Lithium battery polyimide diaphragm and preparation method thereof

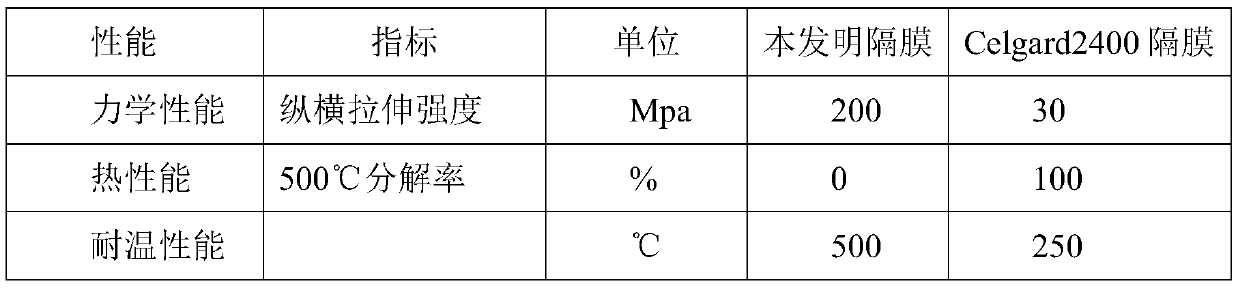

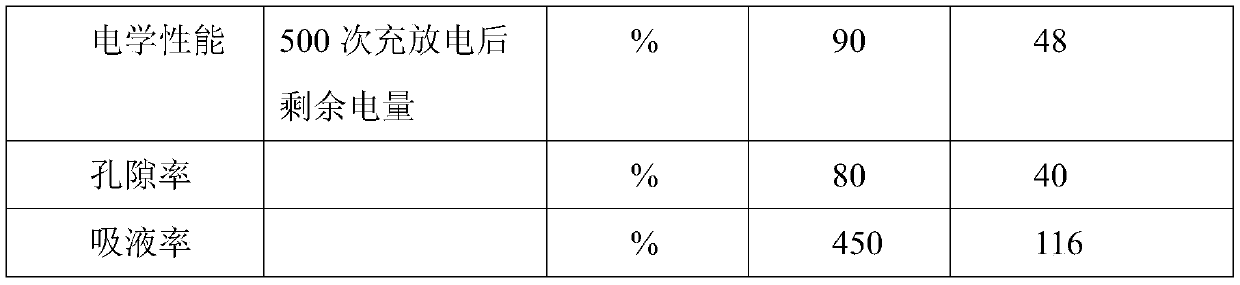

A polyimide and lithium battery technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of lithium battery leakage current, air pollution costs, etc., to improve mechanical strength and temperature resistance, reduce Production cost, effect of reducing tail gas treatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

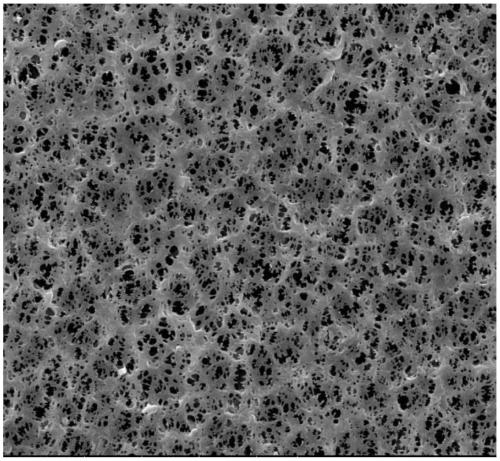

Image

Examples

Embodiment 1

[0033] (1) Preparation of polyamic acid: take 6g nano-sodium bicarbonate and add it to 200g N,N-dimethylacetamide, then take 20g of 4,4'-diaminodiphenyl ether and add it to the solvent, After the diamine was dissolved, 21.8 g of pyromellitic anhydride was added to the above solvent, stirred at 25° C. for 6 hours, and vacuum degassed to obtain a polyamic acid solution with a concentration of 40%. Pour an appropriate amount of polyamic acid solution after degassing on a clean glass plate, scrape the film with a scraper, stay in the air for 30s, and then slowly and uniformly immerse it in 50% ethanol aqueous solution at 25°C to form a film. After forming micropores for 30 minutes, peel off the porous base film with polyamic acid, soak it in deionized water for 30 minutes and take it out;

[0034] (2) Preparation of polyimide diaphragm: Take the above-mentioned porous base film with polyamic acid out of deionized water, program the temperature to imidize, raise the temperature to ...

Embodiment 2

[0038] (1) Preparation of polyamic acid: Weigh 8g of nano-sodium bicarbonate and add it to 200g N,N-dimethylacetamide, then weigh 10.8g of p-phenylenediamine and add it to the above solvent, after the diamine dissolves , 21.8 g of pyromellitic anhydride was added to the above solvent, stirred at 25° C. for 7 hours, and vacuum degassed to obtain a polyamic acid solution with a concentration of 45%. Pour an appropriate amount of polyamic acid solution after degassing on a clean glass plate, scrape the film with a scraper, stay in the air for 30s, and then slowly and uniformly immerse it in 50% ethanol aqueous solution at 25°C to form a film. After forming micropores for 30 minutes, peel off the porous base film with polyamic acid, soak it in deionized water for 30 minutes, and then take it out;

[0039] (2) Preparation of polyimide diaphragm: Take the above-mentioned porous base film with polyamic acid out of deionized water, program the temperature to imidize, raise the tempera...

Embodiment 3

[0042] (1) Preparation of polyamic acid: Weigh 10g of nano-sodium bicarbonate and add it to 200g N,N-dimethylacetamide, then weigh 10.8g of p-phenylenediamine and add it to the above solvent, after the diamine dissolves , 29.4g of biphenyltetracarboxylic dianhydride was added to the above solvent, stirred at 25°C for 8 hours, and vacuum degassed to obtain a polyamic acid solution with a concentration of 50%. Pour an appropriate amount of polyamic acid solution after degassing on a clean glass plate, scrape the film with a scraper, stay in the air for 30s, and then slowly and uniformly immerse it in 50% ethanol aqueous solution at 25°C to form a film. After forming micropores for 30 minutes, peel off the porous base film with polyamic acid, soak it in deionized water for 30 minutes, and then take it out;

[0043] (2) Preparation of polyimide diaphragm: Take the above-mentioned porous base membrane with polyamic acid out of deionized water, program the temperature to imidize, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com