Cellulose polymer electrolyte membrane, and preparation method and application thereof

A technology of cellulose polymers and electrolyte membranes, which is applied in hybrid capacitor electrolytes, hybrid/electric double layer capacitor manufacturing, etc. It can solve the problems of reducing the electrochemical performance of all-solid-state SCs, insufficient flexibility of supercapacitors, and non-renewable electrolytes. , to achieve excellent electrochemical performance, outstanding cycle stability, and superior flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a cellulose polymer electrolyte membrane, comprising the following steps:

[0041] mixing the solvent and the cellulose to obtain a raw material liquid phase mixture;

[0042] Degassing the raw material liquid phase mixture to obtain a degassed system;

[0043] After the degassing system is coated on the surface of the carrier, the humidity control treatment is performed and then replaced in the replacement solution to obtain a hydrogel system;

[0044] The hydrogel system is placed between two polytetrafluoroethylene microporous membrane microplates, and dried to obtain a cellulose membrane;

[0045] The cellulose membrane is adsorbed in the electrolyte to obtain a cellulose polymer electrolyte membrane.

[0046] The invention mixes the solvent and the cellulose to obtain the raw material liquid phase mixture. In the present invention, the solvent is preferably an ionic liquid, a mixed solution of NaOH and urea, or a mix...

Embodiment 1

[0072] Add 50 g (0.286 mol) of [Bmim]Cl ionic liquid into a 250 mL three-necked flask equipped with a condenser, and mechanically stir for 10 min in an oil bath at 85° C. Add 2.08g of bamboo cellulose into the three-necked flask above, and stir mechanically at 85°C until the cellulose is completely dissolved, and the system turns into a transparent viscous liquid for 30 minutes. Pour it into a 100mL beaker and place it in a vacuum drying phase with a temperature of 85°C and a vacuum of 0.01MPa for degassing treatment for 6h to obtain a final uniform and transparent [Bmim]Cl / cellulose system.

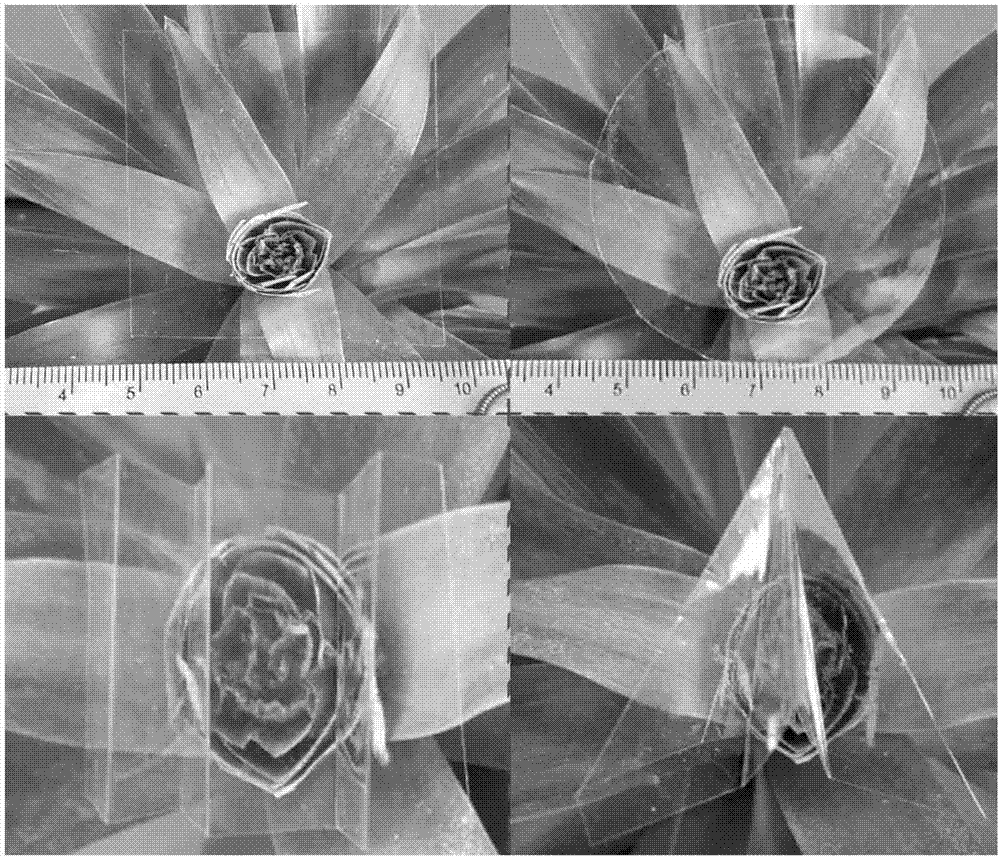

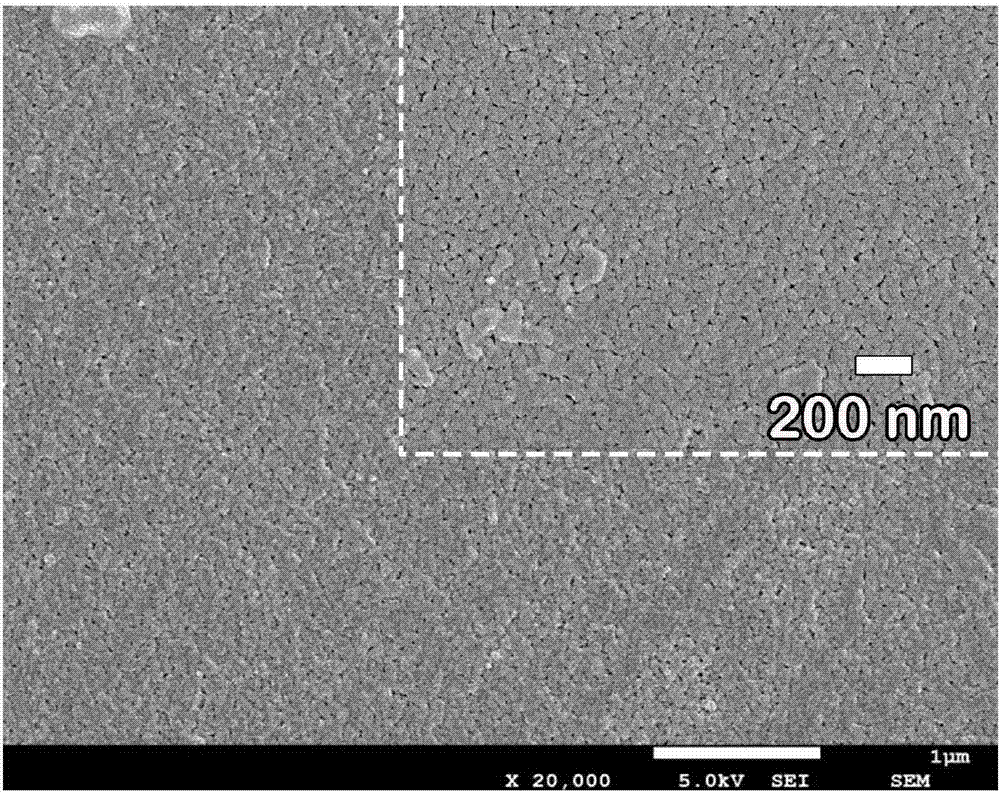

[0073] [Bmim]Cl / cellulose is evenly placed on a polished silicon wafer carrier by spin coating, and the coating thickness is 2mm, and then the cellulose is conditioned in the air with a humidity of 55% for 6h, so that The cellulose has a moisture content of 25%. Then it was placed in distilled water at 30°C, and after the water molecules completely replaced the [Bmim]Cl ionic liquid (60...

Embodiment 2

[0091] A mixed solution of 50 g of NaOH and urea (the mass concentration of NaOH is 8%, and the mass concentration of urea is 13%) was added into a 250 mL three-neck flask, and mechanically stirred for 20 min in an ice bath (-12°C). Add 2.08g of cotton cellulose into the above three-necked flask, and stir mechanically at -12°C until the cellulose is completely dissolved, and the system turns into a transparent viscous liquid for 5 minutes. A uniform and transparent NaOH / urea / cellulose system can be obtained.

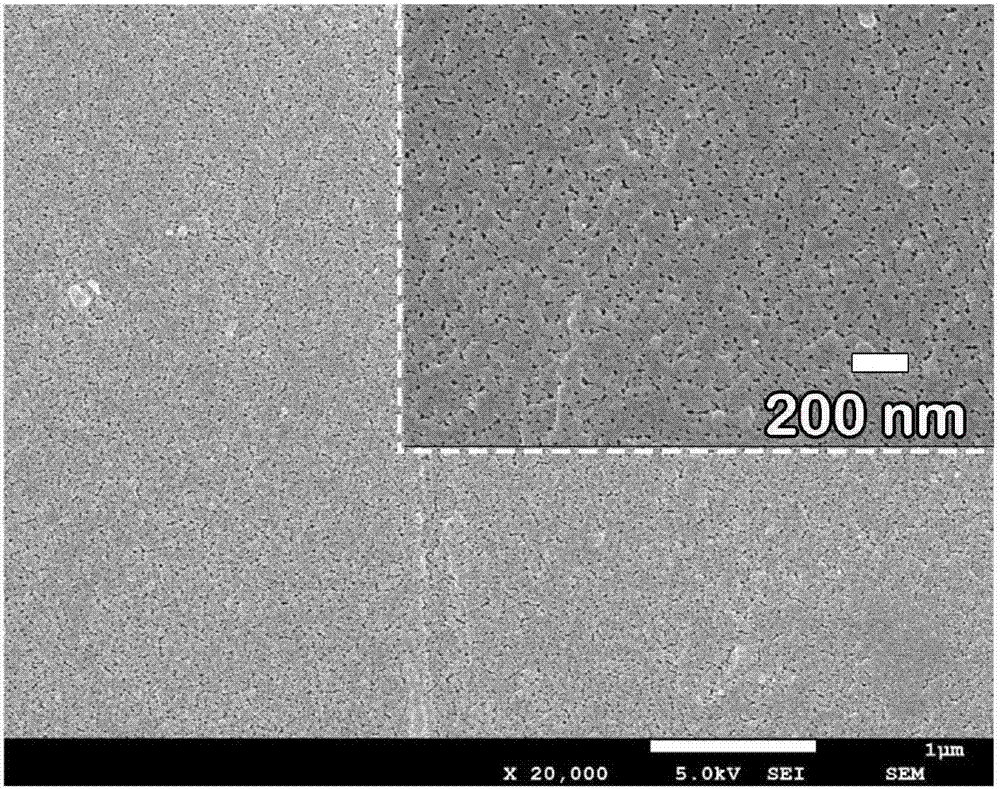

[0092] NaOH / urea / cellulose is evenly placed on the polished silicon wafer carrier by spin coating, and the coating thickness is 2mm, and then the cellulose is left to stand in the air with a humidity of 60% for 5h to adjust the humidity, so that the The humidity of the cellulose reaches 25%. Then put it in distilled water at 30°C, and after about 60 minutes, a uniform transparent hydrogel is formed. The hydrogel was sandwiched between two 0.1 μm PTFE microporous membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com