Method for regulating and controlling pore structure and surface property of silicon carbide film in one step

A technology for regulating silicon carbide film and surface properties, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems affecting efficiency, increase preparation process and preparation cycle, etc., achieve reduced preparation cost, high bending strength and pure water permeability, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method for regulating the pore structure and surface properties of the SiC film in this embodiment, the preparation steps are as follows:

[0033] Weigh 88% SiC particles with an average particle size of 5 μm and 12% NaA(r) with an average particle size of 2 μm according to the mass ratio, put them in a ball mill jar after preliminary mixing, and ball mill at a speed of 200 rpm 2h to obtain mixed powder A; use a 60-mesh metal mesh sieve to sieve the mixed powder A after ball milling to obtain uniform mixed powder B; The mass ratio is fully mixed with the mixed powder B to obtain the mixed powder C, and then pressed into a sheet-shaped green embryo under a molding pressure of 8MPa by a dry pressing method; The heating rate was raised from room temperature to 100°C, and then raised to 1000°C at a rate of 2°C / min, and kept for 2 hours, and finally the furnace temperature was naturally lowered to room temperature to obtain a SiC film.

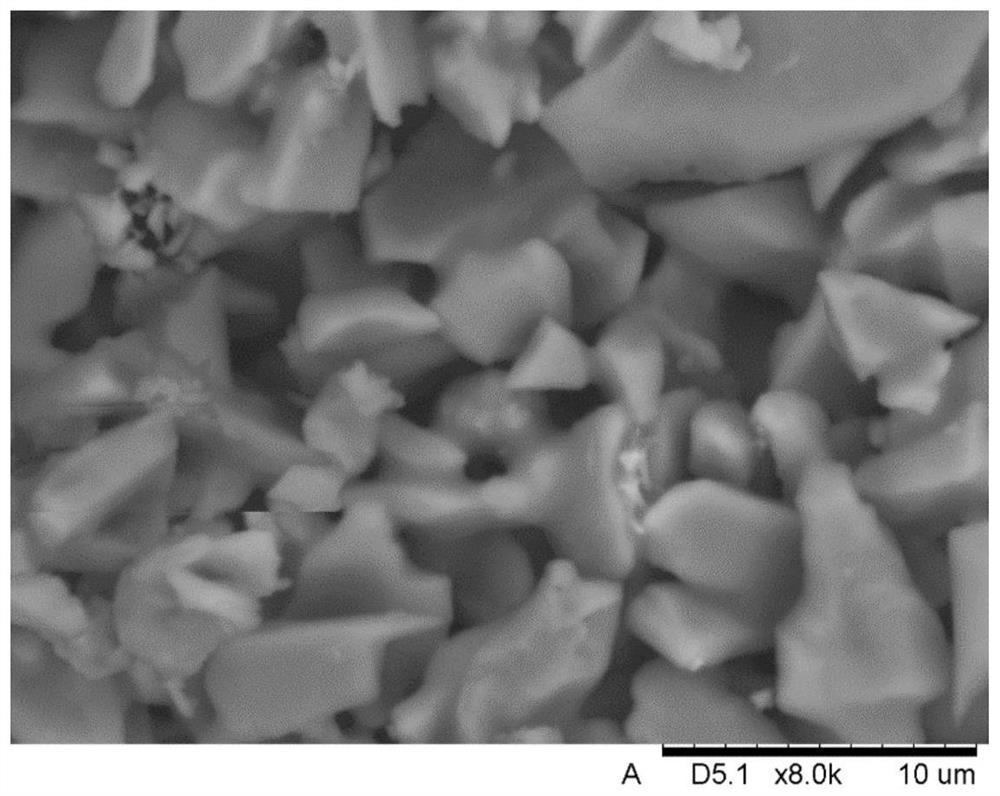

[0034] figure 1 It ...

Embodiment 2

[0036] Weigh 78% SiC (average particle size of 5 μm), 12% industrial grade water glass and 10% zirconia (average particle size of 1 μm) according to the mass ratio, put them in a ball mill jar after preliminary mixing, and grind at 350 rpm Milled at a speed of 1 minute for 2 hours to obtain mixed powder A; use a 100-mesh metal mesh sieve to sieve the mixed powder A after ball milling to obtain uniform mixed powder B; use a mortar to mix the PVA solution with a mass concentration of 15% Fully mixed with mixed powder B at a mass ratio of 0.03:1 to obtain mixed powder C, which was pressed into a sheet-shaped green embryo by dry pressing at a molding pressure of 8 MPa; the green embryo was placed in a precision high-temperature furnace to The heating rate was 0.5 ℃ / min from room temperature to 100 ℃, and then 2 ℃ / min to 600 ℃, and kept for 2 hours. Finally, the furnace temperature was naturally lowered to room temperature to obtain a porous SiC ceramic sheet membrane.

[0037]The ...

Embodiment 3

[0039] Weigh 78% SiC (average particle size 5 μm), 12% industrial grade water glass and 10% zirconia (average particle size 1 μm) according to the mass ratio and place them in a ball mill jar after preliminary mixing. Ball milling at a speed of 1 minute for 2 hours to obtain mixed powder A; use a 60-mesh metal mesh sieve to sieve the mixed powder A after ball milling to obtain uniform mixed powder B; use a mortar to mix the PVA solution with a mass concentration of 10% Fully mixed with mixed powder B at a mass ratio of 0.01:1 to obtain mixed powder C, which was pressed into a sheet-shaped green embryo by dry pressing at a molding pressure of 16 MPa; the green embryo was placed in a precision high-temperature furnace to The heating rate was raised from room temperature to 100 °C at a rate of 2 °C / min, and then raised to 1000 °C at a rate of 4 °C / min, and kept for 4 hours, and finally the furnace temperature was naturally lowered to room temperature to obtain a porous SiC ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com