Composite high-temperature-resistant cable bridge, and coating technology

A cable bridge and high temperature resistance technology, which is applied to the surface coating liquid device, coating, anti-corrosion coating, etc., can solve the problem of high heat dissipation performance and high temperature resistance performance of the bridge frame, easy damage to electrical equipment, and poor high temperature resistance performance To achieve the effect of ensuring corrosion resistance, reducing potential safety hazards, and improving acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

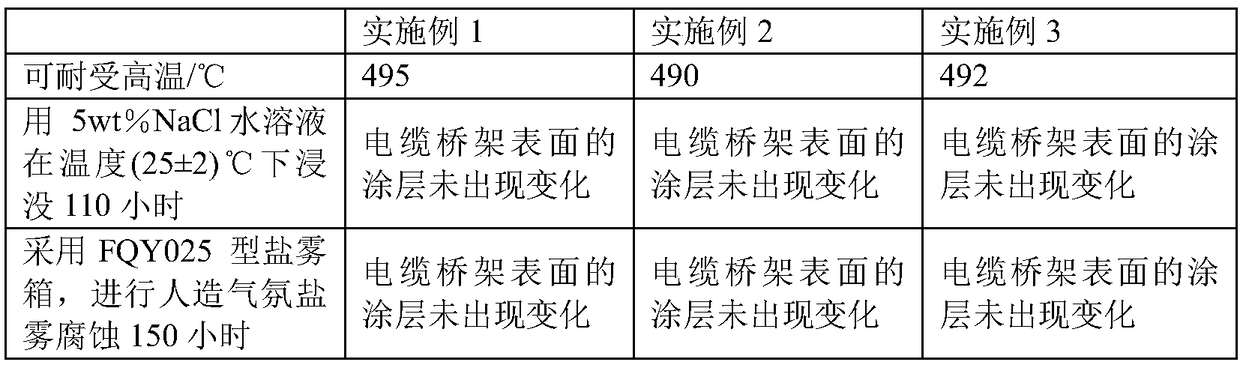

Embodiment 1

[0020] Embodiment 1: A composite type high temperature resistant cable bridge, including a bridge body, the outer surface of the bridge body is coated with a high temperature resistant layer on the inside, and an anti-corrosion layer on the outside, the anti-corrosion layer is coated with epoxy paint, the thickness 1-2mm, the high temperature resistant layer includes the following components by weight: 55 parts of polycarbosilane, 4 parts of glass fiber, 9 parts of isophthalic unsaturated polyester resin, 20 parts of acrylic resin, 13 parts of aluminum oxide , 12 parts of iron oxide, 10 parts of dioctyl phthalate, 5 parts of polyacrylamide, 3 parts of perlite, 2 parts of acetylene carbon black, 4 parts of sodium bicarbonate.

[0021] Among them, the preparation process of the high temperature resistant layer is as follows:

[0022] Add polycarbosilane and acrylic resin to the planetary ball mill together, add grinding balls according to the ratio of ball to material (2-5):1, t...

Embodiment 2

[0033]Example 2: A composite high temperature resistant cable tray, including a bridge body, the outer surface of the bridge body is coated with a high temperature resistant layer on the inside, and an anti-corrosion layer on the outside, the anti-corrosion layer is coated with epoxy paint, the thickness The high temperature resistant layer includes the following components by weight: 60 parts of polycarbosilane, 6.5 parts of glass fiber, 10 parts of isophthalic unsaturated polyester resin, 22.5 parts of acrylic resin, and 13.5 parts of aluminum oxide , 14 parts of iron oxide, 12.5 parts of dioctyl phthalate, 7 parts of polyacrylamide, 4 parts of perlite, 3 parts of acetylene carbon black, and 5.5 parts of sodium bicarbonate.

[0034] Among them, the preparation process of the high temperature resistant layer is as follows:

[0035] Add polycarbosilane and acrylic resin to the planetary ball mill together, add grinding balls according to the ratio of ball to material (2-5):1, ...

Embodiment 3

[0046] Example 3: A composite high temperature resistant cable bridge, including a bridge body, the outer surface of the bridge body is coated with a high temperature resistant layer on the inside, and an anti-corrosion layer on the outside, the anti-corrosion layer is coated with epoxy paint, the thickness The high temperature resistant layer includes the following components by weight: 65 parts of polycarbosilane, 9 parts of glass fiber, 11 parts of isophthalic unsaturated polyester resin, 25 parts of acrylic resin, and 14 parts of aluminum oxide , 16 parts of iron oxide, 15 parts of dioctyl phthalate, 9 parts of polyacrylamide, 5 parts of perlite, 4 parts of acetylene carbon black, 7 parts of sodium bicarbonate.

[0047] Among them, the preparation process of the high temperature resistant layer is as follows:

[0048] Add polycarbosilane and acrylic resin to the planetary ball mill together, add grinding balls according to the ratio of ball to material (2-5):1, then add di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com