Current collector, pole sheet and electrochemical device

A current collector and pole piece technology, applied in electrochemical generators, electrode carriers/current collectors, circuits, etc., can solve problems such as the inability to effectively prevent the short circuit of lithium-ion batteries, the inability to guarantee the continued operation of the battery, and the failure of the battery to continue to work. , to achieve the effects of improving high-rate charge and discharge performance, improving electrolyte wettability, improving long-term reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] 1. Preparation of insulating layer with specific light transmittance

[0120] The material of the insulating layer is PET. Add a certain amount of colorant carbon black to the PET and mix it evenly. After extrusion casting, cold roll rolling and biaxial stretching in the PET hot melt state, a specific light transmittance can be obtained. insulation layer.

[0121] 2. Preparation of current collector:

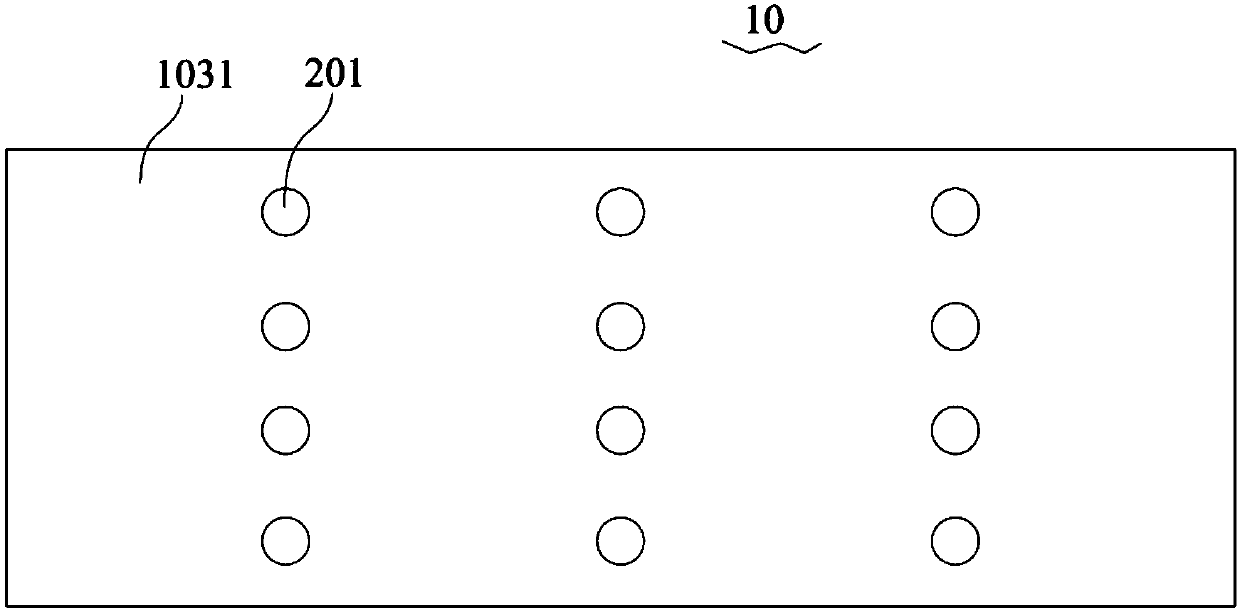

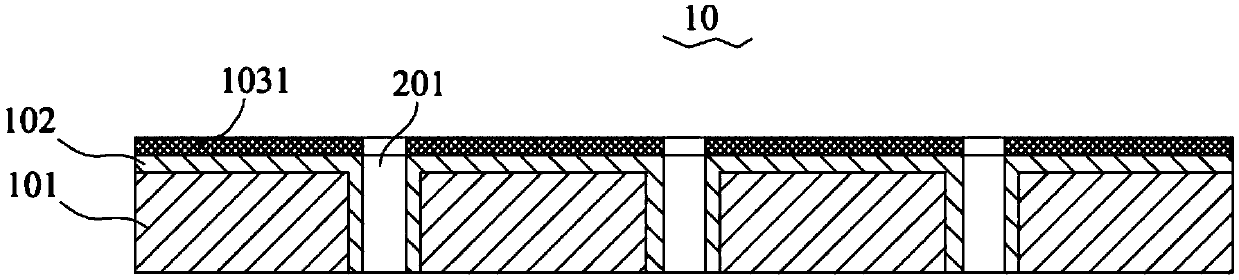

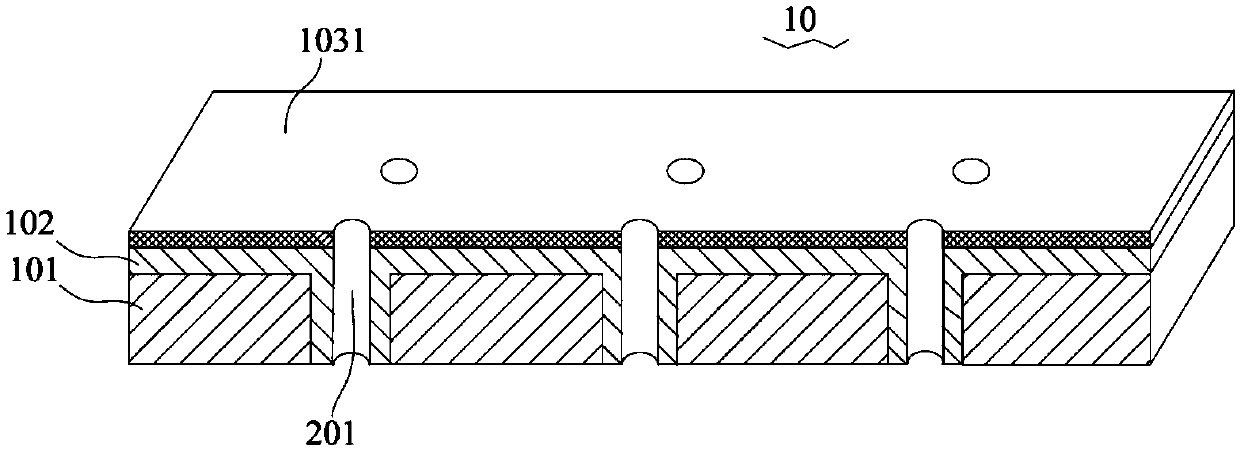

[0122] 2.1 Select an insulating layer of a certain thickness, drill holes in the insulating layer, and then form a conductive layer of a certain thickness by vacuum evaporation, so that the conductive layer is deposited on at least one surface of the insulating layer and the surface of the hole wall of the hole;

[0123] 2.2 Select an insulating layer of a certain thickness, form a conductive layer of a certain thickness on its surface by vacuum evaporation, and then punch holes to form a plurality of holes running through the insulating layer and the conductive layer; ...

experiment example

[0149] 1. Battery cycle life test method:

[0150] Carry out cycle life test on lithium-ion battery, the specific test method is as follows:

[0151] Charge and discharge the lithium-ion battery at two temperatures of 25°C and 45°C, that is, first charge to 4.2V with a current of 1C, and then discharge to 2.8V with a current of 1C, and record the discharge capacity of the first week; Then the battery was subjected to 1000 cycles of 1C / 1C charge and discharge, and the battery discharge capacity of the 1000th cycle was recorded, and the discharge capacity of the 1000th cycle was divided by the discharge capacity of the first cycle to obtain the capacity retention rate of the 1000th cycle.

[0152] The experimental results are shown in Table 3.

[0153] 2. Experimental method and test method of nail penetration experiment:

[0154] Nail piercing test: After the battery is fully charged, fix it. At room temperature, a steel needle with a diameter of 8mm will penetrate the batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com