MOCVD epitaxy processing method of AlInGaN quaternary alloy thin-film material

A technology for quaternary alloys and thin film materials, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of AlInGaN quaternary alloy material growth and preparation difficulties, lattice matching offset, and different bond lengths and bond energies. , to achieve the effect of improving migration ability and metal element incorporation efficiency, highly matching lattice constant, and uniform distribution of metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Production equipment and materials:

[0016] 1. Metal organic chemical vapor deposition MOCVD satellite disk 2-inch 11-chip preparation system.

[0017] 2. Metal-organic MO growth source: trimethylgallium (TMGa), trimethylaluminum (TMAl), and trimethylindium (TMln1, TMln2) are respectively used as sources of gallium, aluminum, and indium in the quaternary alloy AlInGaN material.

[0018] 3. Ammonia (NH 3 ), as a nitrogen source.

[0019] 4. MO source intake auxiliary gas path.

[0020] The MO growth source, ammonia gas and auxiliary gas path are input into the MOCVD reaction chamber through independent pipelines and independent systems.

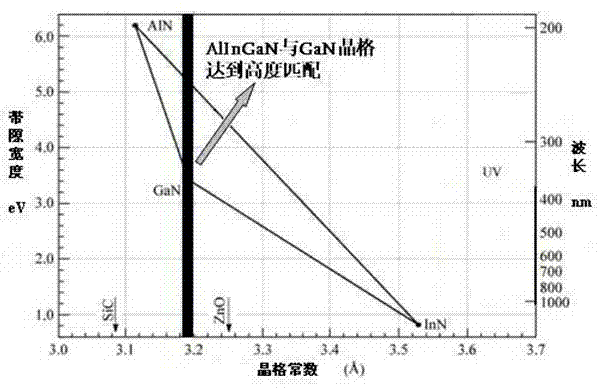

[0021] By adjusting the process parameters such as MOCVD MO source flow, growth temperature, and pressure, the MOCVD MO source flow setting meets: TMA / TMI=4.66, which achieves a high degree of matching with the in-plane lattice constant of the GaN material.

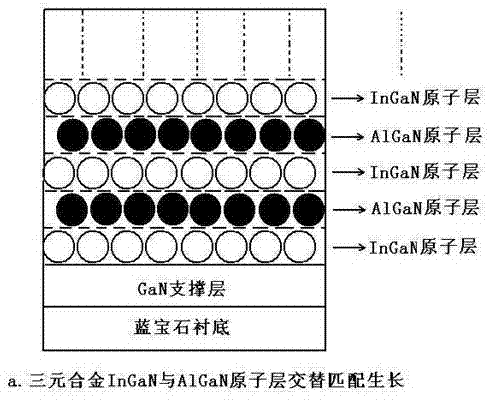

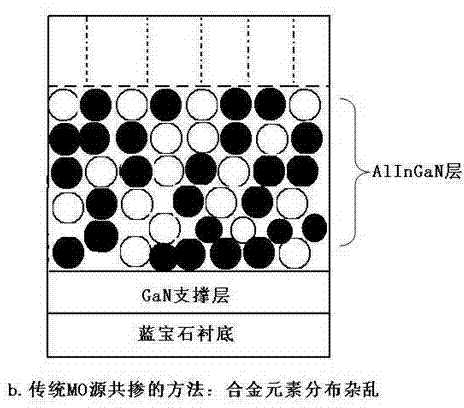

[0022] Such as figure 1 As shown, by adjusting the MO source flow rate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com