Method for measuring microcellular plate-type membrane porosity

A measurement method and porosity technology, which is applied in the field of accurate determination of the porosity of membrane materials, can solve problems such as laborious, time-consuming, and large error in results, and achieve the effects of simple measurement equipment, accurate measurement values, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

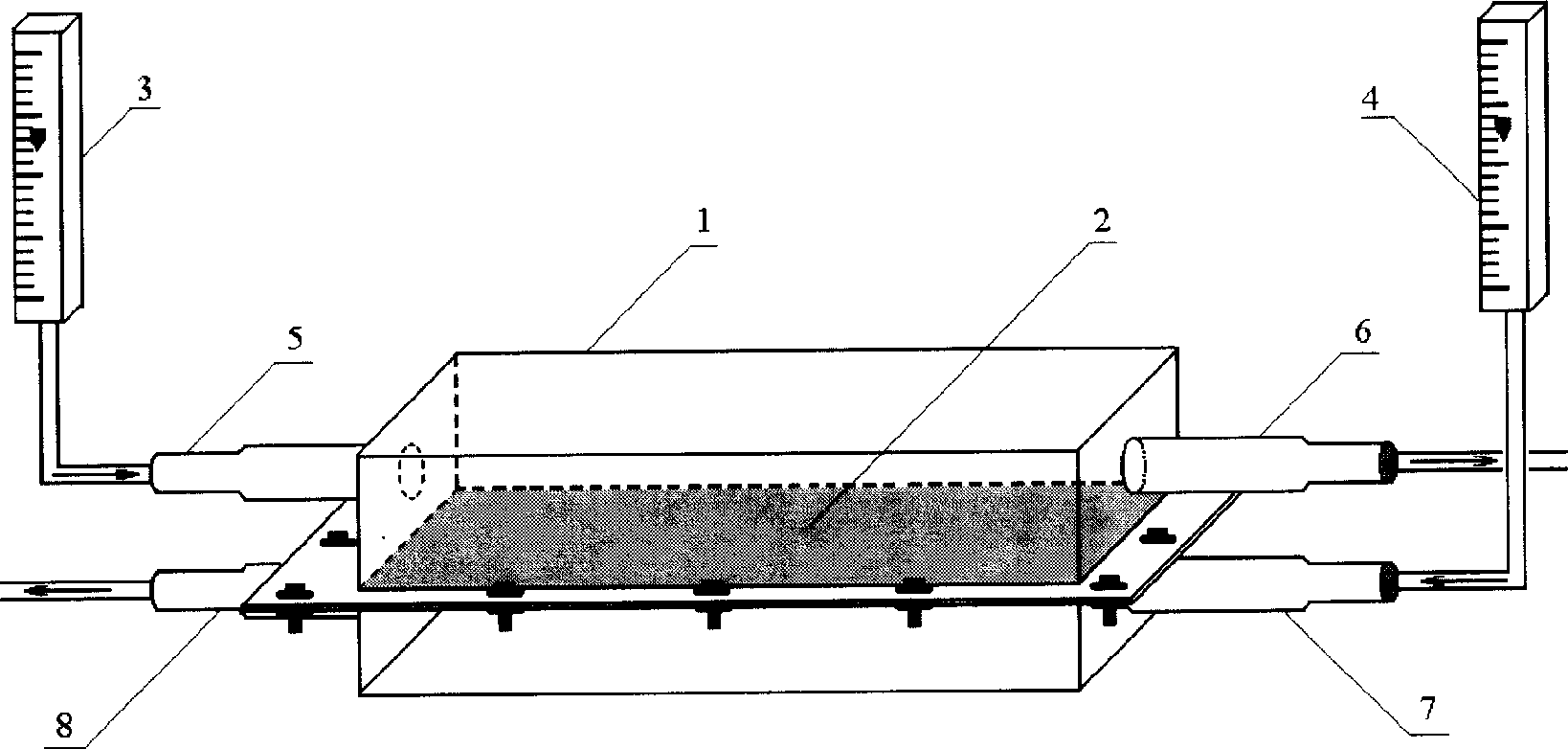

Method used

Image

Examples

Embodiment 1

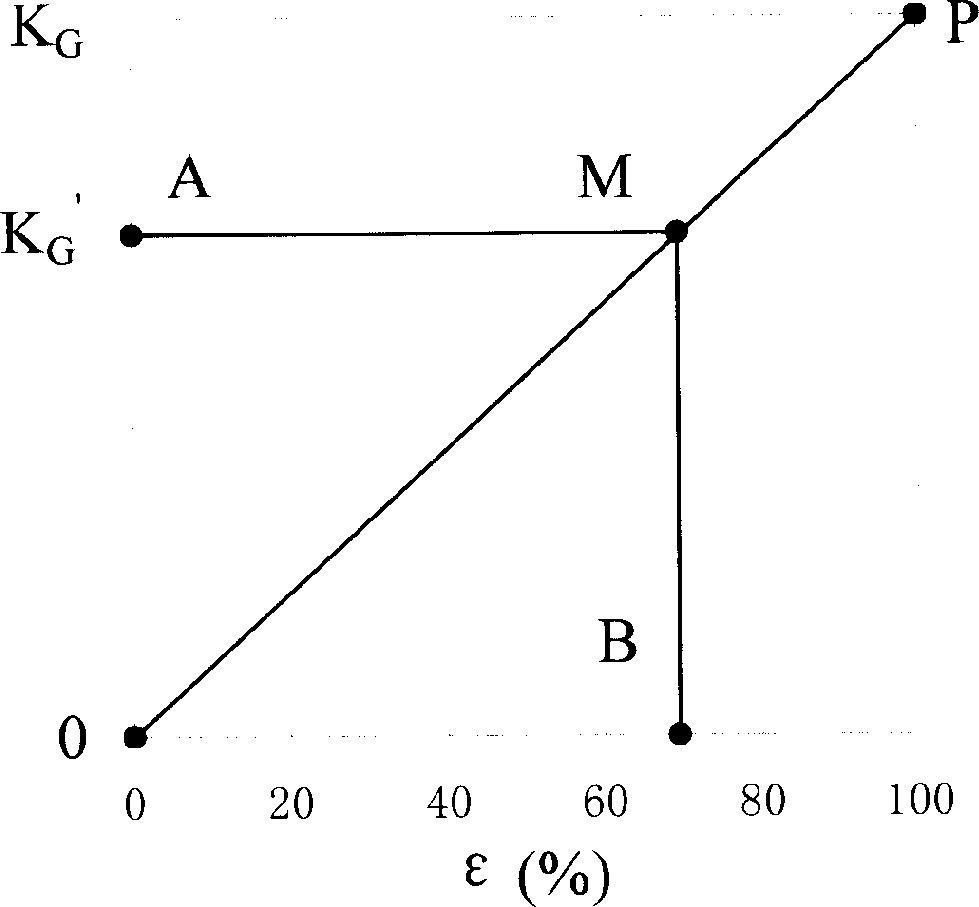

[0039] A. to SO 2 / Air mixed gas-clear water is the measurement test system, and the German sulfonated polyethersulfone flat membrane experiment membrane is selected, and its volume porosity is known to be 72.0%; SO 2 The flow rate of air / air mixture is 400L / h, the flow rate of clear water absorption liquid is 24L / h, when the two phases are in direct contact, the gas phase inlet and outlet concentrations measured by the pararosaniline method are: C g1 =126.86ppm, C g2 =98.04ppm, known SO 2 / Henry coefficient H of the air mixture-clean water system A =24.2, calculated by formula (1), (2), (3): K G =1.997×10 -3 , so as to obtain point P, and draw the linear relationship between the total mass transfer coefficient of the mass transfer system and the membrane porosity image 3 ;

[0040] B. After adding the side membrane, under the same experimental conditions as step A, measure SO according to the method of step 1 2 The inlet and outlet concentrations of / air mixture are C...

Embodiment 2

[0042] A. Change the experimental membrane to be tested into the polyacrylonitrile flat membrane of Zhejiang University Membrane Engineering Company. It is known that its volume porosity is 40.0%. Other conditions are the same as in Example 1, so its total mass transfer coefficient - membrane porosity The linear relationship diagram of the rate is also the same as that of Example 1 image 3 unanimous.

[0043] B. Add the side film to be treated, record the gas phase inlet and outlet concentrations by the method of embodiment 1 and be respectively: C g1 '=126.86ppm, C g2 '=111.01ppm, calculate K G '=0.843×10 -3 ,exist image 3 The M2 point is obtained, and its corresponding porosity value is 41.8%.

Embodiment 3

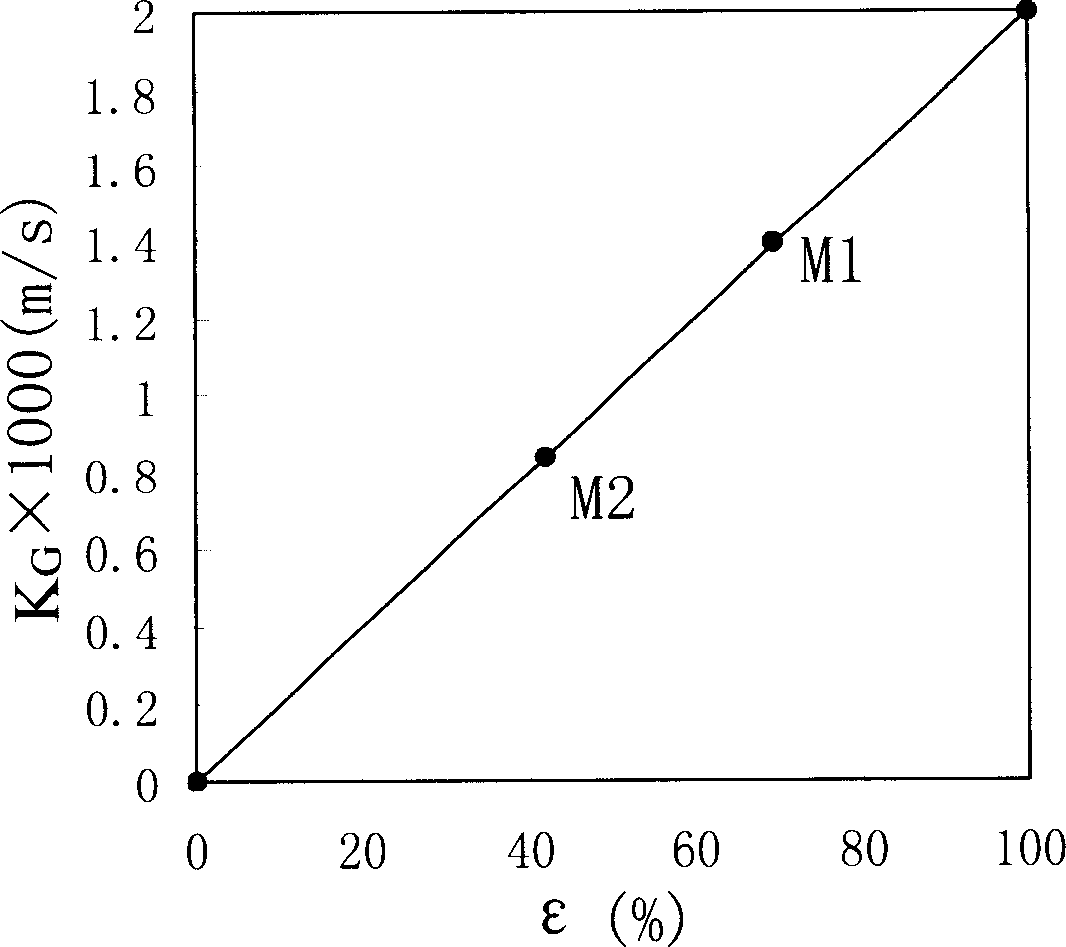

[0045] A. change the liquid phase flow velocity in embodiment 1 into 32L / h, other conditions are all unchanged, when two phases directly contact, record gas phase inlet and outlet concentration to be respectively: C g1 =126.86ppm, C g2 = 95.13 ppm. Calculate K G =2.276×10 -3 , from which the linear relationship between total mass transfer coefficient and membrane porosity is plotted Figure 4 .

[0046] B. After adding the side membrane, under the same experimental conditions as in step A, the gas phase inlet and outlet concentrations measured according to A are: C g1 '=126.86ppm, C g2 '=102.38ppm, K is calculated G '=1.592×10 -3 . According to K G ’ has a value of Figure 4 The M3 point can be determined in , and its corresponding porosity value is 70.3%. This value is in good agreement with the value of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com