Nanoparticle coated lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and nanoparticle technology, which is applied to battery components, circuits, electrical components, etc., can solve problems affecting the pore size and pore size distribution of the diaphragm, hidden dangers, battery short-circuit safety, etc., to ensure ion migration performance and improve porosity rate, improve wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

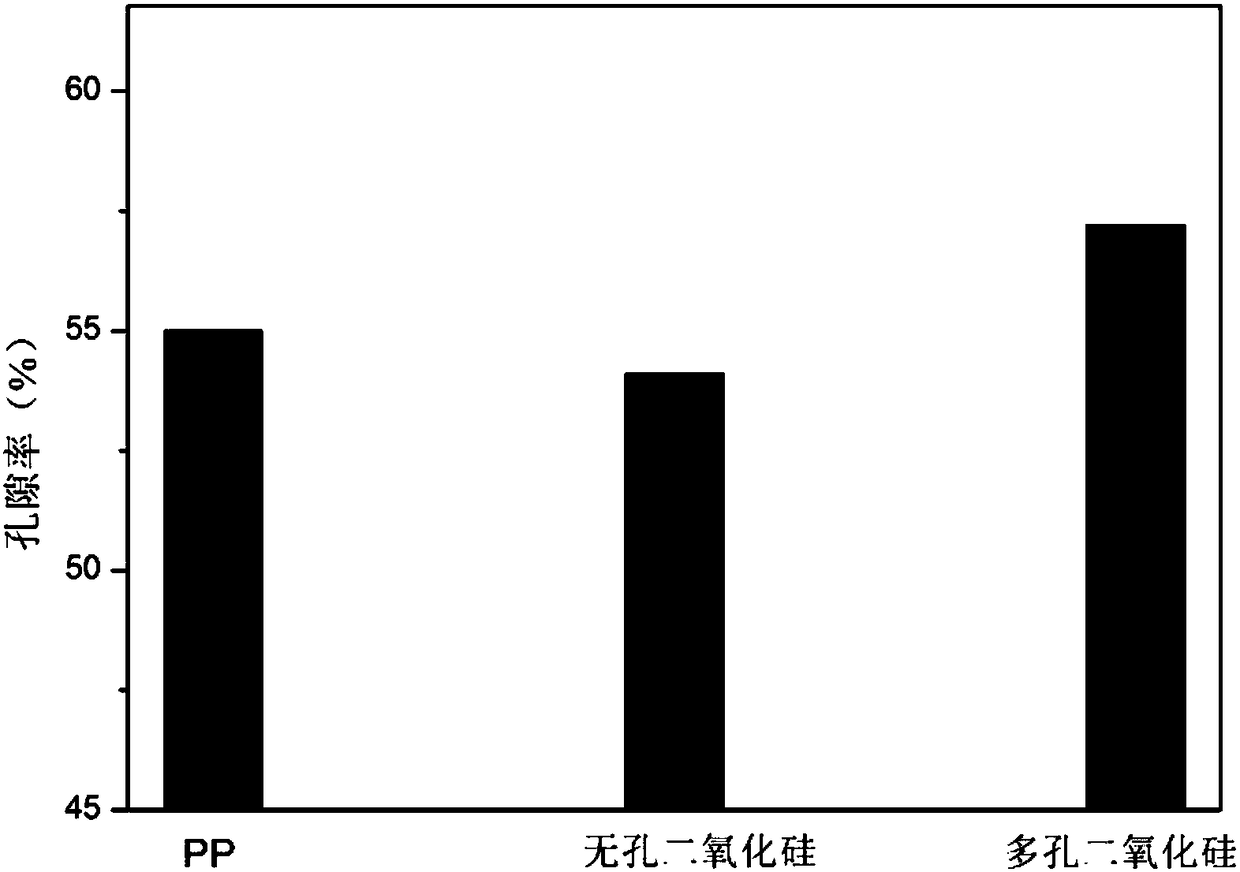

[0041] The nanoparticle-coated lithium-ion battery diaphragm in this example uses nanoparticles with porous structure of aluminum oxide, which is purchased from Sigma-Aldrich with a particle size of 0.5um and a porous channel with a pore size of 1nm-50nm. The base film used is a PP film with a porosity of 55%.

[0042] The preparation method of the nanoparticle-coated lithium-ion battery diaphragm of this example is as follows:

[0043] Add 10 g of porous aluminum oxide to 79.9 g of water, and stir evenly with a mechanical stirrer to form a suspension. Add 10 g of sodium carboxymethylcellulose thickener to the suspension, and stir evenly to form a thickened suspension. Add 0.1 g of polyvinyl alcohol binder to the thickened suspension, and stir evenly to form a coating slurry. The slurry for coating was uniformly coated on one surface of the base film by a roll coating method to obtain a base film coated with nanoparticles. The base film coated with nanoparticles was dried ...

Embodiment 2

[0045] This embodiment is similar to Example 1, but when preparing the coating slurry, the amount of porous aluminum oxide used is 30g, water 60g, sodium carboxymethylcellulose thickener 5g, polyvinyl alcohol binder 5g; All the other are identical with embodiment 1.

[0046] After adopting the same drying method as in Example 1, the nanoparticle-coated lithium-ion battery separator of this example was obtained.

Embodiment 3

[0048]This embodiment is similar to Example 1, but when preparing the coating slurry, the amount of porous aluminum oxide used is 60g, water 29.5g, sodium carboxymethylcellulose thickener 0.5g, polyvinyl alcohol binder 10g; All the other are identical with embodiment 1.

[0049] After adopting the same drying method as in Example 1, the nanoparticle-coated lithium-ion battery separator of this example was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com