Preparation method for lithium ion battery

A lithium-ion battery and conductive agent technology, applied in the field of lithium-ion battery preparation, can solve problems such as increasing the viscosity of the electrolyte, achieve the effects of improving wettability, realizing large-scale industrial production, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

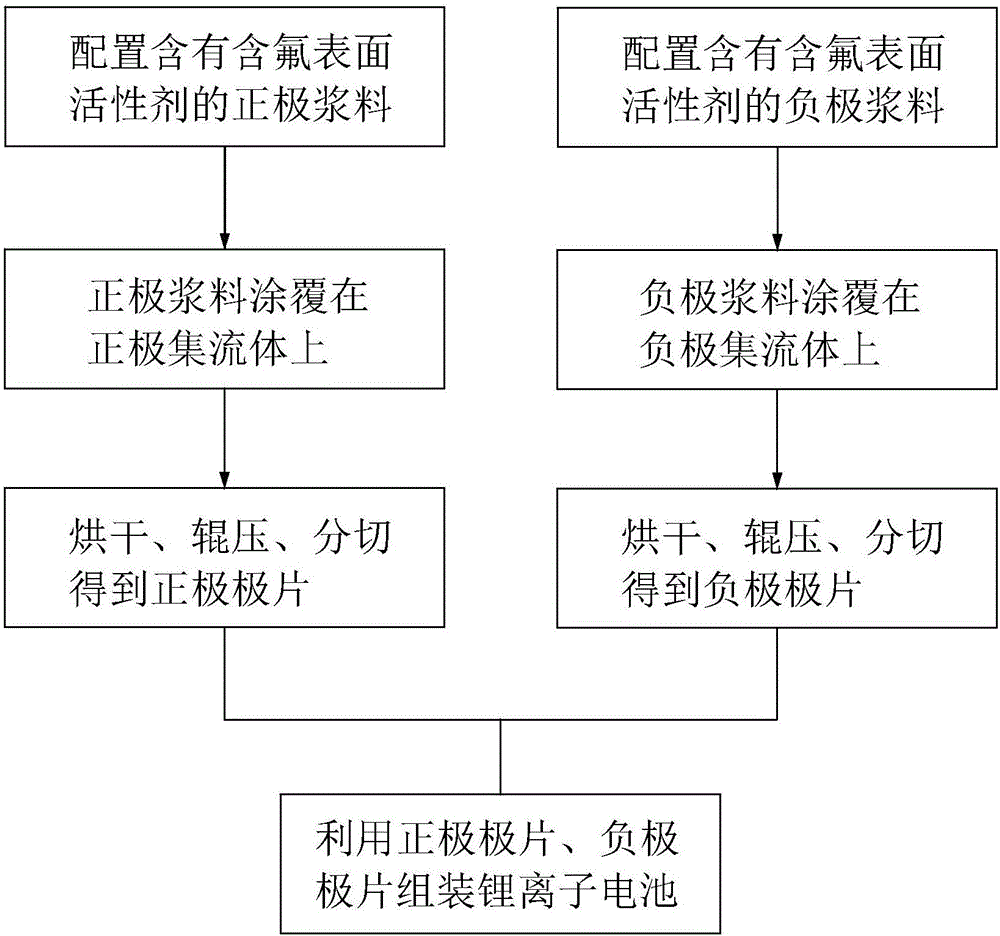

[0026] Please refer to figure 1 , the invention provides a kind of preparation method of lithium ion battery, comprises the following steps:

[0027] 1) The positive electrode active material, conductive agent, binder and fluorine-containing surfactant according to (80%-97%): (1%-10%): (1-10%): (0.5%-10%) The mass ratio is mixed with a solvent to configure a positive electrode slurry; the positive electrode slurry is coated on the positive electrode current collector, dried, rolled, and cut to obtain the positive electrode sheet;

[0028] 2) Negative electrode active material, conductive agent, binder and fluorine-containing surfactant according to (80%-97%): (1%-10%): (1-10%): (0.5%-10%) The mass ratio is mixed with a solvent to configure a negative electrode slurry; the negative electrode slurry is coated on the negative electrode current collector, dried, rolled, and cut to obtain the negative electrode sheet;

[0029] 3) Assembling a lithium-ion battery by using the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com