Preparation method of three-dimensional ordered mesoporous MOF material

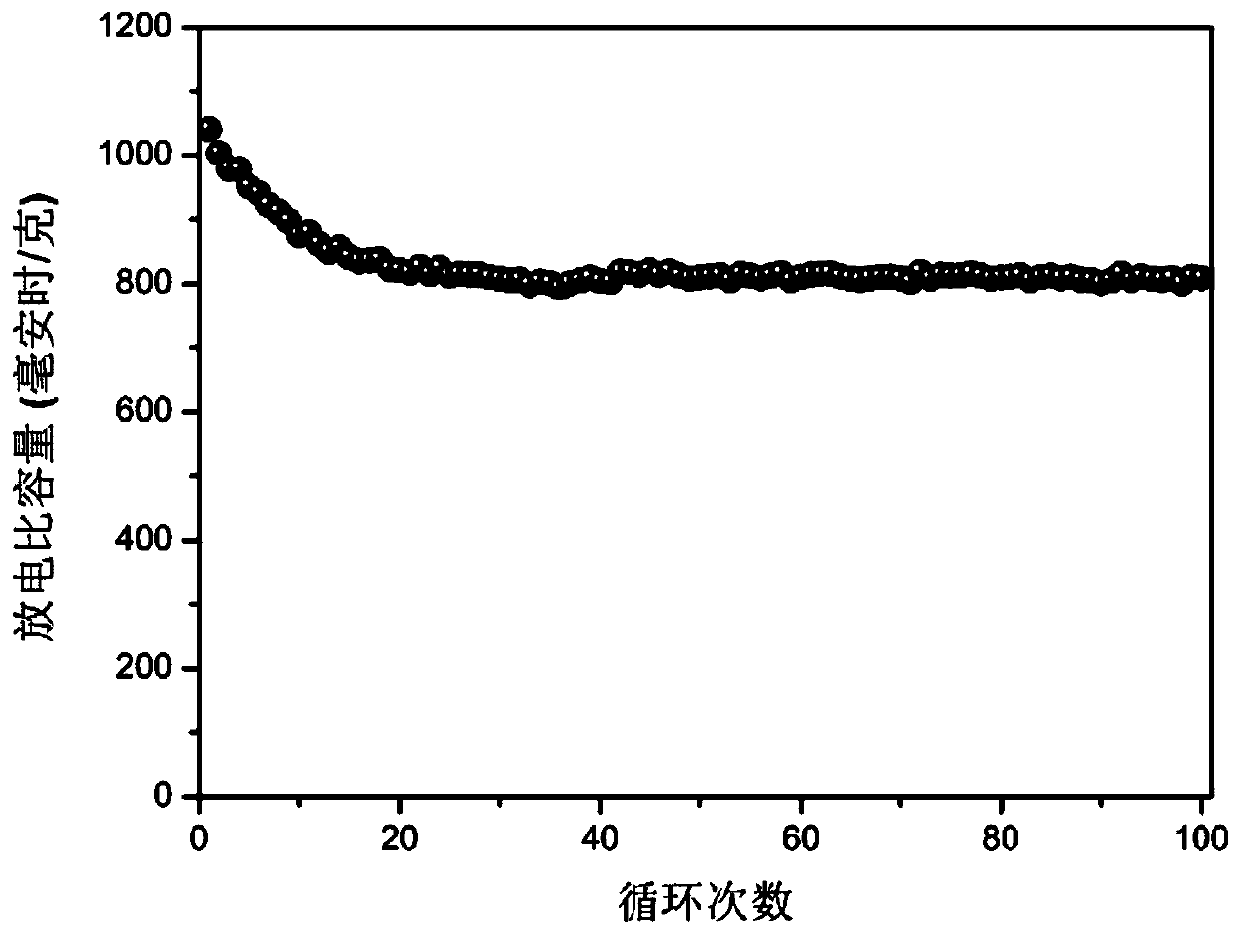

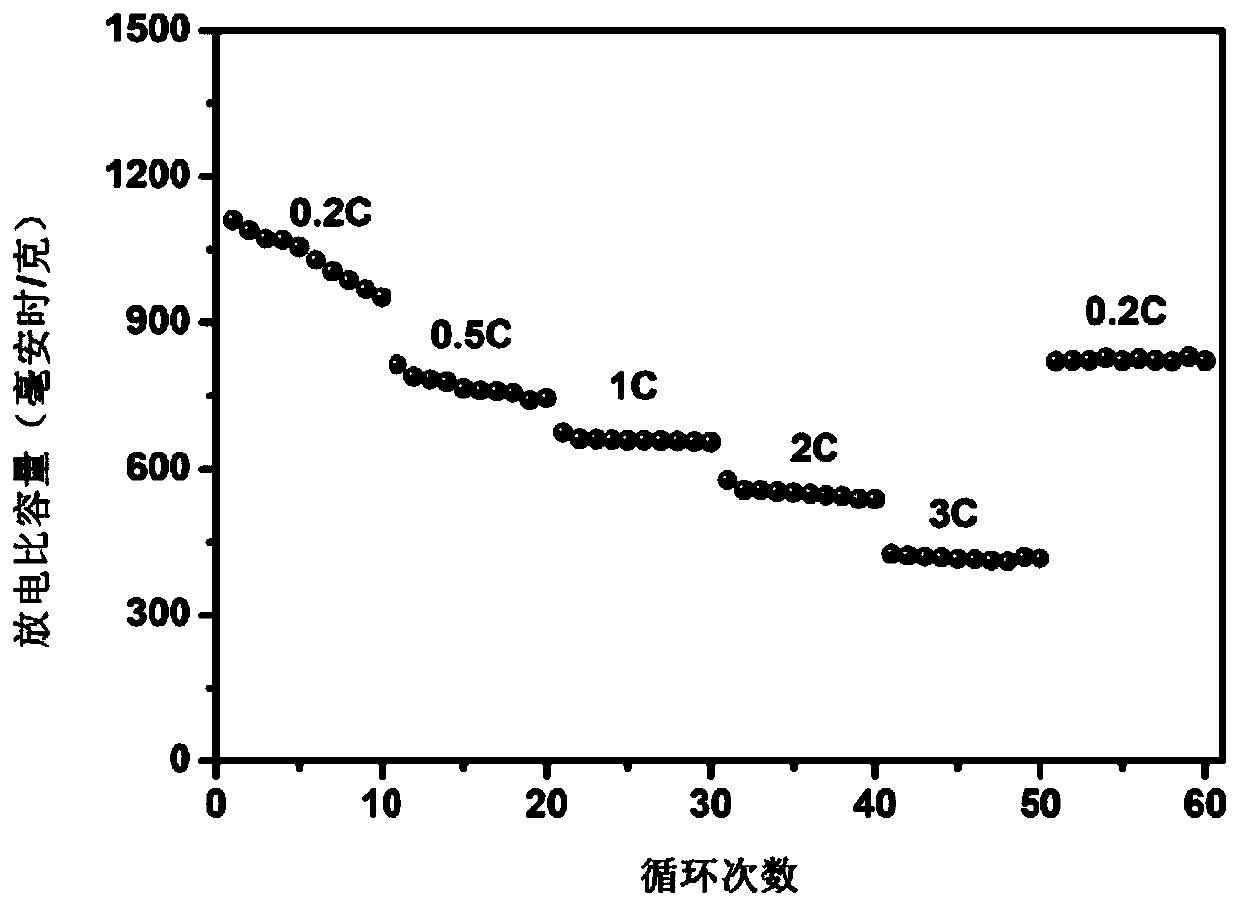

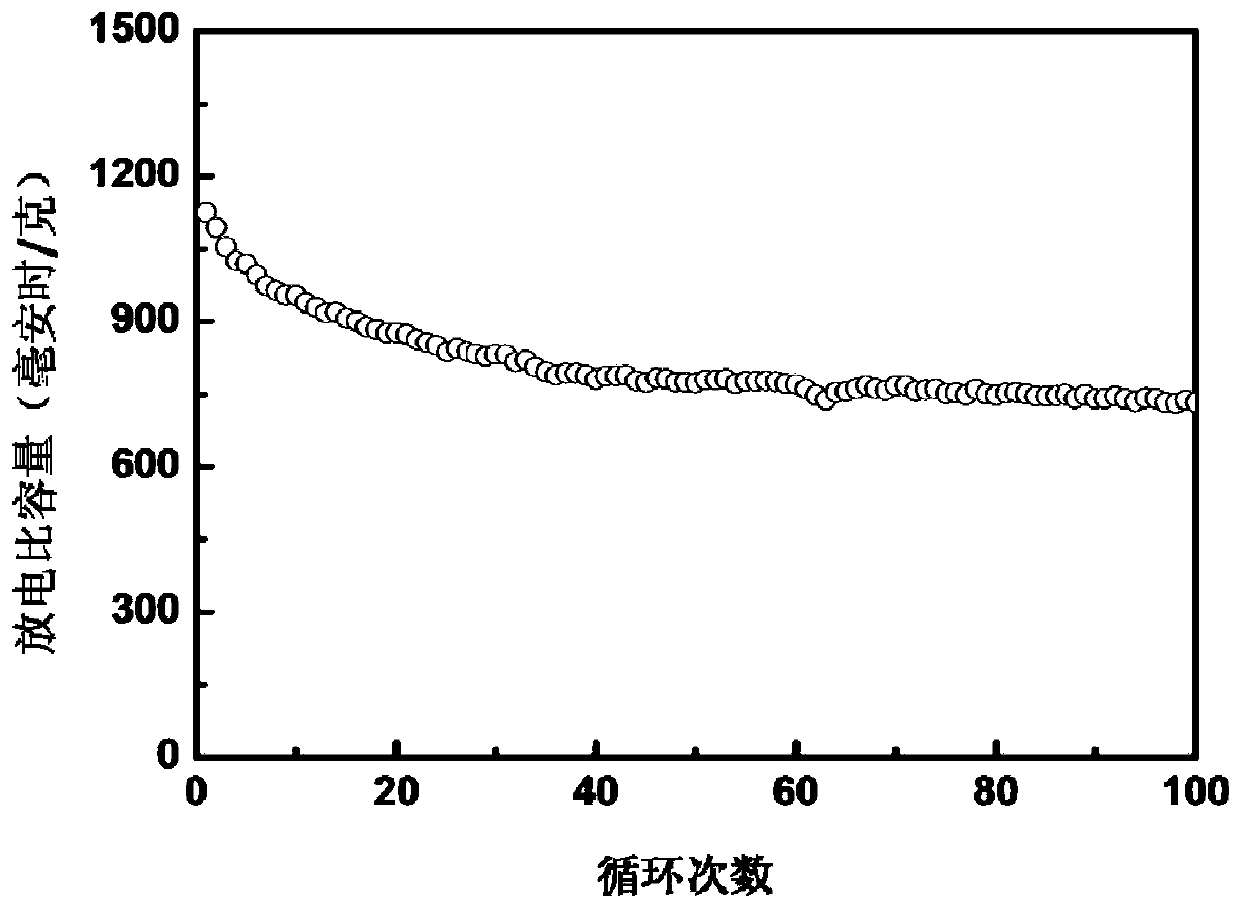

A three-dimensional ordered, mesoporous technology, applied in the field of material chemistry, can solve the problems of electrode material crushing, low charge-discharge specific capacity, poor cycle stability, etc., and achieve the effect of promoting transfer and overcoming low charge-discharge specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step A: preparing polystyrene PS microspheres;

[0038] Add 10 g of styrene and 10 g of polyvinylpyrrolidone into 50 ml of deionized water, stir for 2 hours, then stir for 2 hours in an oil bath in a round bottom flask, the temperature of the oil bath is 70°C, and magnetically stir for 12 hours. Then centrifuge at a speed of 800 rad / min for 3 times, and dry at 60° C. to obtain polystyrene PS spheres.

[0039] Step B: Preparation of 3D ordered mesoporous ZIF8 material

[0040] B1, liquid A: 5mmol zinc nitrate hexahydrate, dispersed in 125ml methanol, liquid B: 20mmol 2-methylimidazole, dispersed in 125ml methanol; pour liquid B into liquid A, and at the same time, add 1g of PS balls in step A Among them, magnetically stir for 3 minutes until uniform, and seal and age for 24 hours.

[0041] B2, after centrifugation, methanol and ethanol were used as solvents, and washed three times respectively; after drying the solid and liquid at 60°C, a 3Dzif8 material with an ordere...

Embodiment 2

[0048] Step A, preparing polystyrene PS microspheres:

[0049] Add 20 g of styrene and 20 g of polyvinylpyrrolidone into 100 ml of deionized water, stir for 5 hours, then stir for 2 hours in an oil bath in a round bottom flask, the temperature of the oil bath is 80°C, and stir for 24 hours. Then centrifuge at 800rad / min for 3 times and dry at 80°C to obtain PS spheres.

[0050] Step B: Preparation of three-dimensional ordered mesoporous zif8 material:

[0051] B1, liquid A: 10mmol zinc nitrate hexahydrate, dispersed in 250ml methanol, liquid B: 40mmol 2-methylimidazole, dispersed in 250ml methanol; pour liquid B into liquid A, and at the same time, add 2g of PS balls in step A to it , stirred for 5 minutes until uniform, sealed and aged for 24 hours.

[0052] B2, after centrifugation, methanol and ethanol were used as solvents, and washed three times respectively; after drying the solid and liquid at 80°C, a 3Dzif8 material with an ordered mesoporous structure was obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com