Patents

Literature

274 results about "CELLULOSE POLYMERS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose has an important place in the story of polymers because it was used to make some of the first synthetic polymers, like cellulose nitrate, cellulose acetate, and rayon. Click here to find out more.

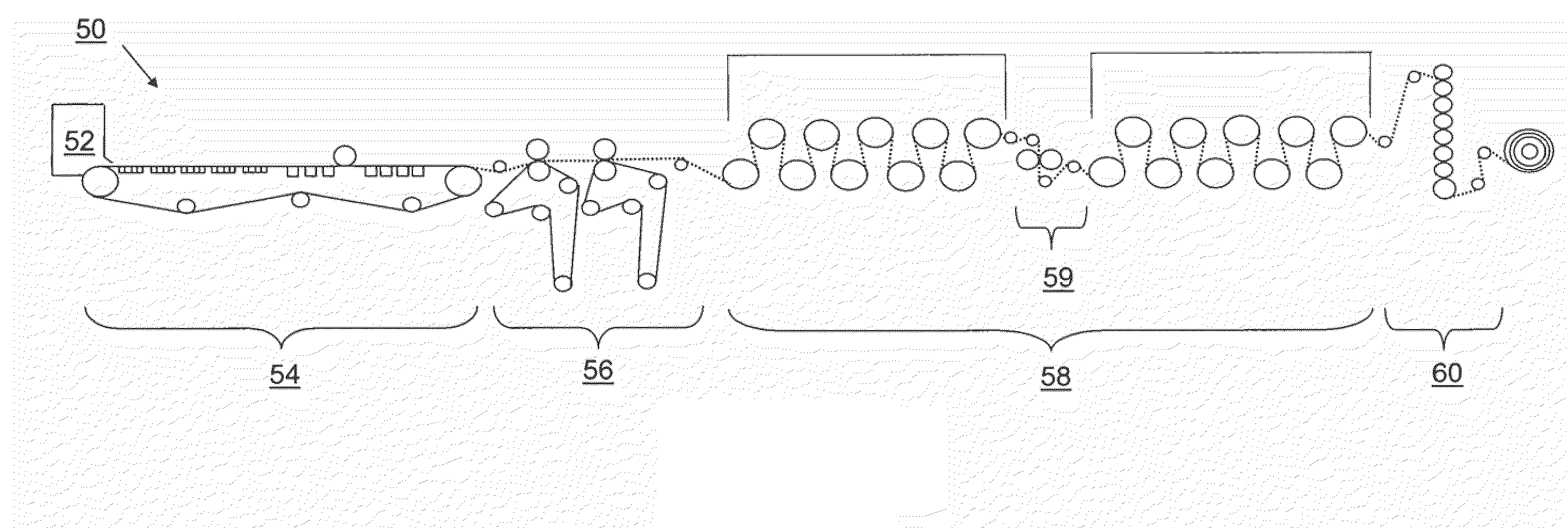

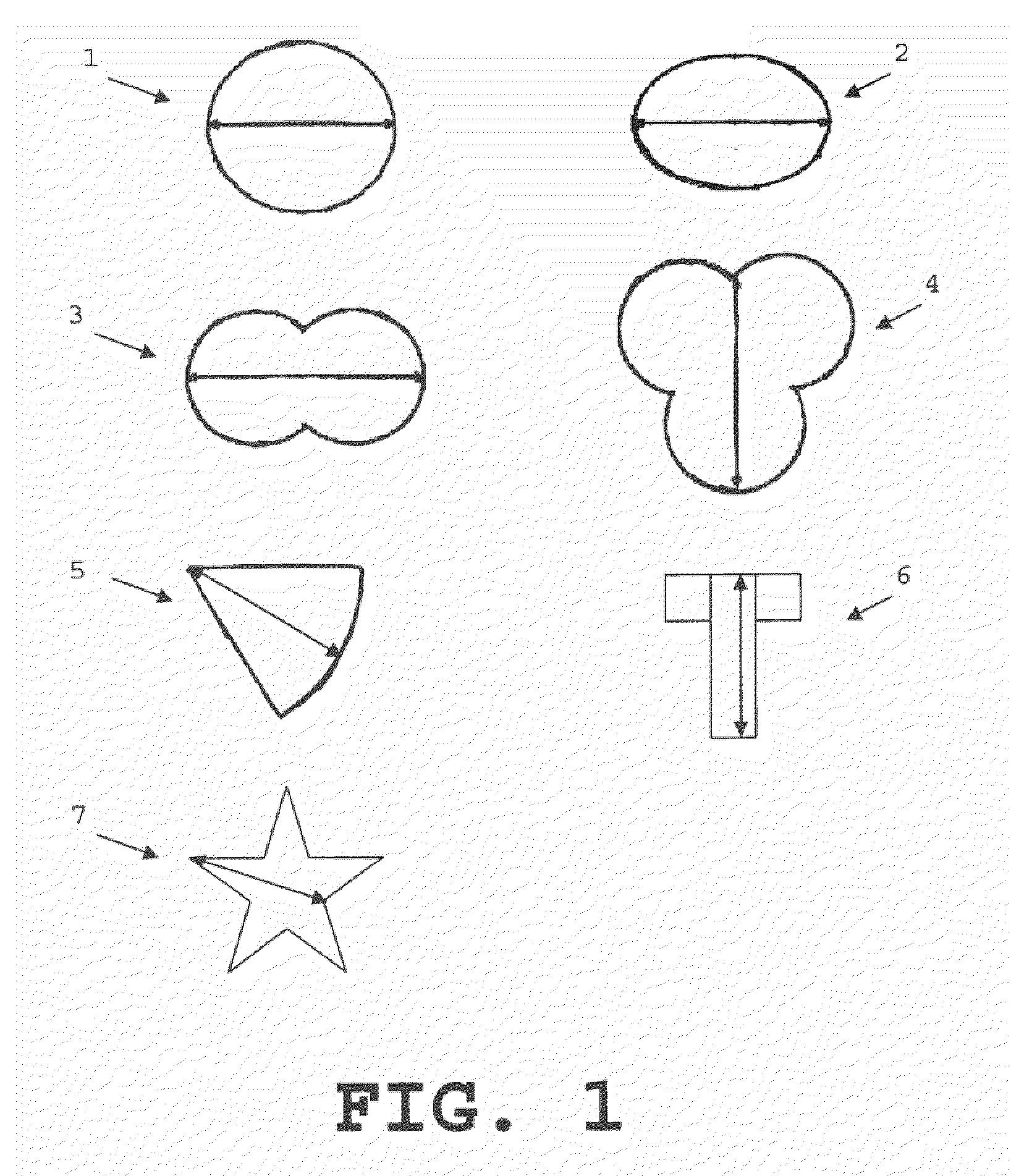

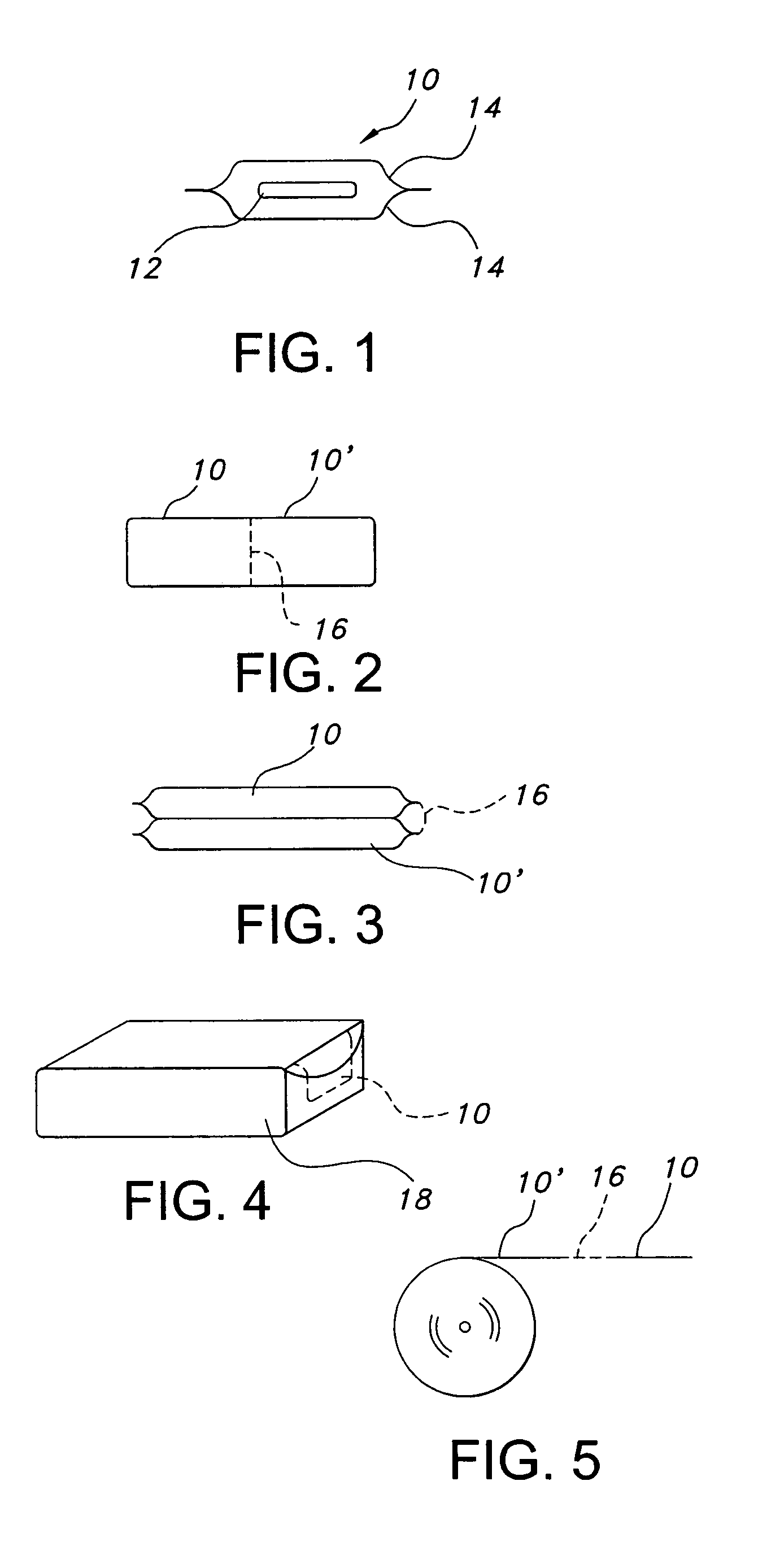

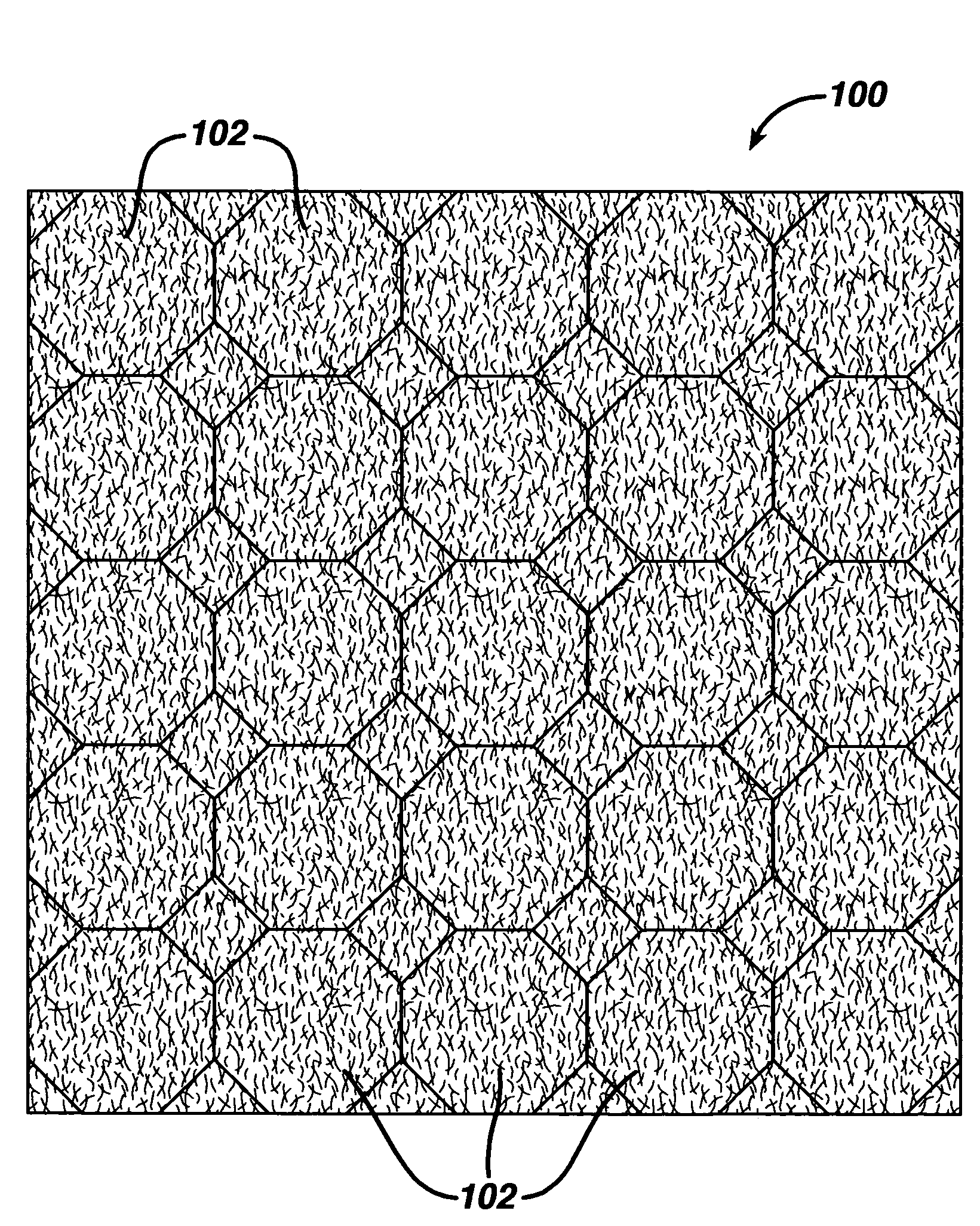

Hydraulically-Formed Nonwoven Sheet with Microfibers

InactiveUS20100272938A1Non-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricMedical device

In a first embodiment, a hydraulically-formed nonwoven sheet, a package comprising such sheet, a method of packaging a medical device using a package with such sheet and a method of manufacturing such sheet are provided. This nonwoven sheet comprises first and second non-cellulosic polymeric fibers. The first non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000; the second non-cellulosic polymeric fibers have an average diameter greater than about 3.5 micron and an average aspect ratio of about 400 to about 1000. In a second embodiment, a hydraulically-formed nonwoven sheet is provided. This nonwoven sheet comprises binding material, non-cellulosic polymeric fibers and cellulosic based materials. The non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000. The second nonwoven sheet has a bacterial filtration efficiency of at least about 98%.

Owner:BEMIS COMPANY INC

Polyethylene oxide-based films and drug delivery systems made therefrom

The invention relates to the film products and methods of their preparation that demonstrate a non-self-aggregating uniform heterogeneity. Desirably, the films disintegrate in water and may be formed by a controlled drying process, or other process that maintains the required uniformity of the film. The films contain a polymer component, which includes polyethylene oxide optionally blended with hydrophilic cellulosic polymers. Desirably, the films also contain a pharmaceutical and / or cosmetic active agent with no more than a 10% variance of the active agent pharmaceutical and / or cosmetic active agent per unit area of the film.

Owner:AQUESTIVE THERAPEUTICS INC

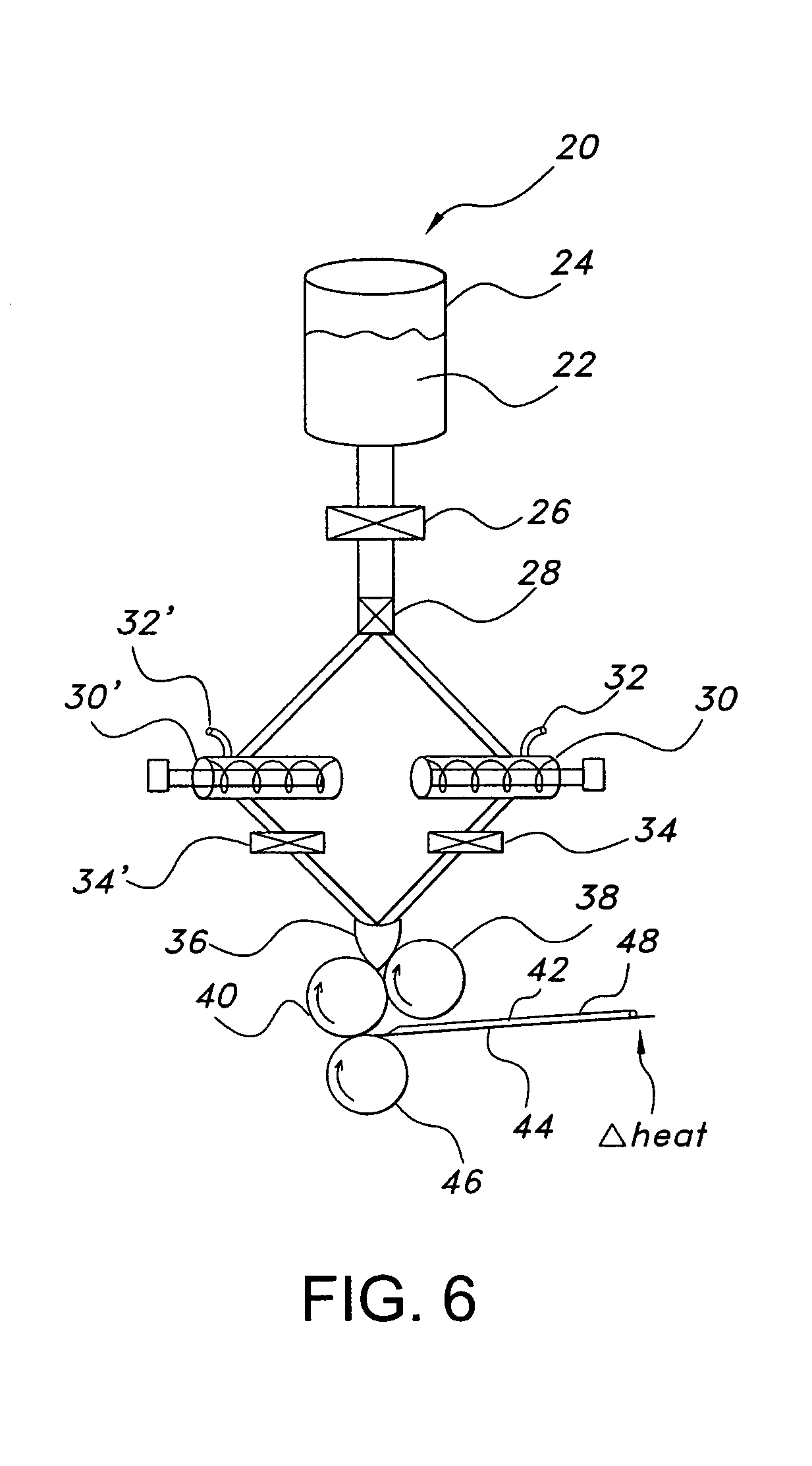

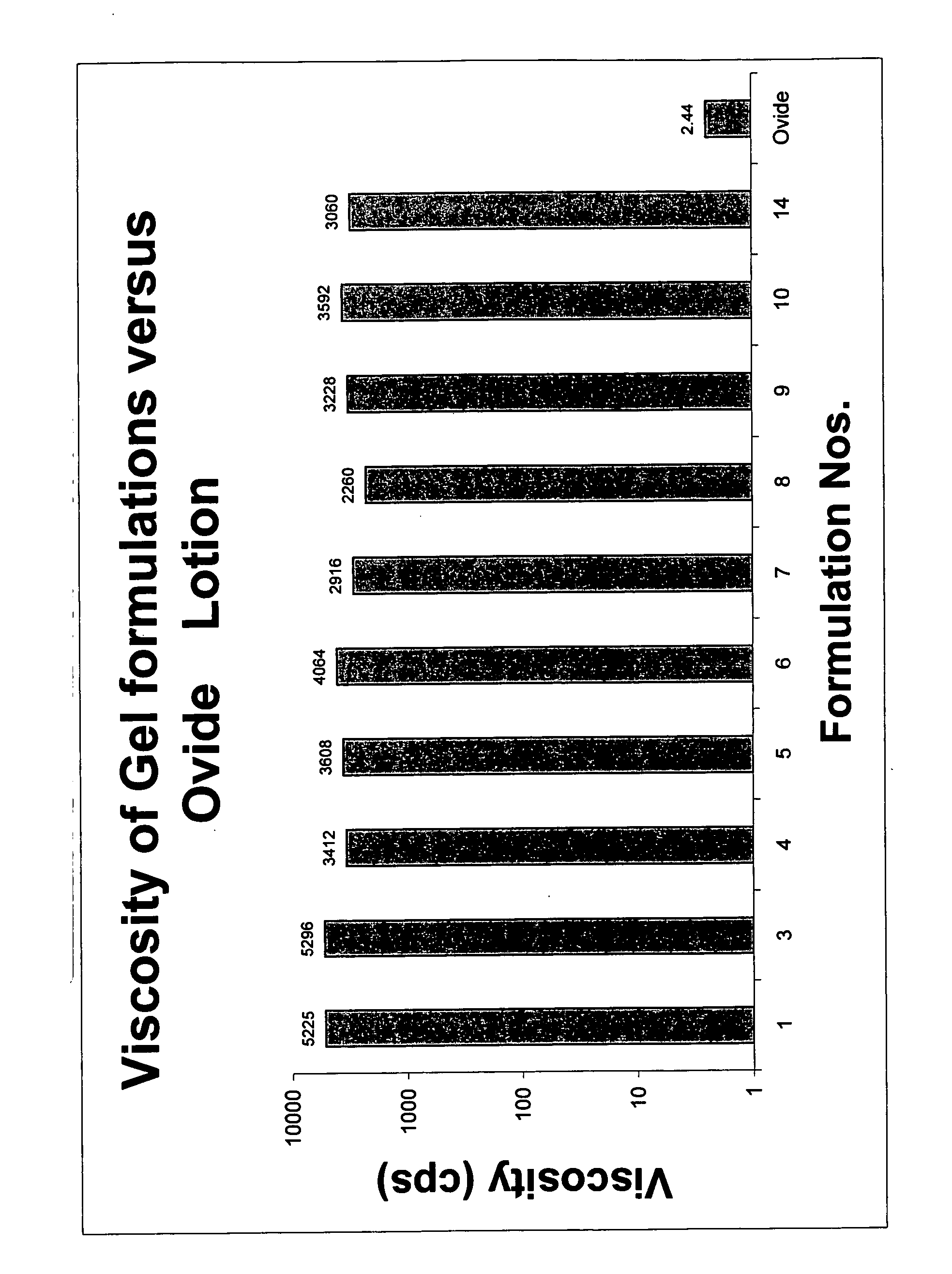

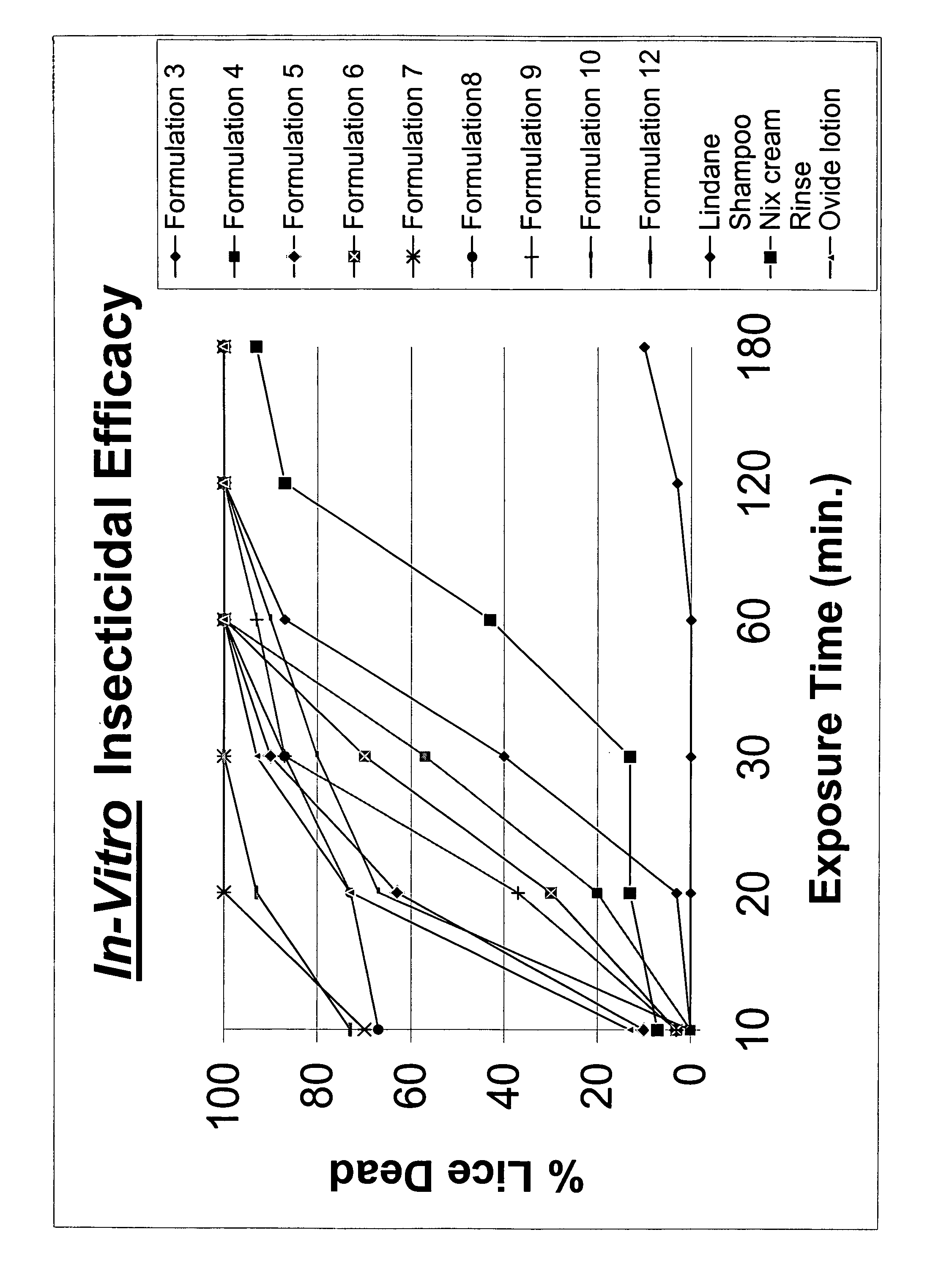

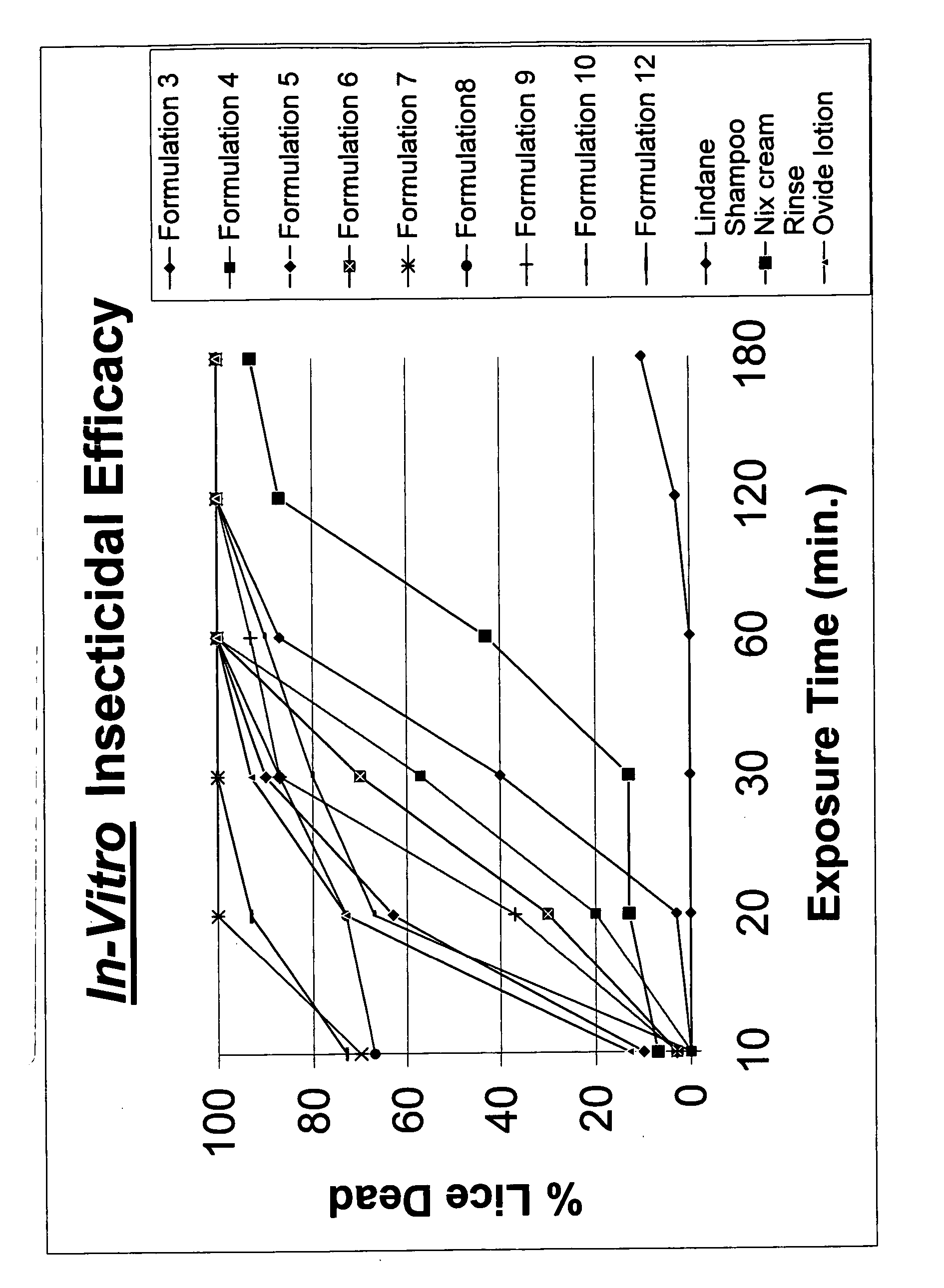

Topical gel formulation comprising insecticide and its preparation thereof

The present invention provides a topical gel pharmaceutical formulation of insecticide suitable for treating an ectoparasite in a mammal, comprising: a) about 0.1-10% by weight of an insecticide; b) at least about 75% by weight of an organic solvent selected from the group consisting of a lower alkyl alcohol, a ketone, a glycol and a mixture thereof, wherein the organic solvent contains at least about 40% by weight of the lower alkyl alcohol; and c) at least one polymer selected from the group consisting of a cellulosic polymer, acrylates, methacrylates, and polyvinyl pyrrolidone. The present invention further provides a process of preparing as well as a method of treating ectoparasites in a mammal using the same.

Owner:GOYAL SANDHYA +4

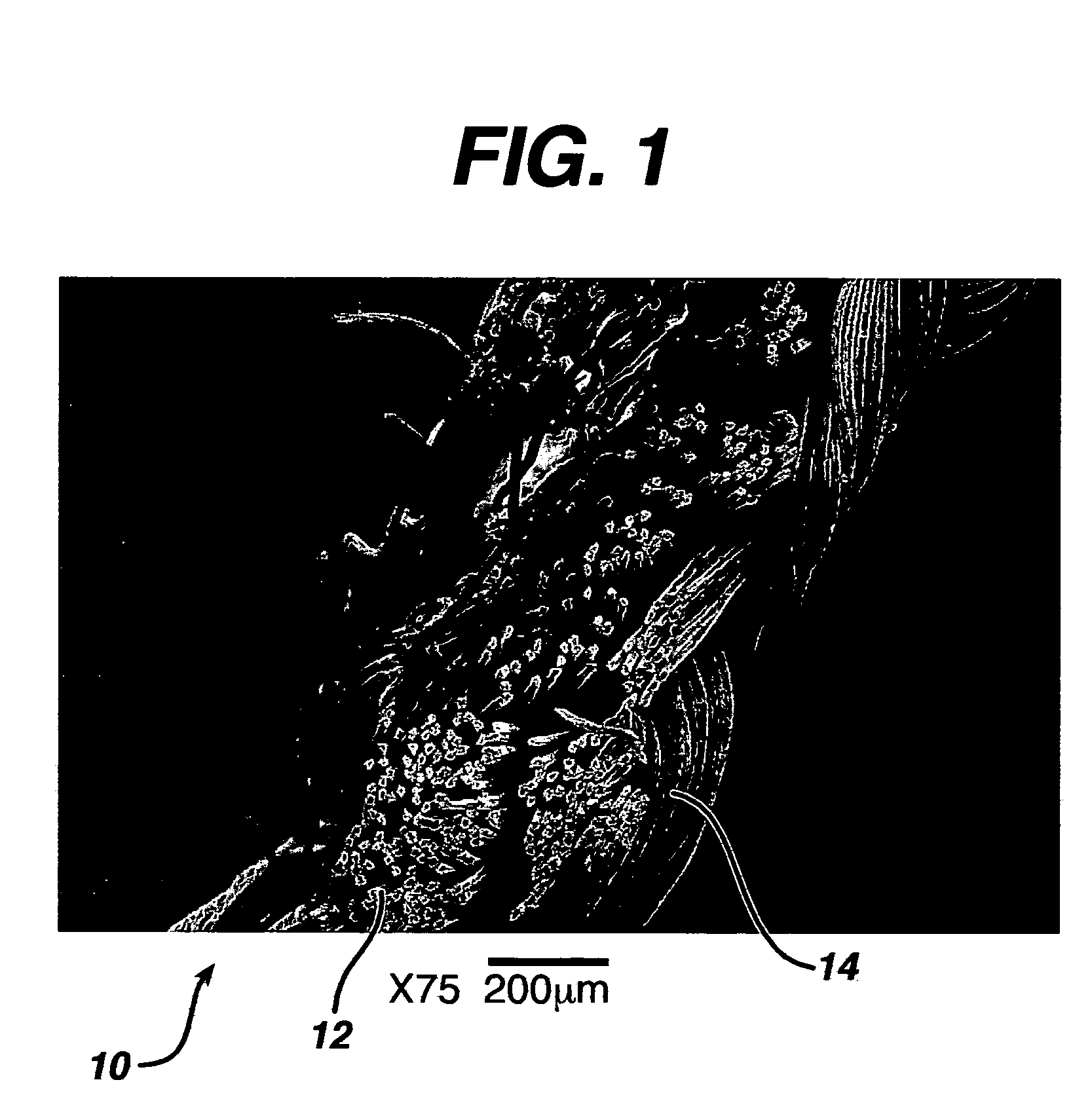

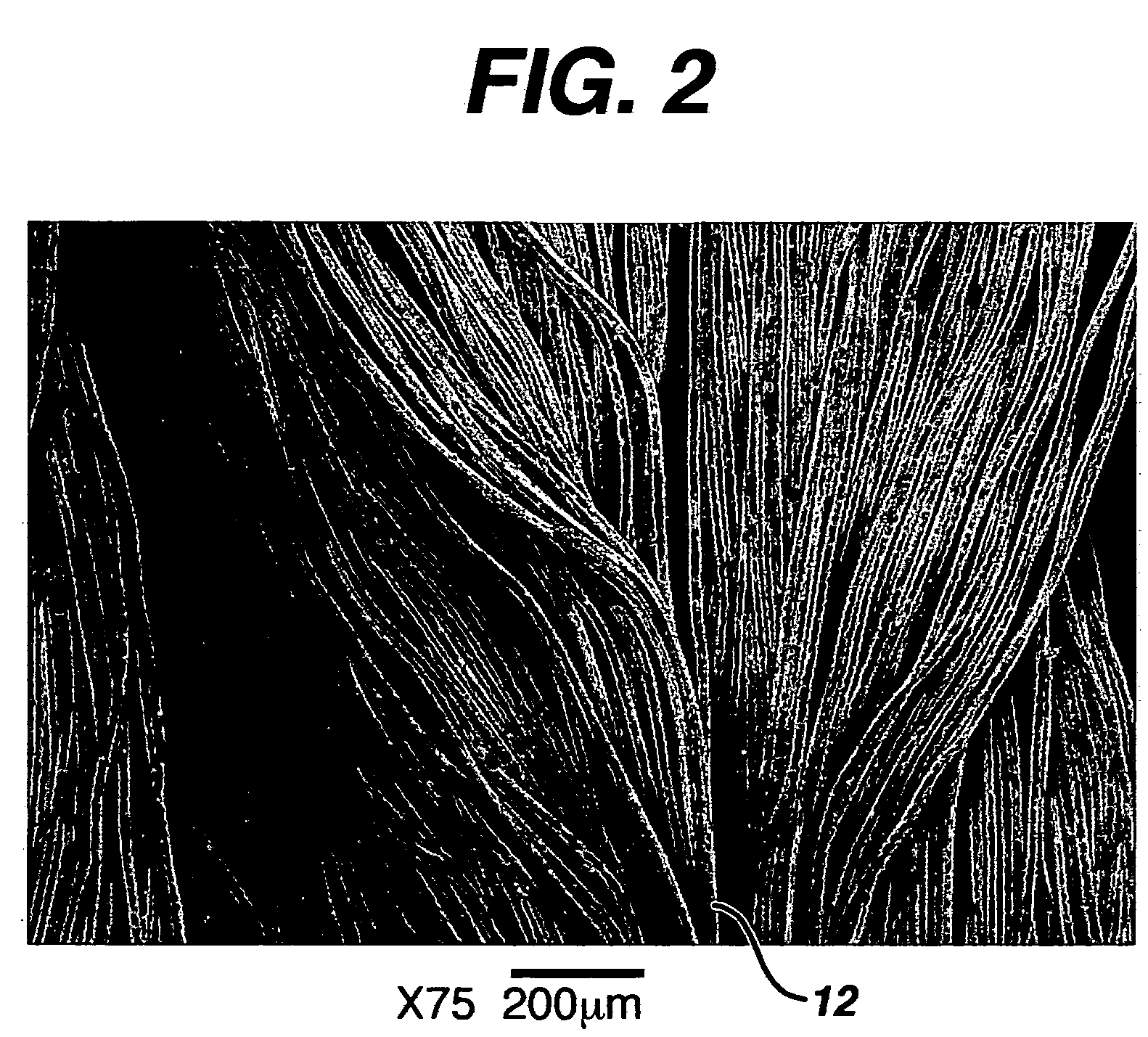

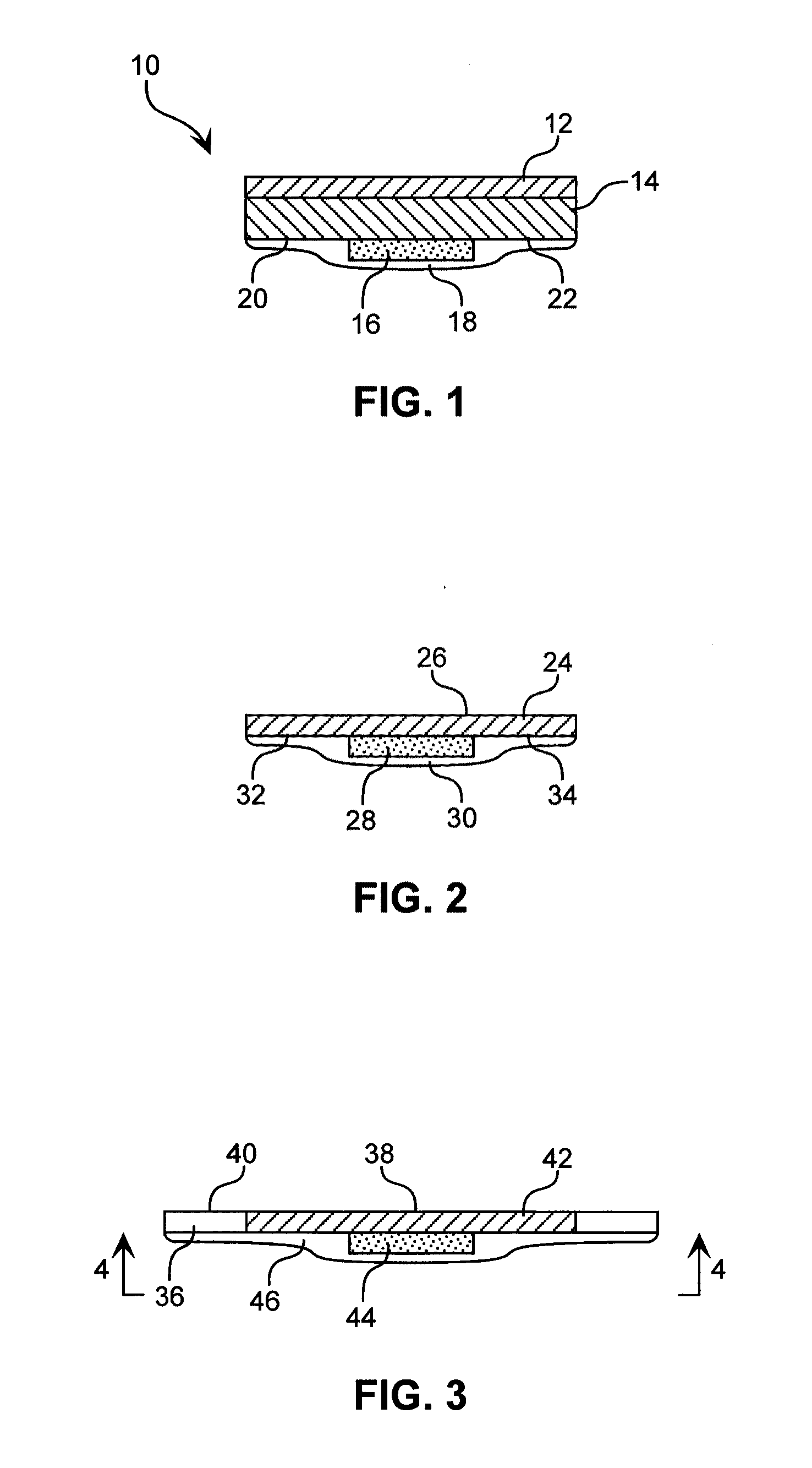

Hemostatic wound dressings and methods of making same

The present invention is directed to a hemostatic wound dressing that utilizes a fibrous, fabric substrate made from carboxylic-oxidized cellulose and containing a first surface and a second surface opposing the first surface, the fabric having flexibility, strength and porosity effective for use as a hemostat; and further having a porous, polymeric matrix substantially homogeneously distributed on the first and second surfaces and through the fabric, the porous, polymeric matrix being made of a biocompatible, water-soluble or water-swellable cellulose polymer, wherein prior to distribution of the polymeric matrix on and through the fabric, the fabric contains about 3 percent by weight or more of water-soluble oligosaccharides.

Owner:ETHICON INC

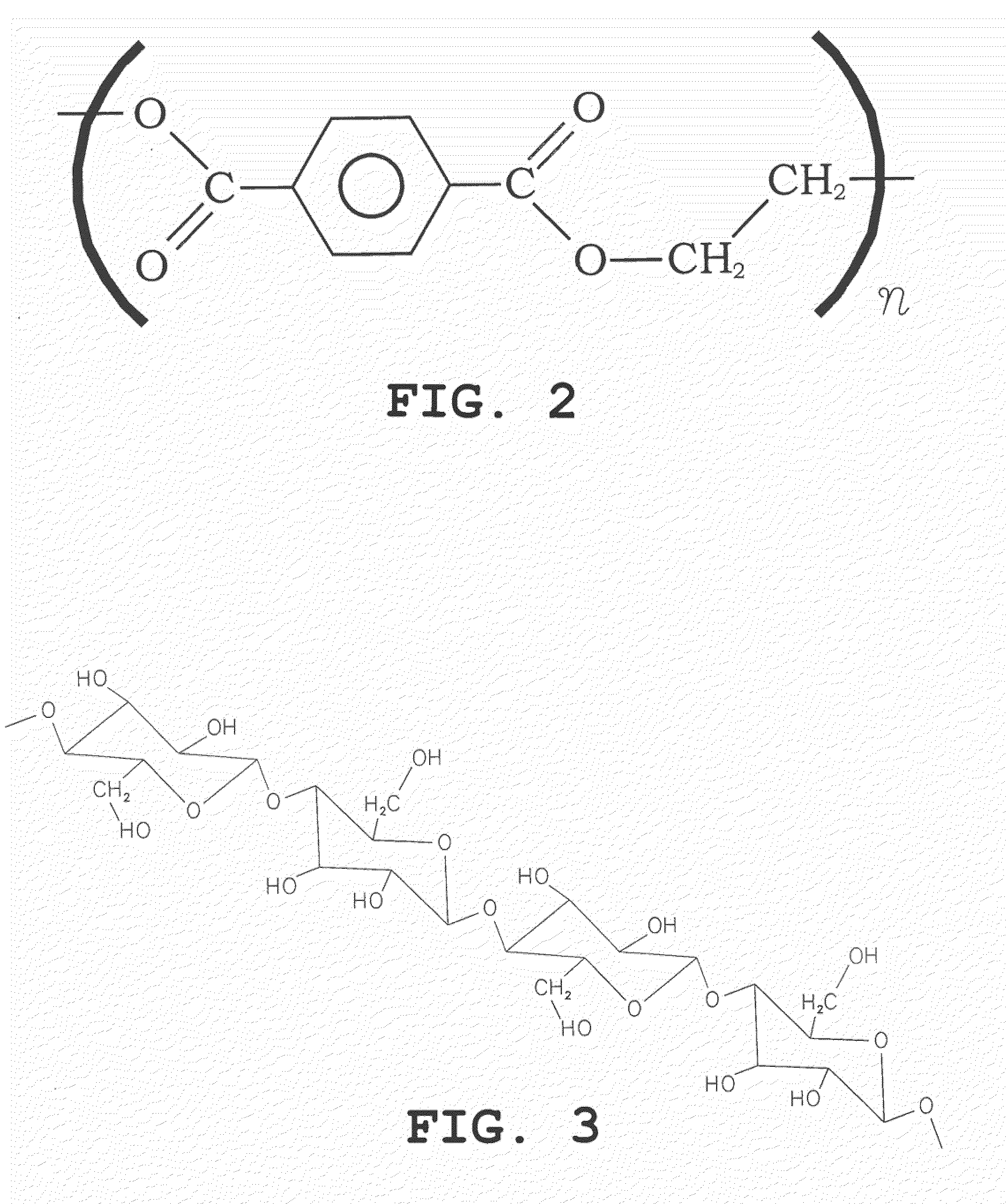

Cellulosic/polymer composite material

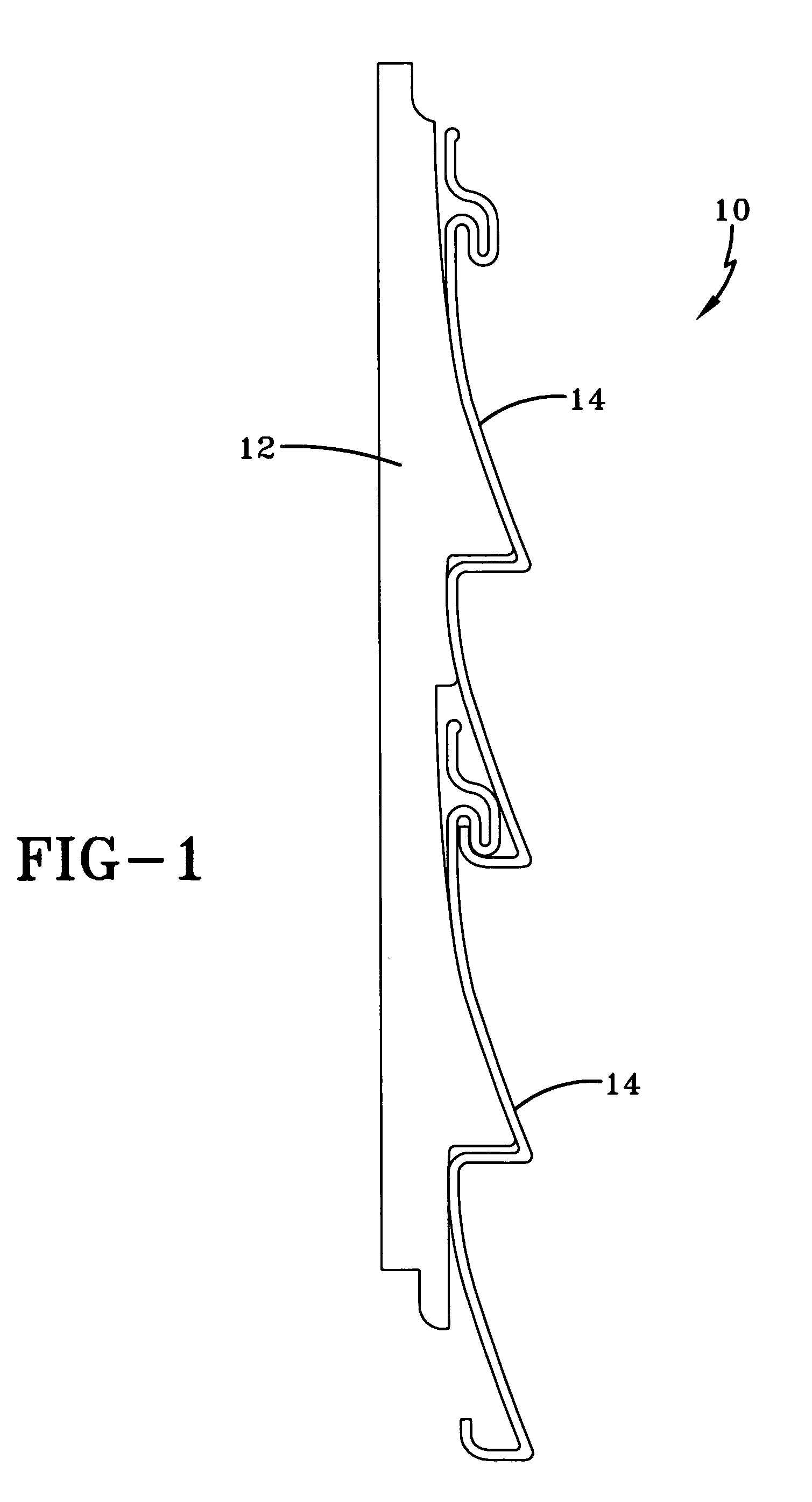

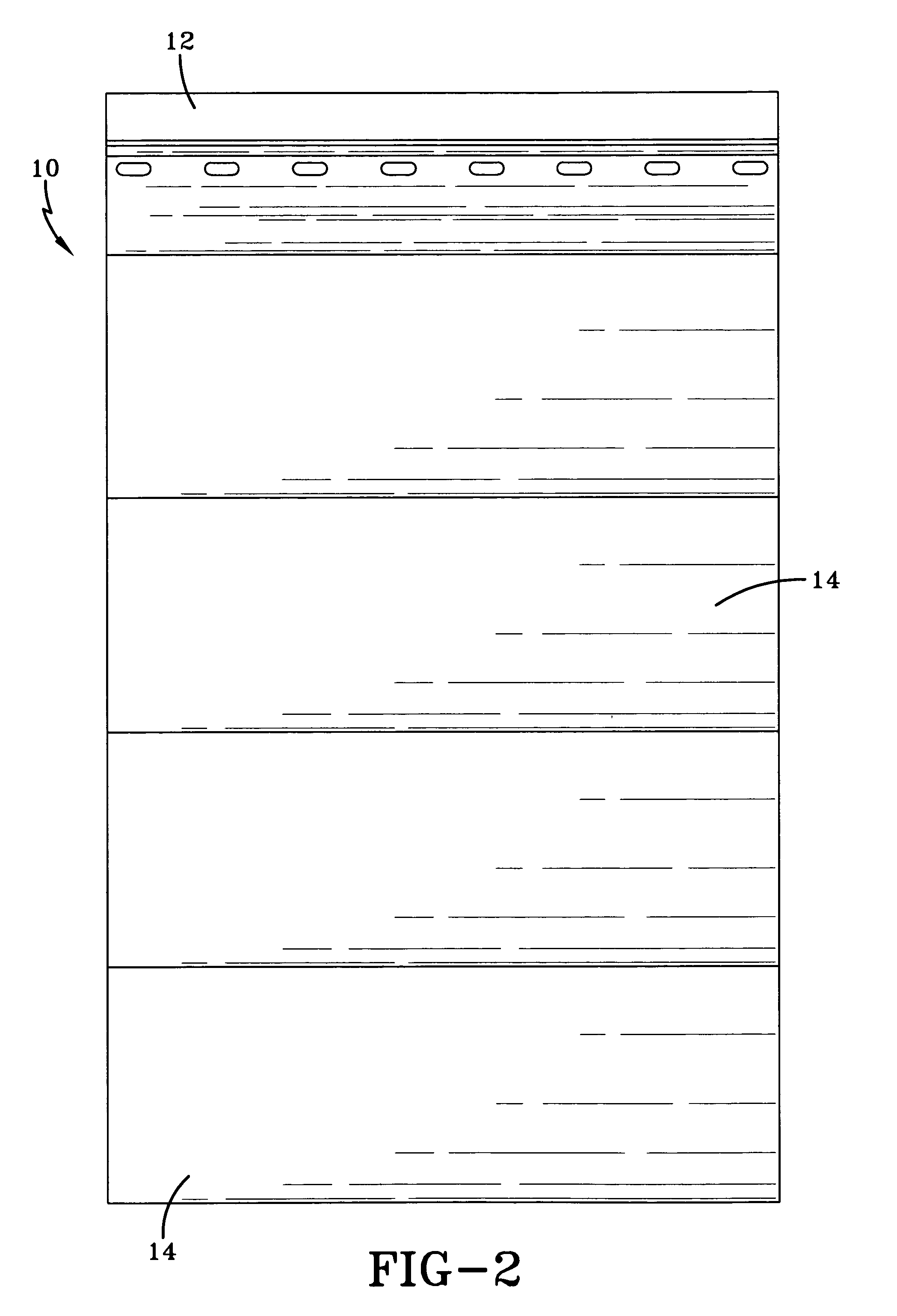

InactiveUS6971211B1Superior resistance to wearGood tearConstruction materialRoof covering using tiles/slatesPolypropylene compositesCellulose

The present invention is a component such as a siding panel that may be comprised of various formulations of cellulosic / polymer composite materials. One embodiment of the present invention is a siding panel that is comprised of a cellulosic / PVC composite material. This composite material may include at least one cellulosic filler in the amount of about 30% to about 60% by weight and a PVC material in the amount of about 40% to about 70% by weight. The PVC material may include about 1 to about 10 parts stabilizer(s) per 100 parts of the PVC resin, about 2 to about 12 parts lubricant(s) per 100 parts of the PVC resin, and about 0.5 to about 8 parts process aid(s) per 100 parts of the PVC resin. Another embodiment of the present invention is a siding panel that may be comprised of a cellulosic / polypropylene composite material. This composite material is comprised of at least one cellulosic filler in an amount of about 30% to about 70% by weight and a polypropylene material in an amount of about 30% to about 70% by weight. The polypropylene material includes at least one lubricant in an amount of about 10 to about 20 parts per 100 parts of a polypropylene resin.

Owner:CPG INT

Physically stable aqueous suspensions of active pharmaceuticals

The present invention concerns methods of making physically stable aqueous suspensions of sparingly soluble to insoluble in water, active pharmaceuticals. More particularly, the invention provides an aqueous pharmaceutical suspension composition comprising an active pharmaceutical component which is sparingly soluble to insoluble in water; a water soluble, low viscosity grade cellulose polymer with a viscosity range of 3 mPa·s to 50 mPa·s as a surfactant; a suspending agent; and water.

Owner:TRIAD GRP

Bacterial cellulose/polymer composite film and preparation method thereof

The invention relates to a bacterial cellulose / polymer composite film and a preparation method thereof. The bacterial cellulose / polymer composite film is formed by compounding bacterial cellulose fibers on a polymer porous material in situ. The method comprises the following steps of: (1) activating strains, finally inoculating into a liquid culture medium to culture, infiltrating the surface of the porous polymer film in the liquid culture medium and exposing in air; (2) repeating the operation every 2-3 days until a composite film is formed; (3) post-treating the composite film to be neutral to obtain a bacterial cellulose / polymer composite gel film; and (4) drying the gel film obtained in the step (3) to constant weight to obtain the bacterial cellulose / polymer composite dry film. The invention solves the problem of low mechanical strength of a single bacterial cellulose film. By utilizing hydrogen bonding produced by hydroxyl groups on cellulose macromolecules, the strength, the durability and the water absorbability of the bacterial cellulose / polymer composite gel film and the composite dry film are improved.

Owner:DONGHUA UNIV

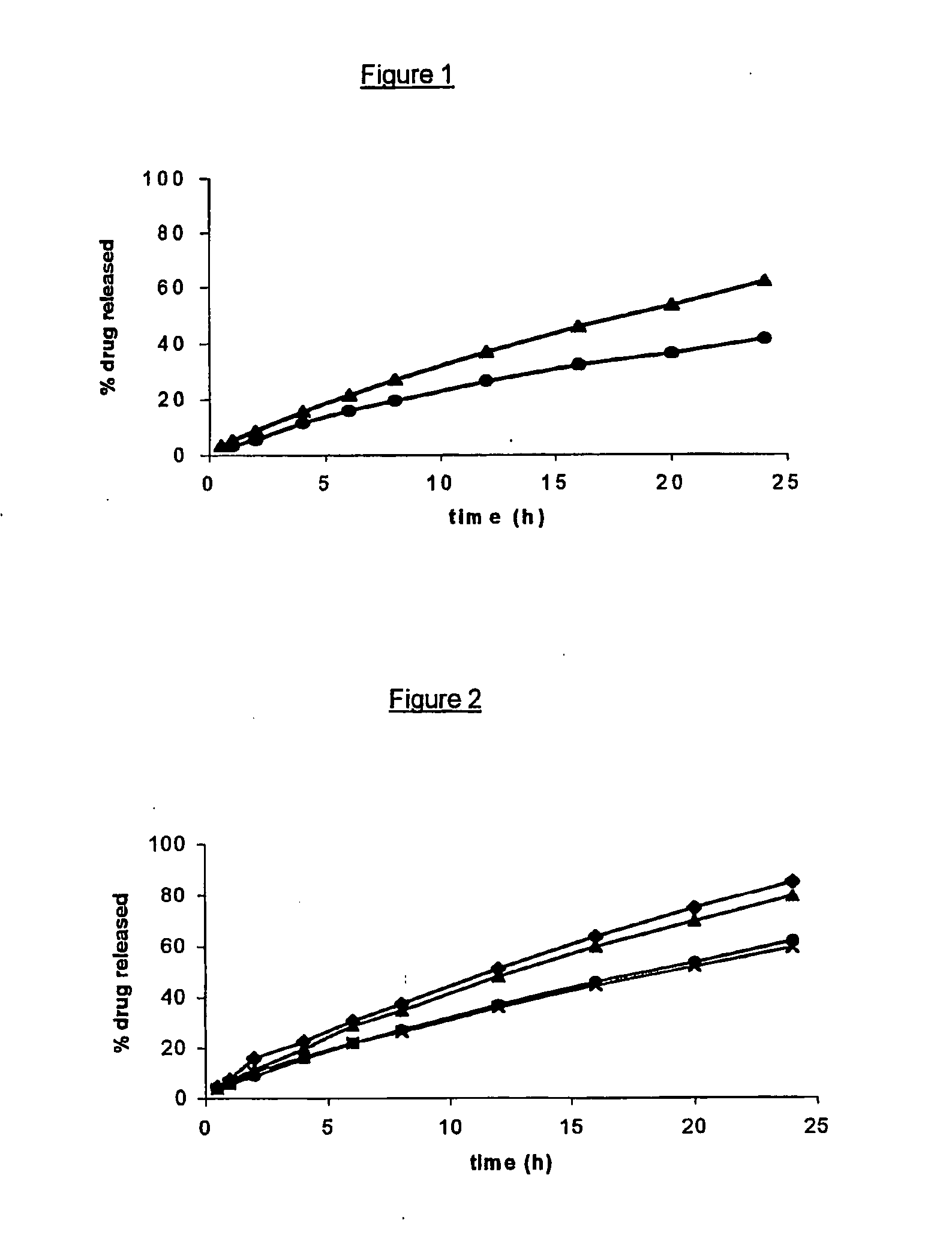

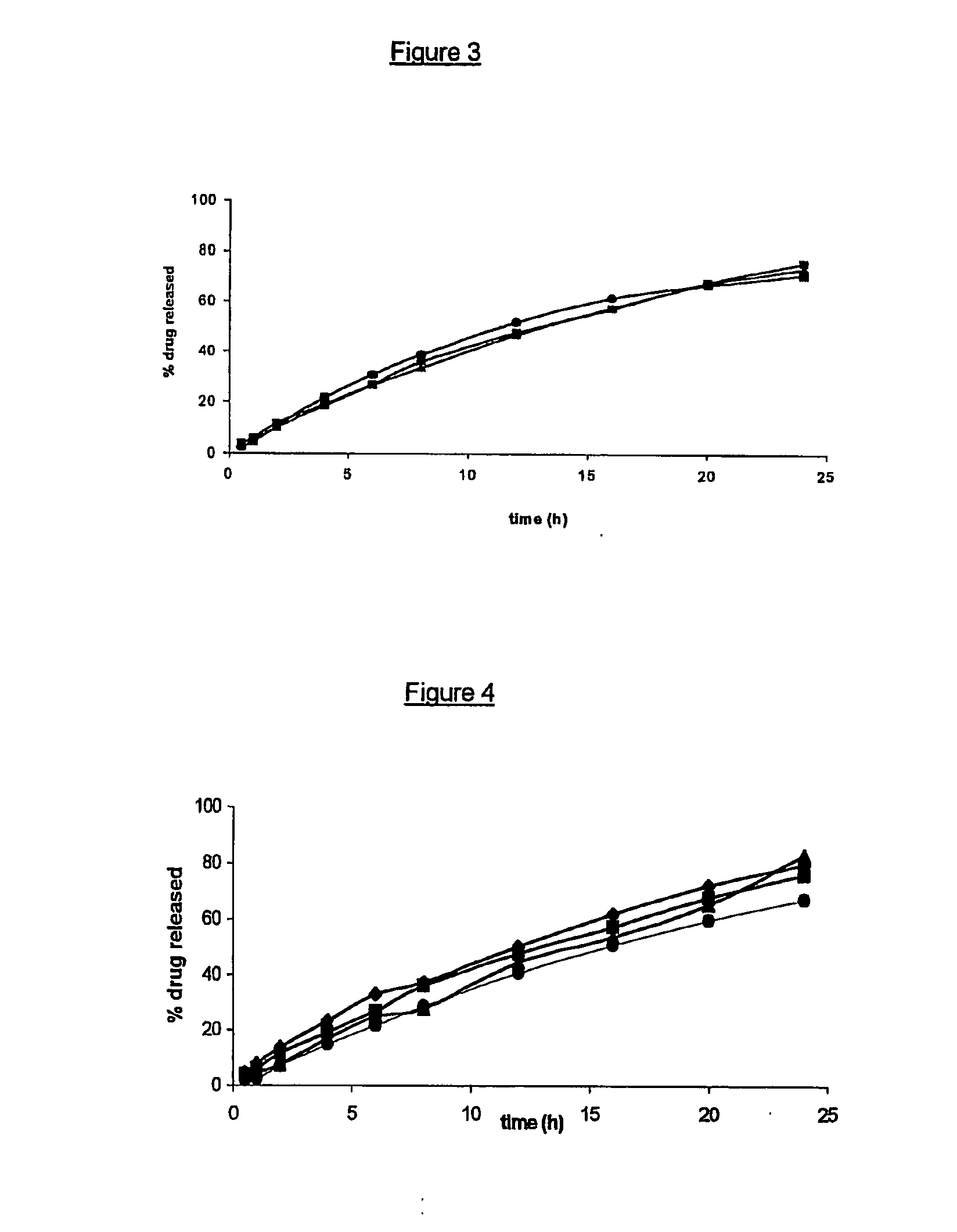

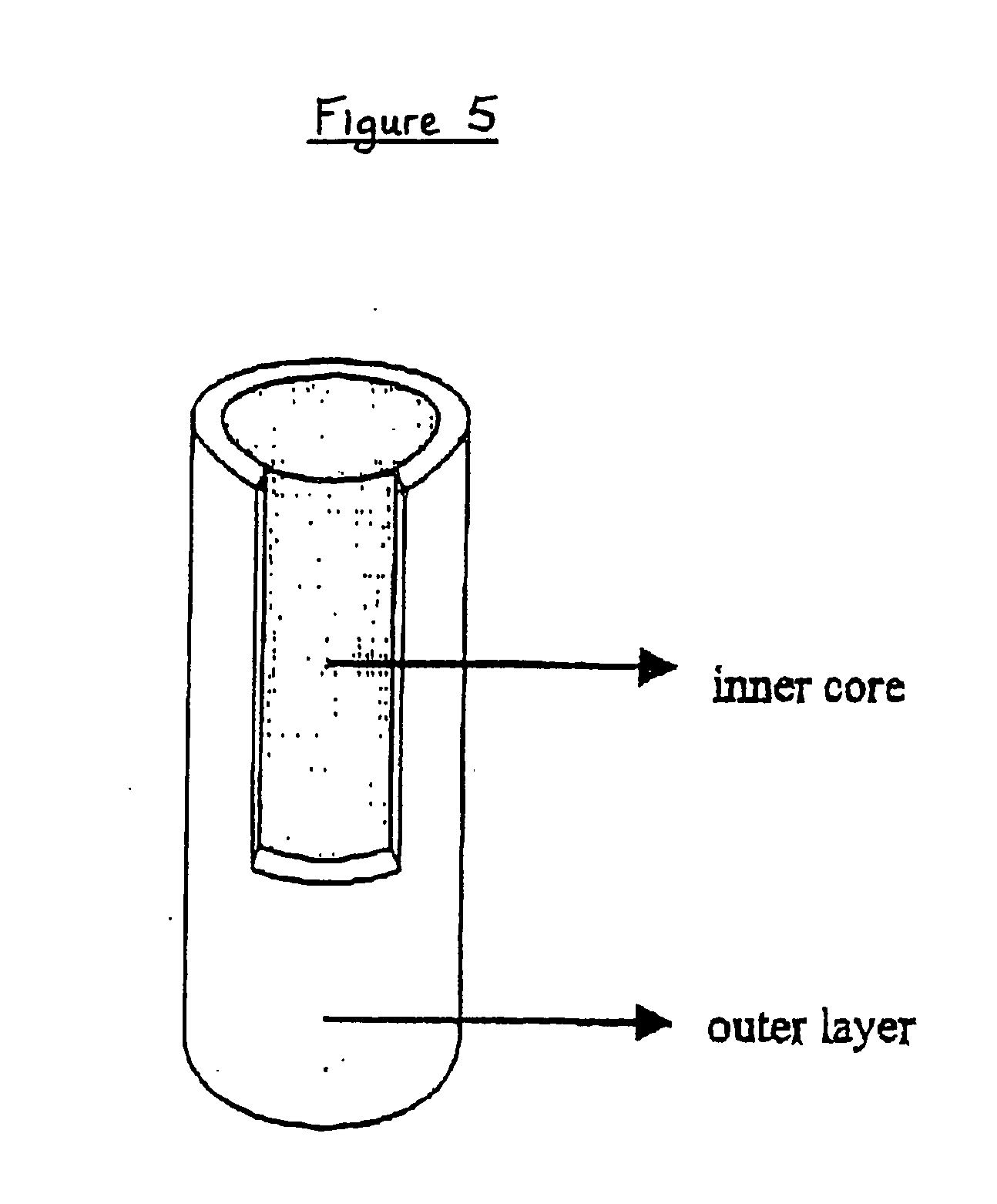

Controlled delivery system for bioactive substances

A biologically active composite solid shaped article comprising: (a) an outer layer, and (b) an inner core filling the said outer layer and comprising: at least a biologically active ingredient, and an excipient comprising at least a hydrophilic cellulose polymer and an amphiphilic material in the form of a blend with the said hydrophilic cellulose polymer, the weight ratio of the hydrophilic cellulose polymer to the amphiphilic material being from 0.2:1 to 0.6:1, provides improved sustained release of the biologically active ingredient.

Owner:UNIV GENT

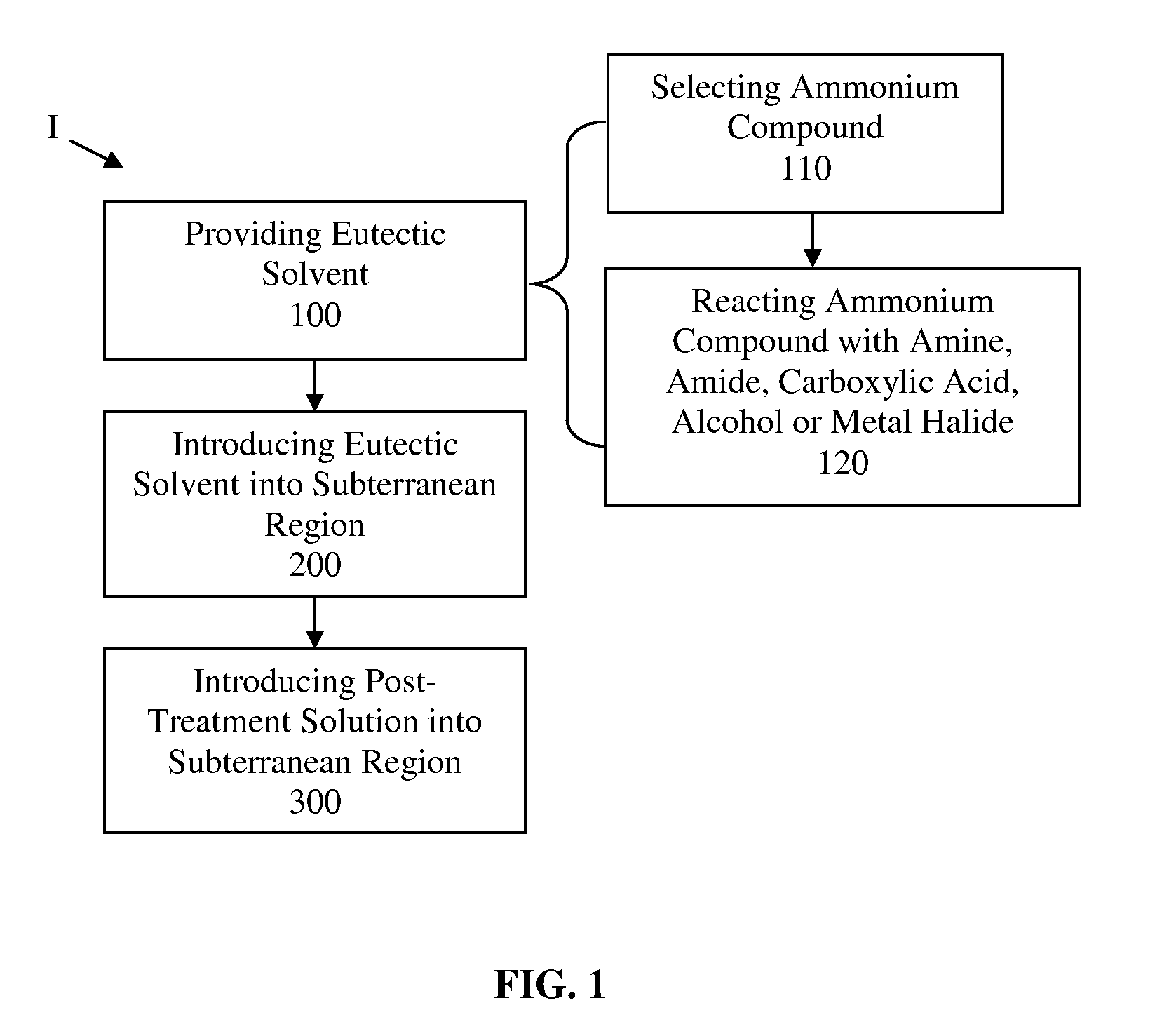

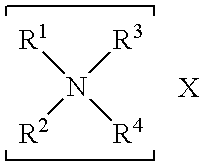

Deep eutectic solvents and applications

A method of solubilizing / removing cellulose or chemically-modified cellulosic polymers utilized in subterranean drilling operations such as fracturing. The method involves introducing a deep eutectic solvent (DES) into a subterranean region. Deep eutectic solvents useful as cellulose solvents include quaternary ammonium compounds, including choline chloride and chlorcholine chloride, reacted with a compound selected from amides, amines, carboxylic acids alcohols, and metal halides. The DES material can be pumped downhole after fracturing operations to remove cellulosic material used, for example, to thicken fracturing fluid which is left behind in the created fractures, on the face of the formation, along the wellbore, or elsewhere within the subterranean region. The DES can be used alone or in a sequential treatment protocol, whereby the DES is introduced into the subterranean region, followed by post-treatment introduction of water, caustic, acid or anhydride into the subterranean as a flush.

Owner:SHRIEVE CHEM PRODS

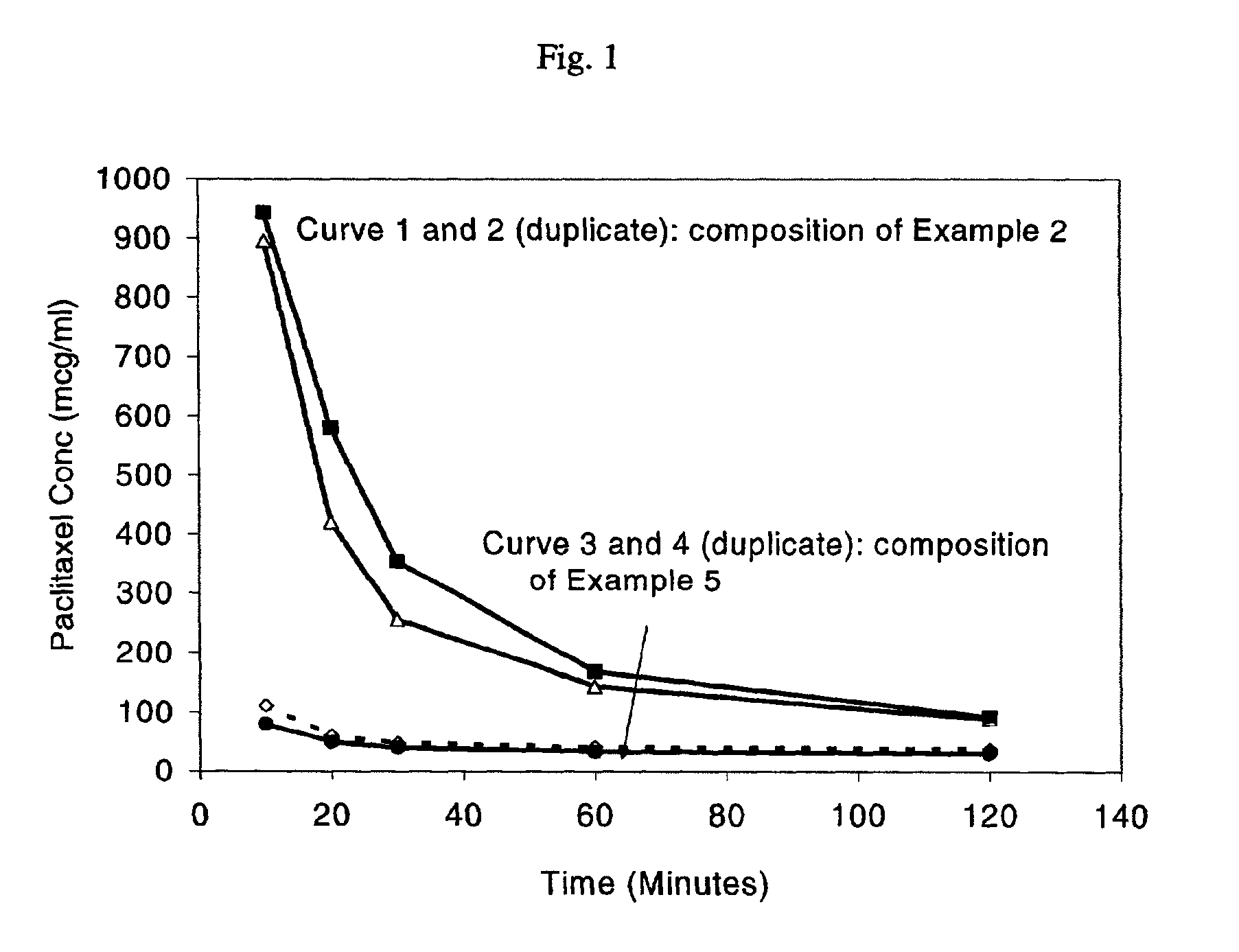

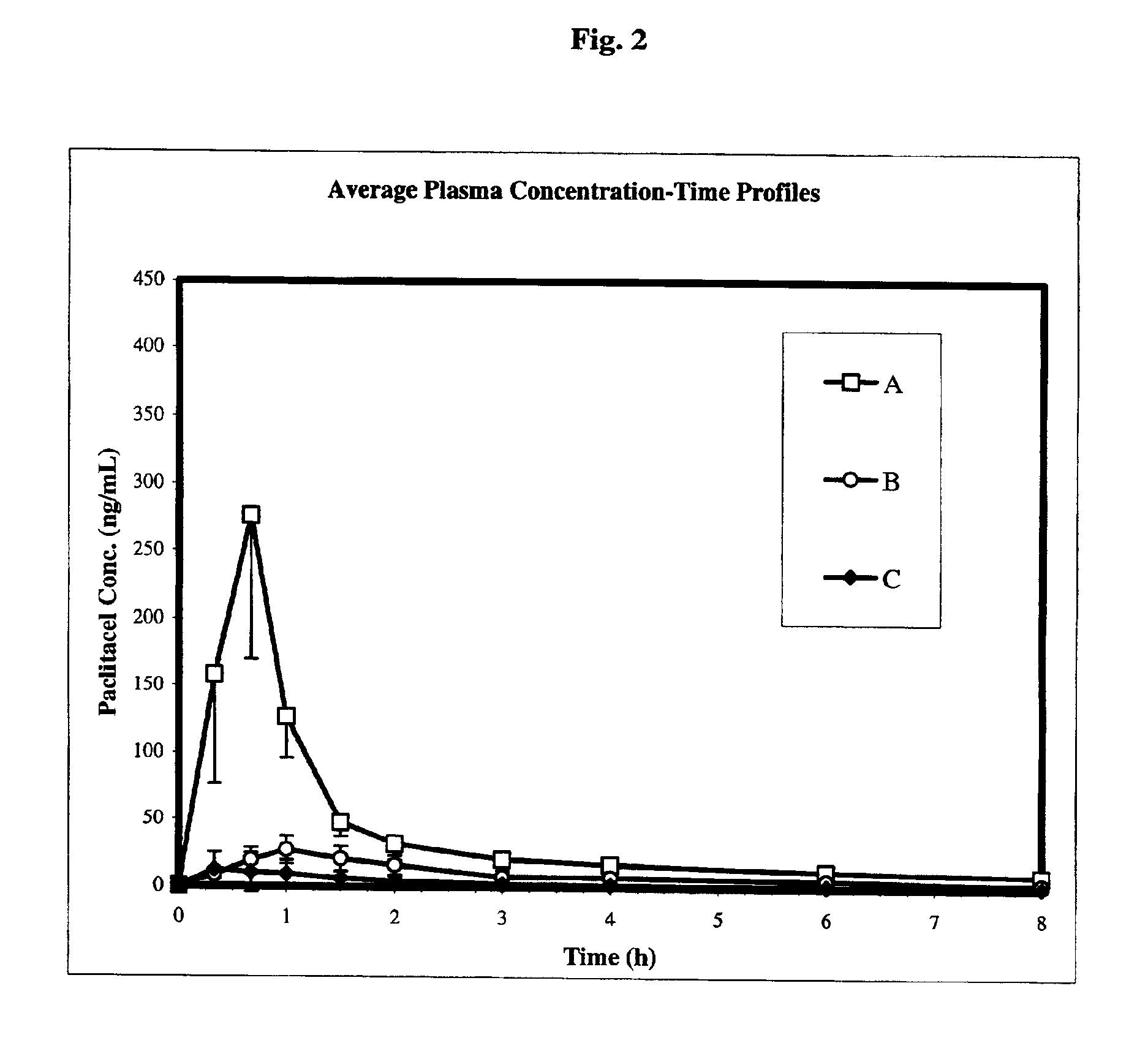

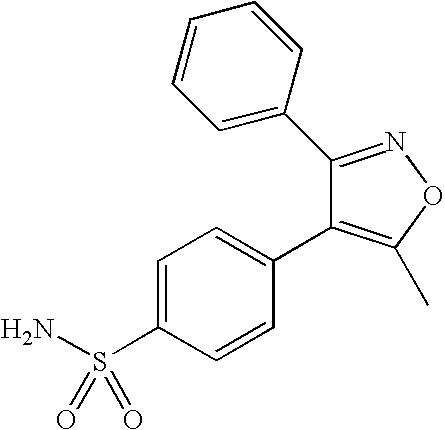

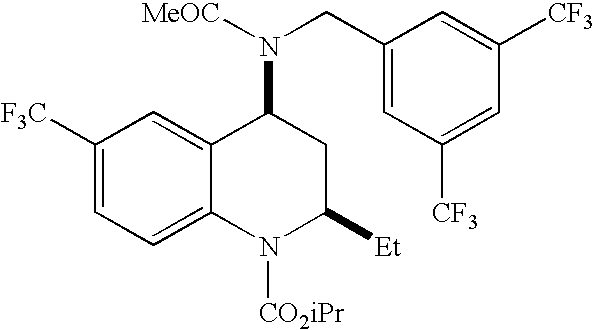

Chemotherapeutic microemulsion compositions of paclitaxel with improved oral bioavailability

InactiveUS7115565B2Rapid and efficient absorptionImprove bioavailabilityBiocideNervous disorderMonoglycerideSolvent

Pharmaceutical compositions suitable for oral administration comprising paclitaxel, a solvent, a surfactant, a substituted cellulosic polymer, and optionally but preferably a P-glycoprotein inhibitor. The composition may further comprise a diglyceride or mixture of diglyceride and monoglyceride. The composition generates a supersaturated paclitaxel microemulsion upon contact with water resulting in improved oral bioavailability of paclitaxel.

Owner:PHARMACIA & UPJOHN CO

Pearlescent film coating systems and substrates coated therewith

ActiveUS6902609B2High degreeExcellent oxygen barrier propertiesConfectioneryPretreated surfacesPowder mixtureMedicine

The present invention is directed to film coating systems for use on oral dosage forms such as compressed tablets and orally-ingestible substrates which have improved pearlescent qualities. The film coating systems can be applied either directly to a substrate or after the substrate has been coated with a subcoat. In preferred aspects, the pearlescent film coating is prepared as a dry powder mixture containing a cellulosic polymer, a detackifier, a gloss enhancer, and a pearlescent pigment. Film coating compositions containing an aqueous suspension of the powder mixtures, methods of applying the coatings to substrates and the coated substrates are also disclosed.

Owner:BPSI HLDG LLC

High performance water-based mud system

InactiveUS20050187113A1Premature consumptionEffectively stopFluid removalFlushingWater basedPolystyrene

A drilling fluid or mud additive having several components, including leonardite (humic acid); potassium acetate; partially hydrolyzed polyacrylamide (PHPA); polyanionic cellulose polymer (PAC); sulfonated asphalt; sulfoalkylated tannin; polystyrene maleic anhydride copolymer; micronized cellulose fiber; and calcium carbonate. These components are preferably premixed in a dry formulation as a powder or as pellets, and shipped to the site in bags or bulk tanks. This offers substantial advantages over the prior art in that the drilling mud of the present invention may be formed simply by adding the dry mix to a predetermined amount of water, and is thus much easier to make than the prior art wet mix drilling fluids, which typically require precise ratios of several different powders and liquids to be mixed together. Hydration buffers help keep the powder or pellets dry and flowable.

Owner:HAYES JAMES R

Hydrogel compositions

InactiveUS8481059B2Less tackyProperty is limitedCosmetic preparationsToilet preparationsElastomerHydrophilic polymers

Owner:CORIUM PHARMA SOLUTIONS INC

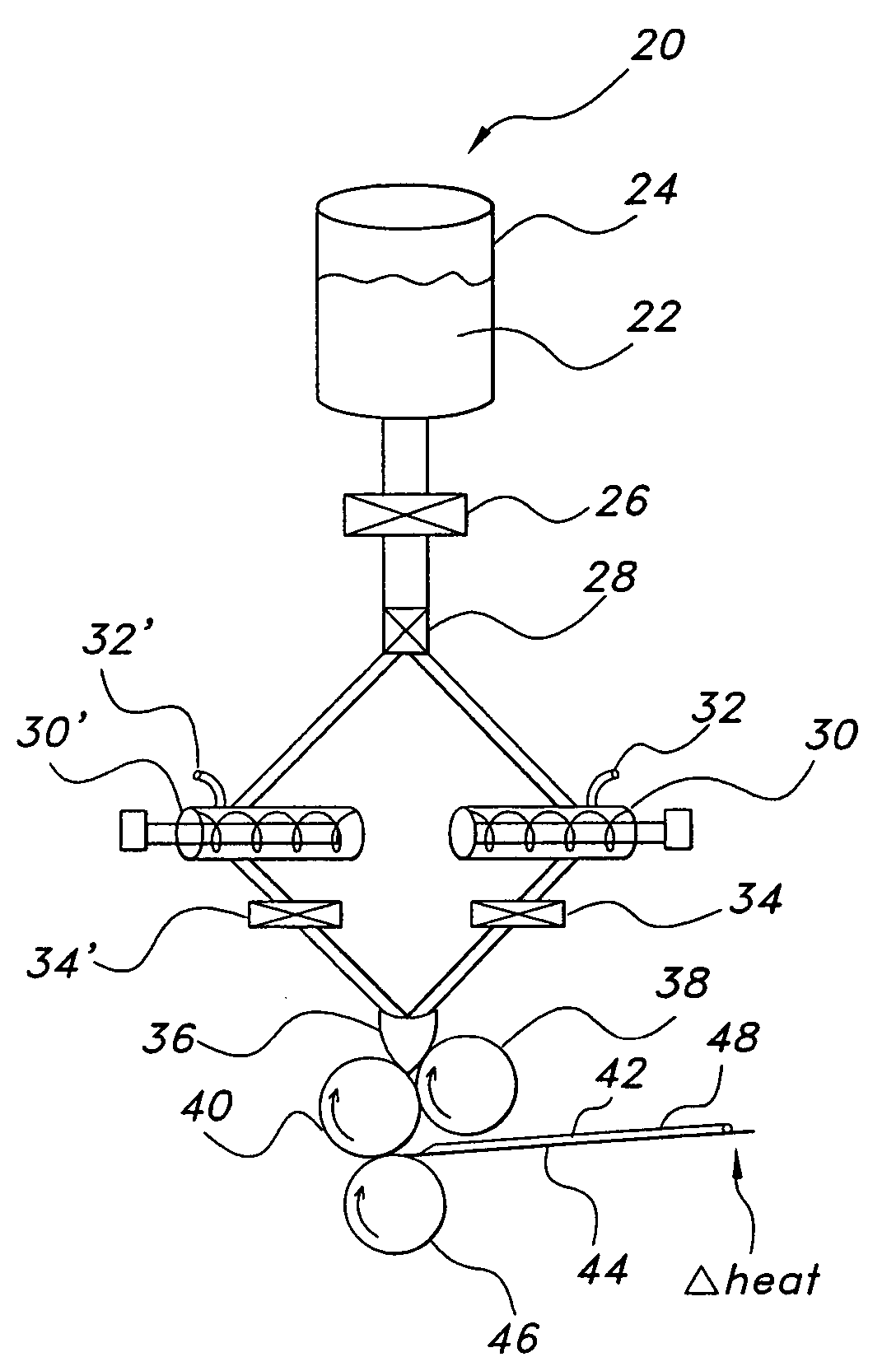

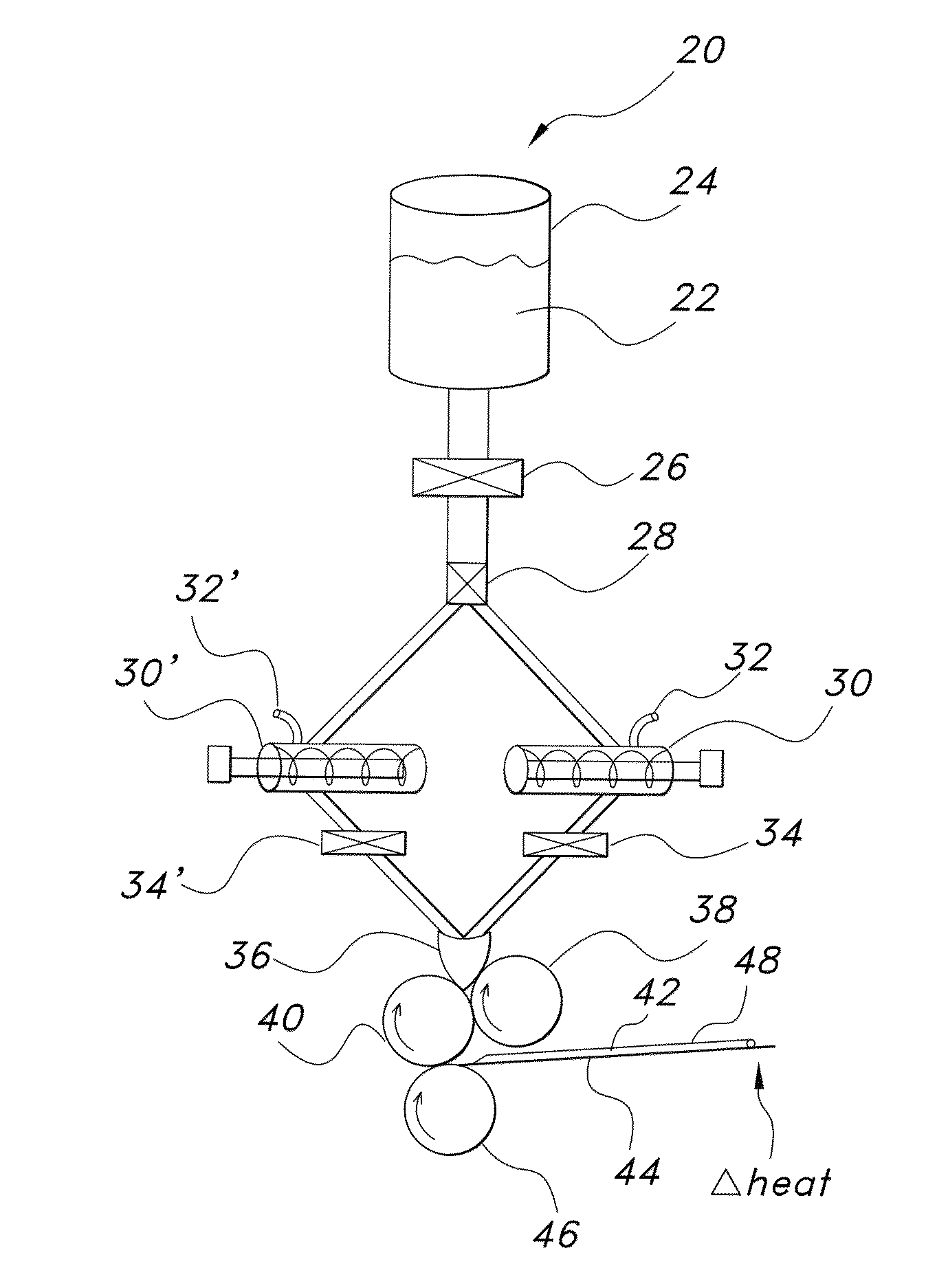

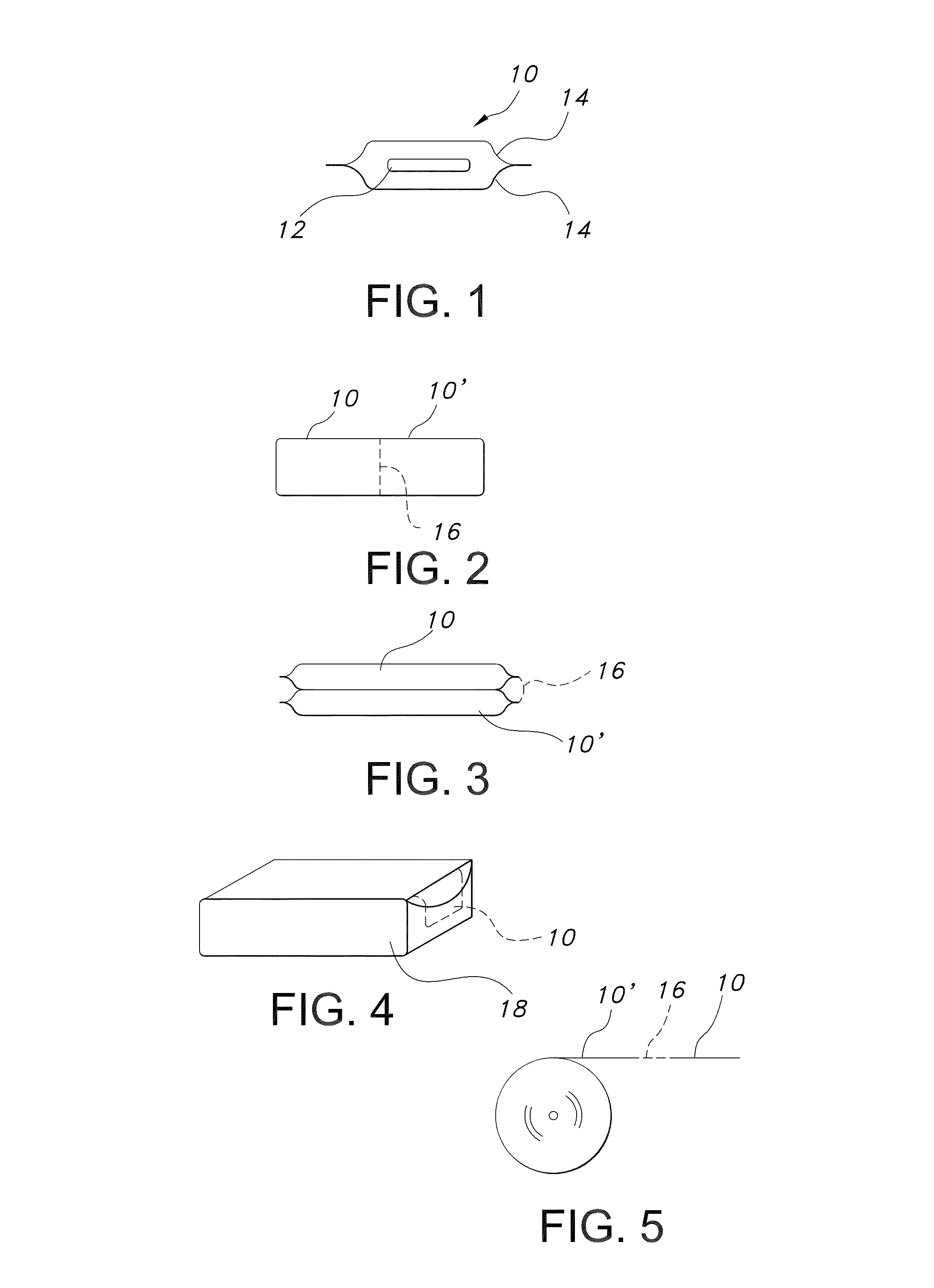

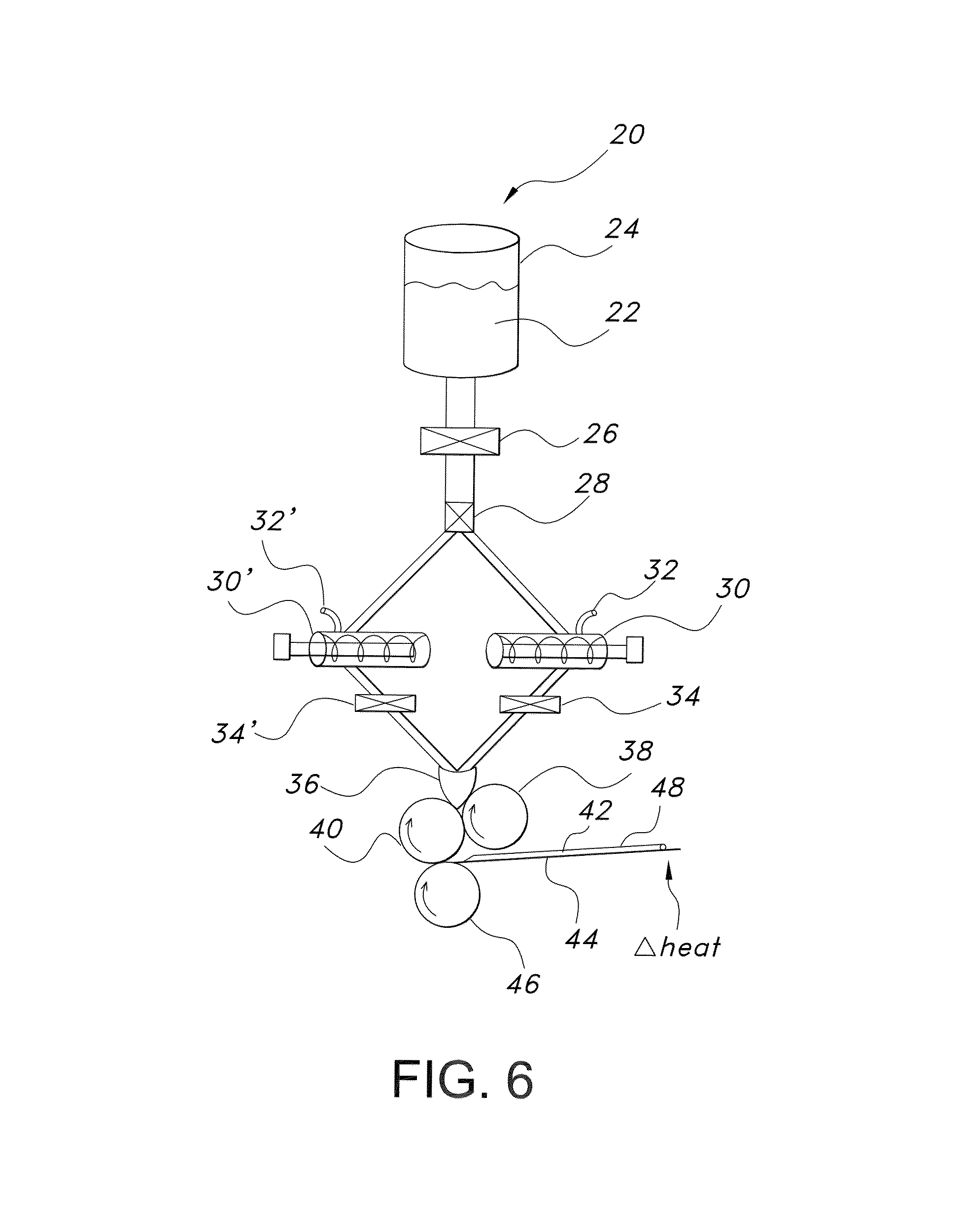

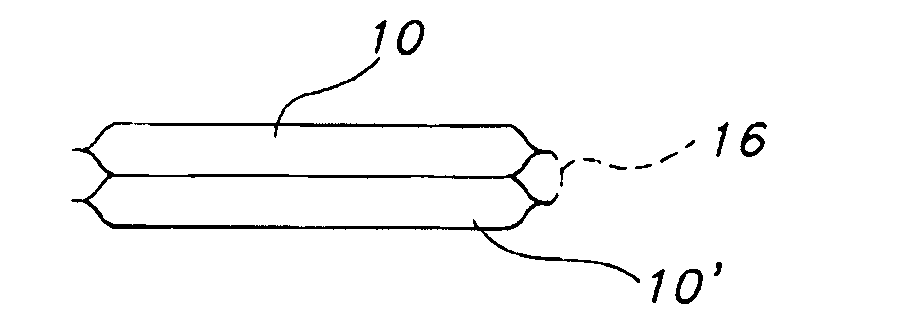

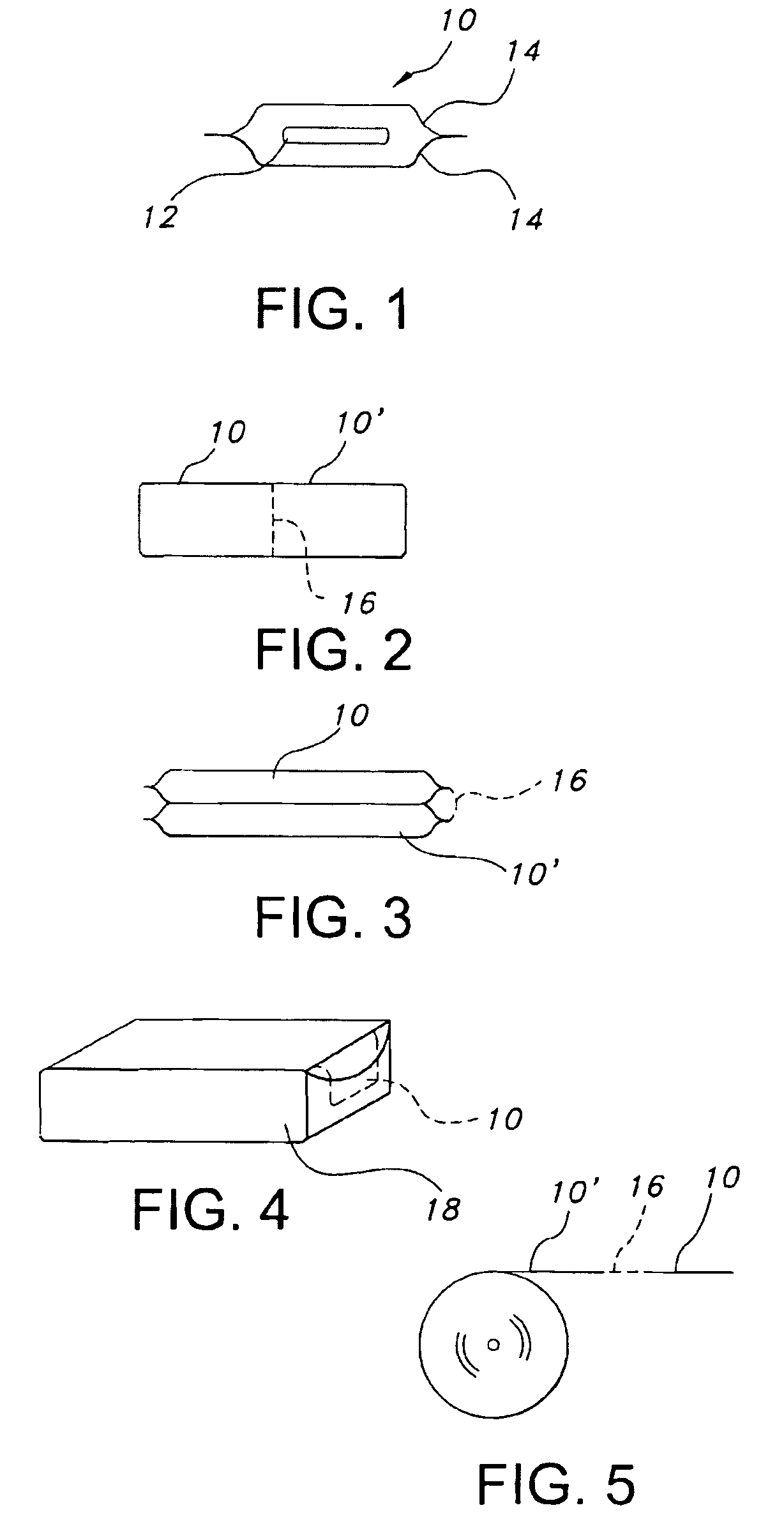

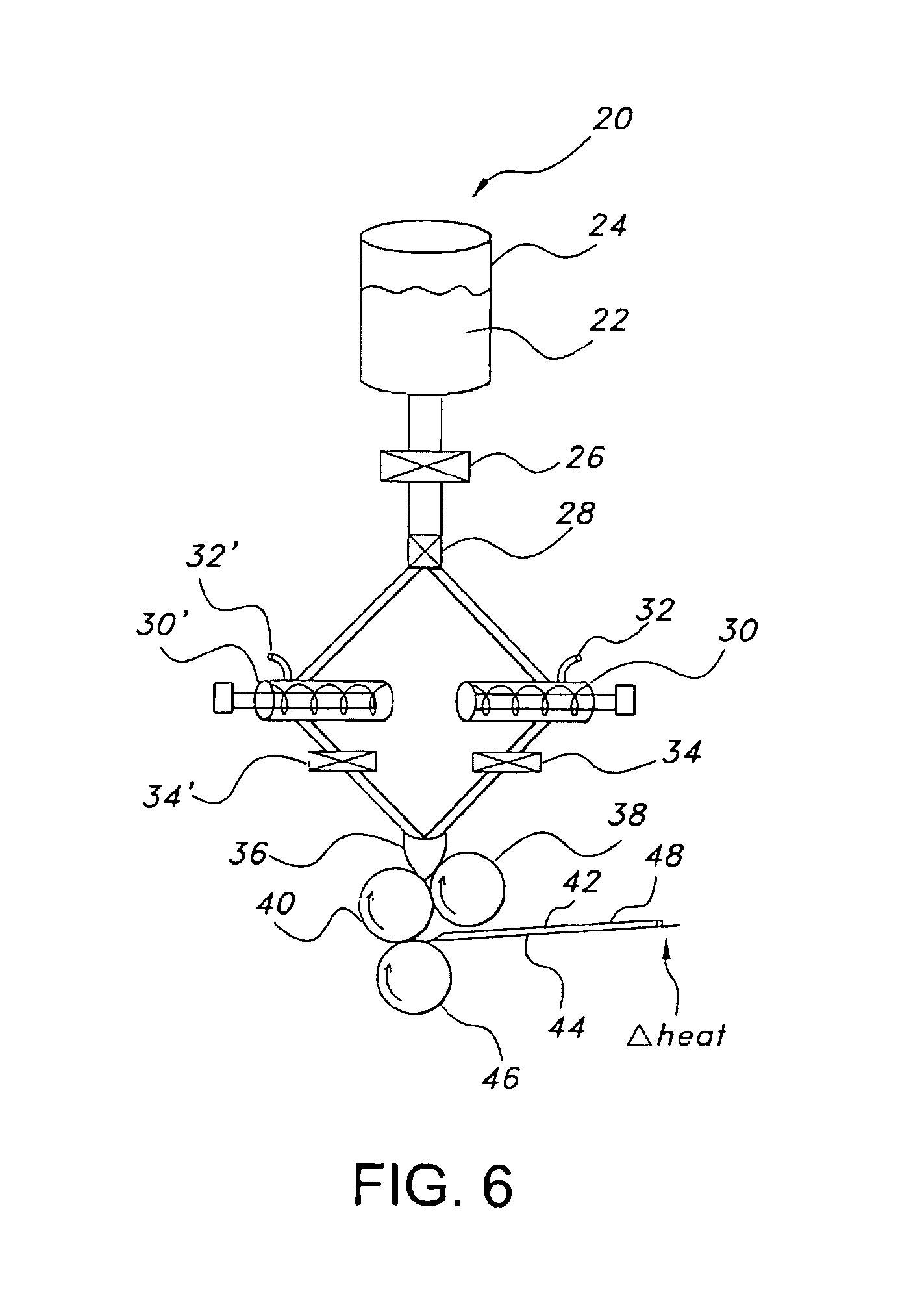

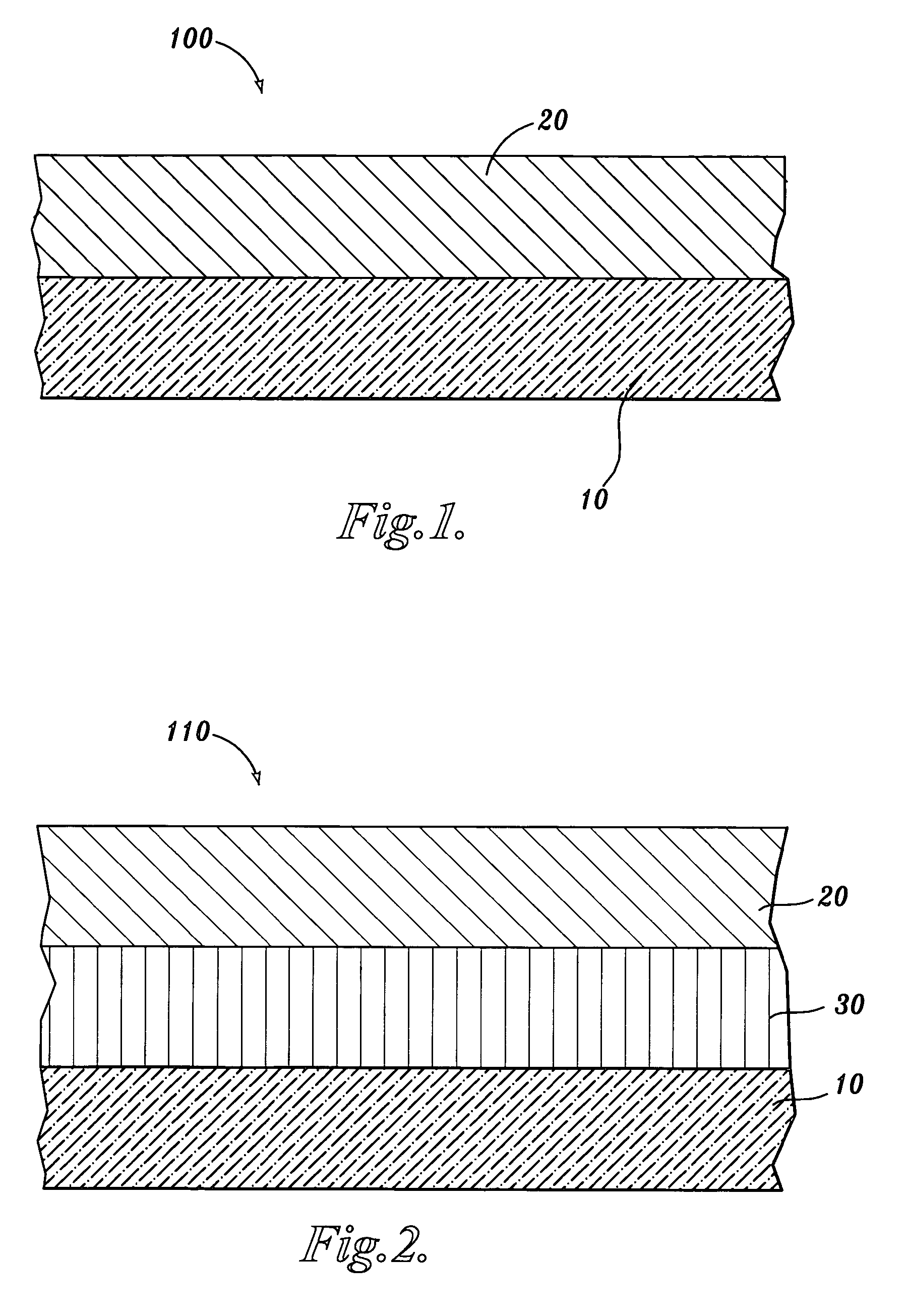

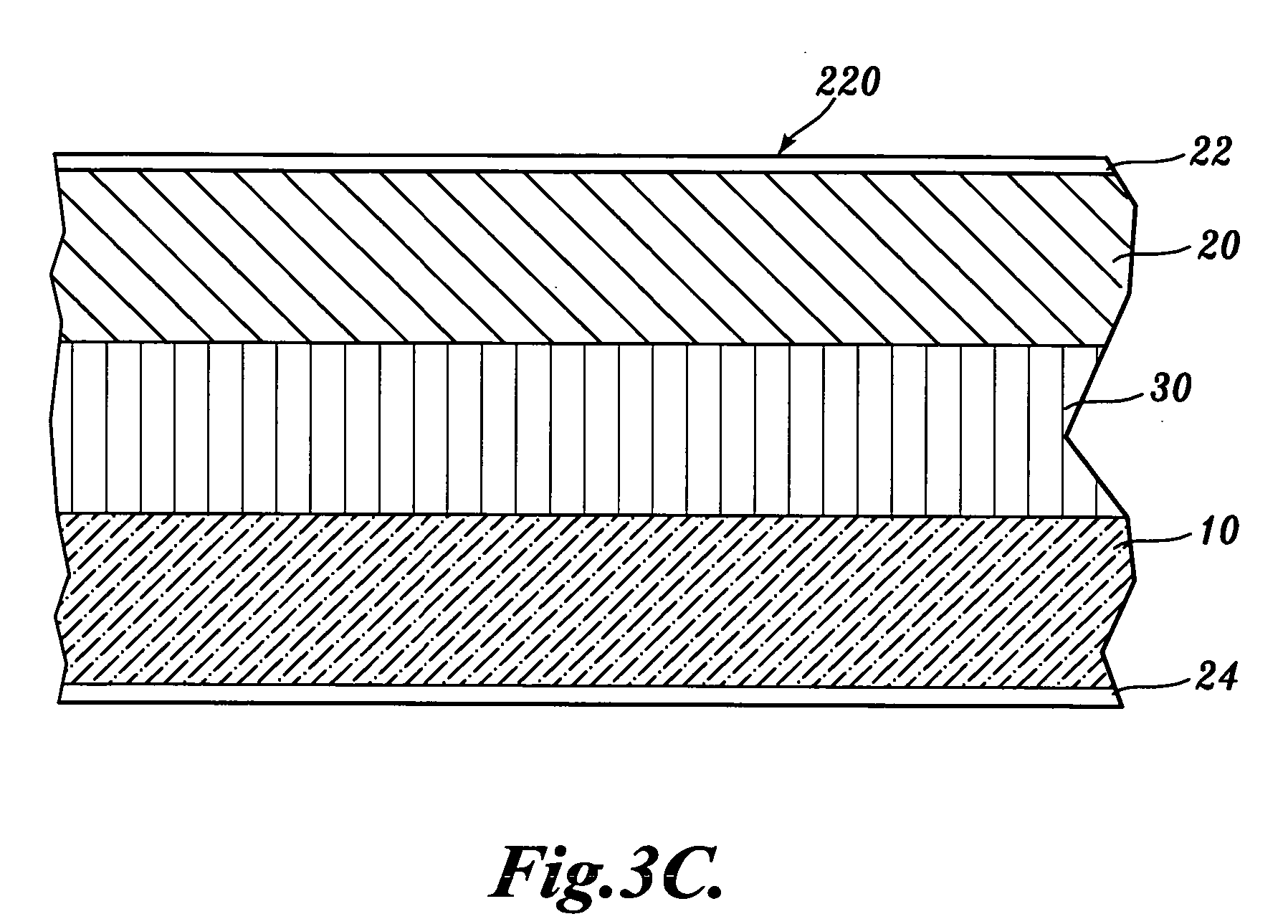

Process for manufacturing a resulting multi-layer pharmaceutical film

The invention relates to the film products and methods of their preparation that demonstrate a non-self-aggregating uniform heterogeneity. Desirably, the films disintegrate in water and may be formed by a controlled drying process, or other process that maintains the required uniformity of the film. The films contain a polymer component, which includes polyethylene oxide optionally blended with hydrophilic cellulosic polymers. Desirably, the films also contain a pharmaceutical and / or cosmetic active agent with no more than a 10% variance of the active agent pharmaceutical and / or cosmetic active agent per unit area of the film.

Owner:AQUESTIVE THERAPEUTICS INC

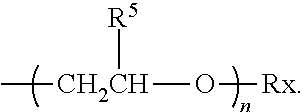

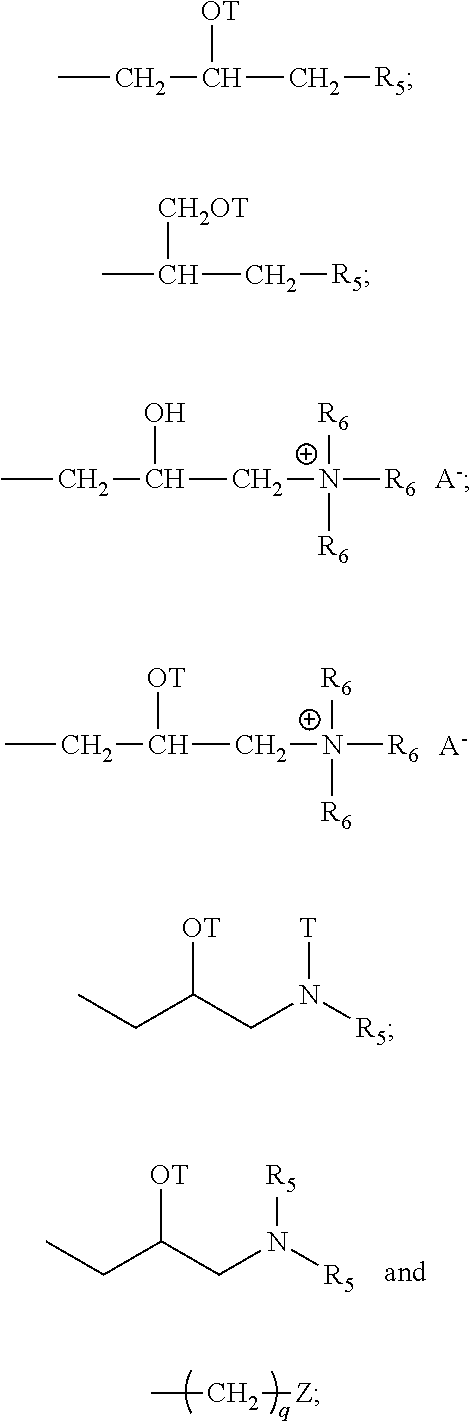

Hydrogel Compositions

InactiveUS20090258060A1Improve attributesLess tackyCosmetic preparationsPowder deliveryElastomerHydrophilic polymers

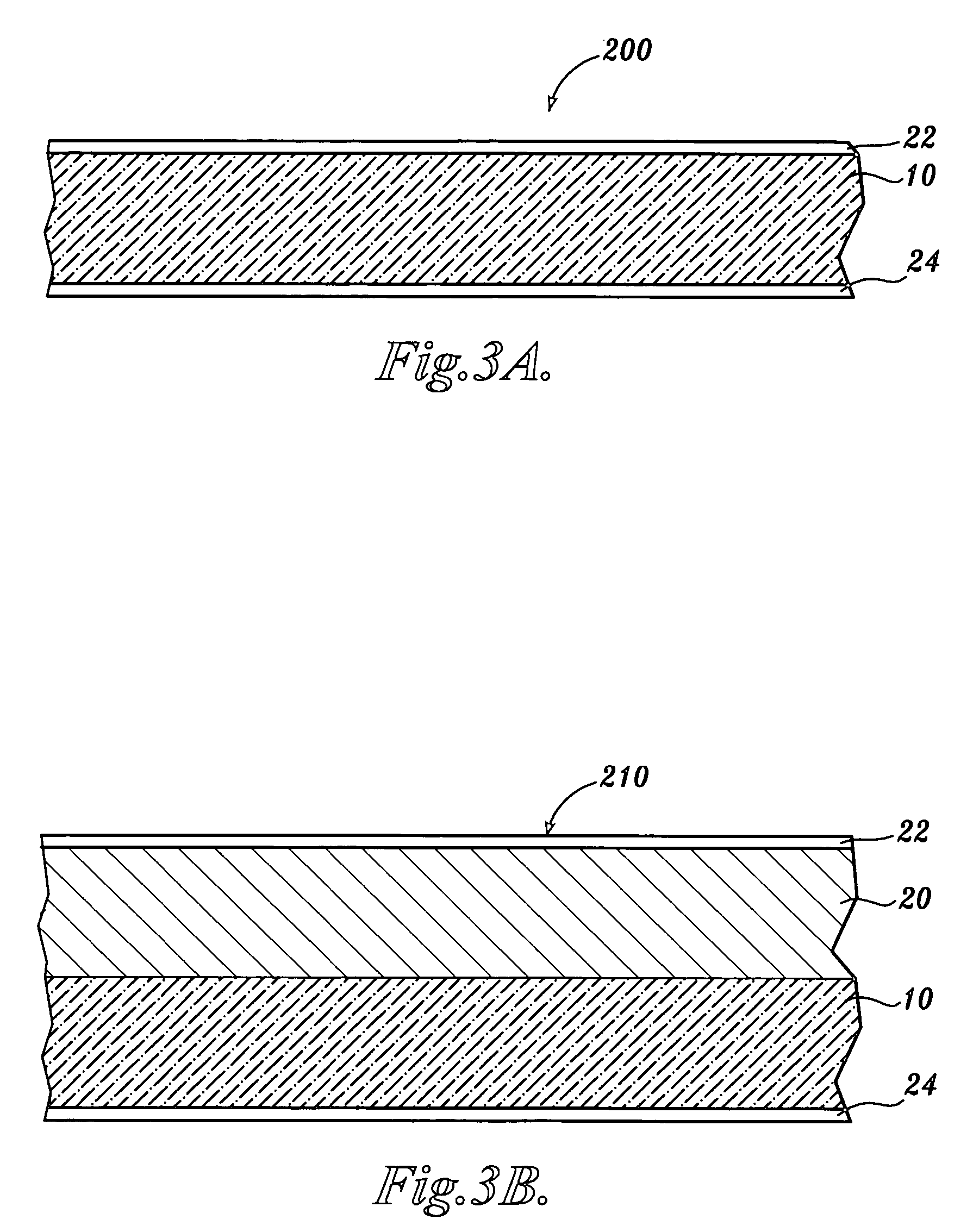

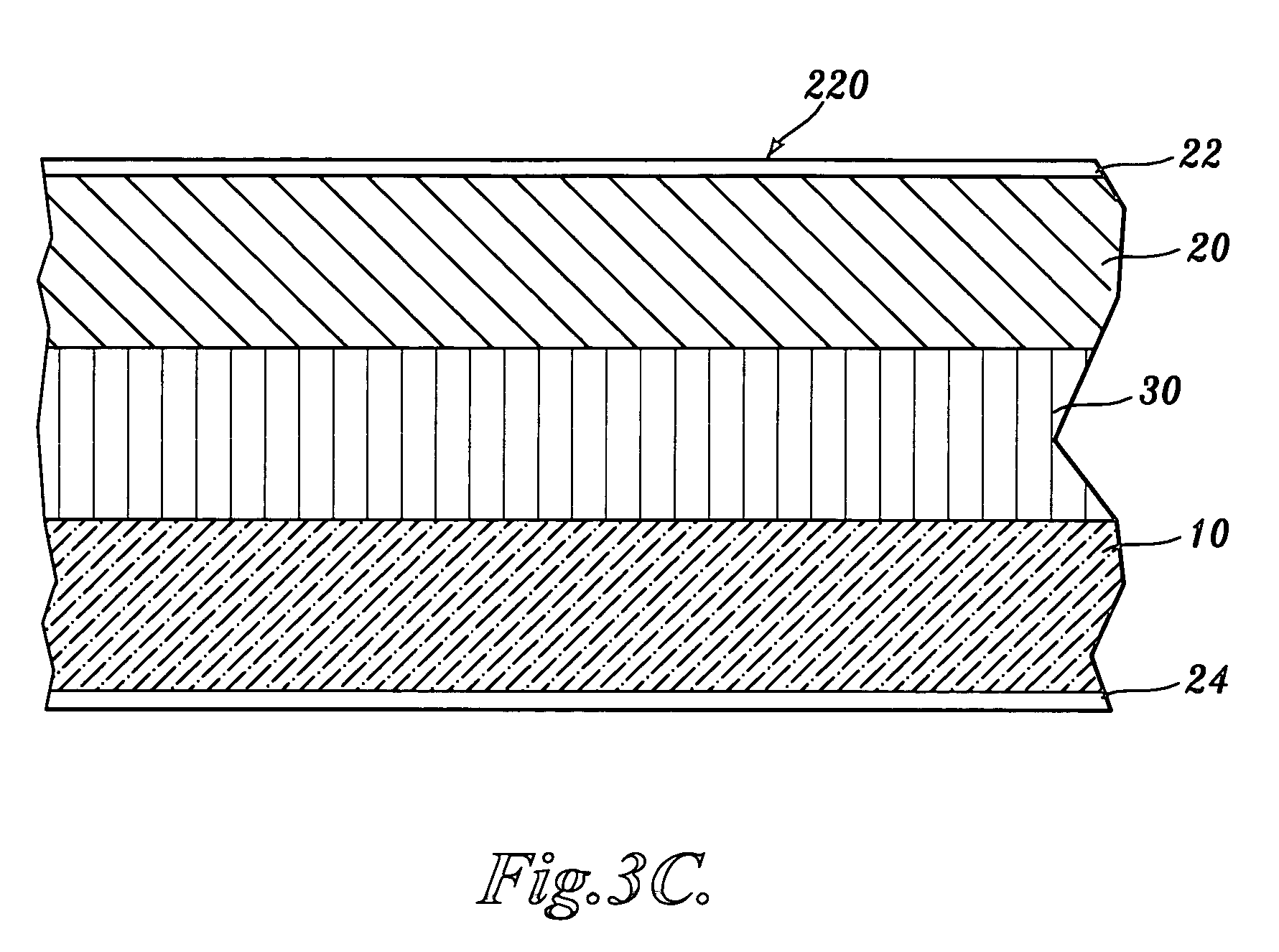

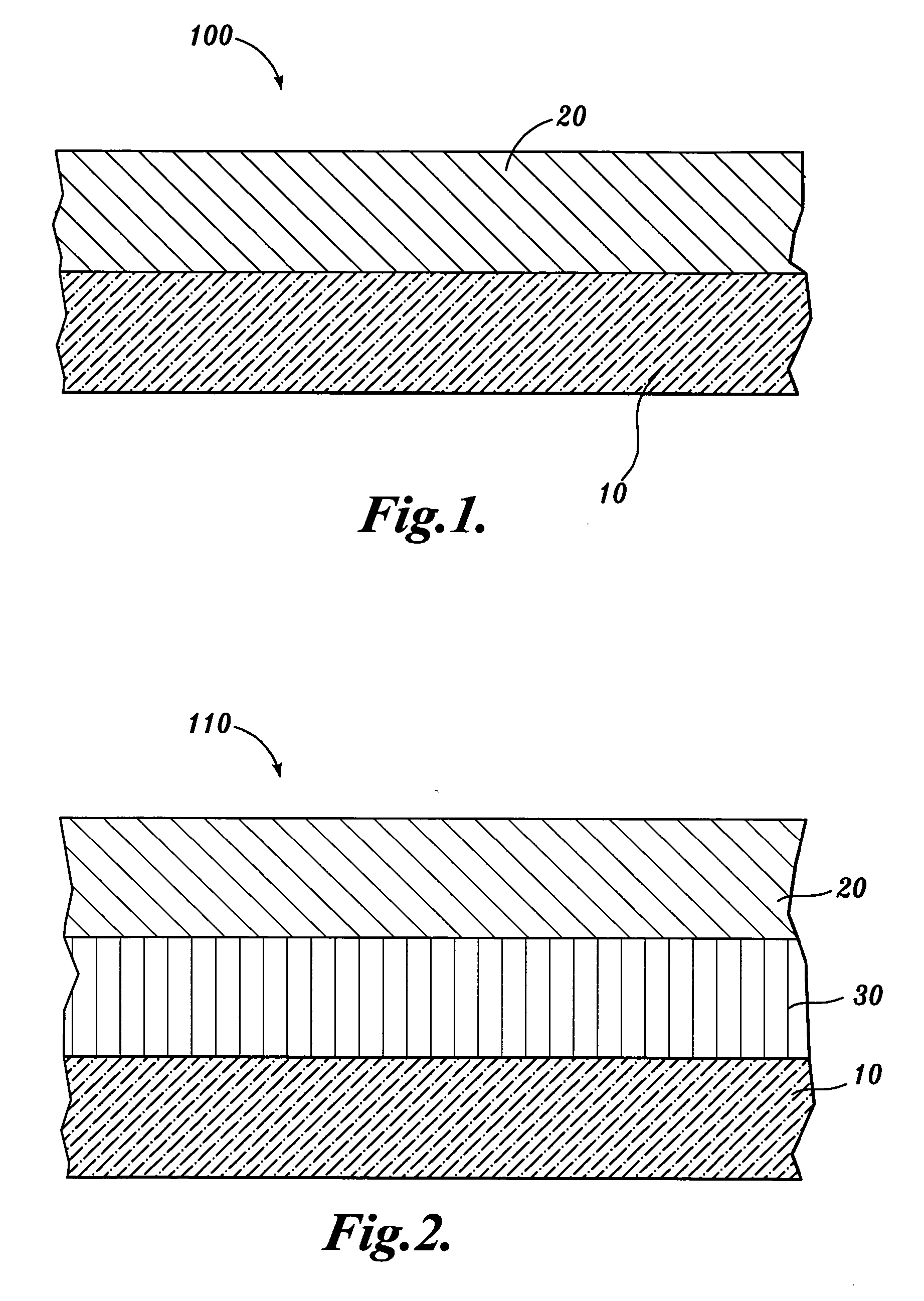

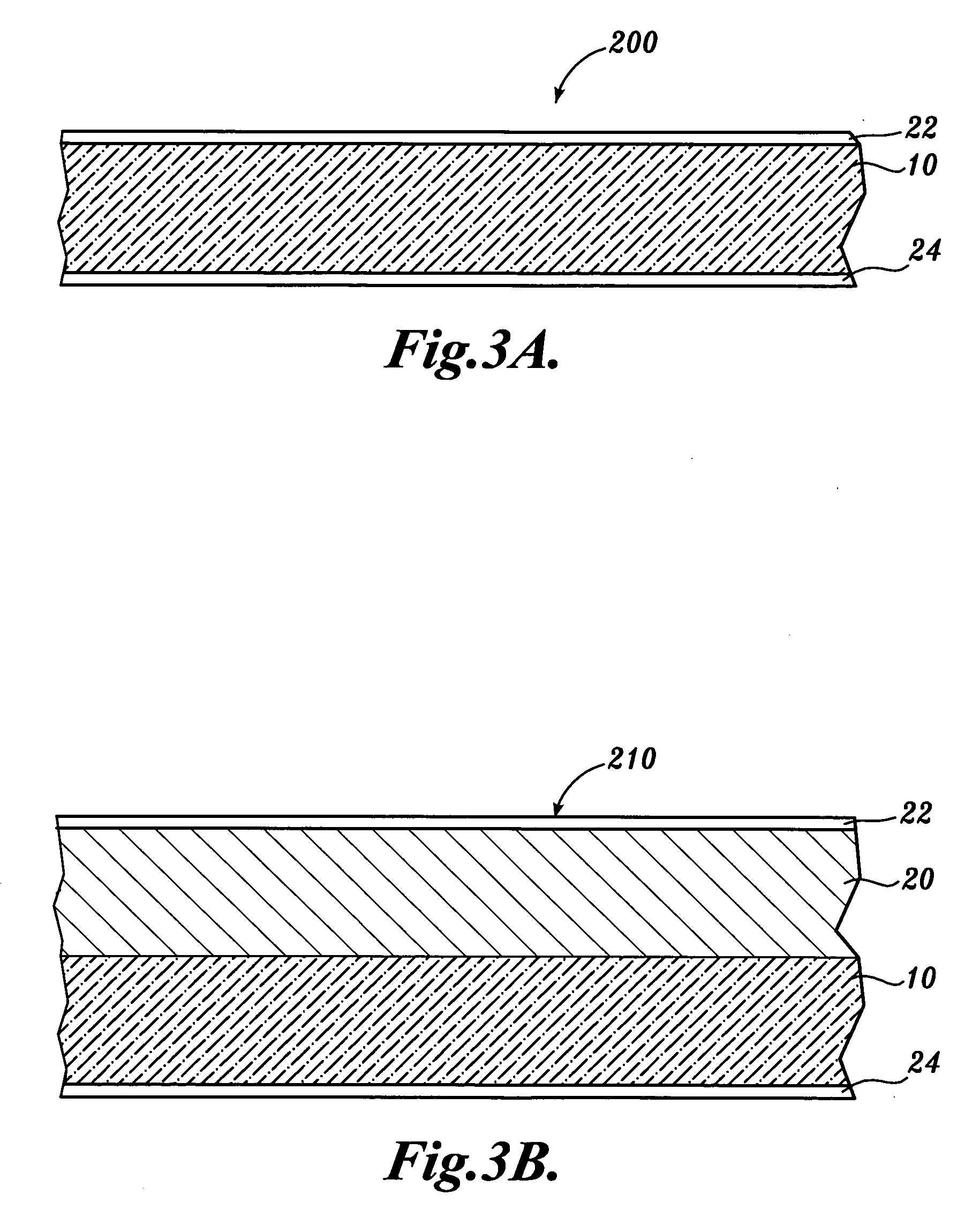

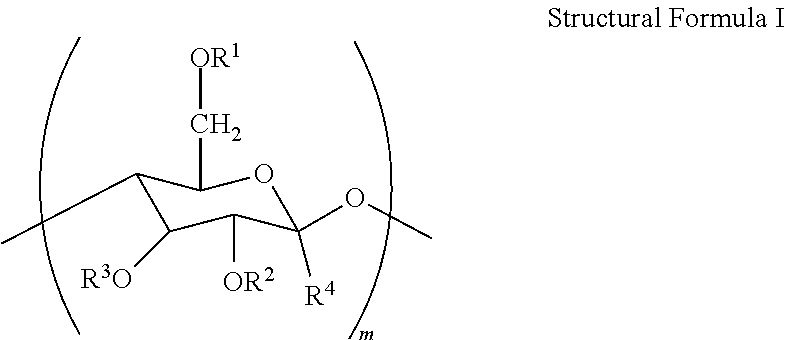

Hydrogel compositions are provided (a) that have a continuous hydrophobic phase and a discontinuous hydrophilic phase, (b) that have a discontinuous hydrophilic phase and a continuous hydrophilic phase, or (c) that are entirely composed of a continuous hydrophilic phase. The hydrophobic phase, if present, is composed of a hydrophobic polymer, particularly a hydrophobic pressure-sensitive adhesive (PSA), a plasticizing elastomer, a tackifying resin, and an optional antioxidant. The discontinuous hydrophilic phase, if present, is composed of a crosslinked hydrophilic polymer, particularly a crosslinked cellulosic polymer such as crosslinked sodium carboxymethylcellulose. For those hydrogel compositions containing a continuous hydrophilic phase, the components of the phase include a cellulose ester composition or an acrylate polymer or copolymer, and a blend of a hydrophilic polymer and a complementary oligomer capable of hydrogen bonding thereto. Films prepared from hydrogel compositions containing or entirely composed of the aforementioned continuous hydrophilic phase can be made translucent, and may be prepared using either melt extrusion or solution casting. A preferred use of the hydrogel compositions is in wound dressings, although numerous other uses are possible as well.

Owner:CORIUM PHARMA SOLUTIONS INC

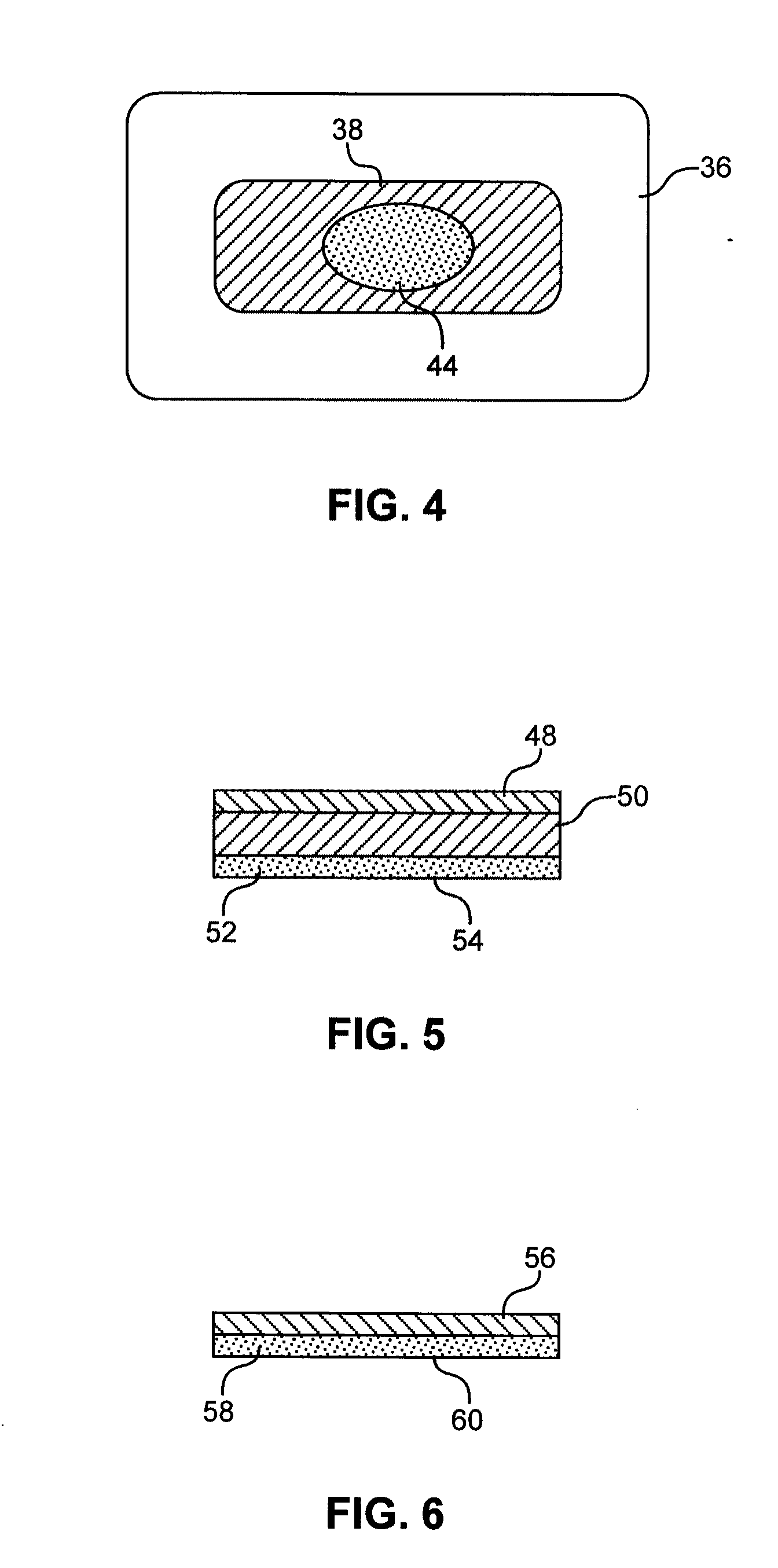

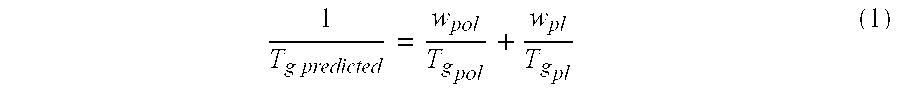

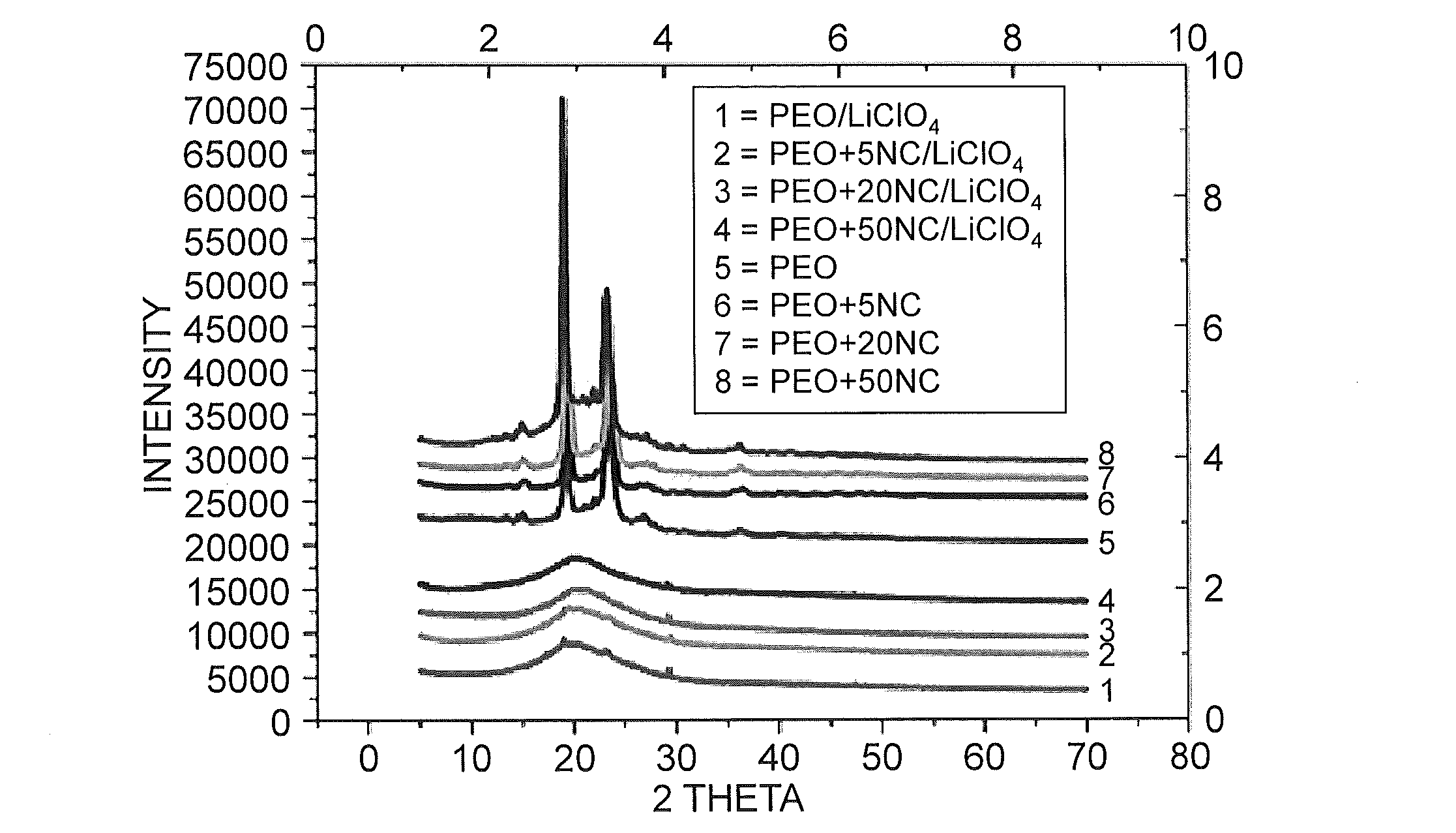

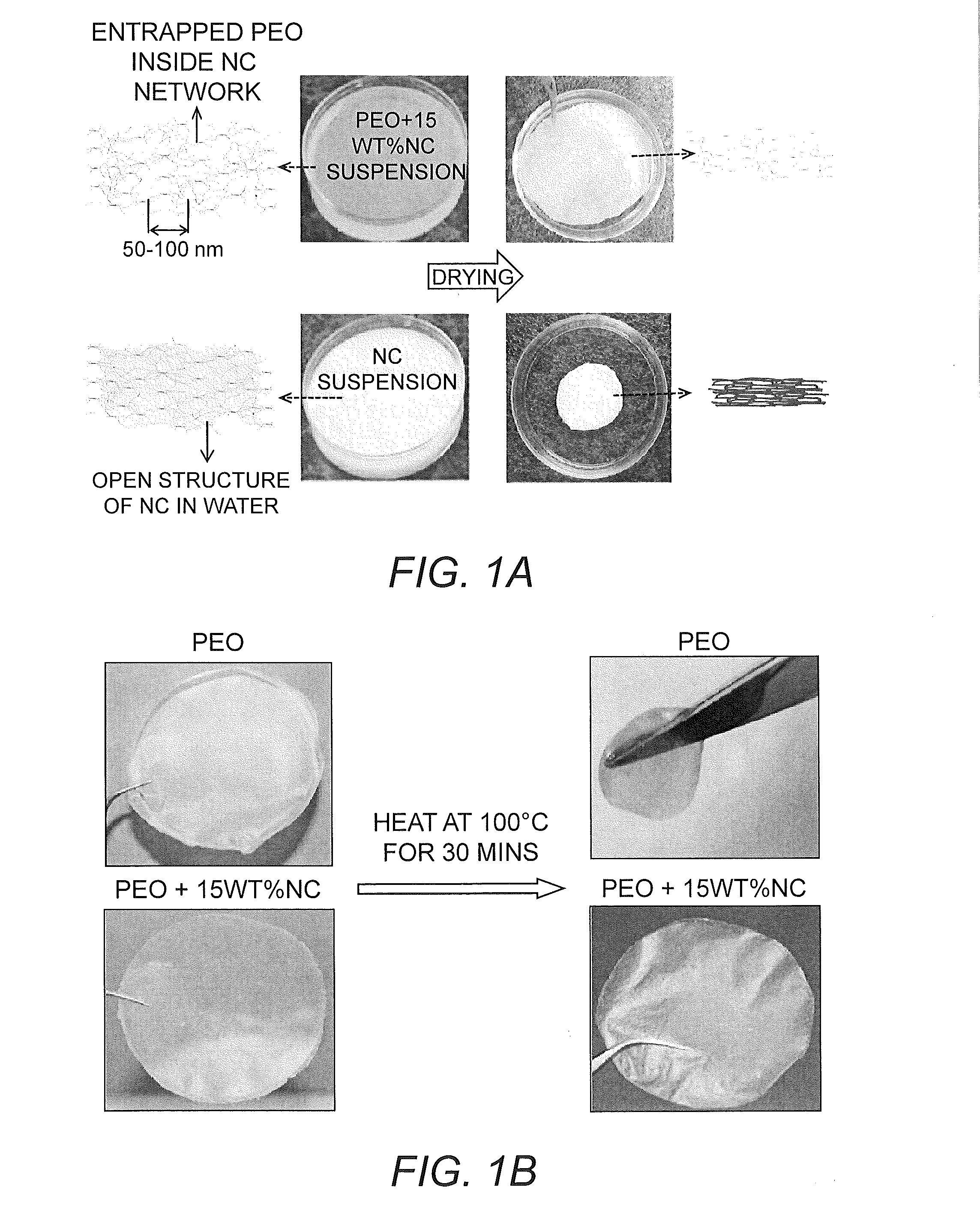

Fabrication of cellulose polymer composites and their application as solid electrolytes

InactiveUS20130189589A1High strengthHigh modulusSolid electrolytesFinal product manufacturePolymer electrolytesElectrolyte composition

A solid polymer electrolyte composition is made by hydrolyzing cellulose in a dissolution media to form a first mixture; then combining said first mixture with an antisolvent to form a precipitate; and then (in any order) separating said precipitate from excess antisolvent and excess dissolution media; optionally adjusting or neutralizing the pH of said precipitate; optionally washing said precipitate with water; combining said precipitate with an electrolyte salt and a hydrophilic polymer to form a wet polymer electrolyte composition; and then drying said wet polymer electrolyte composition to produce a solid polymer electrolyte composition. Solid polymer electrolyte compositions produced by the process, along with films formed therefrom and devices containing the same, are also described.

Owner:MASDAR INST OF SCI & TECH

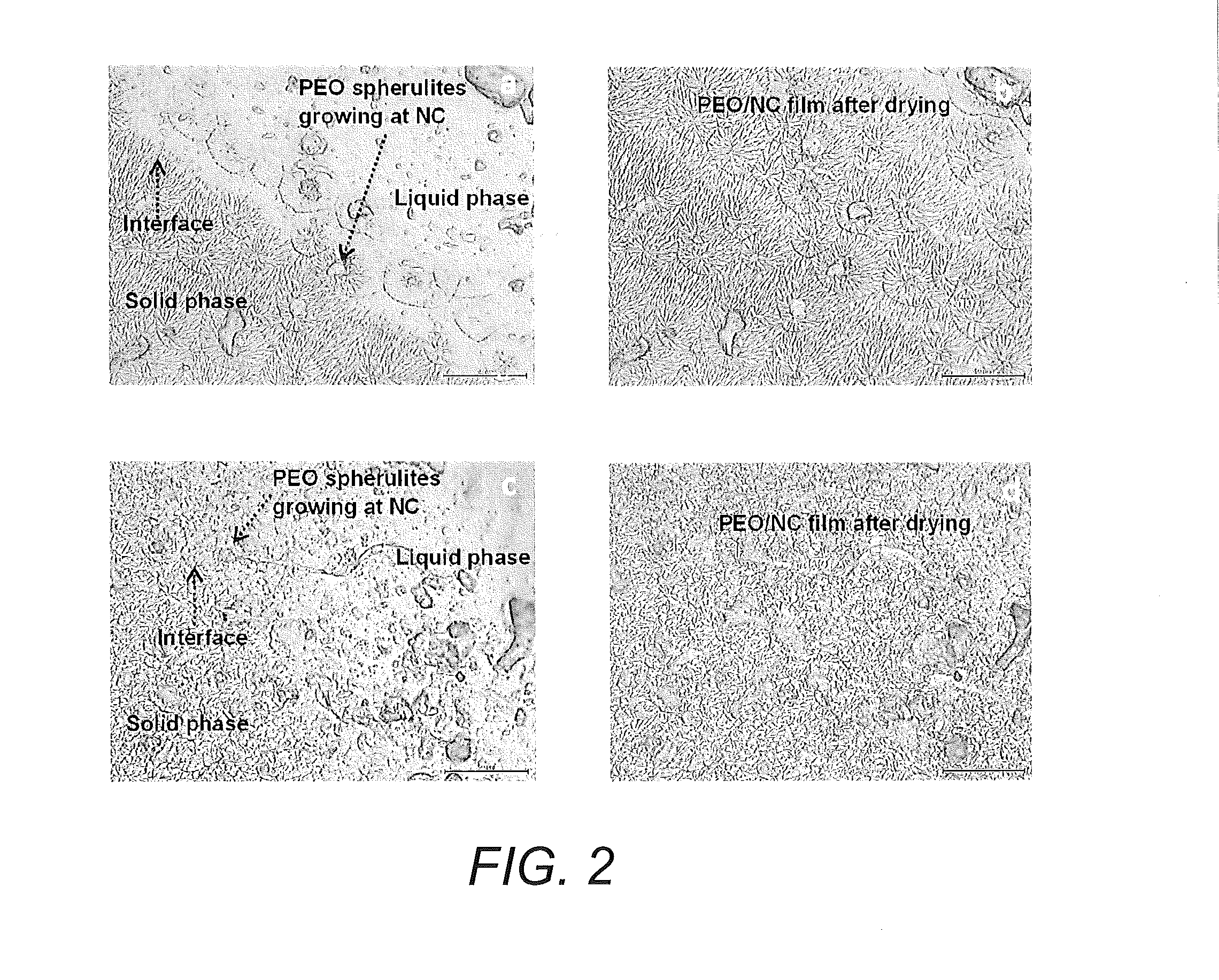

Polyethylene oxide-based films and drug delivery systems made therefrom

The invention relates to the film products and methods of their preparation that demonstrate a non-self-aggregating uniform heterogeneity. Desirably, the films disintegrate in water and may be formed by a controlled drying process, or other process that maintains the required uniformity of the film. The films contain a polymer component, which includes polyethylene oxide optionally blended with hydrophilic cellulosic polymers. Desirably, the films also contain a pharmaceutical and / or cosmetic active agent with no more than a 10% variance of the active agent pharmaceutical and / or cosmetic active agent per unit area of the film.

Owner:AQUESTIVE THERAPEUTICS INC

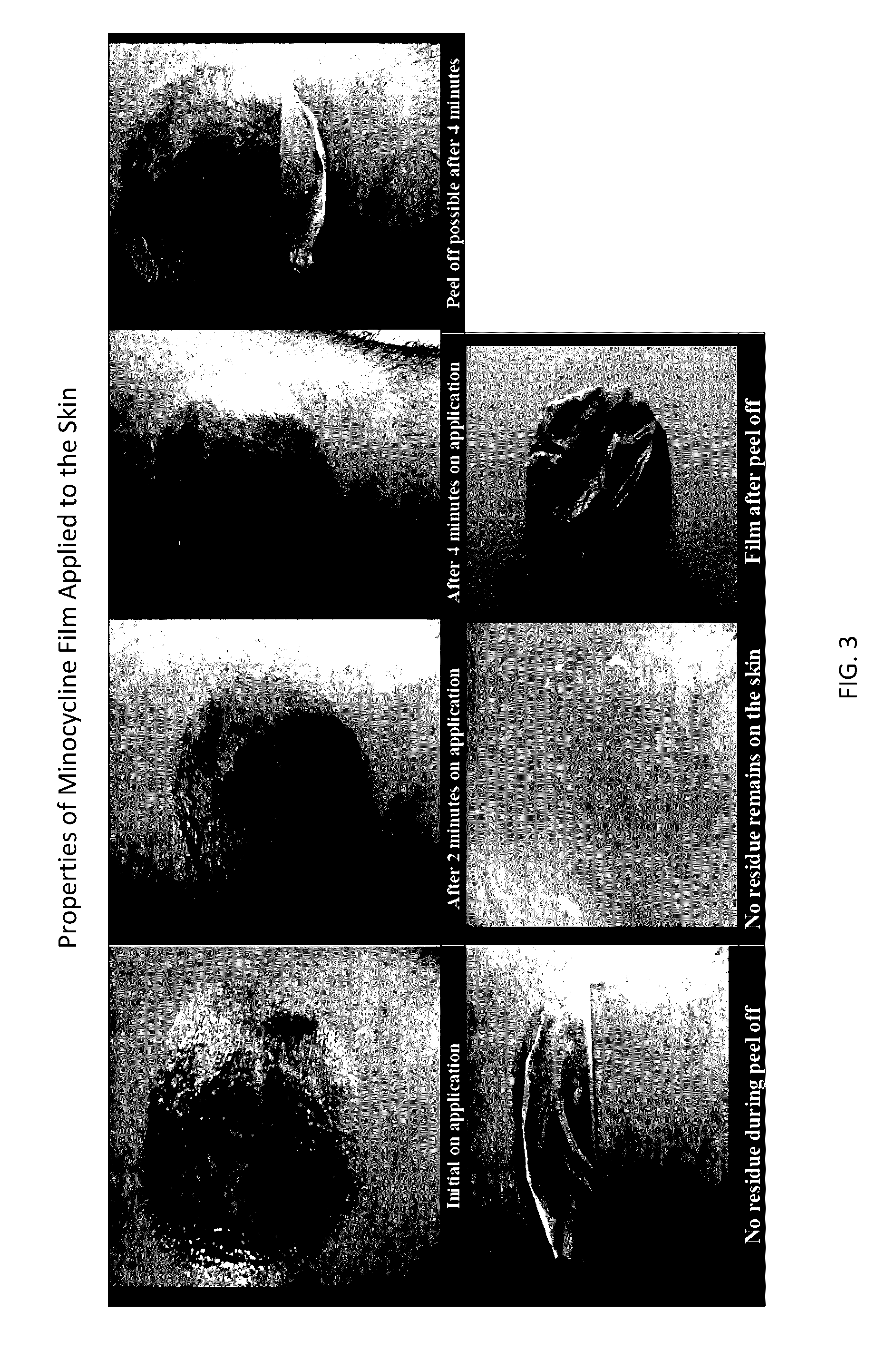

Topical film delivery system

ActiveUS20170049712A1Effective treatmentHydroxy compound active ingredientsTetracycline active ingredientsDiseaseActive agent

Owner:SIDMAK LAB INDIA PVT LTD

Carboxyalkyl cellulose polymer network

Owner:WEYERHAEUSER CO

Method for making sulfoalkylated cellulose polymer network

Owner:WEYERHAEUSER CO

Oral and Personal Care Compositions and Methods

InactiveUS20080160056A1Improve stabilityControlled deliveryCosmetic preparationsToilet preparationsPersonal careBiomedical engineering

A dentifrice composition comprising an orally acceptable vehicle having distributed therein a water hydratable film flakes having a matrix comprised of a water soluble hydroxy alkyl cellulose polymer and a starch, and having entrained therein a constituent selected from therapeutic cosmetic and decorative materials.

Owner:COLGATE PALMOLIVE CO

Stable Compositions Comprising Cationic Cellulose Polymers and Cellulase

InactiveUS20110319310A1Good benefitImprove performanceNon-surface-active detergent compositionsDetergent compounding agentsPolymer scienceWater soluble

The need for a stable, compact composition providing improved fabric care benefit, that is also convenient to use, can be met by incorporating a cationic cellulose polymer and cellulase enzyme into a non-aqueous composition. The non-aqueous composition can be made even more convenient to use, by encapsulating in a water-soluble or dispersible film to form a unit-dose article. Such unit dose articles provide improved fabric feel in addition to improved colour maintenance.

Owner:THE PROCTER & GAMBLE COMPANY

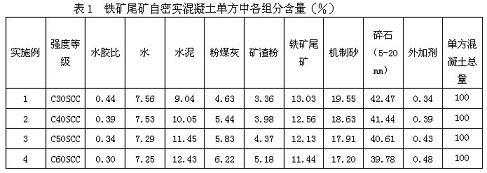

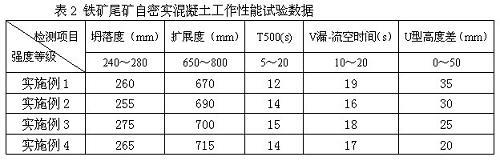

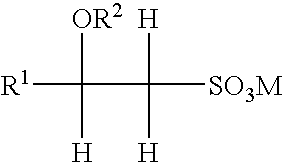

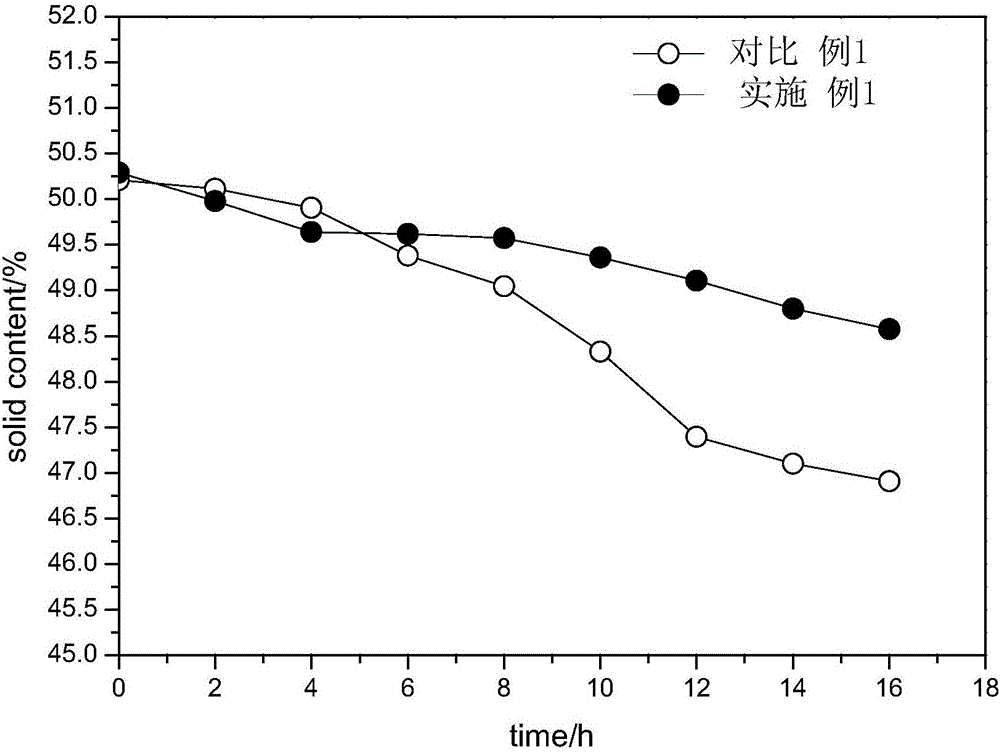

Self-compacting concrete prepared from iron ore tailings, and preparation method thereof

The present invention discloses a self-compacting concrete prepared from iron ore tailings, and a preparation method thereof. The self-compacting concrete is prepared through adding 38.00-46.00% of a coarse aggregate, 23.00-37.00% of a fine aggregate, cement, 15-24% of a cementing material and 0.30-0.48% of an additive to water. The coarse aggregate is prepared through mixing crushed stones with particle sizes of 5-20 mm. The fine aggregate is the mixed sands prepared from iron ore tailings and machine-made sands or natural sands, wherein the mixed sands meet the technical requirements of thesands in the region II, preferably that a mass ratio of the iron ore tailings to the machine-made sands or the natural sands is 3:7-7:3. The cementing material is a mixture, wherein the mixture comprises cement, fly ash and ground slag powder. A mass ratio of the water to the cementing material is 0.30-0.50. The additive is a mixture, wherein the mixture comprises a water reducing agent and a tackifier, the water reducing agent is a polycarboxylic superplasticizer, the tackifier comprises a cellulose polymer or an amide polymer. With the present invention, the damage to the ecology environment due to the natural sand mining is reduced; the damage to the environment due to the iron ore tailings is reduced; the waste can be utilized; a purpose of reutilization of the resource is achieved; with adopting the iron ore tailings, the concrete cost can be substantially reduced, and significant social benefits and economic benefits are provided.

Owner:CHINA MCC17 GRP

Rheology modifying systems and detersive compositions comprising same

Owner:THE PROCTER & GAMBLE COMPANY

Dry-powder film coating composition and method of preparation

InactiveUS6884288B2Component is expensiveLow costPowder deliveryOrganic active ingredientsPlasticizerGum acacia

An edible dry-powder formulation of a film coating for pharmaceuticals and confectioneries using gum acacia as a low-cost film former is provided. A cellulosic polymer such as hydroxypropyl methylcellulose is used in addition to the gum acacia. A plasticizer such as propylene glycol is also added. The resulting formulation is a dry, free flowing powder that can be put into solution and applied to a tablet or other substrate without an extended waiting period. The resulting film coating is clear, shiny, durable and extremely economical. Because the formulation is a dry powder, it has along shelf life and low shipping costs.

Owner:BPSI HLDG LLC

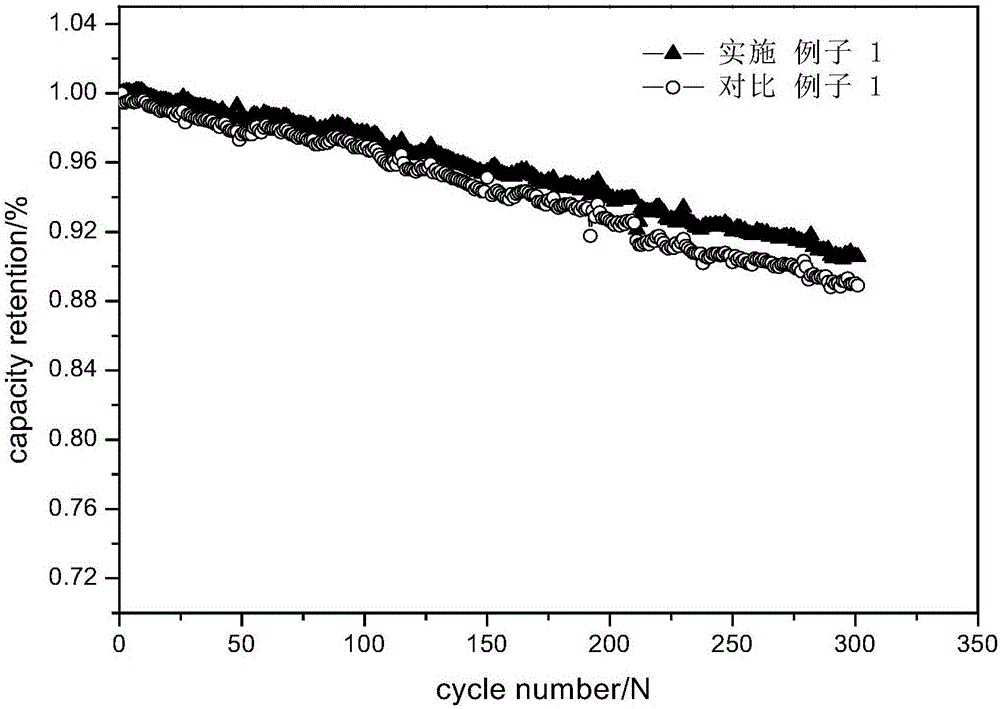

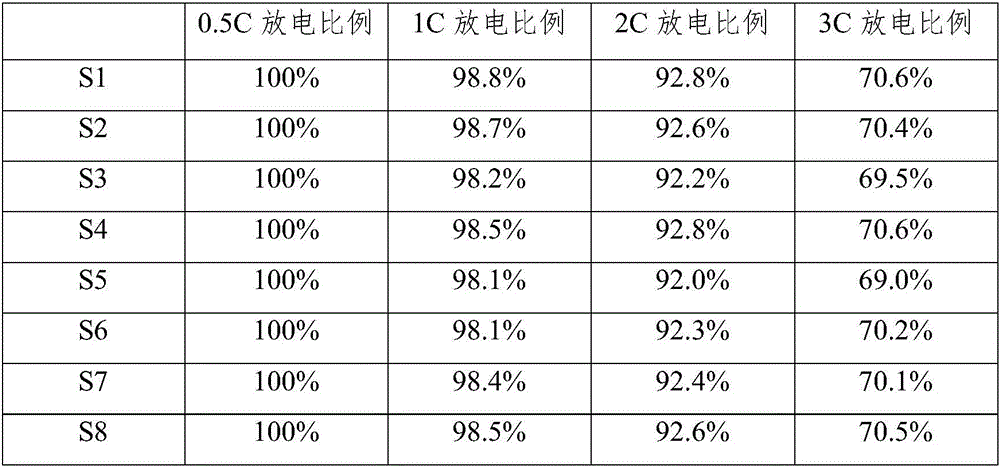

Lithium ion battery cathode composite cathode, preparation method thereof, and lithium ion battery

InactiveCN106374110AImprove performanceGood storage stabilityCell electrodesSecondary cells servicing/maintenanceAluminium-ion batteryAdhesive

In order to solve the problem that electrical properties of a lithium ion battery are influenced by insufficient dispersibility of the existing lithium ion battery cathode composite, the invention provides a lithium ion battery cathode composite. The lithium ion battery cathode composite comprises an active material, a first thickening agent, a second thickening agent and an adhesive, wherein lithium can be removed from or embedded into the active material; the first thickening agent is a non-ionic cellulose polymer, and the weight-average molecular weight of the first thickening agent is 0.1 to 300 thousand; the second thickening agent is sodium carboxymethyl cellulose or ammonium carboxymethyl cellulose, the weight-average molecular weight of the second thickening agent is 30 to 200 thousand, and the substitution degree is 0.6 to 1.5. Meanwhile, the invention also discloses a lithium ion battery cathode, a preparation method, and a lithium ion battery comprising the cathode. According to the lithium ion battery cathode composite, the dispersing effect of a cathode active material in slurry is improved, so that related electrical properties of the lithium ion battery are improved.

Owner:湖南三迅新能源科技有限公司 +1

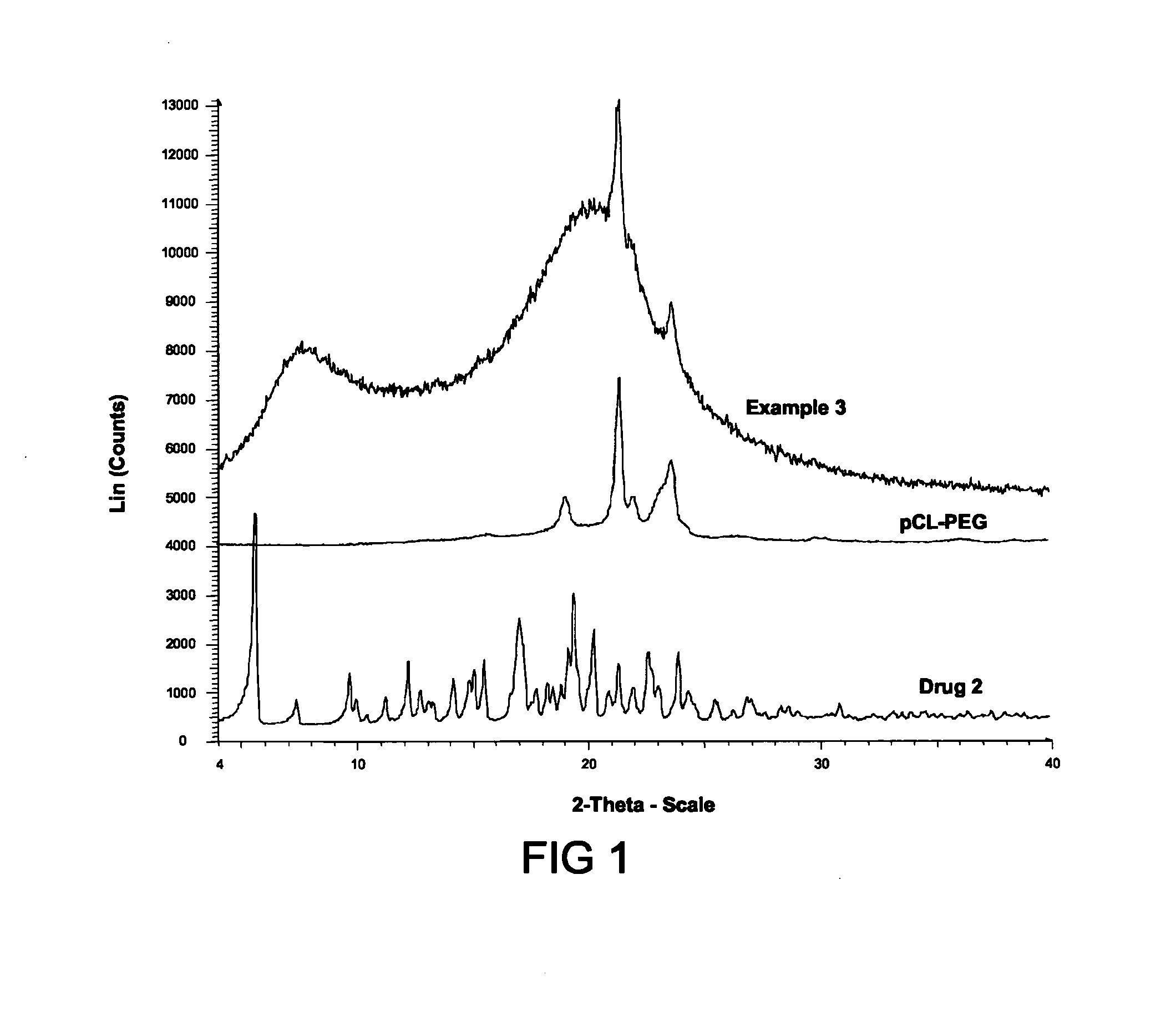

Nanoparticles comprising a non-ionizable cellulosic polymer and an amphiphilic non-ionizable block copolymer

InactiveUS20100323014A1Improve drug bioavailabilityImprove performanceBiocidePowder deliveryNanoparticleWater soluble

Owner:BEND RES

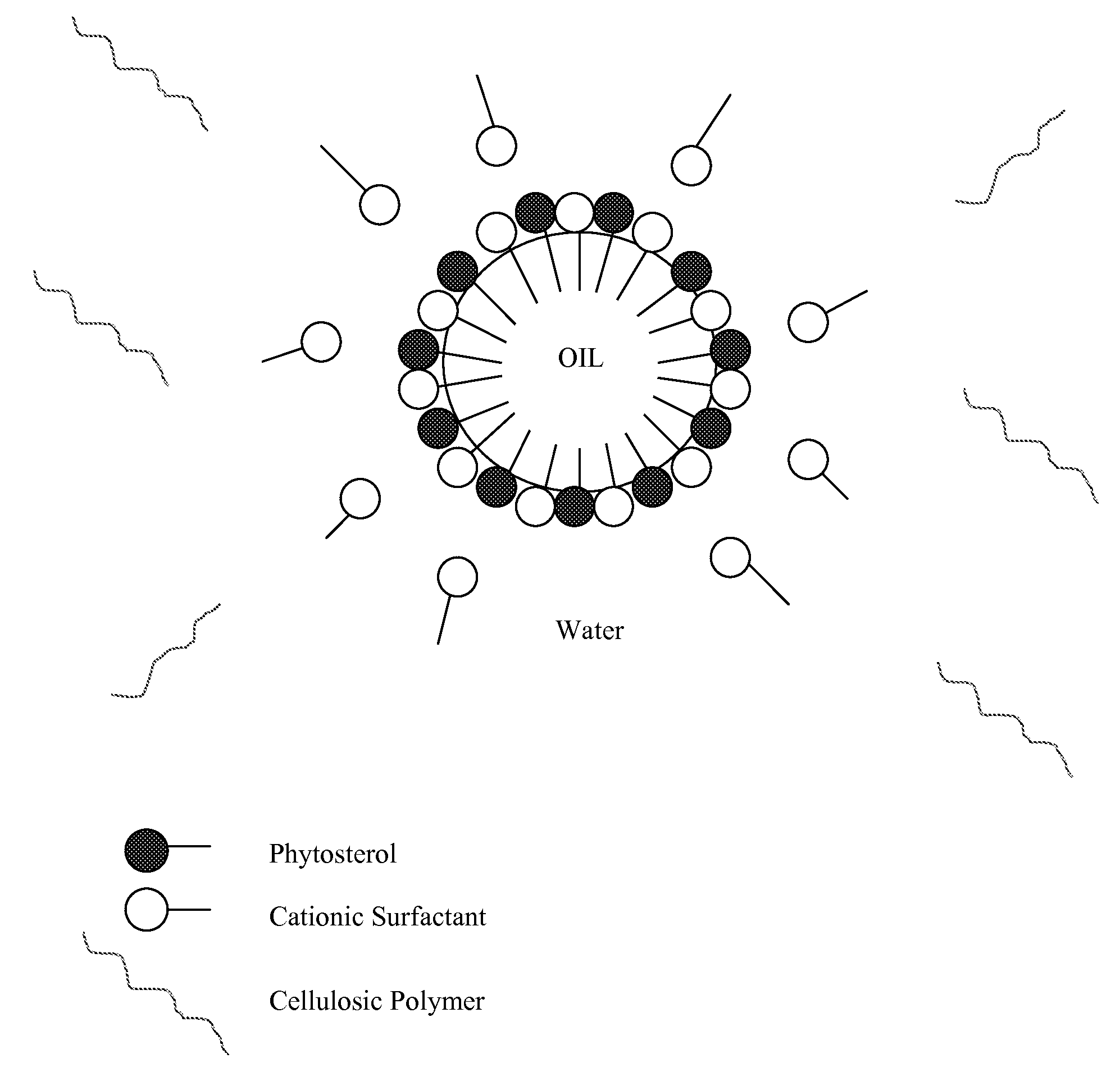

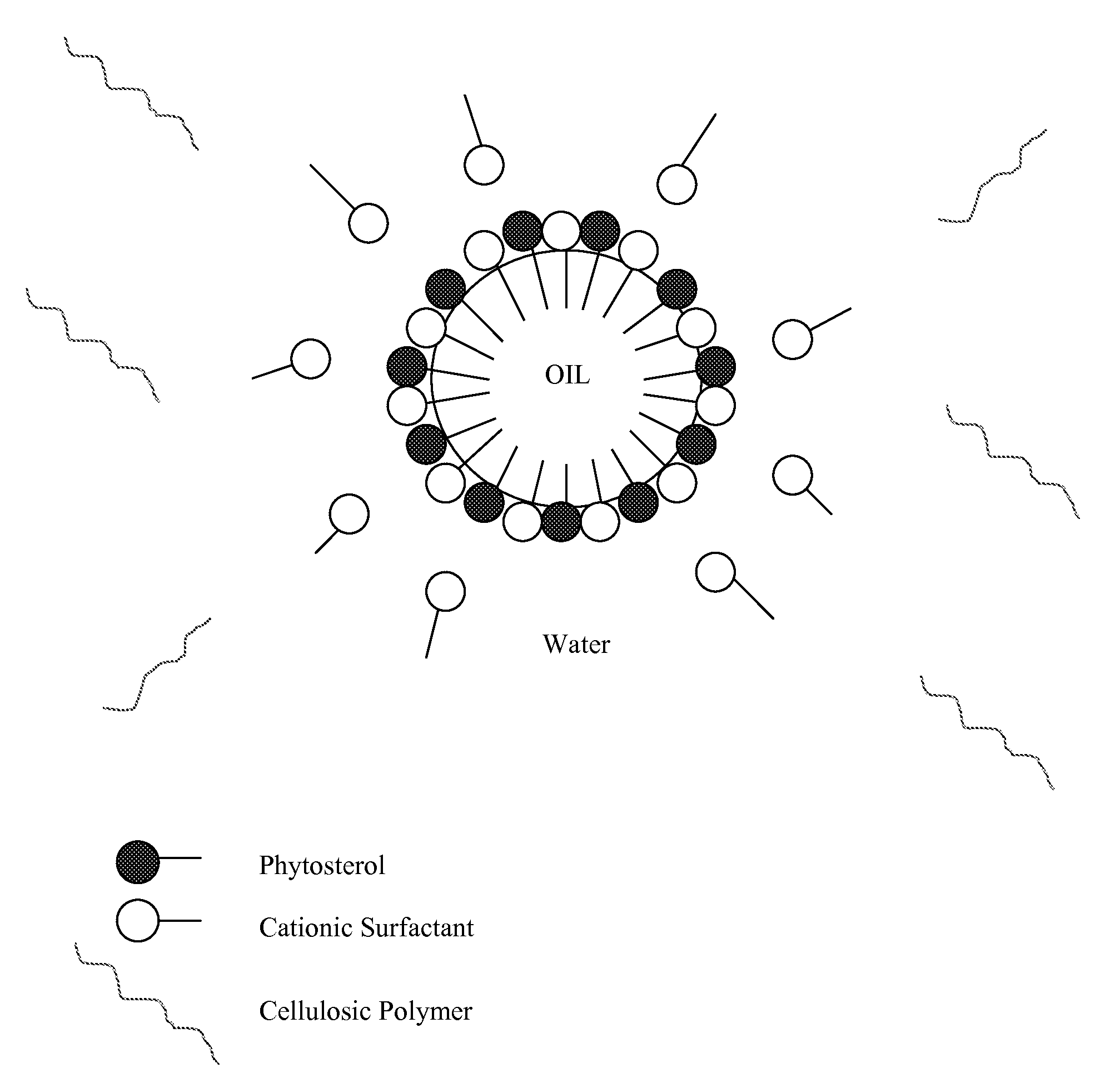

Continuous Moisturization Compositions

An aqueous hair moisturizing composition is provided. The composition includes a cationic component, an oil containing about 70 percent or greater unsaturated fatty acids with chain length of C18 or greater, a phytosterol and a cellulosic polymer. Also provided is a method of imparting extended moisturization to the hair including the steps of applying to the hair in need of extended moisturization a composition including a cationic component, an oil containing about 70 percent or greater unsaturated fatty acids with chain length of C18 or greater, a phytosterol and a cellulosic polymer, and retaining the composition in contact with the hair for a time sufficient to impart extended moisturization to the hair.

Owner:A VEDA CORPORATION

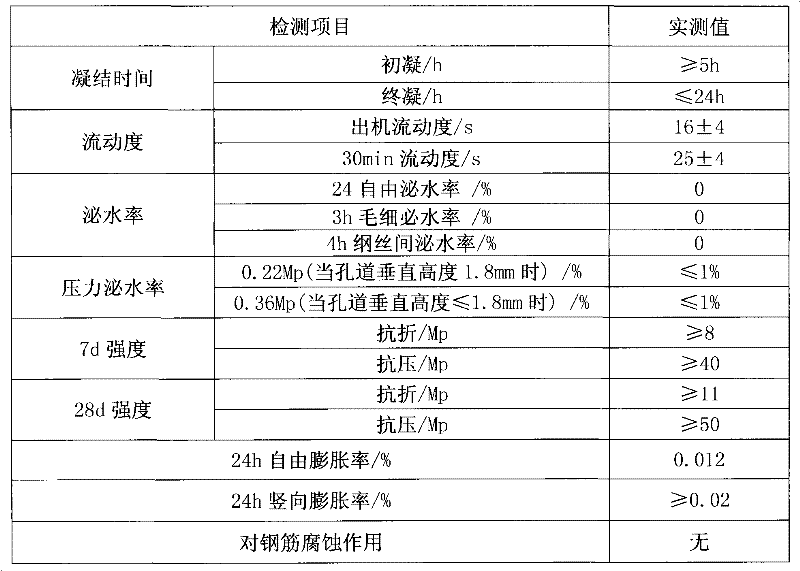

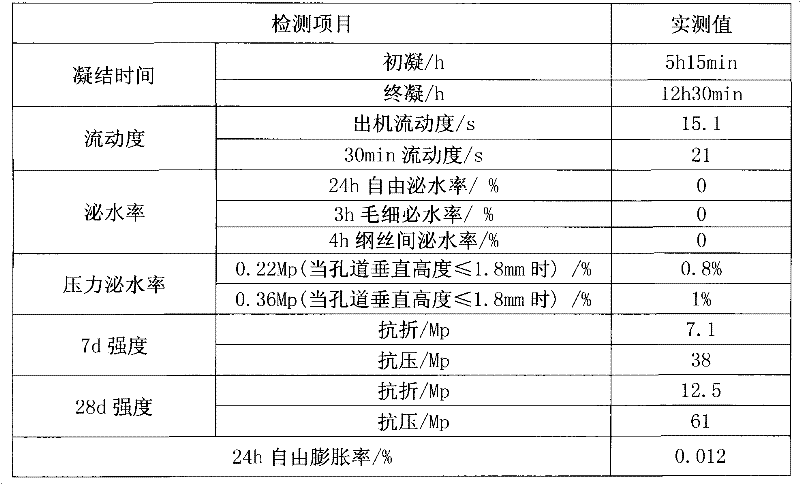

Grouting material, premix of grouting material, and preparation method of premix

The invention relates to a premix of a grouting material. The premix is characterized in that the premix comprises the following components, by weight, 65-90% of ordinary portland cement with the strength level of 42.5MPa or low alkaline cement with the strength level of greater than 42.5MPa, wherein the water demand for normal consistency is less than 25%, and the tricalcium aluminate content is lower than 8%; 2-29.696% of an ultrafine mineral admixture with a specific surface area of greater than 450m<2> / kg, a water demand ratio of less than 95%, and a 28d activity index of greater than 90%; 5-15% of calcium sulphoaluminate; 0.1-1.5% of a melamine water reducer; 0.002-0.2% of a cellulose polymer, an acrylic polymer or polyoxyethylene; 0.1-1.0% of a carbohydrate, a hydroxycarboxylic acid compound and salts thereof, a sulfate, a carbonate, or calcium formate; 0.002-0.1% of vinyl acetate-ethylene copolymerized rubber powder; and 0.1-1.0% of a chromate or a borate.

Owner:王小清

Compositions containing benefit agent delivery particles

The present disclosure relates to benefit agent delivery particles containing at least one benefit agent and at least one cellulosic polymer. The disclosure further relates to compositions containing benefit agent delivery particles and processes for making and using such compositions. The disclosure further relates to methods of imparting a benefit delivery capability to a cleaning composition.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com