Fiber meshed modified lithium sulfur battery diaphragm and preparation method and application thereof

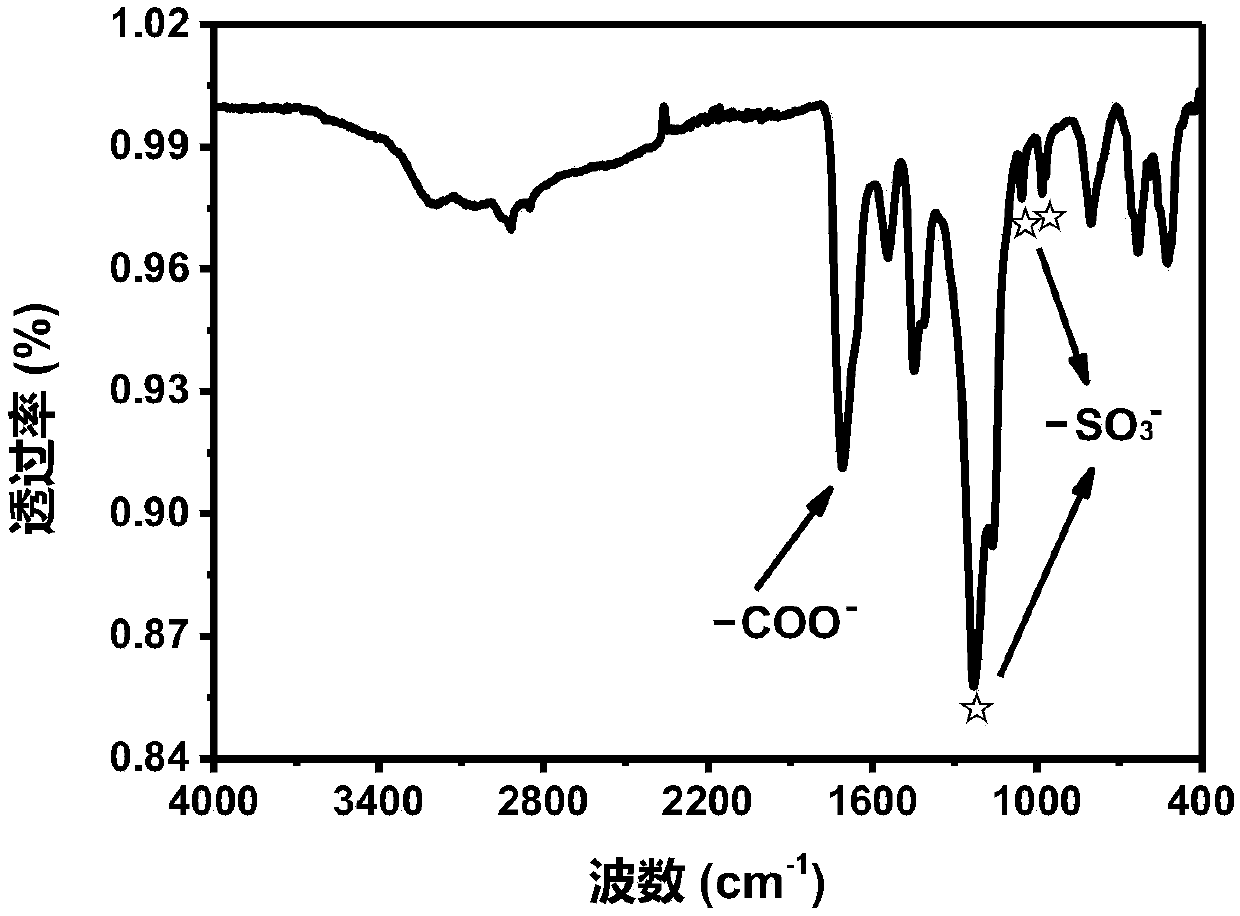

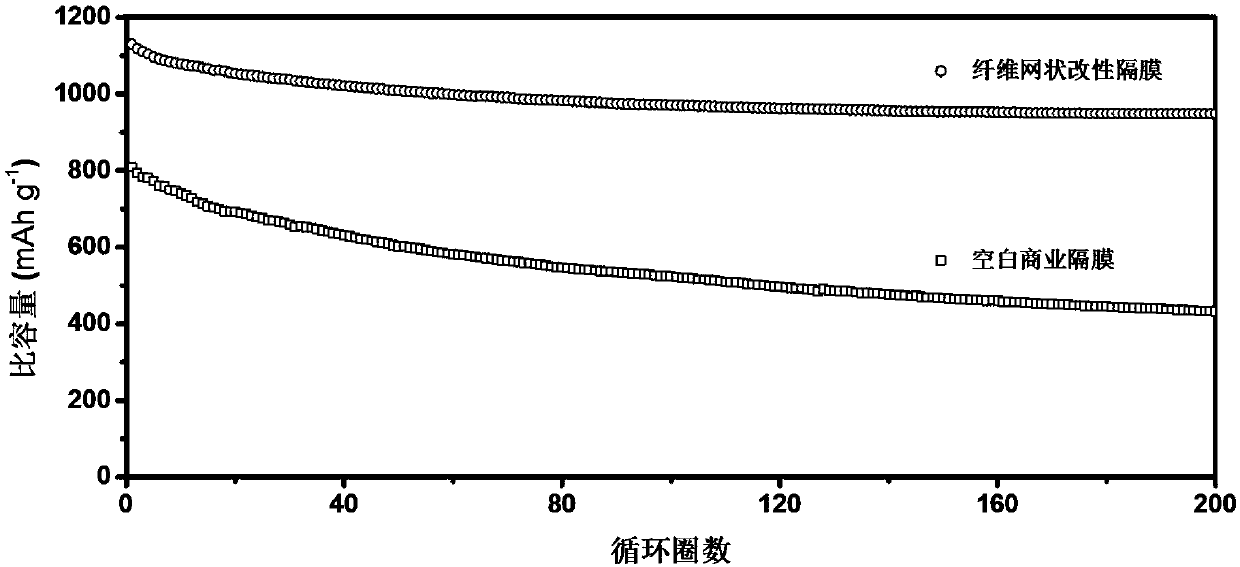

A lithium-sulfur battery, fiber mesh technology, applied in the field of lithium-sulfur battery modified diaphragm and its preparation, can solve the problems of poor electrolyte wettability, fast battery capacity decay, high electrochemical impedance, etc., and achieve excellent electrochemical performance , Inhibit capacity attenuation, increase wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of the modified diaphragm of the fiber mesh lithium-sulfur battery, the specific steps are as follows:

[0035] 1) Dissolve 0.5 g of polyacrylic acid powder in a mixed solvent of 9.5 g of water and n-propanol, the mass ratio of solvent water and n-propanol is 5:1, stir magnetically for 2 h, mix well, and the solution is transparent and colorless;

[0036] 2) Add 10 g of the commercial Nafion solution with a mass fraction of 5% to the polyacrylic acid solution in 1), and stir magnetically for 2 h to mix evenly, and the solution is transparent and colorless. After stopping the stirring, let it stand for 10 h to remove the air bubbles in the solution.

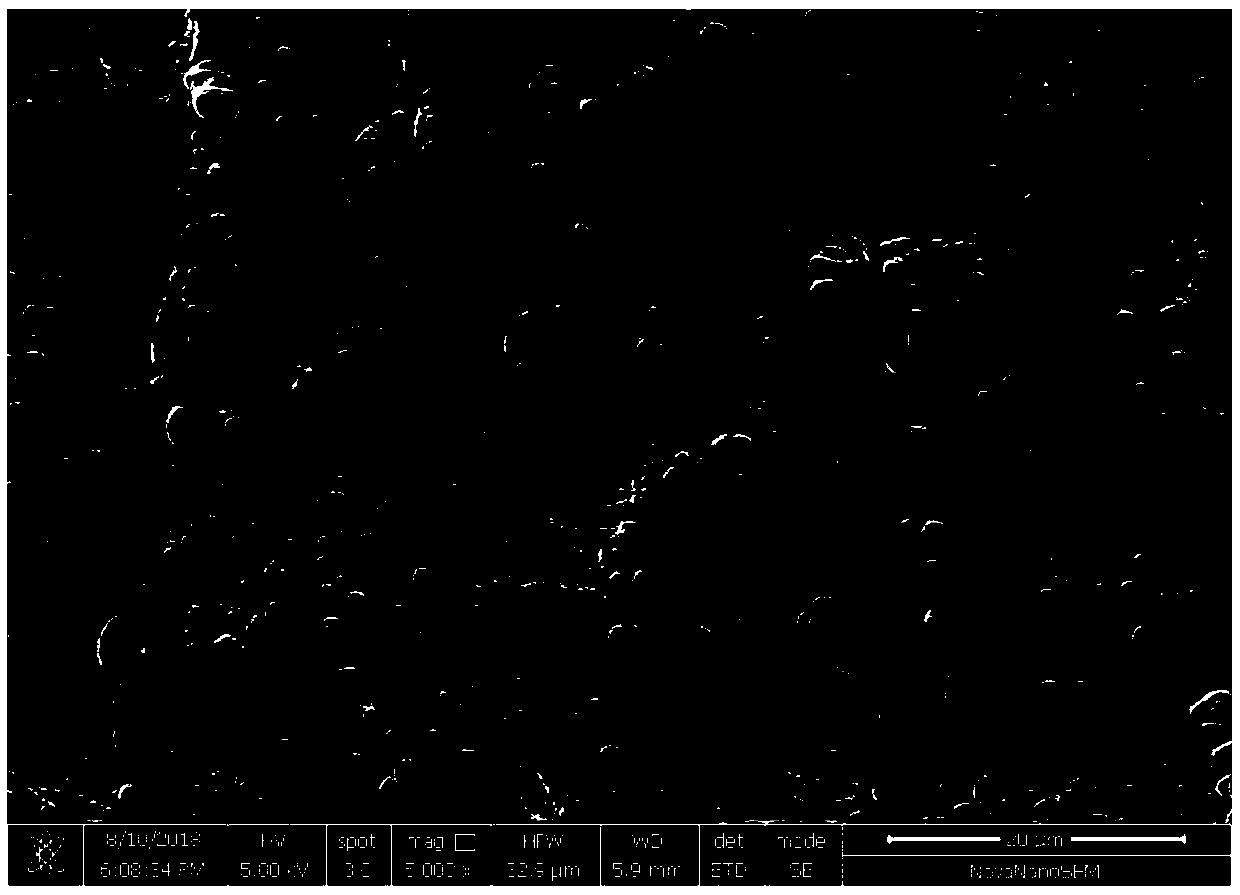

[0037] 3) The Nafion / polyacrylic acid mixed solution obtained in 2) was injected into a 5 ml medical syringe, placed in an electrospinning device, and spun at an injection speed of 0.3 ml / h and a voltage of 7 kV. A layer of commercial polyethylene diaphragm was wound on the roller receiver, the roller speed...

Embodiment 2

[0045] The preparation of the modified diaphragm of the fiber mesh lithium-sulfur battery, the steps are as follows:

[0046] 1) Dissolve 0.6 g of polyacrylic acid powder in a mixed solvent of 6.9 g of water and n-propanol, the ratio of solvent water and n-propanol is 4:1, stir magnetically for 3 h, mix well, and the solution is transparent and colorless;

[0047] 2) Add 8 g of the commercial Nafion solution with a mass fraction of 10% to the polyacrylic acid solution in 1), stir magnetically for 3 h and mix evenly, the solution is transparent and colorless; after stopping the stirring, let stand for 12 h to remove the bubbles in the solution;

[0048] 3) The Nafion / polyacrylic acid mixed solution obtained in 2) was injected into a 5 ml medical syringe, placed in an electrospinning device, and spun at an injection speed of 0.5 ml / h and a voltage of 8 kV. A layer of commercial polyethylene diaphragm was wound on the roller receiver, the roller speed was 50 r / min, and the distan...

Embodiment 3

[0053] The preparation of the modified diaphragm of the fiber mesh lithium-sulfur battery, the steps are as follows:

[0054] 1) Dissolve 0.6 g of polyacrylic acid powder in a mixed solvent of 4.4 g of water and n-propanol, the ratio of solvent water and n-propanol is 1:1, stir for 4 h under magnetic force, mix well, and the solution is transparent and colorless;

[0055] 2) Add 5 g of the commercial Nafion solution with a mass fraction of 5% to the polyacrylic acid solution in 1), stir magnetically for 6 h and mix evenly, the solution is transparent and colorless; after stopping the stirring, let stand for 15 h to remove the bubbles in the solution;

[0056] 3) The Nafion / polyacrylic acid mixed solution obtained in 2) was injected into a 5 ml medical syringe, placed in an electrospinning device, and spun at an injection speed of 0.5 ml / h and a voltage of 10 kV. A layer of commercial polypropylene diaphragm was wound on the roller receiver, the roller speed was 50 r / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com