Structure control method of outer surface of polypropylene separation membrane

A technology of structure control and polypropylene, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low membrane flux and dense skin on the outer surface of the membrane, and achieve simple methods, increased porosity, The effect of eliminating the possibility of large pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for controlling the structure of the outer surface of a polypropylene separation membrane, the specific steps are as follows:

[0041] (1) Add polypropylene and diluent in the spinning kettle with stirring device, the mass fraction of polypropylene is 25%, the melt index is 2.7g / 10min, with soybean oil as diluent, the mass fraction of diluent is 75% %, heated to 200°C, and stirred for 0.5h under the condition of nitrogen flow, and left to defoam for 0.5h after stopping the stirring to obtain the casting solution;

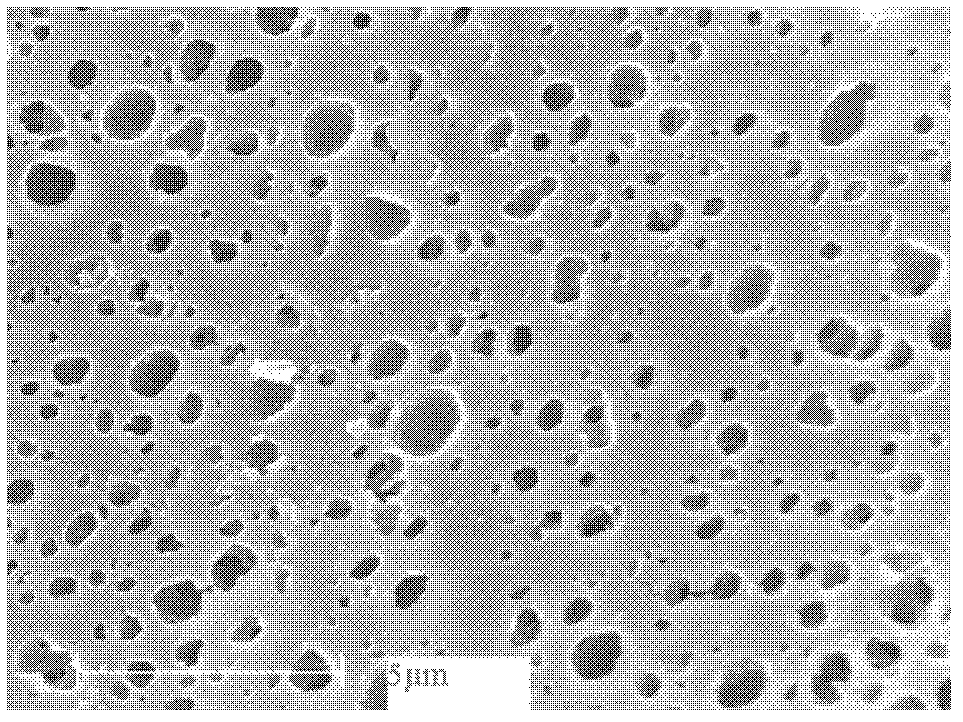

[0042] (2) The casting liquid is filtered through a stainless steel filter, and the casting liquid is transported to the spinneret by a gear-type metering pump, and nitrogen is used as the inner core liquid to introduce into the spinneret to form a hollow fiber. The temperature of the spinneret is 175°C ; Extrude the hollow fiber, first pass through an air gap of 1 cm, and then enter 100% soybean oil at 20°C for cooling and solidification.

[0043] (3...

Embodiment 2

[0046] A method for controlling the structure of the outer surface of a polypropylene separation membrane, the specific steps are as follows:

[0047] (1) Add polypropylene and diluent to the spinning kettle with a stirring device, the mass fraction of polypropylene is 40%, the melt index is 8g / 10min, dilute with the mixture of soybean oil and dioctyl phthalate agent, the mass fraction of dioctyl phthalate in the mixture is 10%, the mass fraction of the diluent is 60%, heated to 175°C, and stirred for 3h under the condition of nitrogen flow, after stopping the stirring, let stand for defoaming for 2h, and obtain Casting solution;

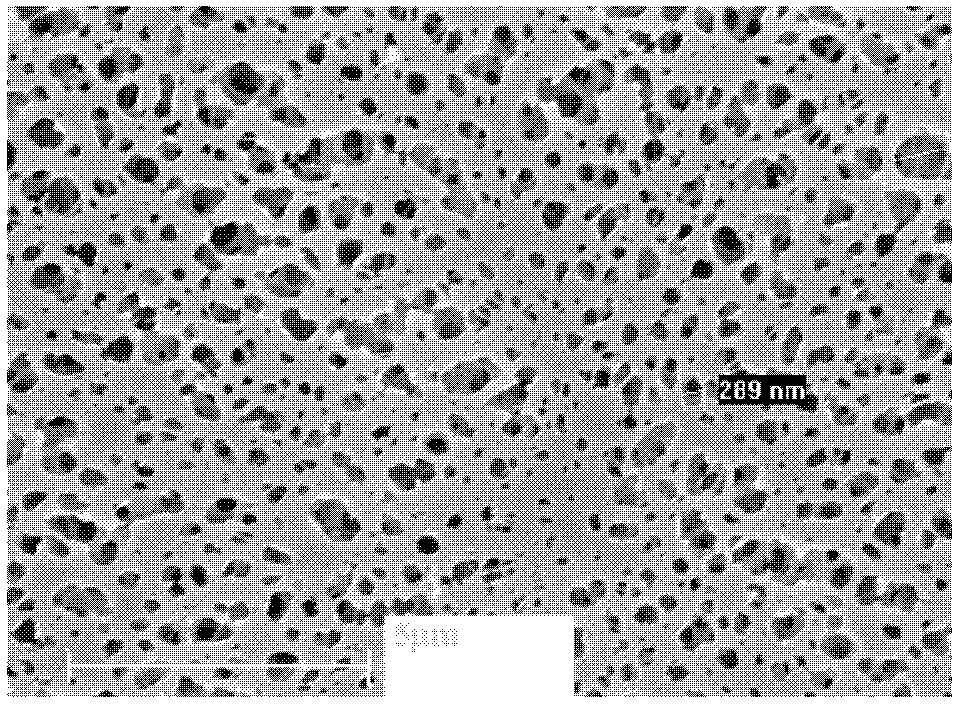

[0048] (2) The casting solution is filtered through a stainless steel filter, and the casting solution is transported to the spinneret by a gear-type metering pump, and nitrogen is used as the inner core liquid to introduce into the spinneret to form a hollow fiber. The temperature of the spinneret is 140°C ; The hollow fiber is extruded, first pas...

Embodiment 3

[0052] A method for controlling the structure of the outer surface of a polypropylene separation membrane, the specific steps are as follows:

[0053] (1) Add polypropylene resin and diluent in the spinning kettle with stirring device, the mass fraction of polypropylene resin is 27%, and the melt index is 3g / 10min, with the mixture of soybean oil and dibutyl phthalate As a diluent, the mass fraction of dibutyl phthalate in the mixture is 90%, the mass fraction of the diluent is 73%, heat to 180°C, and stir for 1h under the condition of nitrogen flow, stop stirring and stand for defoaming for 1h , to obtain the casting solution;

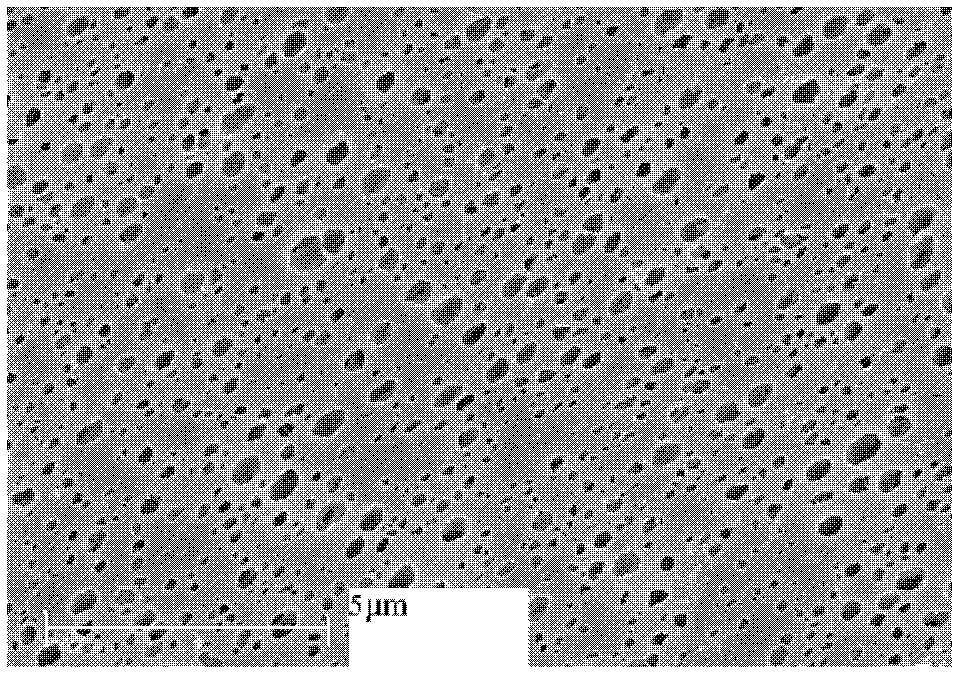

[0054] (2) After the casting solution is filtered by a stainless steel filter, the casting solution is transported to the spinneret by a gear-type metering pump, and nitrogen is introduced into the spinneret as the inner core liquid to form a hollow fiber. The temperature of the spinneret is 145 °C; the hollow fiber is extruded, first passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com