High-efficiency condenser and air conditioner with same

A condenser and high-efficiency technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problem of not fully considering the difference in heat exchange between front and rear rows, imperfect design parameters of double-row heat exchangers, and inability to heat exchangers. Unbalance adjustment and other problems, to achieve the effect of improving heat exchange efficiency, shortening fluorine injection time, and uniform and orderly liquid separation at the inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

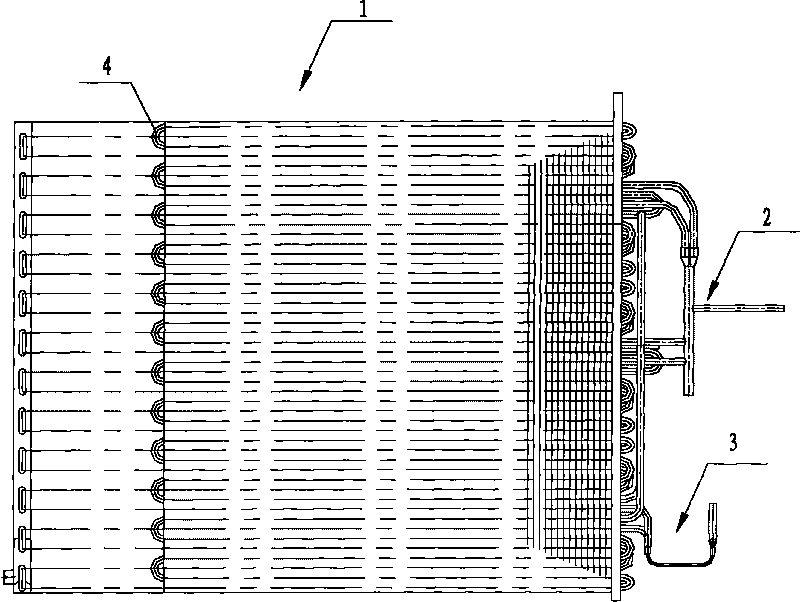

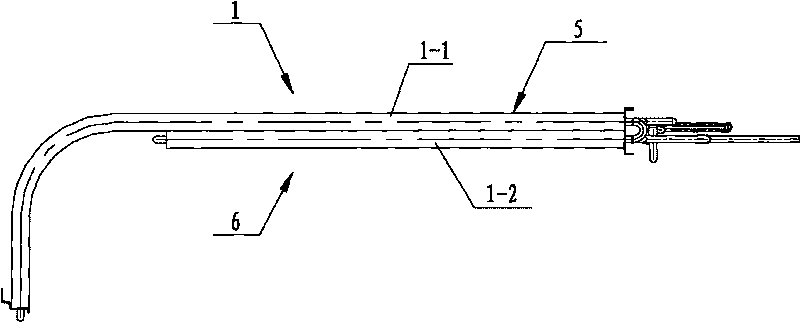

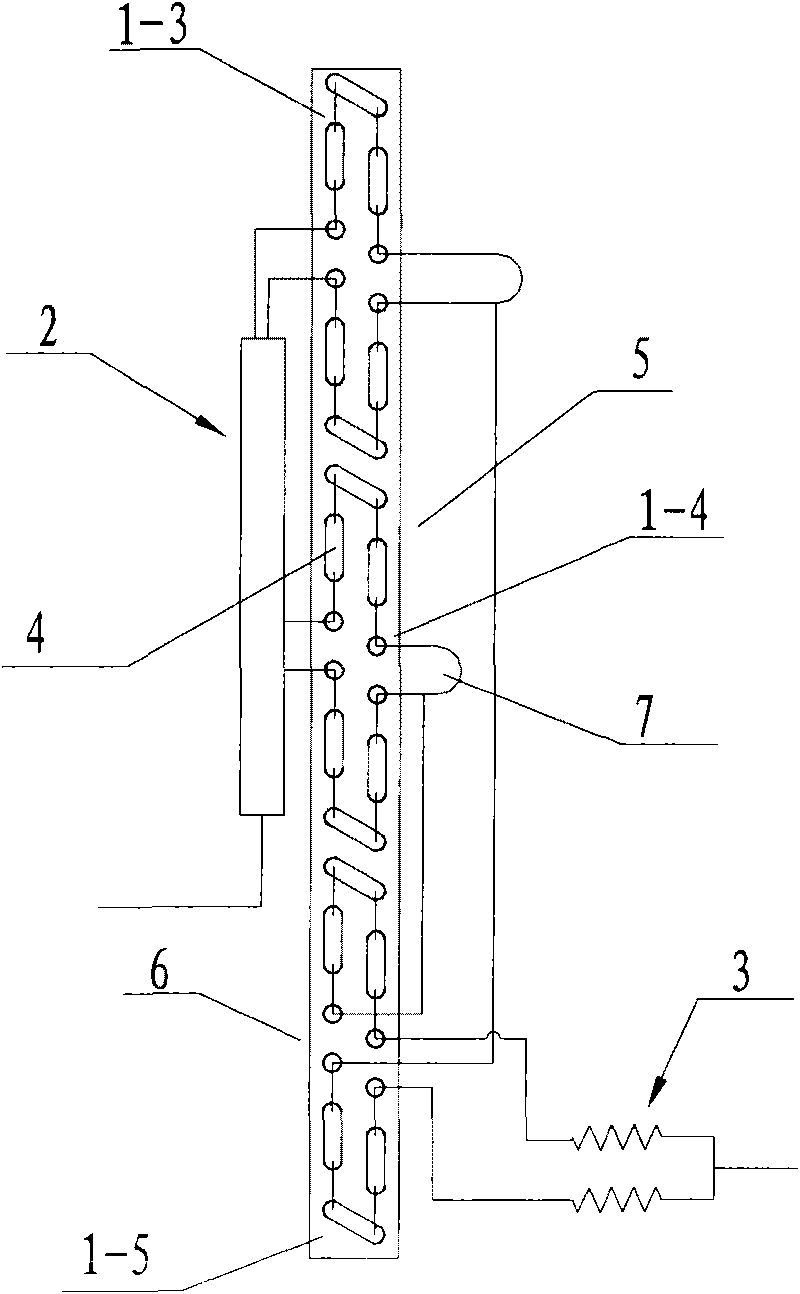

[0038] see figure 1 , figure 2 and image 3 , Condenser 1 is a double row, that is, it is divided into front and rear rows of condensers. The front and rear condensers adopt a long and short row structure, the windward front row condenser 1-1 adopts a long row form, and the leeward rear row condenser 1-2 adopts a short row form. The distance between the end plates of the front row condenser 1-1 is 771mm, that is, the total length is 771mm, the distance between the pieces is 1.4mm, and the number of pieces is 551 pieces; mm, the number of pieces is 362 pieces. The use of long and short row design and appropriate sheet pitch configuration relationship can not only reduce the cost, but also help to improve the overall heat exchange efficiency of the heat exchanger.

[0039] see image 3 , the diversion branches of the superheating section 1-3 and the saturation section 1-4 in the front and rear condensers 1-1 and 1-2 are 4 paths, and the inlet pipe group 2 and the middle li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com