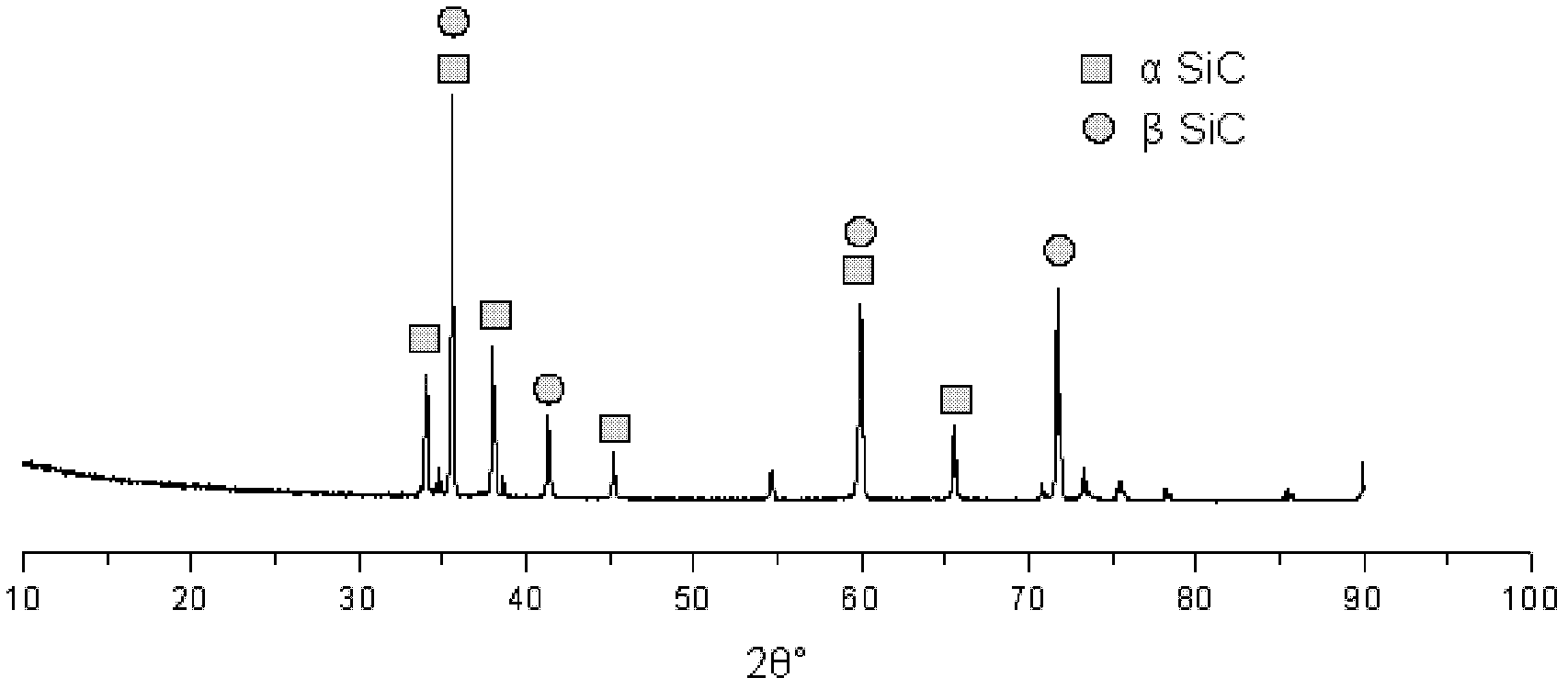

Pure silicon carbide filtering membrane and preparation method thereof

A technology for filtering membrane layer and silicon carbide membrane, which is applied in chemical instruments and methods, membrane technology, ceramic products, etc., can solve problems such as limiting the application process of silicon carbide filter materials, difficult pore structure for backflushing and cleaning, and filter damage and failure. , to achieve the effect of easy regeneration, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

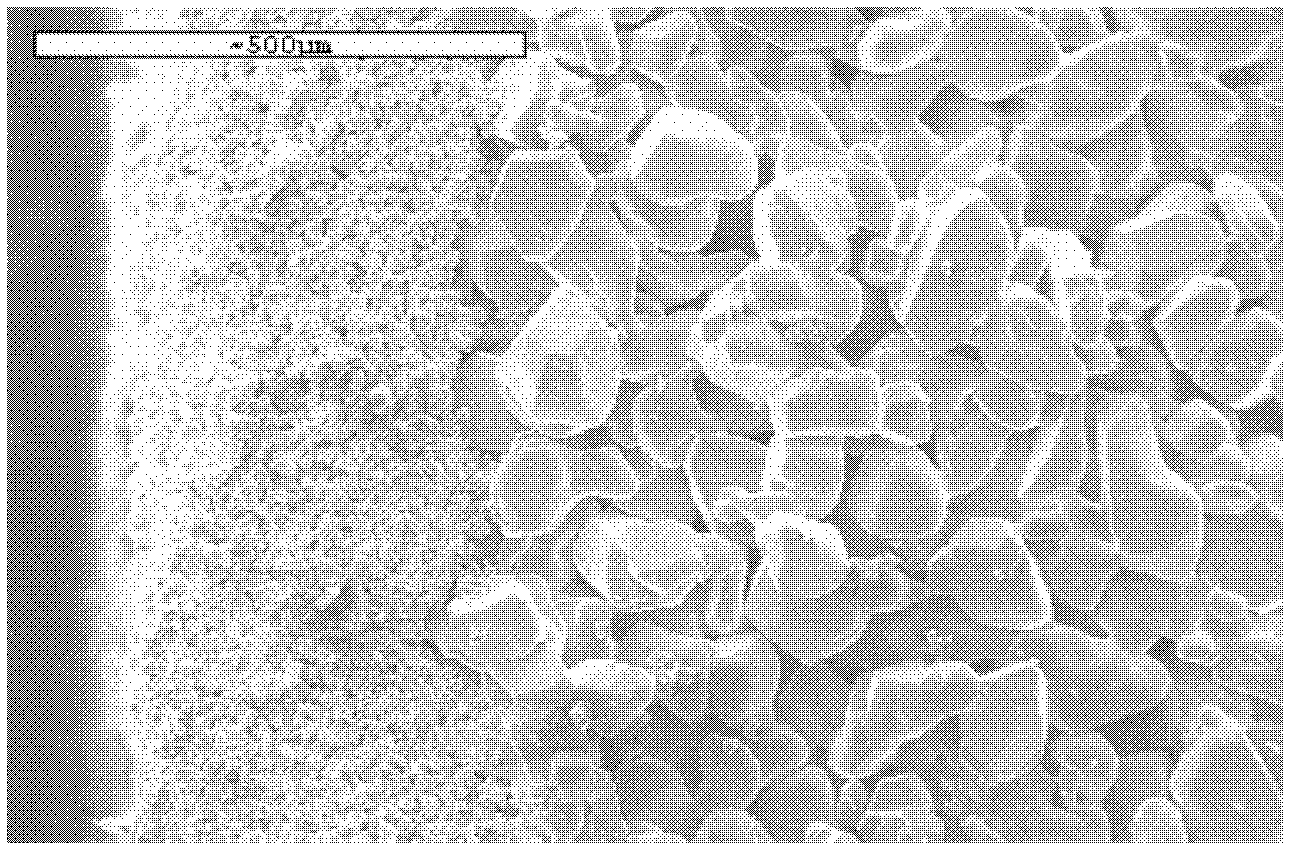

Examples

Embodiment 1

[0058] 300 μm silicon carbide particles, 5 μm silicon powder, phenolic resin, and p-toluenesulfonic acid were blended in ethanol at a mass percentage ratio of 80:20:15:1, and the ethanol content accounted for 20wt% of the total amount. After mechanical stirring, ball milled for 1.5 hour to obtain a slurry, and then dry and pulverize at 80° C. to obtain a raw material composite powder. Put the above composite powder in the isostatic pressing sheath, and use mechanical vibration during filling. The isostatic pressing sheath is designed to be 2000mm long, with an inner diameter of 40mm and an outer diameter of 60mm, and then put it into a cold isostatic press. The pressurized pressure is 150MPa, the pressure is maintained for 5 minutes, and then the jacket is removed to obtain a prefabricated support body.

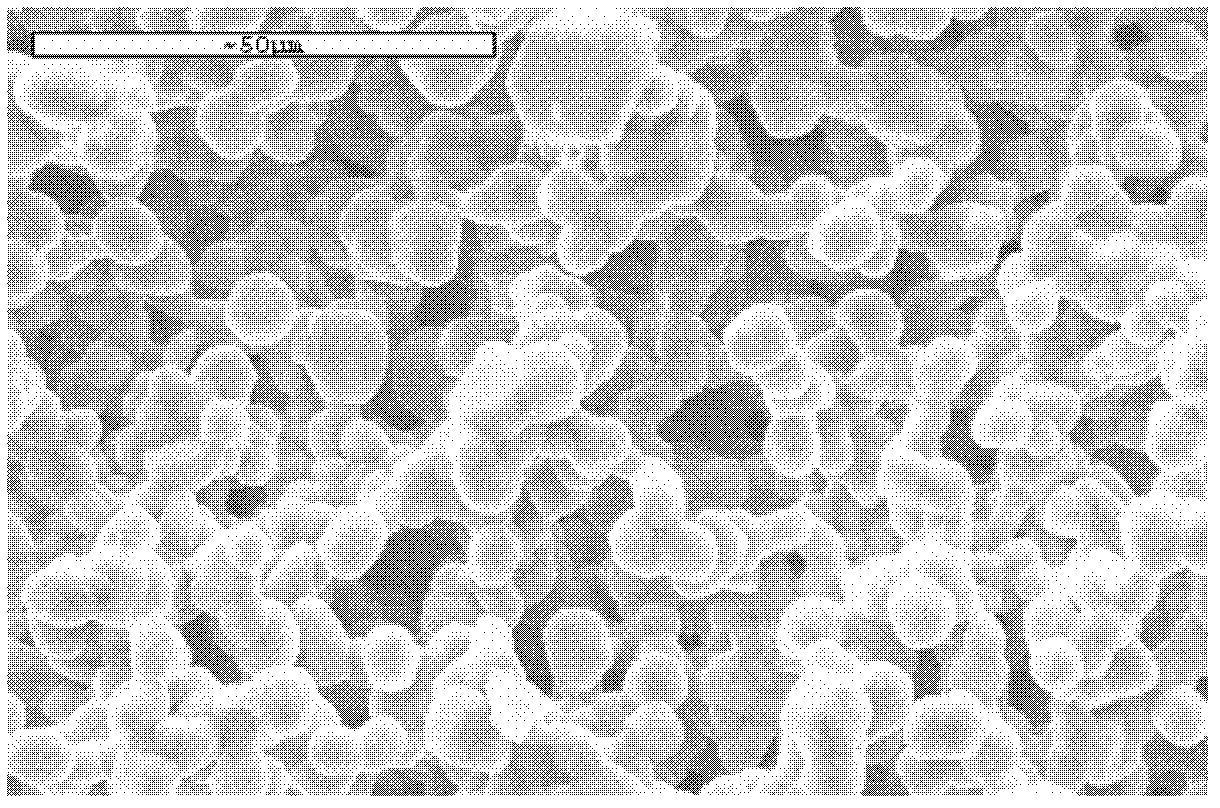

[0059] Blend 1.5 μm silicon carbide powder, 1.5 μm silicon powder, epoxy resin, cellulose, and p-toluenesulfonic acid in ethanol at a mass ratio of 70:15:20:10:2, and the eth...

Embodiment 2

[0066] The difference from Example 1 is:

[0067] Blend 25 μm silicon carbide particles, 10 μm silicon oxide powder, furfural resin, and p-toluenesulfonic acid in ethanol at a mass percentage ratio of 70:15:20:2. The ethanol content accounts for 30wt% of the total amount, and ball mill after mechanical stirring The slurry was obtained for 2 hours, and then dried and pulverized at 80° C. to obtain the raw material composite powder. Put the above-mentioned composite powder in the isostatic pressing sheath, and use mechanical vibration during the filling. The isostatic pressing sheath is designed to have a tube blank size of 1000mm long, 80mm inner diameter, and 100mm outer diameter, and then put it into the cold isostatic pressing machine. The pressurized pressure is 100 MPa, and the pressure is maintained for 12 minutes, and then the jacket is removed to obtain a prefabricated support body.

[0068] 0.5 μm silicon carbide powder, 0.5 μm silicon powder, phenolic resin, polyviny...

Embodiment 3

[0072] The difference from Example 1 is:

[0073] 25 μm silicon carbide particles, 5 μm silicon powder, furfural resin, and p-toluenesulfonic acid were blended in ethanol at a mass percentage ratio of 70:15:20:2, and the ethanol content accounted for 30wt% of the total amount, and ball milled for 2 hour to obtain a slurry, and then dry and pulverize at 80° C. to obtain a raw material composite powder. Put the above-mentioned composite powder in the isostatic pressing sheath, and use mechanical vibration during the filling. The isostatic pressing sheath is designed to have a tube blank size of 1000mm long, 20mm inner diameter, and 30mm outer diameter, and then put it into the cold isostatic pressing machine. The pressurized pressure is 100 MPa, and the pressure is maintained for 12 minutes, and then the jacket is removed to obtain a prefabricated support body.

[0074] 0.5 μm silicon carbide powder, 0.5 μm silicon powder, phenolic resin, polyvinyl alcohol, and oxalic acid were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com