Three-dimensional porous graphene nanomaterial and its preparation method and application

A technology of three-dimensional porous and nanomaterials, which is applied in the field of nanocarbon materials and their preparation, can solve the problems of long growth cycle of redox method, low production efficiency of liquid phase exfoliation method, difficulty in large-scale production, etc., and achieve rich mesopore or Large pore structure, rich hierarchical pore structure, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

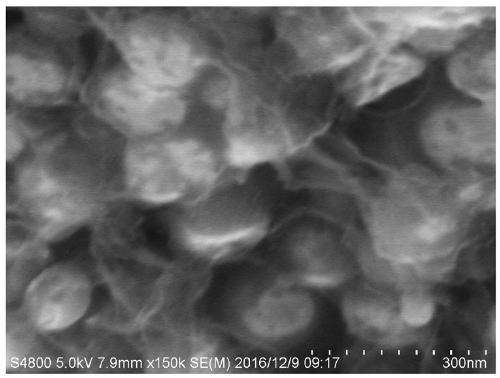

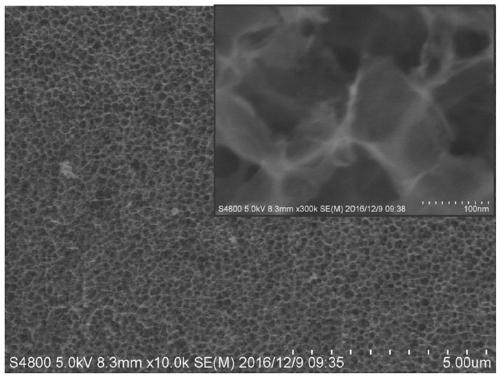

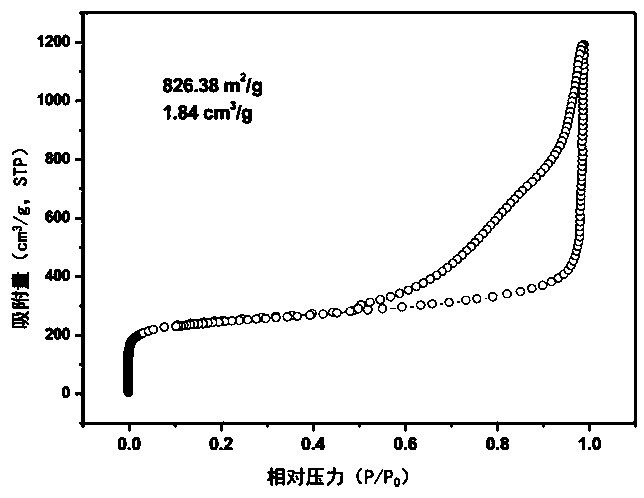

[0035] A three-dimensional porous graphene nano material. The three-dimensional porous graphene nano material is a three-dimensional porous conductive network structure composed of layered graphene, and the pore diameter of the macropores in the three-dimensional porous conductive network structure is 150 nm to 200 nm.

[0036] In this embodiment, the three-dimensional porous graphene nanomaterial has a rich and uniformly distributed macropore structure.

[0037] A method for preparing the three-dimensional porous graphene nanomaterial of this embodiment described above includes the following steps:

[0038] (1) Under magnetic stirring, add 15ml of tetraethylorthosilicate to a mixed solvent consisting of 10ml of ammonia, 200ml of ethanol and 100ml of water, stir at 30℃ for 10min, and then add 10ml of resorcinol in ethanol (Containing 1.44g resorcinol), 2.12g formaldehyde aqueous solution (the mass fraction of formaldehyde is 37wt%), continue to stir for 12h, and finally hydrothermall...

Embodiment 2

[0051] A three-dimensional porous graphene nano material. The three-dimensional porous graphene nano material is a three-dimensional porous conductive network structure composed of layered graphene, and the pore diameter of the macropores in the three-dimensional porous conductive network structure is 150 nm to 200 nm.

[0052] In this embodiment, the three-dimensional porous graphene nanomaterial has a rich and uniformly distributed macropore structure.

[0053] A method for preparing the three-dimensional porous graphene nanostructure of the above embodiment includes the following steps:

[0054] (1) Under magnetic stirring, add 15ml of tetraethylorthosilicate to a mixed solvent consisting of 10ml of ammonia, 200ml of ethanol and 100ml of water, stir at 30℃ for 2h, then add 10g of glucose, stir for 2h, and place The reaction was carried out in a hydrothermal kettle at 190°C for 12 hours, and the product was centrifuged and filtered to obtain caramelized glucose-coated silica nanosp...

Embodiment 3

[0060] A three-dimensional porous graphene nano material. The three-dimensional porous graphene nano material is a three-dimensional porous conductive network structure composed of layered graphene, and the pore diameter of the macropores in the three-dimensional porous conductive network structure is 150 nm to 200 nm.

[0061] In this embodiment, the three-dimensional porous graphene nanomaterial has a rich and uniformly distributed macropore structure.

[0062] A method for preparing the three-dimensional porous graphene nanomaterial of this embodiment described above includes the following steps:

[0063] (1) Under magnetic stirring, add 15ml of tetraethylorthosilicate to a mixed solvent consisting of 10ml of ammonia, 200ml of ethanol and 100ml of water, stir at 30℃ for 2h, then add 3g of silane coupling agent MPS, and react for 24h , After centrifugal washing, disperse in a mixed solution of 95ml ethanol and 5ml water, add 0.5g initiator azobisisobutyronitrile AIBN and 2g dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com