Parallel pre-formation module composed of low-cost high-space-utilization lithium ion battery

A lithium-ion battery, high-space technology, applied in small-sized batteries/battery packs, large-sized batteries/battery packs, battery pack components, etc. Large problems, such as excellent electrolyte wettability and thermal stability, reduce the risk factor, and reduce the effect of exhaust steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Attached below Figure 1~5 To further explain this patent:

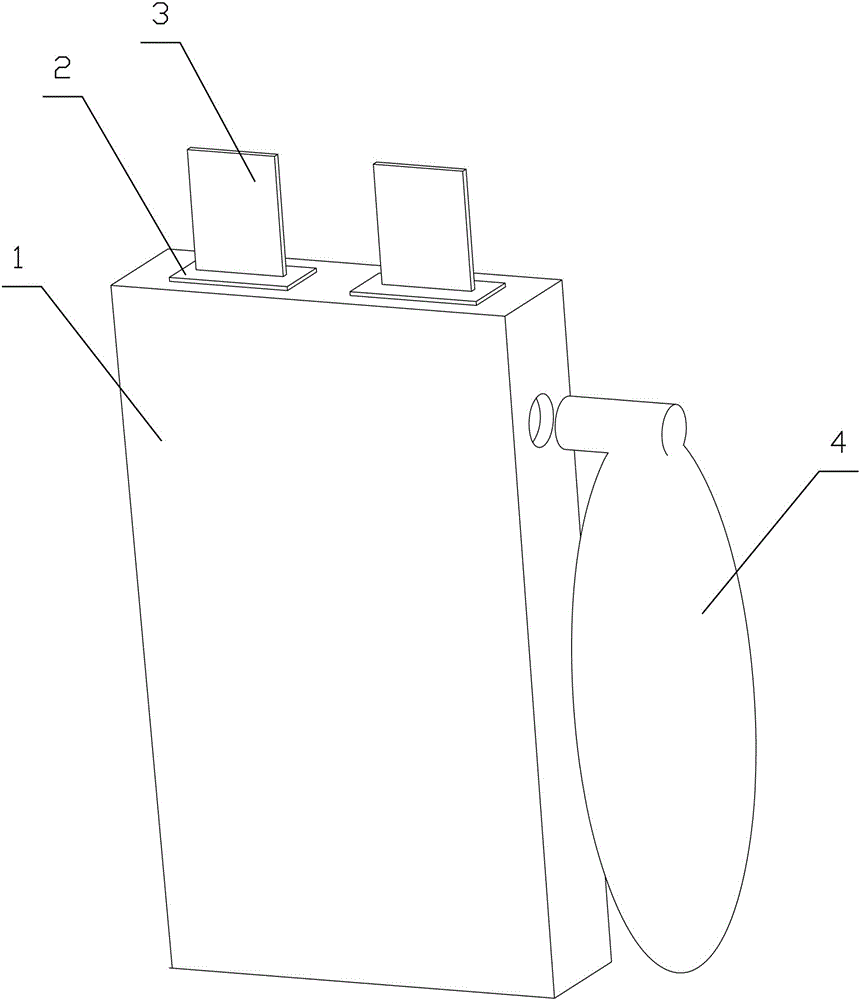

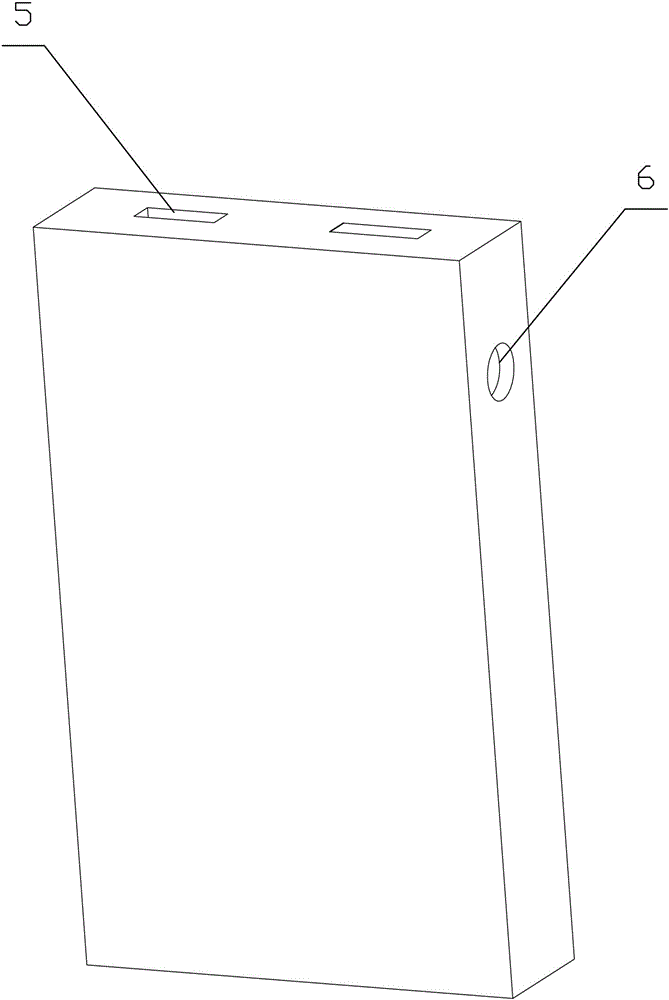

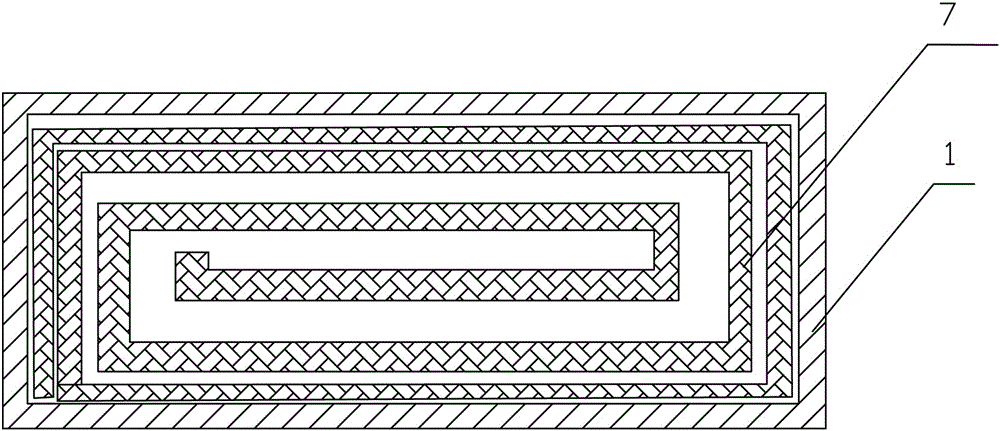

[0025] 1. A lithium-ion battery with low cost and high space utilization, comprising an aluminum case 1, characterized in that: the aluminum case 1 is provided with a winding core 7 in a winding manner, and the winding core 7 adopts the same side of the tab 3, and the aluminum There are two openings 5 on the top surface of the shell 1. The aluminum-plastic film 2 is welded at the opening 5. The aluminum-plastic film 2 has a hole through which the tab 3 passes. The aluminum shell 1 is equipped with an air bag 4. The side of the aluminum shell 1 is provided with a side The opening 6 and the side opening 6 are connected with connection holes of the airbag 4 .

[0026] The core 7 includes a diaphragm, which is characterized in that: the diaphragm 5 includes a microporous PET film 9 and a microporous material layer 8, and the microporous PET film 9 is distributed with straight micropores arranged along the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com