Sulfur/iron oxide/graphene battery cathode material, preparation method and lithium sulfur battery

A battery cathode and graphene technology, applied in the field of nanomaterials, can solve the problems of poor cycle stability and safety performance, short service life of lithium-sulfur batteries, and inability to effectively fix elemental sulfur, so as to improve capacity stability and service life, The effect of improving electrical conductivity and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

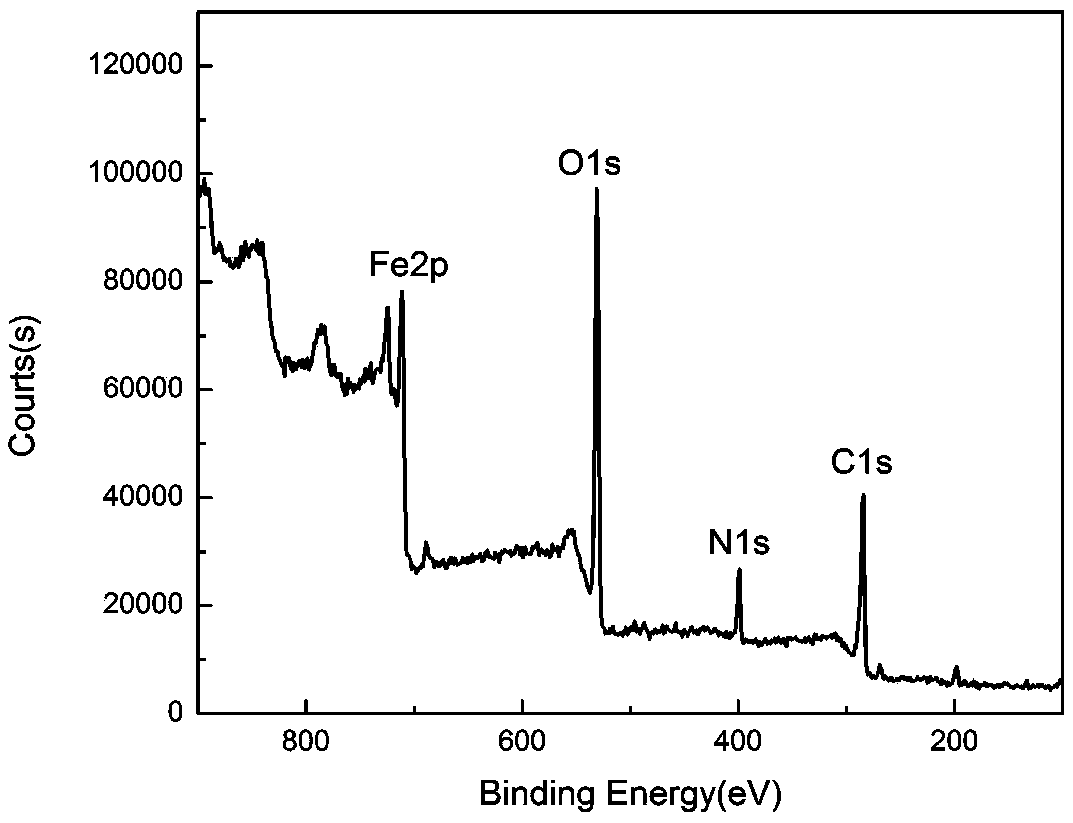

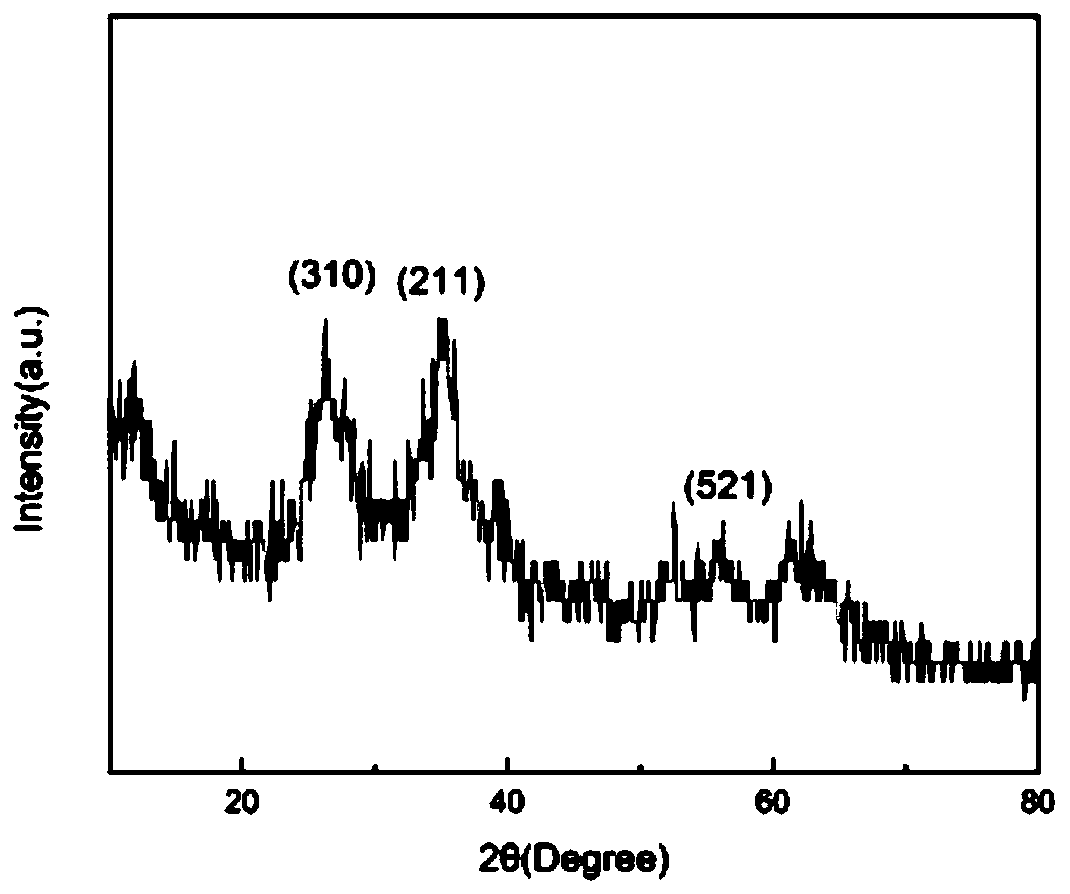

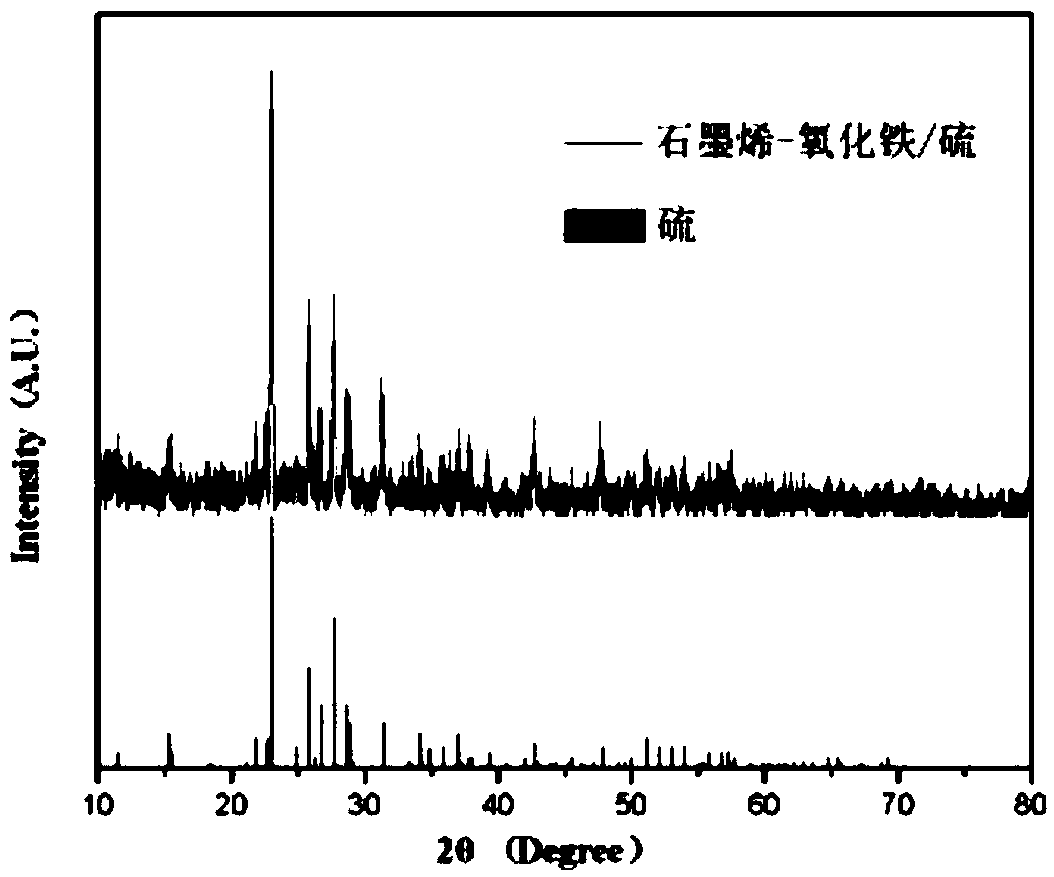

[0042] Preparation of nitrogen-doped graphene: Measure 400ml of 1.0mg / ml graphene oxide aqueous solution and place it in a 500ml three-necked flask, then add 16ml of 50wt% cyanamide aqueous solution, stir well, react at 90°C for 36h, and the obtained After natural cooling, the product was subjected to suction filtration, freezing, and freeze-drying to obtain nitrogen-doped graphene with active sites.

[0043] Preparation of graphene-iron oxide nanocomposites: Weigh 75 mg of the above-mentioned nitrogen-doped graphene, add it to 480 ml of ethanol for ultrasonic dispersion, and then take 0.75 mmol of FeCl 3 , dissolved in 10ml of absolute ethanol, and added to the dispersed graphene solution to obtain a uniform dispersion of iron salt and nitrogen-doped graphene, then add 8ml of deionized water, and transfer the dispersion to the reactor In the process, the hydrothermal reaction was carried out at a temperature of 90° C. for 6 hours. After the reaction, the product was naturally...

Embodiment 2

[0052] Preparation of nitrogen-doped graphene: Weigh 200mg of graphene oxide and place it in a 500ml three-necked flask, add 400ml of deionized water, then add 10mg of urea, stir to dissolve and disperse, react at 100°C for 30h, and the product obtained after the reaction is cooled naturally , carry out suction filtration, freezing, and freeze-drying to prepare nitrogen-doped graphene.

[0053] Preparation of graphene-iron oxide nanocomposite material: take 75mg of nitrogen-doped graphene, add it into 480ml of acetone for ultrasonic dispersion, then take 3.0mmol of ferrous chloride (FeCl 2 ), dissolved in 10ml of absolute ethanol, added to the dispersed graphene solution to obtain a uniform dispersion of iron salt and nitrogen-doped graphene, then add 16ml of deionized water, and transfer the dispersion to the reaction In the kettle, heat preservation at a temperature of 100° C. for 4 hours to carry out hydrothermal reaction. After the reaction, the product is naturally cooled...

Embodiment 3

[0056] Preparation of nitrogen-doped graphene: Measure 20ml of 10mg / ml graphene oxide aqueous solution and place it in a 500ml beaker, add 380ml of deionized water, stir evenly, then add 16ml of 50wt% cyanamide, transfer to a three-necked flask, React at 90°C for 24 hours, and the product obtained after the reaction is naturally cooled, then subjected to suction filtration, freezing, and freeze-drying to obtain nitrogen-doped graphene.

[0057] Prepare graphene-iron oxide nanocomposite material: take 75mg nitrogen-doped graphene, join in the ethanol of 470ml and ultrasonically disperse, then get 4.5mmol of ferric nitrate (Fe(NO 3 ) 3 ), dissolved in 20ml of absolute ethanol, added to the dispersed graphene solution to obtain a uniform dispersion of iron salt and nitrogen-doped graphene, then add 10ml of deionized water, and transfer the dispersion to the reaction In the kettle, the temperature is 120°C, the holding time is 2h, and the hydrothermal reaction is carried out. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com