Composite nano-silicon negative electrode and preparation and application thereof

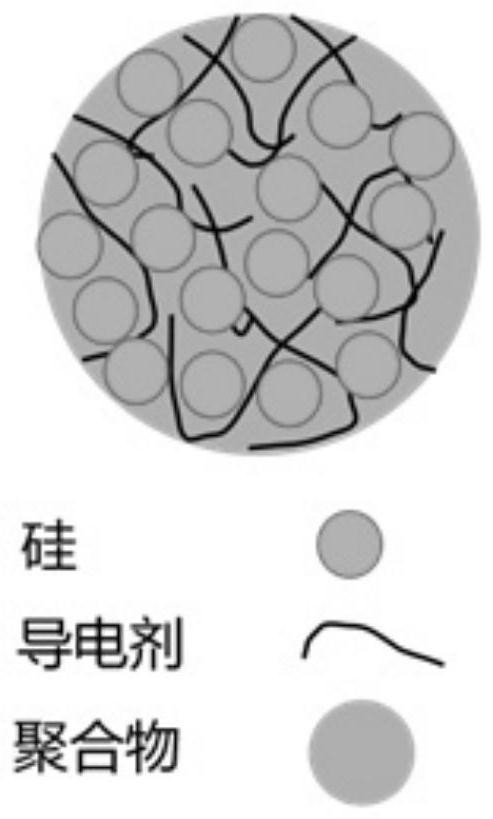

A technology of nano-silicon and negative electrode, which is applied in the field of composite nano-silicon negative electrode and its preparation and application. It can solve the problems of battery cycle performance degradation, silicon-containing negative electrode materials are easy to expand and have low conductivity, and achieve harmony uniformity and good electrolyte infiltration. Sexuality and flexibility, the effect of mitigating direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

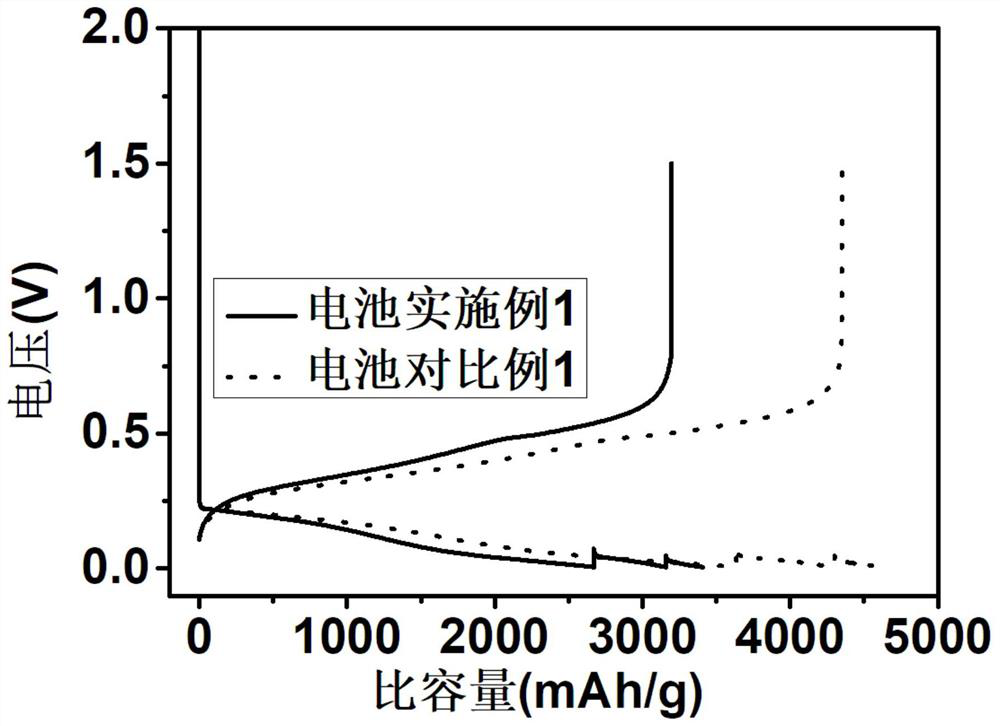

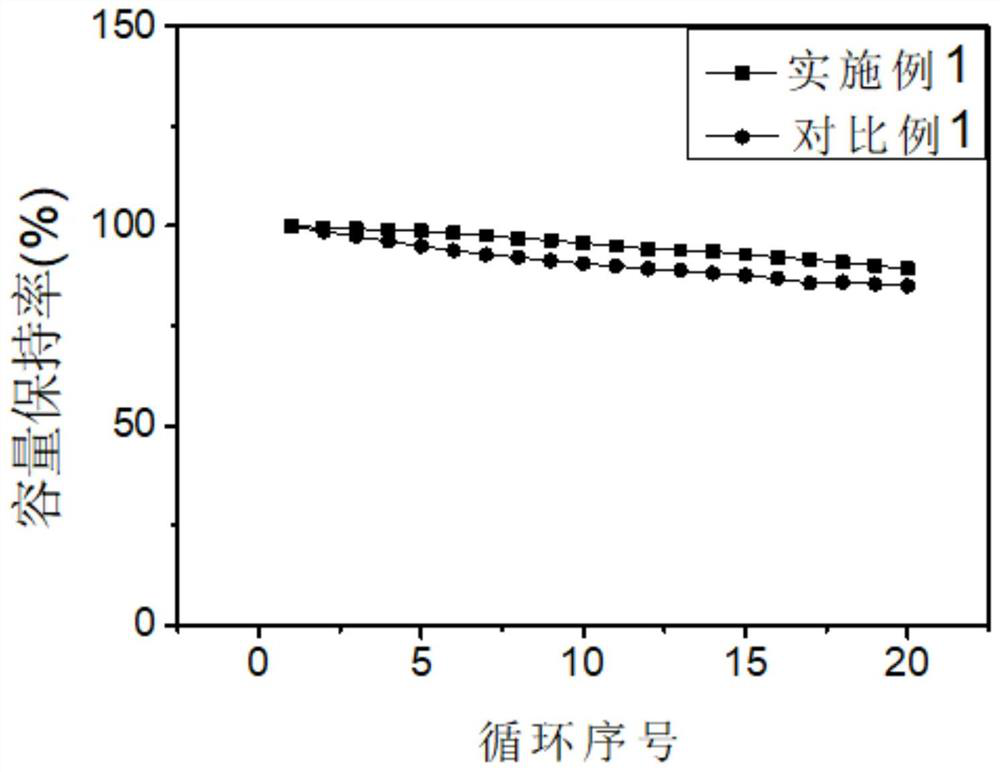

[0034] Under an inert atmosphere, take a total of 10g of material according to the mass percentage of crystalline nano-silicon: carbon nanotube: polymer monomer = 80%: 5%: 15%, wherein the polymer monomer is based on styrene: methacrylic acid: butadiene Acrylic acid = 3:3:4, then add the above materials into 72g of isopropanol and stir evenly, add 0.5% concentration of ammonium persulfate initiator, stir at 80°C for 3 hours, crush for 1 hour, and vacuum-dry to obtain a three-dimensional Nano silicon composite anode material.

Embodiment 2

[0036] Under an inert atmosphere, a total of 20g of materials is weighed according to the mass percentage of amorphous porous nano-silicon: acetylene black: polymer monomer = 85%: 5%: 10%, wherein the polymer monomer is based on acrylic acid: methyl methacrylate = 3 : 7 calculations, then the above-mentioned materials were added in 142g dimethoxyethane and stirred evenly, bisphenol A initiator was added, stirred at 70°C for 4h, sand milled for 1h, and heated and dried to obtain a three-dimensional nano-silicon composite negative electrode material.

Embodiment 3

[0038] Under an inert atmosphere, according to the mass percentage of crystalline carbon-coated nano-silicon: graphite: polyvinylidene fluoride = 84%: 3%: 13%, a total of 8g of material was weighed, added to 66g of N-methylpyrrolidone, and then the above-mentioned material was ball milled and stirred. The three-dimensional nano-silicon composite negative electrode material can be prepared after spray drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com