A preparation method of modified barium titanate material, battery diaphragm and lithium ion battery

A barium titanate and modified technology, applied in secondary batteries, battery pack parts, secondary battery repair/maintenance, etc., can solve problems such as functional monomer limitations, improve electrochemical performance, improve powder removal, The effect of high liquid retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

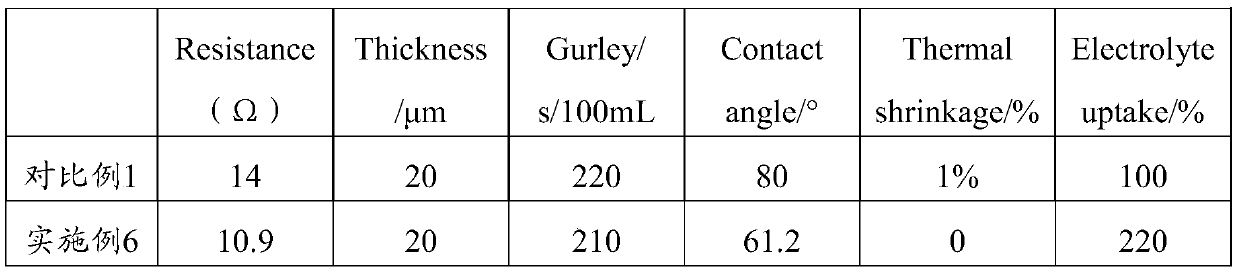

Examples

Embodiment 1

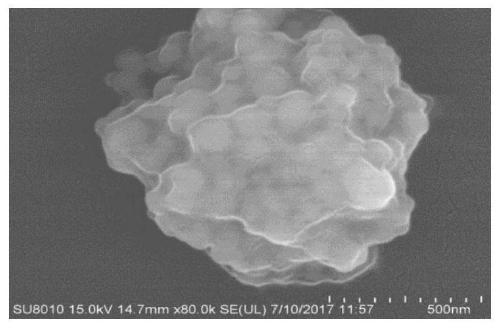

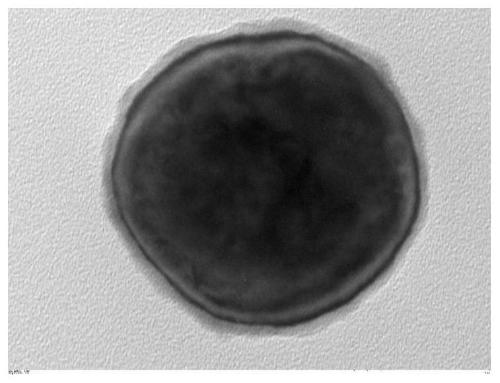

[0034] 1. Preparation of modified barium titanate powder

[0035] a) adding barium titanate particles (particle size: 50nm) and hexachlorocyclotriphosphazene into the reaction solvent acetonitrile at a mass ratio of 1:1, and ultrasonically dispersed for 2 hours to obtain the first mixed solution;

[0036] b) Then, add the monomer 1,4-butanediol and the catalyst triethylamine, stir the reaction at 25°C for 4h, filter, wash the solid product alternately with deionized water and acetone, and dry it by blowing at 80°C to obtain a solid powder .

[0037] Wherein, the reaction molar ratio of hexachlorocyclotriphosphazene, 1,4-butanediol and triethylamine is 1:3:6.

[0038] 2. Preparation of coating slurry

[0039] Add the solid powder to the first solvent and stir. Wherein, the mixing mass ratio of the solid powder and the first solvent is 1:5, and the first solvent is deionized water. In other embodiments, the first solvent may also be acetone or ethanol, or two or three of wat...

Embodiment 2

[0043] 1. Preparation of modified barium titanate powder

[0044] a) adding barium titanate particles (particle size: 1 μm) and hexachlorocyclotriphosphazene into the reaction solvent acetonitrile at a mass ratio of 1:1, and ultrasonically dispersed for 2 hours to obtain the first mixed solution;

[0045] b) Then, add the monomer 1,4-butanediol and the catalyst triethylamine, stir the reaction at 25°C for 4h, filter, wash the solid product alternately with deionized water and acetone, and dry it by blowing at 80°C to obtain a solid powder .

[0046] Wherein, the reaction molar ratio of hexachlorocyclotriphosphazene, 1,4-butanediol and triethylamine is 1:3:6.

[0047] 2. Preparation of coating slurry

[0048] Add the solid powder to the first solvent and stir. Wherein, the mixing mass ratio of the solid powder and the first solvent is 1:5, and the first solvent is deionized water.

[0049] 3. Assemble the lithium-ion battery

Embodiment 3

[0052] 1. Preparation of modified barium titanate powder

[0053] a) adding barium titanate particles (particle size: 50nm) and hexachlorocyclotriphosphazene into the reaction solvent acetonitrile at a mass ratio of 1:1, and ultrasonically dispersed for 2 hours to obtain the first mixed solution;

[0054] b) Then, add the monomer 1,4-butanediol and the catalyst triethylamine, stir the reaction at 25°C for 4h, filter, wash the solid product alternately with deionized water and acetone, and dry it by blowing at 80°C to obtain a solid powder .

[0055] Wherein, the reaction molar ratio of hexachlorocyclotriphosphazene, 1,4-butanediol and triethylamine is 1:6:6.

[0056] 2. Preparation of coating slurry

[0057] Add the solid powder to the first solvent and stir. Wherein, the mixing mass ratio of the solid powder and the first solvent is 1:5, and the first solvent is deionized water.

[0058] 3. Assemble the lithium-ion battery

[0059] The coating slurry is evenly coated on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com