Carbon-sulfur composite material used for positive pole of lithium-sulfur battery and preparation method of material

A composite material, lithium-sulfur battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of battery cycle life to be improved, limited active material utilization, active material loss, etc., to achieve large specific capacity, inhibit dissolution , Improve the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

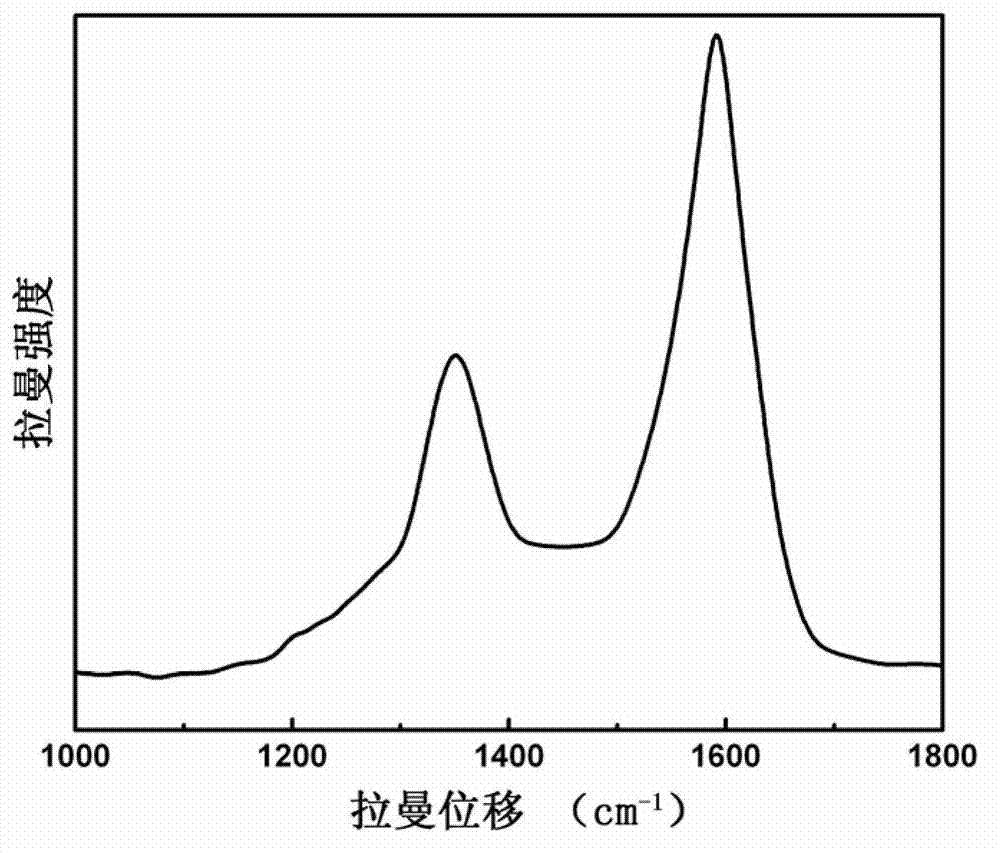

[0027] A method for preparing a carbon-sulfur composite material for a positive electrode of a lithium-sulfur battery, the steps are as follows:

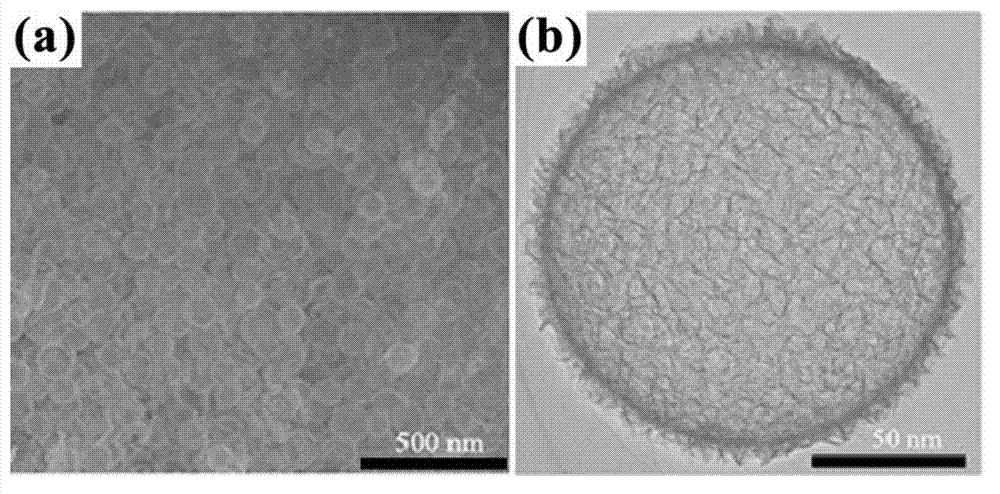

[0028] (1) Preparation of porous hollow carbon spheres

[0029] 1) Dissolve 0.5g of 2123# thermoplastic phenolic resin in 20mL of absolute ethanol to obtain a mixed solution, stir in a water bath at 50°C, add tetraethyl orthosilicate, the mass ratio of tetraethyl orthosilicate to the mixed solution is 1:12 , continue to stir for 15 minutes to form a light yellow transparent mixture;

[0030] 2) Quickly pour 50mL of ammonia-water-ethanol mixed solution with a volume ratio of 1:4 into the above-mentioned transparent mixed solution, stir vigorously, react at 50°C for 3h, slowly evaporate to dryness, and dry at 60°C for 12h to obtain a solid product ;

[0031]3) Grind the above solid product evenly, heat it to 850°C in an argon atmosphere at a heating rate of 5°C / min, react for 2 hours, and then pour it into a hydrofluoric acid soluti...

Embodiment 2

[0043] A method for preparing a carbon-sulfur composite material for a positive electrode of a lithium-sulfur battery, the steps are as follows:

[0044] The preparation of porous hollow carbon spheres is the same as in Example 1.

[0045] The preparation of the carbon-sulfur composite material is basically the same as in Example 1, but the mass ratio of sublimated sulfur to porous hollow carbon spheres is 2:1.

[0046] The assembly and testing of the positive electrode sheet, the negative electrode sheet and the button cell are the same as in Example 1.

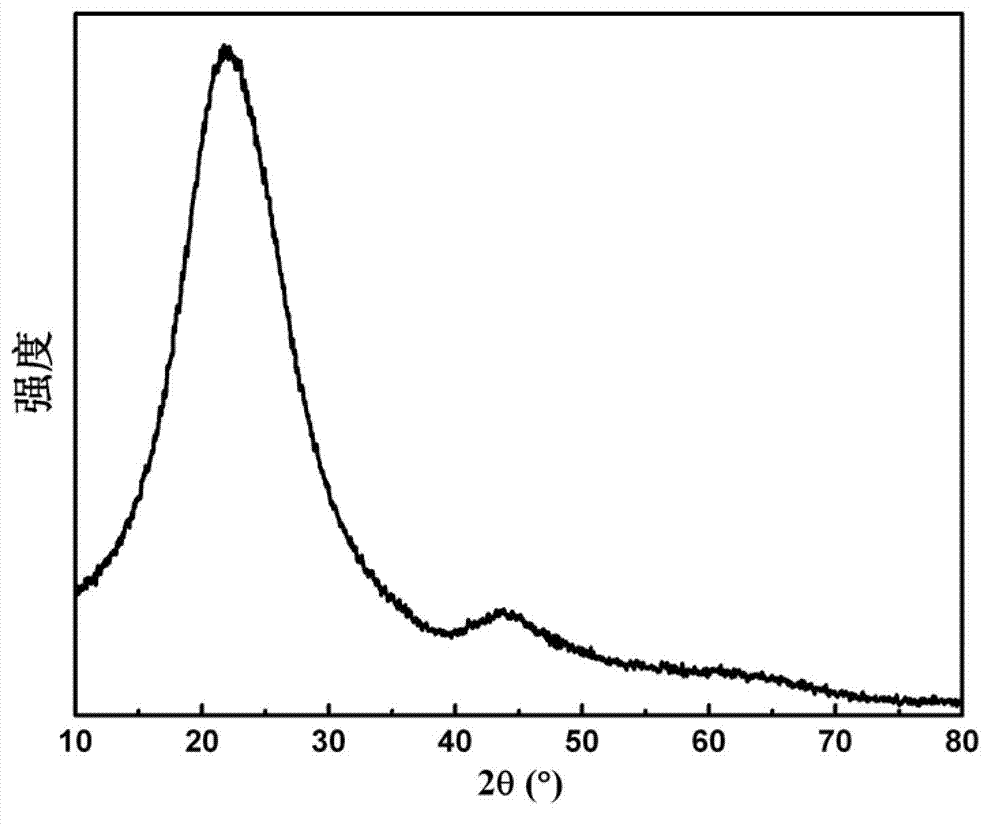

[0047] The X-ray diffraction pattern shows that a small amount of sulfur is not dispersed in the pores of the porous hollow carbon spheres, and the diffraction peaks of elemental sulfur have appeared, such as Figure 4 shown. Figure 8 It is the first constant current charge and discharge curve of the battery. The two discharge platforms are located at about 2.05 and 2.30V respectively, and the discharge specific capacity ...

Embodiment 3

[0049] A method for preparing a carbon-sulfur composite material for a positive electrode of a lithium-sulfur battery, the steps are as follows:

[0050] The preparation of porous hollow carbon spheres is the same as in Example 1.

[0051] The preparation of the carbon-sulfur composite material is basically the same as in Example 1, but the mass ratio of sublimated sulfur to porous hollow carbon spheres is changed to 3:1.

[0052] The assembly and testing of the positive electrode sheet, the negative electrode sheet and the button cell are the same as in Example 1.

[0053] The X-ray diffraction pattern shows that part of the sulfur exists outside the pores of the porous hollow carbon spheres, the carbon wrapping peak is not obvious, and the diffraction peak of the elemental sulfur is stronger, as shown in Figure 4 shown. Figure 9 It is the first constant current charge and discharge curve of the battery. The two discharge platforms are respectively located at about 2.05 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com