Automatic pressure test machine for horizontal type collector flow channel

A technology of heat collectors and test presses, applied in the field of test presses, can solve the problems of prolonging the running time of equipment, damage to pipelines and pipe fittings, and inconvenient product assembly, so as to shorten the time of water injection, prolong the service life and improve the work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is the best example of the collector runner horizontal automatic pressure test machine described in the present invention, and does not therefore limit the protection scope of the present invention.

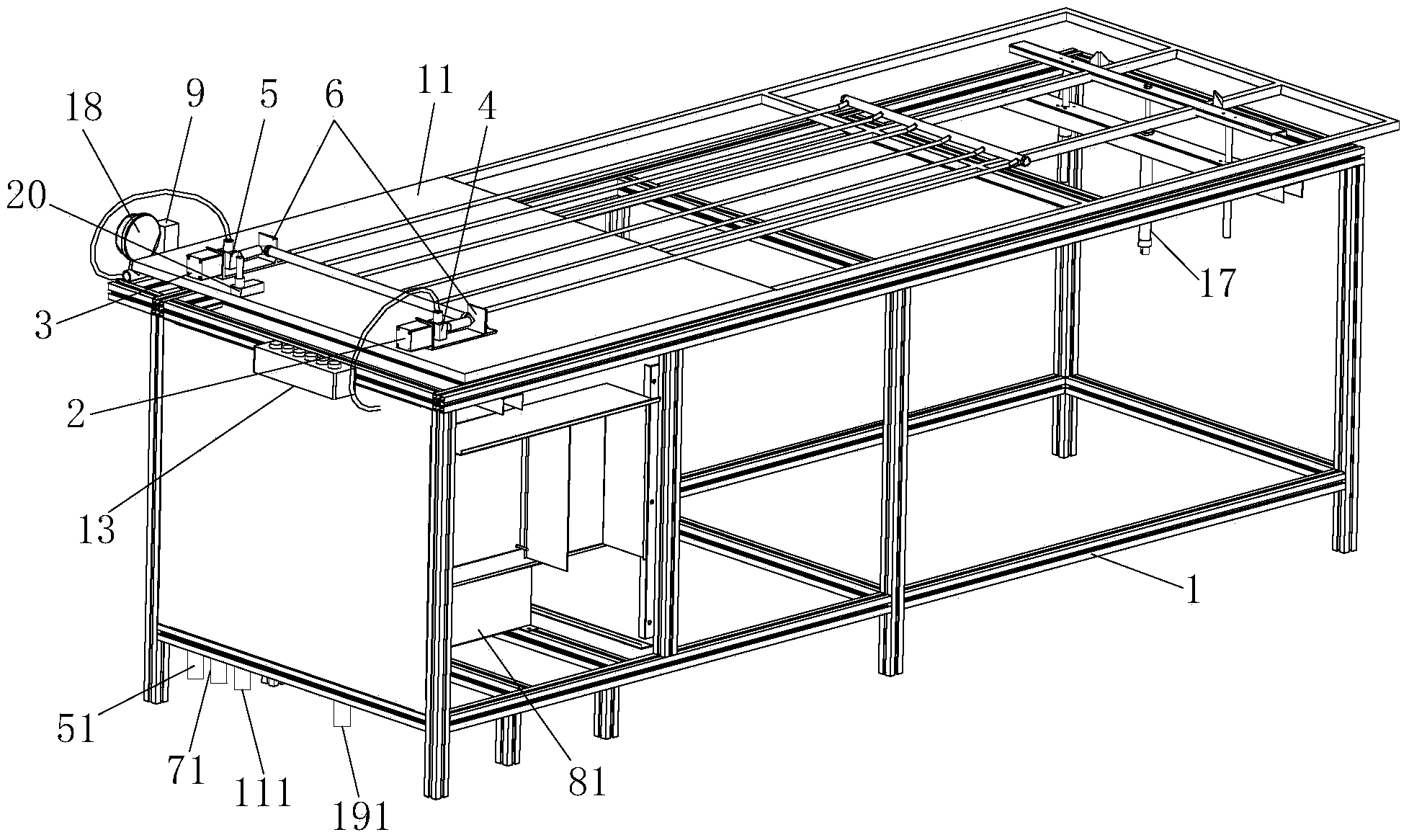

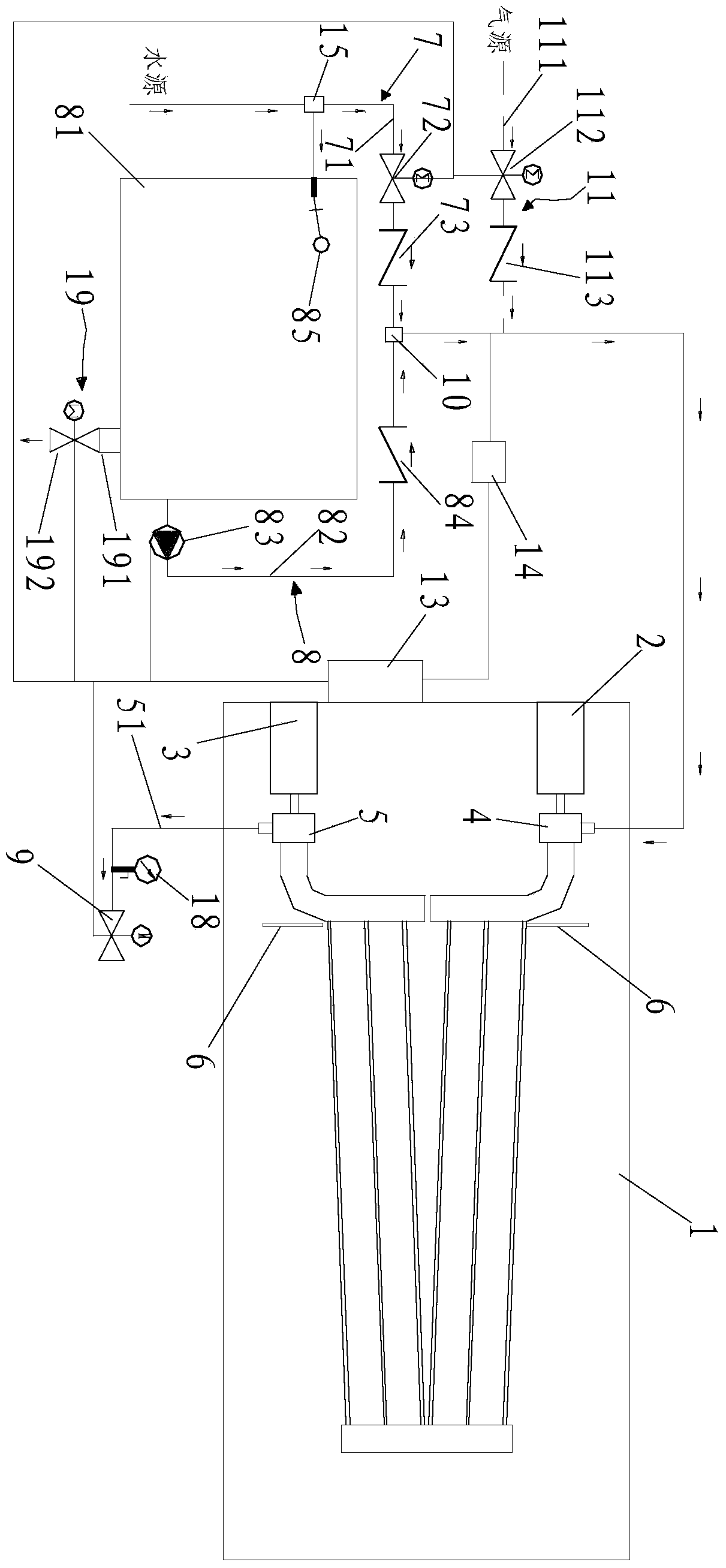

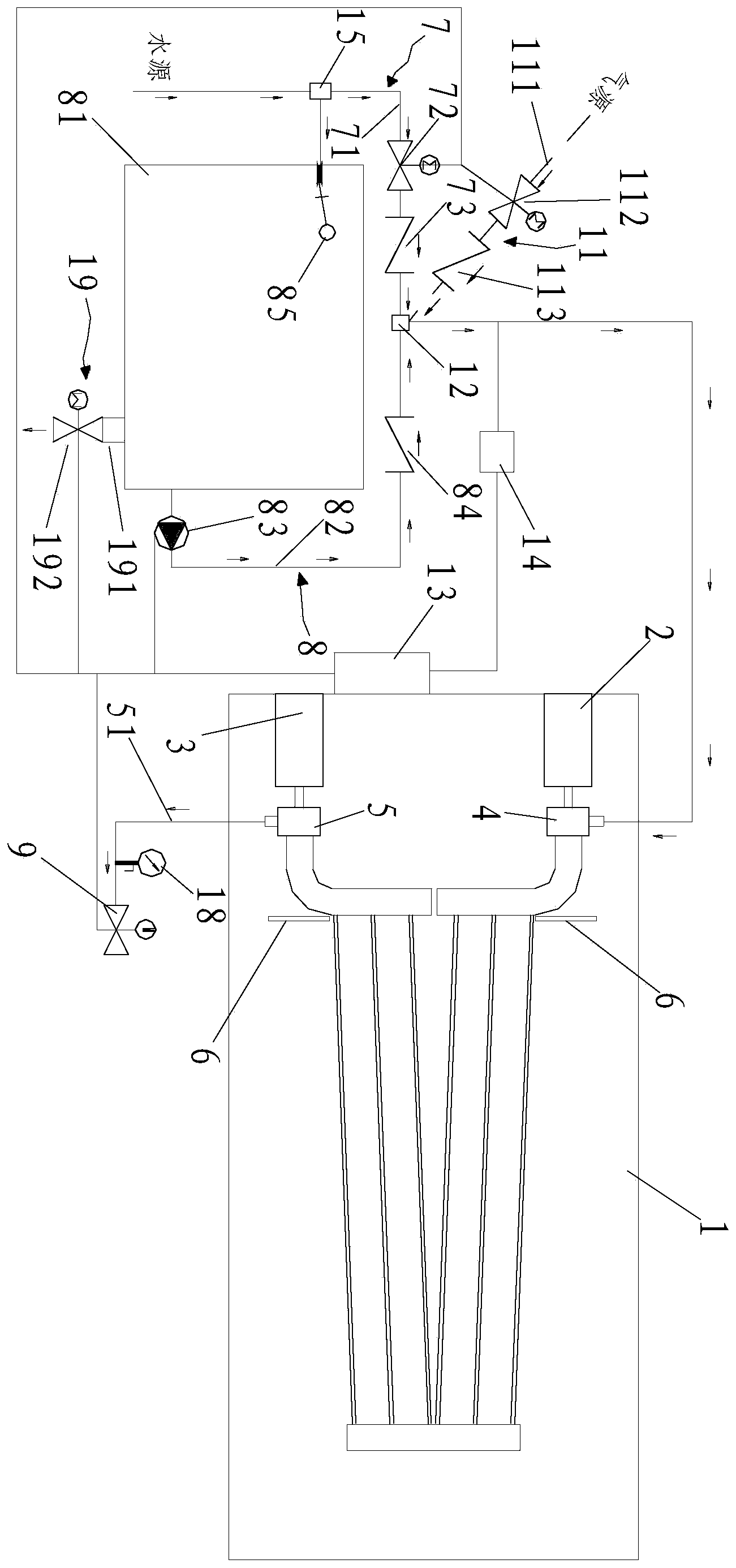

[0027] Please refer to Figure 1-5 , the figure shows a collector runner horizontal automatic pressure test machine, including a bracket 1, a movable bracket table 11 installed on the bracket 1, the movable bracket table 11 is equipped with a first driving device 2, The second driving device 3, the water inlet joint 4 connected to the first driving device 2, the water outlet joint 5 connected to the second driving device 3, and a water injection system connected in parallel with the water inlet pipeline of the water inlet joint 4 7 and the pressurization system 8 and the slowly closing valve 9 installed on the outlet pipe 51 of the water outlet joint 5 to eliminate water hammer. By using the slowly closing valve 9, the water hammer can be eliminated, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com