High-temperature Fabry-Perot (FP) composite micro/nano fiber temperature and pressure sensor

A technology of temperature sensor and pressure sensor, applied in thermometers, thermometers with physical/chemical changes, fluid pressure measurement using optical methods, etc., can solve the problems of double-parameter cross-sensitivity, low temperature resistance limit, etc., to improve high temperature resistance Extreme, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

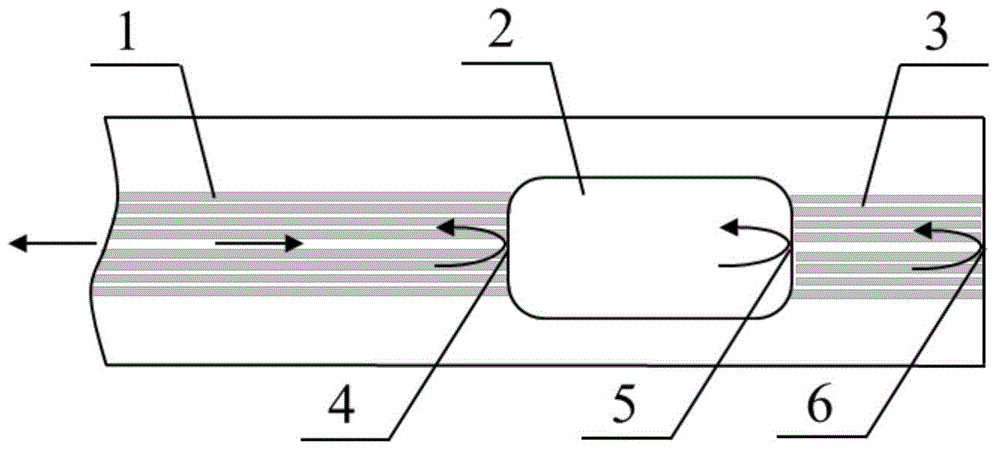

[0026] A kind of high temperature temperature and pressure optical fiber Fabry Perot composite micro-nano sensor of the present invention, its structure is as follows figure 1 As shown, it includes fiber access section 1, pressure sensor section 2, and temperature sensor section 3, which are connected in sequence, and is made of an endless single-mode photonic crystal fiber; fiber access section 1 is used to continuously introduce broadband optical signals into high-temperature environments The multifunctional sensor in the sensor will feed back the modulated signal; the pressure sensor section 2 is used to modulate the optical signal under high temperature and pressure, and the temperature sensor section 3 is used to modulate the optical signal under high temperature;

[0027] processing method:

[0028] Take two sections of uncut single-mode photonic crystal fiber of appropriate length, and use laser to process a cylindrical microcavity along the axis on one end face of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com