High-fluidity samarium-iron-nitrogen flexible bonded permanent magnet for injection molding and preparation method thereof

A technology of bonding permanent magnets and high fluidity. It is applied in the fields of magnetic objects, inductors/transformers/magnets, magnetic materials, etc. It can solve the problems of unfavorable devices, not clearly pointed out, and restrict the use environment, and achieve the upper limit of use temperature. , the effect of broadening the field of use, increasing stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides a high-fluidity samarium-iron-nitrogen flexible bonded permanent magnet for injection molding, which includes the following preparation components: 90-94 parts by weight of samarium-iron-nitrogen magnetic powder, 3-5 parts by weight of rubber binder, and conforms to ROHS2.0 2-3 parts by weight of standard plasticizer, 0.5-1 part by weight of heat stabilizer and 0.5-1 part by weight of lubricant, wherein the samarium iron nitrogen magnetic powder is commercially available isotropic or anisotropic magnetic powder.

[0032] The above-mentioned bonded permanent magnet requires high fluidity and heat resistance. The rubber-based binder component is a blend system composed of chlorinated polyethylene, polyvinyl chloride, and thermoplastic polyurethane elastomer. The components are as follows: 5-15 parts by weight of polyethylene, 40-45 parts by weight of polyvinyl chloride and 45-50 parts by weight of thermoplastic polyurethane elastomer. Among them, the...

Embodiment 2

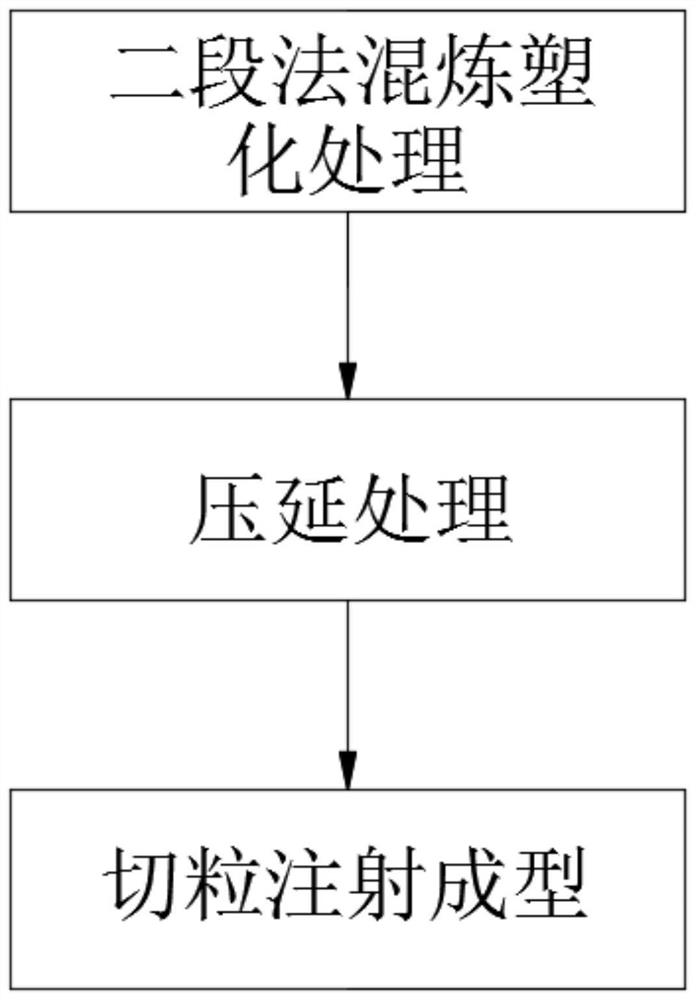

[0041] This implementation case provides a method for preparing a high-fluidity samarium-iron-nitrogen flexible bonded permanent magnet for injection molding. The steps are as follows:

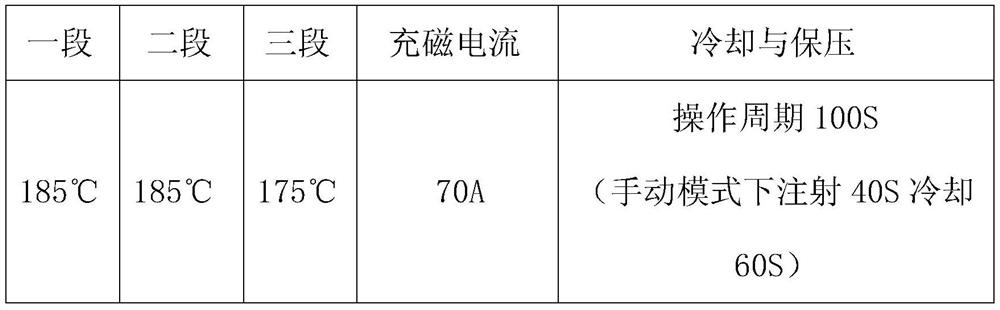

[0042] In terms of mass fractions, first 94 parts by weight of samarium-iron-nitrogen magnetic powder, 3 parts by weight of rubber binder (mass percentage of its composition is: 5 parts by weight of chlorinated polyethylene, 45 parts by weight of polyvinyl chloride and thermoplastic 50 parts by weight of polyurethane elastomer), 2 parts by weight of plasticizer meeting the ROHS2.0 standard (the mass percentage of its composition is: 85 parts by weight of modified citrate plasticizer and 15 parts by weight of epoxy soybean oil), heat 0.5 parts by weight of stabilizer (mass percentage of its composition is: 75 parts by weight of calcium zinc stabilizer, 25 parts by weight of magnesium oxide), 0.5 parts by weight of lubricant (mass percentage of its composition is: modified ethylene bis fatty acid...

Embodiment 3

[0048] This implementation case provides a preparation method of a high-fluidity samarium-iron-nitrogen flexible bonded permanent magnet for injection molding. The preparation method is as follows:

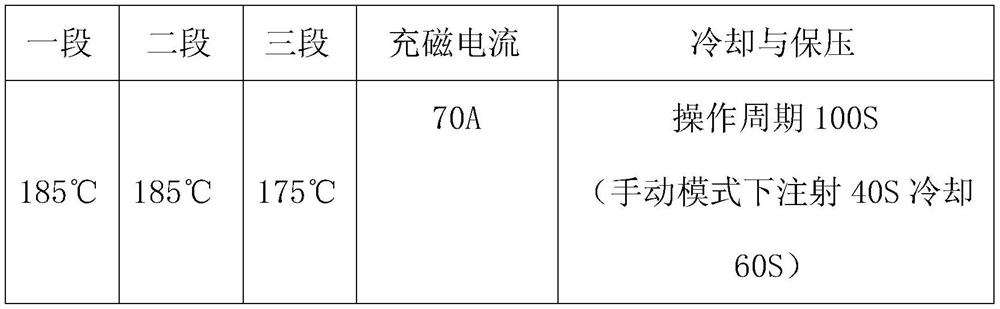

[0049] In terms of mass fractions, first 92 parts by weight of samarium-iron-nitrogen magnetic powder, 4 parts by weight of rubber binder (mass percentage of its composition is: 10 parts by weight of chlorinated polyethylene, 43 parts by weight of polyvinyl chloride and thermoplastic 47 parts by weight of polyurethane elastomer), 2.5 parts by weight of plasticizer meeting the ROHS2.0 standard (the mass percentage of its composition is: 75 parts by weight of modified citrate plasticizer and 25 parts by weight of epoxy soybean oil), heat 0.75 parts by weight of stabilizer (mass percentage of its composition is: 70 parts by weight of calcium zinc stabilizer, 30 parts by weight of magnesium oxide), 0.75 parts by weight of lubricant (mass percentage of its composition is: 30 parts by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com