Metal organic framework-modified polymer film and preparation method and application thereof

A technology of metal-organic framework and polymer film, which is applied in spinning solution preparation, textile and paper making, electrical components, etc. It can solve the problems of loss of polysulfide barrier effect, lower battery energy density, structural damage, etc., and achieve good electrolysis Liquid wettability and thermal stability, low production cost, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The polyacrylonitrile (PAN) base film of ZIF-67 modification, it comprises the steps:

[0028] 1) Add 1.2g Co(acac) 2 Disperse in 15ml N,N-dimethylformamide;

[0029] 2) Add 1.5 g of polyacrylonitrile powder to the solution obtained in step 1) and heat and stir at 70° C. for 10 hours;

[0030] 3) The solution obtained in step 2) was used for electrospinning for 12 hours to obtain Co 2+ - PAN nanofiber film;

[0031] 4) Put the nanofiber film obtained in step 3) and dimethylimidazole into a vacuum oven at 100° C. for low-pressure chemical vapor deposition for 10 hours to obtain a ZIF-67-PAN nanofiber film.

[0032] 5) The obtained ZIF-67-PAN nanofiber film was directly used as a lithium-sulfur battery separator, and the lithium-sulfur battery was assembled in an argon glove box, and the electrochemical performance test was performed.

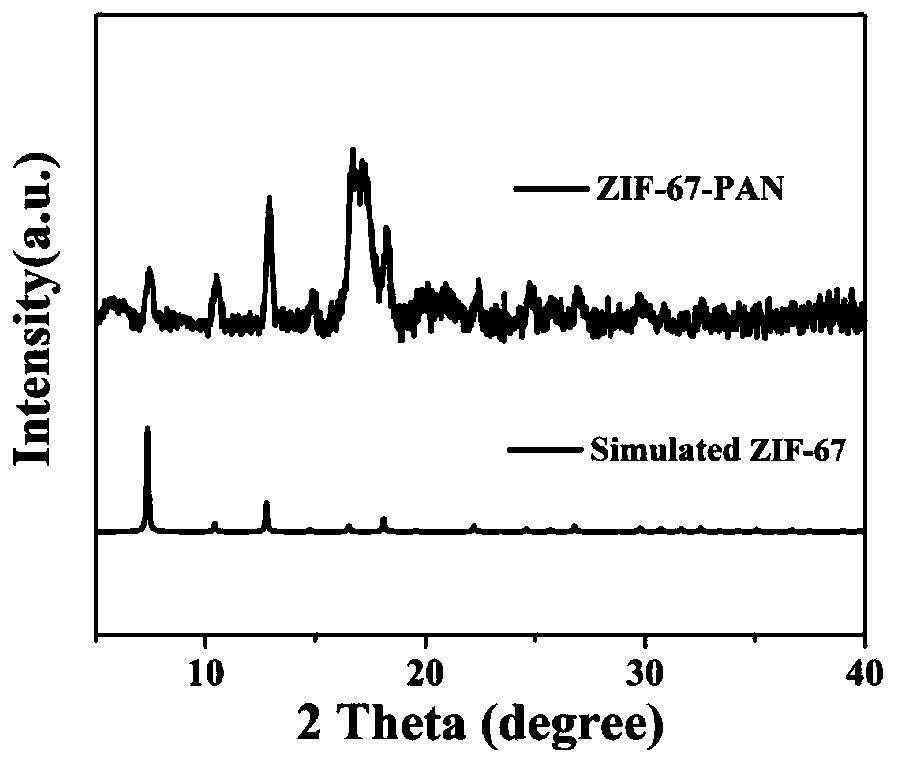

[0033] Take this example product ZIF-67-PAN film as an example, figure 1 is the X-ray diffraction pattern, it can be seen that Co 2...

Embodiment 2

[0037] The polyvinylidene fluoride (PVDF) base film of ZIF-67 modification, it comprises the steps:

[0038] 1) Add 1.2g Co(acac) 2 Disperse in 15ml N,N-dimethylformamide;

[0039] 2) Add 1.8 g of polyvinylidene fluoride film powder to the solution obtained in step 1) and heat and stir at 65° C. for 8 hours;

[0040] 3) The solution obtained in step 2) was used for electrospinning for 14 hours to obtain Co 2+ - PAN nanofiber film;

[0041] 4) Put the nanofiber film obtained in step 3) and dimethylimidazole into a vacuum oven at 100° C. for low-pressure chemical vapor deposition for 8 hours to obtain a ZIF-67-PVDF nanofiber film.

[0042] 5) The obtained ZIF-67-PVDF nanofiber film was directly used as a lithium-sulfur battery separator, and the lithium-sulfur battery was assembled in an argon glove box, and the electrochemical performance test was performed.

[0043]From the obtained ZIF-67-PVDF film, it can be seen that the nanofibers that make up the film are uniform in s...

Embodiment 3

[0045] The polyimide (PI) base film of ZIF-67 modification, it comprises the steps:

[0046] 1) 1.5g Co(NO 3 ) 2 ·6H 2 O was dispersed in 15ml N,N-dimethylformamide;

[0047] 2) Add 1.8 g of polyimide powder to the solution obtained in step 1) and heat and stir at 80° C. for 8 hours;

[0048] 3) The solution obtained in step 2) was used for electrospinning for 12 hours to obtain Co 2+ - PI nanofiber film;

[0049] 4) Put the double-layer nanofiber film obtained in step 3) and dimethylimidazole into a vacuum oven at 120° C. for low-pressure chemical vapor deposition for 10 hours to obtain a ZIF-67-PI film.

[0050] 5) The obtained ZIF-67-PI nanofiber film was directly used as a lithium-sulfur battery separator, and the lithium-sulfur battery was assembled in an argon glove box, and the electrochemical performance test was performed.

[0051] From the obtained ZIF-67-PI film, it can be seen that the nanofibers that make up the film are uniform in size, with a diameter of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com