinery Co., Ltd. product model ZHDS-22 double-shaft high-speed disperser, stirring slowly (stirring speed 60rpm) and heating to 160 ℃ at the same time; Weigh Jing Tianwei Chemical Co., Ltd. Antioxidant 0.04kg of the 1010 model product was slowly added (adding time 15 minutes) into the paraffin oil in the above-mentioned dispersing equipment, turned on the ultrasonic equipment, 20Hz, 1000w, stirring speed 80rpm, stirring time 40 minutes; Weigh Sinoma Technology Membrane Materials Co., Ltd. High density polyethylene powder (particle size 50μm, density ASTMD-7920.948g / cm 3 Melt flow rate 190°C / 21.6kg) 1.5kg, slowly added to ...

Embodiment 3

[0059] The configuration of the coating solution: select 30kg of ZB0005 industrial special-grade deionized water from Shanghai Huanqi Environmental Protection Technology Co., Ltd., add a sonochemical mixer equipped with ultrasonic pulverization, emulsification, dispersion and focusing (product of Hangzhou Chenggong Ultrasonic Equipment Co., Ltd., product model: YP) and The heating system of Zhongshi (Shanghai) Machinery Co., Ltd. product model is ZHDS-22 double-shaft high-speed dispersing machine; select Guangdong Province Dongguan Jinhu Plastic Materials Co., Ltd. product polyvinylidene fluoride hexafluoropropylene (PVDF-HFP) 2kg was first uniformly dissolved in 3kg acetone (product of Shanghai Rongrong Chemical Co., Ltd.), slowly added in the above-mentioned deionized water, stirred while adding, adding time 20 minutes, stirring time 40 minutes, stirring speed 500rpm, ultrasonic wave 20Hz, 800w ( The whole compounding process does not stop); 4kg of high-purity silica sol from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com