Full-ceramic diaphragm for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and ceramic diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of easy shrinkage, decomposition, and thermal stability of diaphragms at high temperatures, and achieve the elimination of safety issues and good electrolyte Wettability, effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

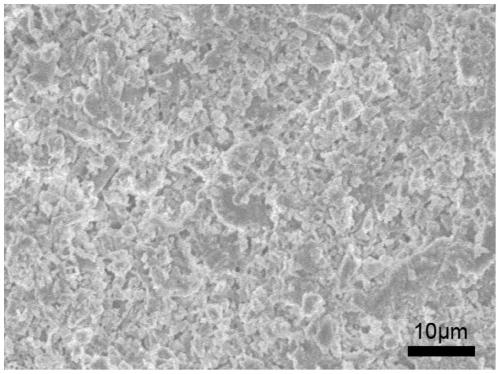

[0013] Diatomaceous earth, lithium carbonate, titanium dioxide, polyvinylidene fluoride (PVDF), and N-methylpyrrolidone (NMP) are mixed uniformly at a certain mass ratio of 40:55:0.2:0.8:4, molded, and dried at 75°C; The dried molded sample was placed in a muffle furnace and calcined to 810° C., the heating rate was 6° C. / min, and the temperature was maintained for 10 hours; the calcined sample was surface polished to obtain the all-ceramic separator for lithium-ion batteries.

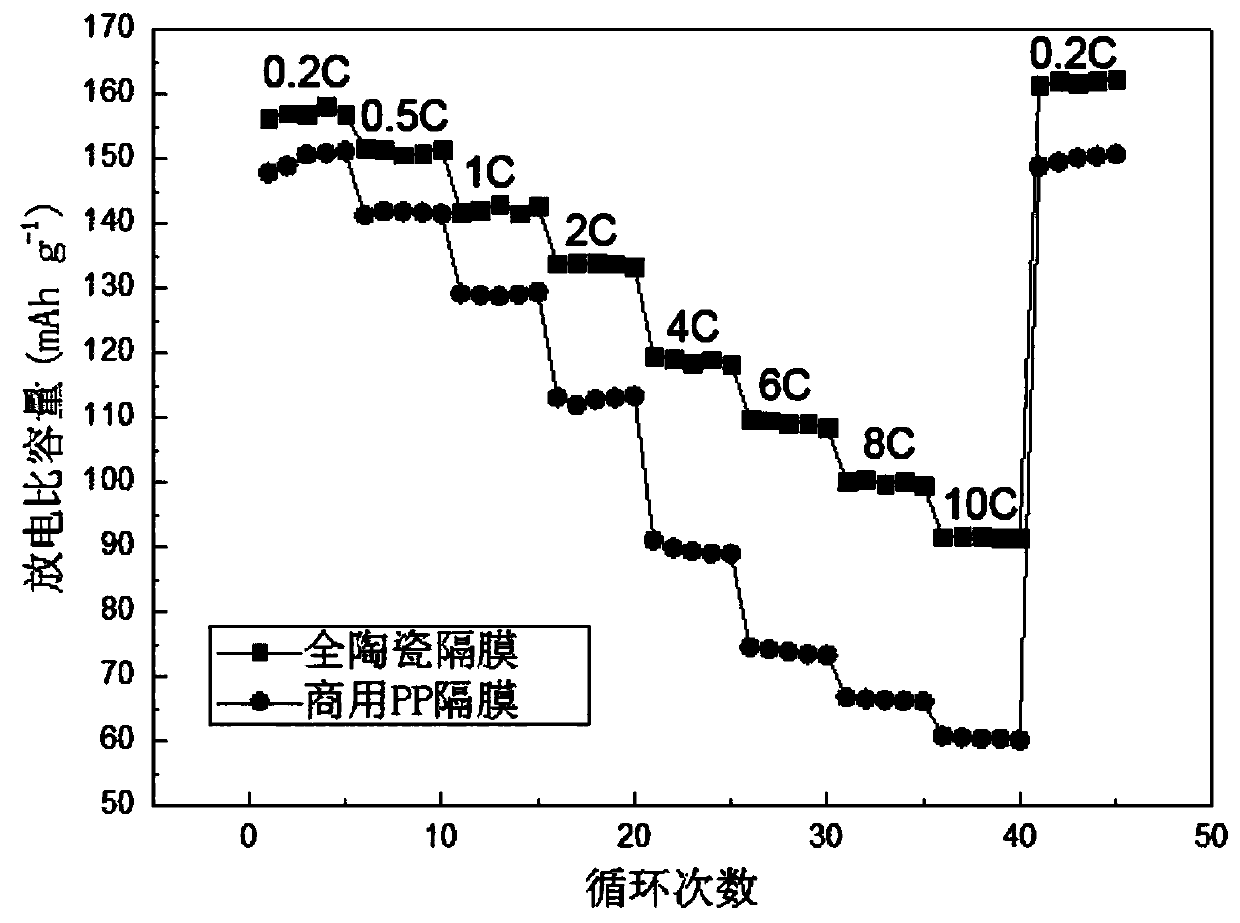

[0014] The all-ceramic diaphragm for lithium-ion batteries has a porosity of 56.3%, a liquid absorption rate of 193%, and a discharge specific capacity of 91.8mAh g at a rate of 10C. -1 (lithium iron phosphate battery system).

Embodiment 2

[0016] Diatomaceous earth, lithium carbonate, titanium dioxide, polyvinylidene fluoride (PVDF), and N-methylpyrrolidone (NMP) are mixed uniformly at a certain mass ratio of 50:45:0.4:0.6:4, molded, and dried at 75°C; The dried molded sample was placed in a muffle furnace and calcined to 830° C., the heating rate was 5° C. / min, and the temperature was maintained for 9 hours; the calcined sample was surface polished to obtain the all-ceramic separator for lithium-ion batteries.

[0017] The all-ceramic separator for lithium-ion batteries has a porosity of 57.9%, a liquid absorption rate of 202%, and a discharge specific capacity of 92.1mAh g at a rate of 10C. -1 (lithium iron phosphate battery system).

Embodiment 3

[0019] Diatomaceous earth, lithium carbonate, titanium dioxide, polyvinylidene fluoride (PVDF), N,N-dimethylformamide (DMF) are mixed uniformly at a certain mass ratio of 55:40:0.5:0.5:4, molded, 75°C Drying; the dried molded sample was placed in a muffle furnace and calcined to 840°C, the heating rate was 4°C / min, and kept for 8 hours; the calcined sample was surface polished to obtain the all-ceramic separator for lithium ion batteries.

[0020] The all-ceramic separator for lithium-ion batteries has a porosity of 52.4%, a liquid absorption rate of 183%, and a discharge specific capacity of 89.8mAh g at a rate of 10C. -1 (lithium iron phosphate battery system).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com