Preparation method and application of graphene-loaded high-conductivity molybdenum sulfide nanoflower material

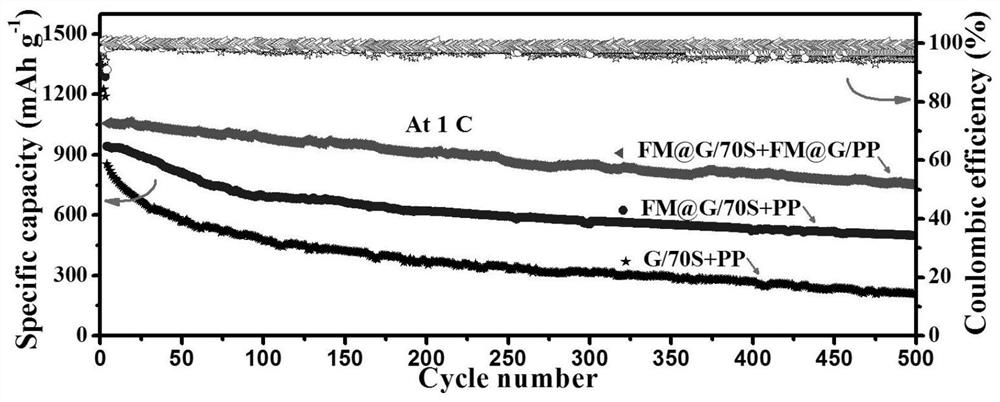

A graphene, high-conductivity technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that affect the advantages of high energy density, low sulfur content, and poor rate performance of lithium-sulfur batteries , achieving good cycle stability and excellent Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

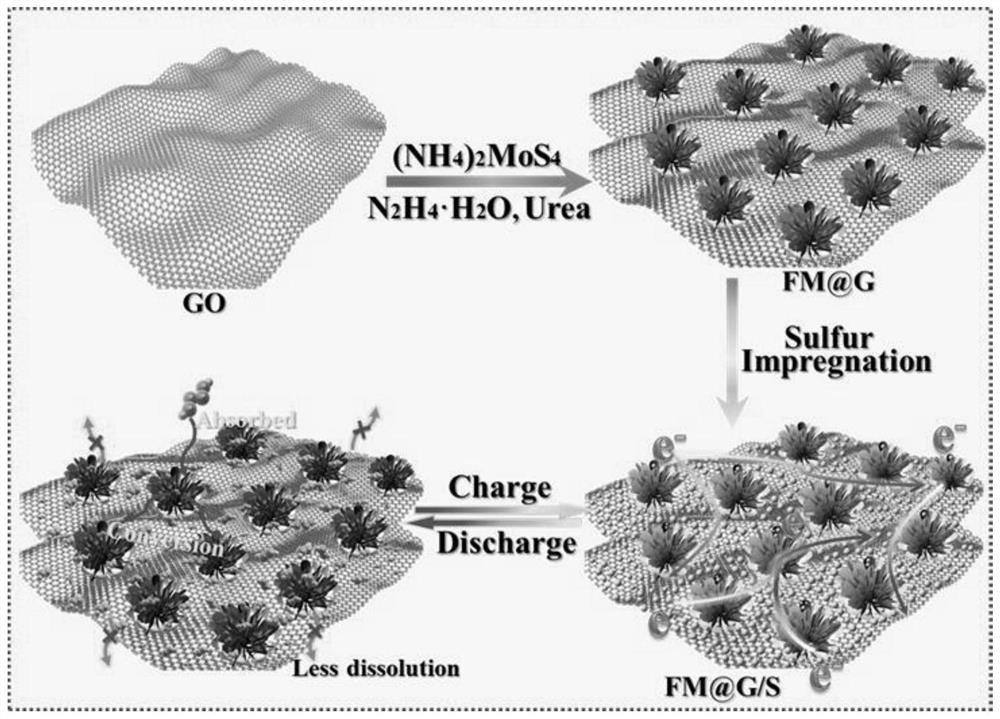

[0035] This embodiment provides a method for preparing an FM@G material, which specifically includes the following steps:

[0036] 30 mg graphene oxide was sonicated in 50 mL DMF until completely dispersed, and 30 mg (NH 4 ) 2 MoS 4 and 30 mg urea, after ultrasonic treatment for 1 hour, add 100 μL hydrazine hydrate, stir for 30 minutes, ultrasonic treatment for 20 minutes to form a uniform suspension, place the suspension at 180 ° C for 10 hours, cool, centrifugal filter, use The FM@G material was obtained after washing and drying with deionized water and ethanol.

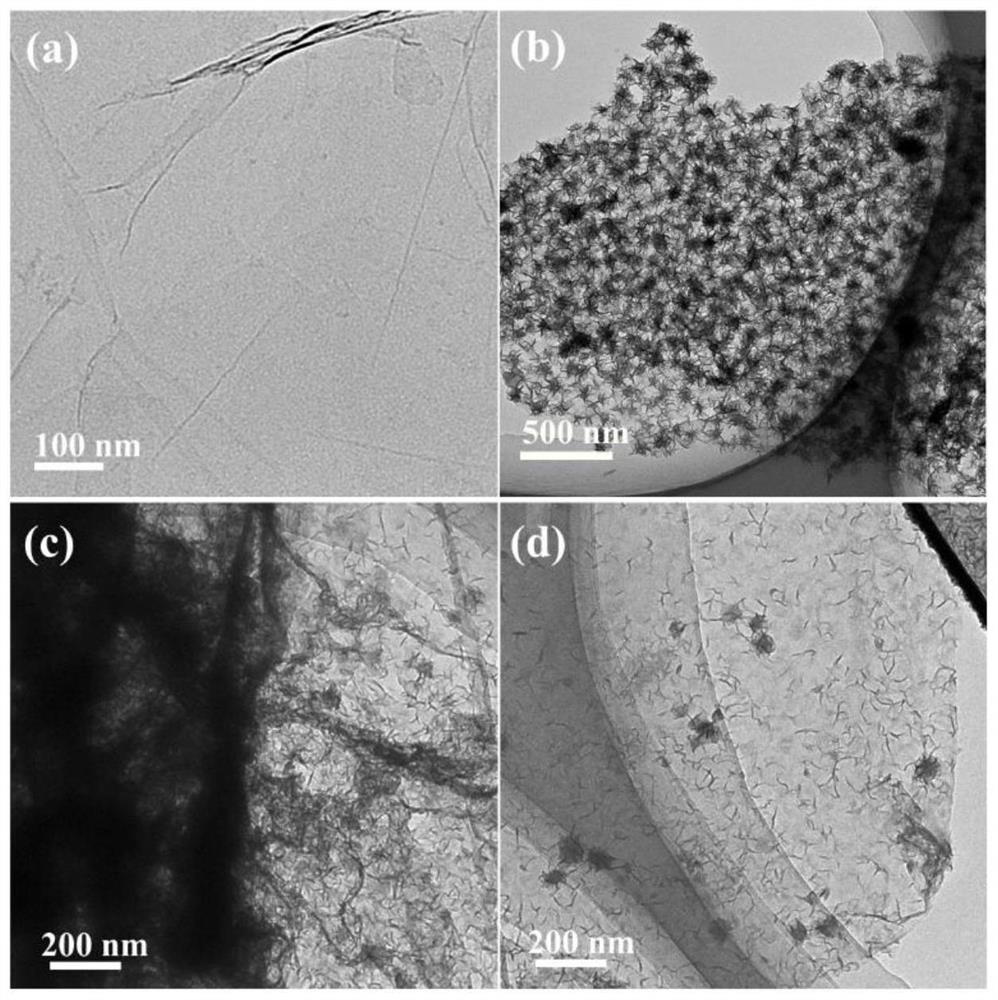

[0037] The TEM image of FM@G prepared in this example shows that the MoS 2 After loading on graphene, the two-dimensional nanosheet structure is well maintained, and the MoS 2 Nanoflowers are in close contact with the graphene surface, which is beneficial for electron transfer in graphene and MoS 2 freely transfer between them. The molybdenum sulfide nanoflowers are uniformly distributed on the graphene surfa...

Embodiment 2

[0039] This embodiment provides a preparation method of FM@G-PP modified diaphragm material, which specifically includes the following steps:

[0040] Add 16 mg FM@G and 2 mg PVDF to 18 mL ethanol solution and sonicate for 45 min at room temperature. After the end of ultrasonication, the dispersion was stirred for 5 minutes, and the resulting dispersion was vacuum filtered to one side of the commercial PP membrane. The resulting FM@G-coated separator was dried under vacuum at 40 °C for 36 h to obtain the FM@G / PP separator material.

Embodiment 3

[0042] This embodiment provides a preparation method for loading sulfur on a graphene-loaded highly conductive molybdenum sulfide nanoflower material, which specifically includes the following steps:

[0043]Disperse the FM@G material and sulfur powder prepared in Example 1 in the carbon disulfide solution at a mass ratio of 3:7, stir until the carbon disulfide is completely evaporated, and react at 150-180°C to obtain the FM@G / 70S composite material , that is, the graphene-supported highly conductive molybdenum sulfide nanoflower material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com