Microporous polyethylene film with improved strength, permeability and surface energy

A technology of microporous polyethylene and puncture strength, which is applied in household appliances, transportation and packaging, and other household appliances, and can solve the problems of mechanical strength decline and ion permeability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

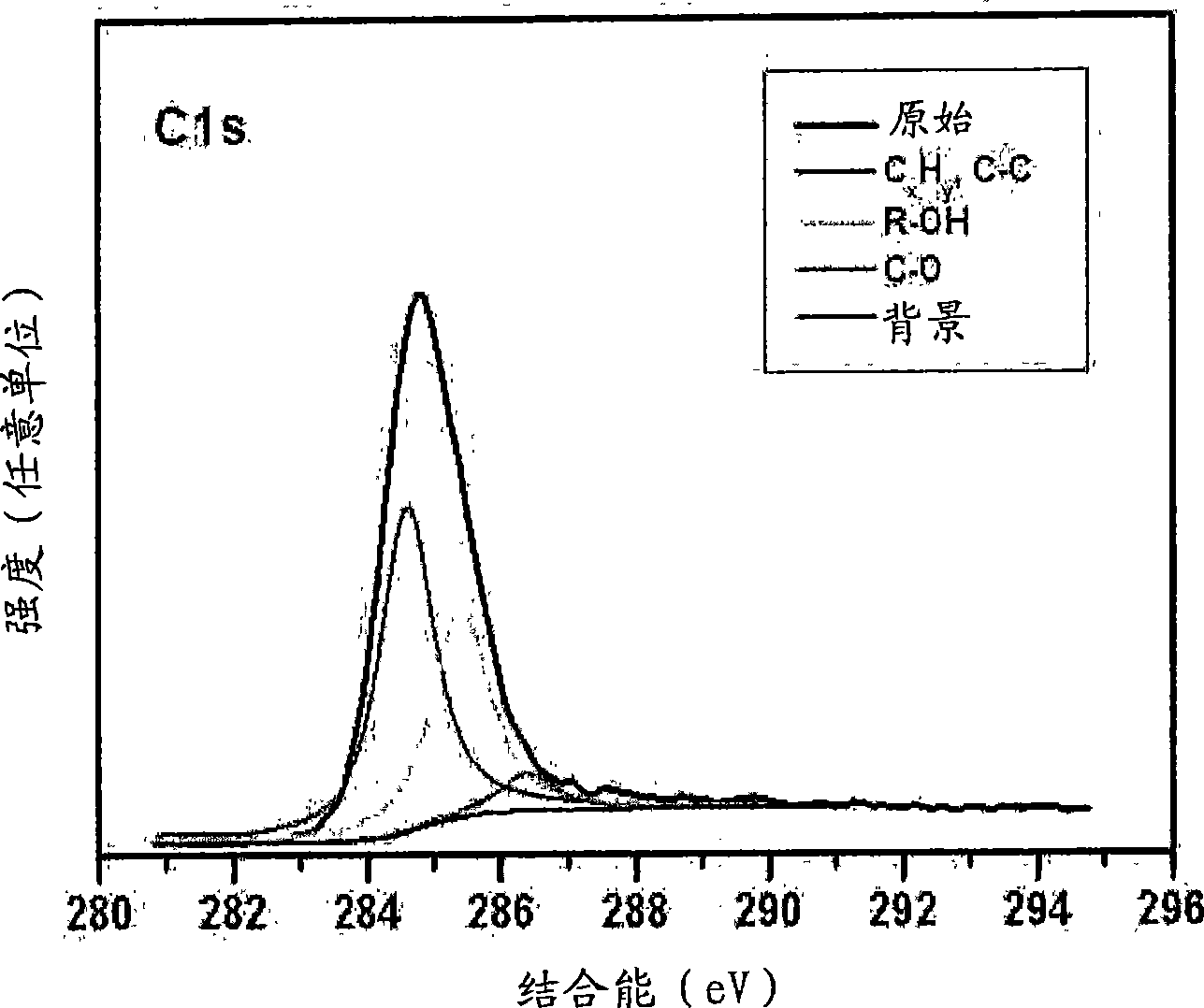

[0035] The preparation of the microporous polyethylene membrane of the present invention includes the steps of: preparing a membrane with high porosity, large pore size and excellent mechanical strength by optimizing the liquid-liquid phase separation conditions in the wet process and the molecular weight and concentration of polyethylene , and plasma-treating the membrane under atmospheric pressure to enhance the surface energy of the membrane.

[0036] First, the steps to prepare the separator are described as follows:

[0037] Low molecular weight organic substances partially compatible with polyethylene (hereinafter referred to as diluents) can form a thermodynamically single phase with polyethylene at temperatures above the melting point of polyethylene. When a thermodynamically single-phase solution of polyethylene and diluent is slowly cooled, phase separation of polyethylene and diluent occurs before the polyethylene crystallizes into a solid. Since the phase separati...

Embodiment approach

[0083] The following examples describe the present invention in more detail, but they are not intended to limit the scope of the present invention.

Embodiment 1

[0129] The weight average molecular weight is 2.1×10 5 , a high-density polyethylene having a melting temperature of 135° C. was used as component I, and dibutyl phthalate (component A in the table below) was used as component II. The contents of component I and component II were 40% by weight and 60% by weight, respectively.

[0130]Zone 15 to The temperature of the 20th zone was set at 185° C. (below the temperature of liquid-liquid phase separation) for phase separation. The stretching temperature was 127°C, and the stretching ratios in the longitudinal direction and transverse direction were each 6 times. After extraction of Component II by impregnation with dichloromethane for two minutes, heat setting was carried out at 120° C. for 15 seconds. Then, plasma was generated by discharge at atmospheric pressure (power=3.6kW, voltage=12kV) by using a dielectric barrier discharge type electrode, supplying nitrogen as a carrier gas at 300ml / min and oxygen as a reactive gas at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com