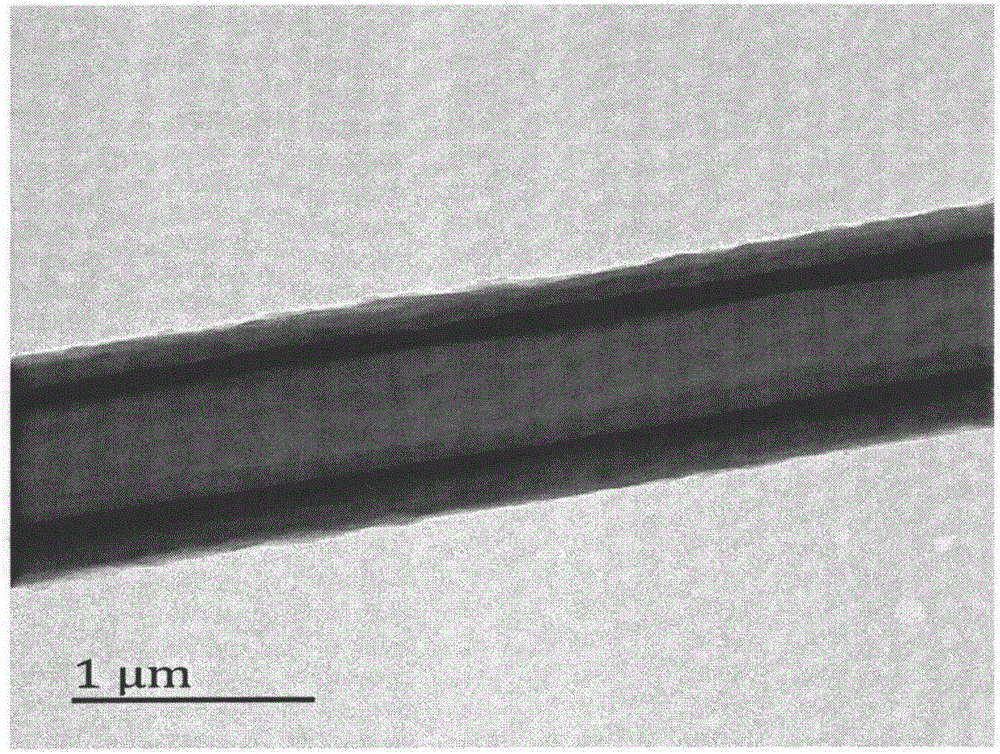

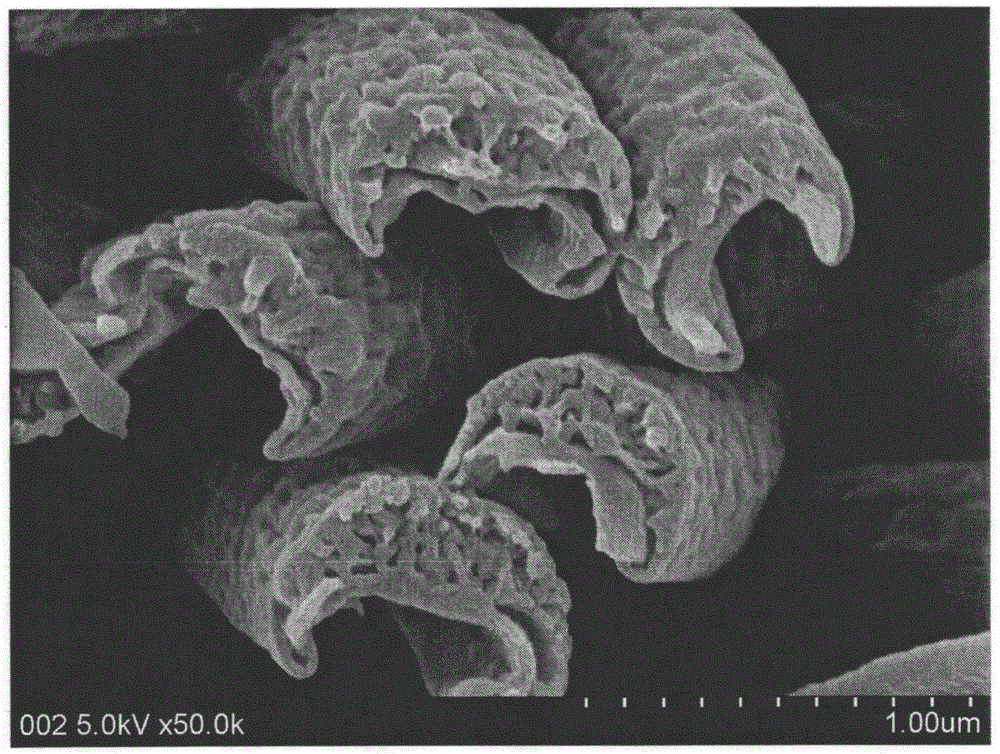

Type-C core-shell nanofiber membrane and eccentric-shaft electrostatic spinning preparation method thereof

A nanofiber membrane and electrospinning technology, which is applied in electrospinning, fiber treatment, chemical instruments and methods, etc., can solve the problems of easy wetting of membrane pores, low membrane porosity, and low thermal conversion efficiency, and achieve improved porosity The effect of low, increased porosity, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a C-type core-shell nanofiber membrane by eccentric axis electrospinning, the specific steps are:

[0028] (1) Polystyrene (PS) (Sigma-Aldrich Trading Co., Ltd., weight average molecular weight: 192000g / mol) 25g is dissolved in 75gN, as shell solution in N-dimethylformamide (DMF) solvent, will Polyacrylonitrile (PAN) (Shanghai Jinshan Co., Ltd., weight-average molecular weight: 136000g / mol) 8g is dissolved in 92gN, in the N-dimethylformamide (DMF) solvent as the core layer solution, the shell layer solution and the core layer solution Stir in an oil bath at 40° C. for 24 hours to obtain a uniform and transparent electrospinning solution.

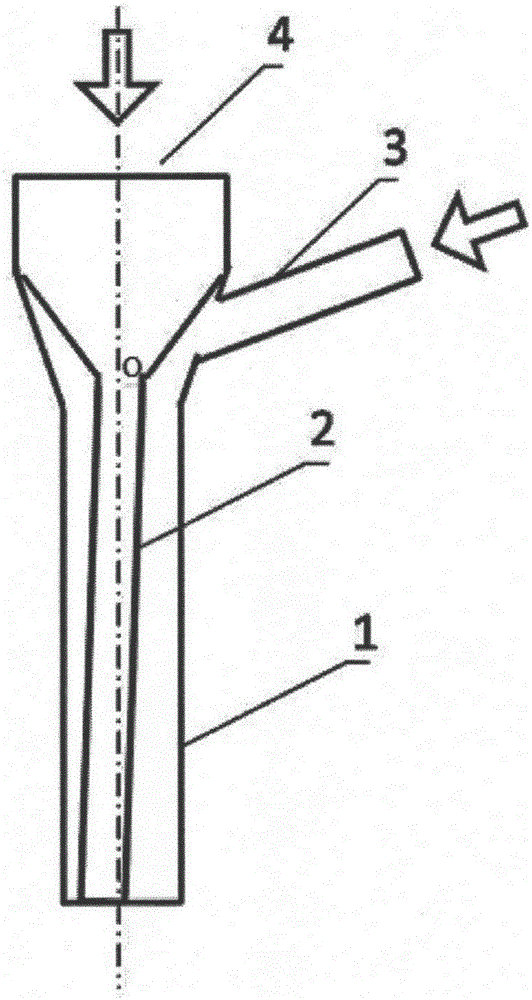

[0029] (2) Add the shell layer electrospinning solution and the core layer electrospinning solution in (1) respectively into the container, and inject it into such as image 3 and Figure 4In the outer needle 1 and inner needle 2 of the eccentric shaft electrospinning needle shown, the extrusion rate is contro...

Embodiment 2

[0035] A method for preparing a C-type core-shell nanofiber membrane by eccentric axis electrospinning, the specific steps are:

[0036] (1) Dissolve 15 g of polyvinylidene fluoride (PVDF) (Solvay Co., Ltd., weight average molecular weight: 573000 g / mol) in 85 g of N, N-dimethylformamide (DMF) as a shell solution, and polypropylene Nitrile (PAN) (Shanghai Jinshan Co., Ltd., weight-average molecular weight: 136000g / mol) 8g is dissolved in 92gN, in N-dimethylformamide (DMF) solvent, as core layer solution, shell layer solution and core layer solution are respectively in Stir in an oil bath at 60° C. for 24 hours at a constant temperature to obtain a uniform and transparent electrospinning solution.

[0037] (2) Add the shell layer electrospinning solution and the core layer electrospinning solution in (1) respectively into the container, and inject it into such as image 3 and Figure 4 In the outer needle 1 and inner needle 2 of the eccentric shaft electrospinning needle show...

Embodiment 3

[0043] A method for preparing a C-type core-shell nanofiber membrane by eccentric axis electrospinning, the specific steps are:

[0044] (1) Dissolve 18 g of polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP) (Sigma-Aldrich Trading Co., Ltd., weight average molecular weight: 455000 g / mol) in 82 g of N, N-dimethylformamide (DMF ) as the shell solution, 10 g of polyethersulfone (PES) (Solvay Co., Ltd., weight average molecular weight: 62000 g / mol) was dissolved in 90 g of N, N-dimethylformamide (DMF) solvent as the core layer solution , the shell layer solution and the core layer solution were stirred in an oil bath at 60° C. for 24 hours at a constant temperature to obtain a uniform and transparent electrospinning solution.

[0045] (2) Add the shell layer electrospinning solution and the core layer electrospinning solution in (1) respectively into the container, and inject it into such as image 3 and Figure 4 In the outer needle 1 and inner needle 2 of the ec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com