Preparation method of three-dimensional porous carbon aerogel material and application of three-dimensional porous carbon aerogel material in lithium-sulfur battery

A carbon aerogel and lithium-sulfur battery technology, which is applied in the preparation/purification of carbon, lithium batteries, battery electrodes, etc., can solve the problems of low application value, low sulfur load on the positive electrode of lithium-sulfur batteries, and low sulfur utilization rate, etc. problems, to achieve high degree of graphitization, improve cycle stability, high specific capacity and sulfur loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

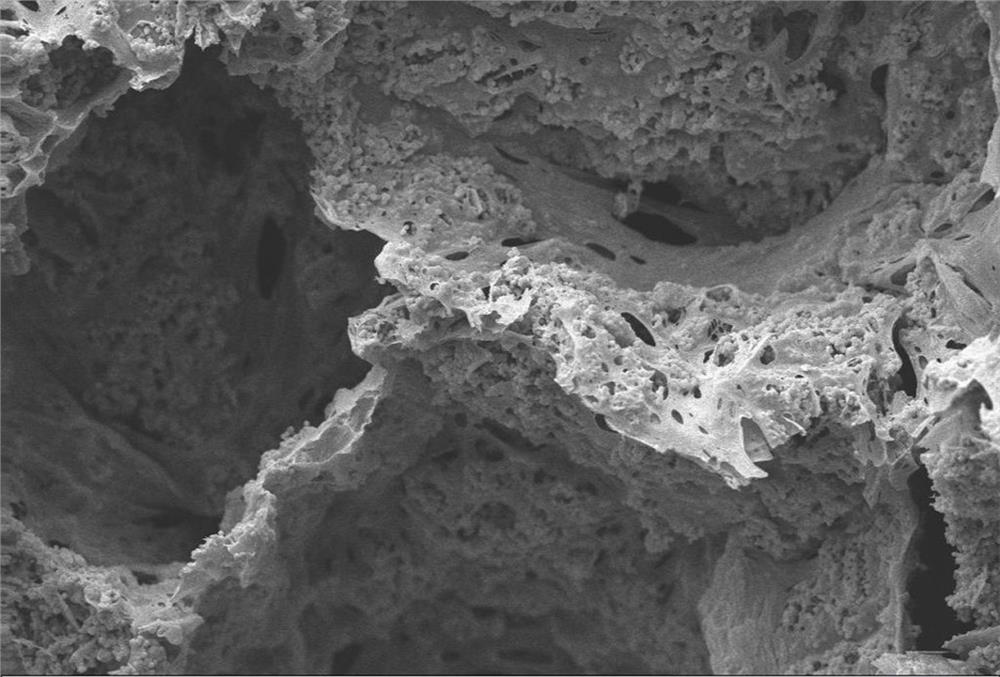

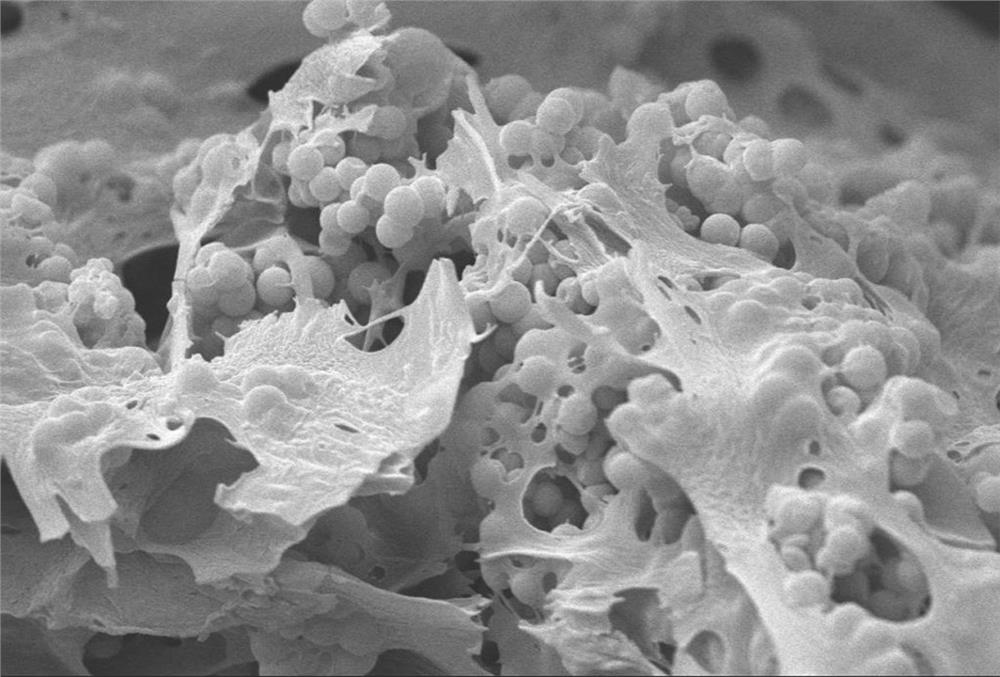

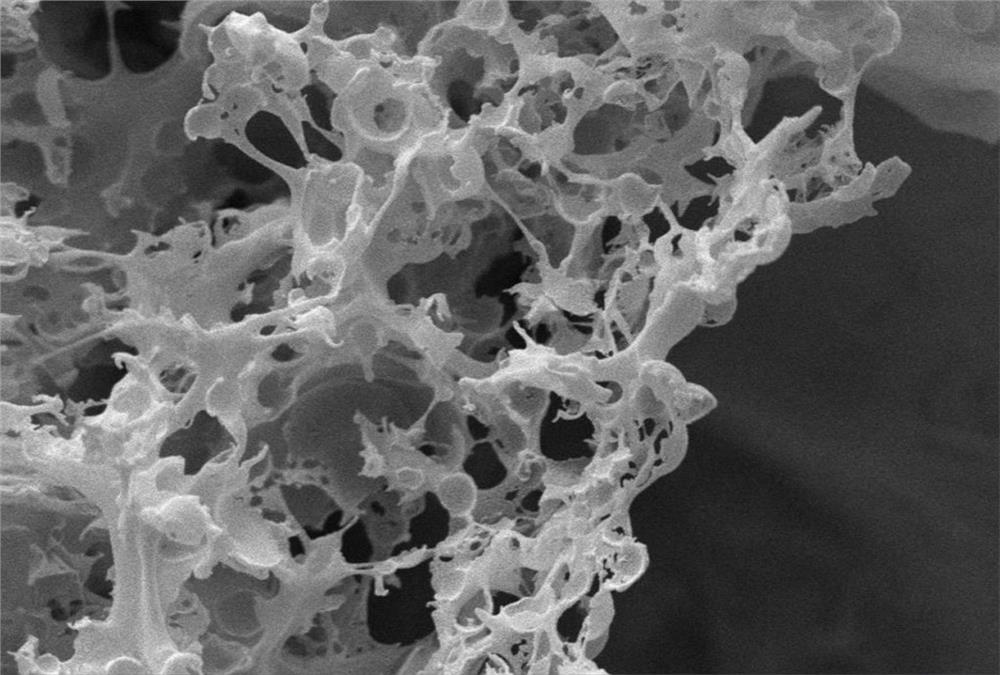

[0027] A preparation method for a lithium-sulfur battery cathode material, comprising the steps of:

[0028] (1) Add 1.75 g of melamine and 2.5 mL of triethanolamine to 3.5 mL of 37% formaldehyde aqueous solution and mix well, heat in a water bath at 75 °C in a single-necked flask and keep stirring until the solution is clear and transparent, then add hydrochloric acid (1 mol / L) adjusting the pH to 3;

[0029] (2) Add 1 g of lignin to 10 mL of distilled water, adjust the pH to 11 with concentrated ammonia water to fully dissolve the lignin, and then adjust the pH to 3 with hydrochloric acid (1mol / L) to precipitate the lignin as nanoparticles;

[0030] (3) Add 0.02 g of hydrophilic silica, 1.5 mL of the solution obtained in step (1) and 0.5 mL of the solution obtained in step (2) to a 20 mL finger bottle and mix well to prepare as the aqueous phase of the Pickering emulsion.

[0031] (4) Slowly add 12 mL of toluene dropwise to 2 mL of the solution obtained in step (3) under c...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is: a lithium-sulfur battery positive electrode material, comprising the following steps:

[0036] (1) Add 1.5 g of melamine and 2.5 mL of triethanolamine to 3.5 mL of 37% formaldehyde aqueous solution and mix evenly, heat in a water bath at 70°C in a single-necked flask and keep stirring until the solution is clear and transparent, then add hydrochloric acid (1 mol / L) Adjust the pH to 3.

[0037] (2) Add 1 g of lignin to 10 mL of distilled water, add concentrated ammonia solution to adjust the pH to 11, and then add hydrochloric acid (1 mol / L) to adjust the pH to 3.

[0038] (3) Add 0.04 g of hydrophilic silica, 1.5 mL of the solution obtained in step 1 and 0.5 mL of the solution obtained in step 2 into a 20 mL finger bottle and mix well.

[0039] (4) Slowly add 12 mL of toluene dropwise to 2 mL of the solution obtained in step 3 under continuous stirring to prepare an oil-in-water emulsion with an internal phas...

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is: a lithium-sulfur battery positive electrode material, comprising the following steps:

[0044] (1) Add 1.25 g of melamine and 2.5 mL of triethanolamine to 3.5 mL of 37% formaldehyde aqueous solution and mix evenly, heat in a water bath at 70°C in a single-necked flask and keep stirring until the solution is clear and transparent, then add hydrochloric acid (1mol / L) Adjust the pH to 3.

[0045] (2) Add 1.5 g of lignin to 10 mL of distilled water, add concentrated ammonia solution to adjust the pH to 11, and then add hydrochloric acid (1 mol / L) to adjust the pH to 3.

[0046] (3) Add 0.06 g of hydrophilic silica, 1.5 mL of the solution obtained in step 1 and 0.5 mL of the solution obtained in step 2 into a 20 mL finger bottle and mix well.

[0047] (4) Slowly add 13 mL of toluene dropwise to 2 mL of the solution obtained in step 3 under continuous stirring to prepare an oil-in-water emulsion with an internal ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com