Silicon-modified hyperbranched polyurethane and preparation method thereof

A technology of hyperbranched polyurethane and silicon modification, which is applied in the field of polymer materials, can solve the problems of limited application scope and field, poor heat resistance of water-based hyperbranched polyurethane, etc., and achieve the reduction of raw material types and dosage, mild reaction conditions and low temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

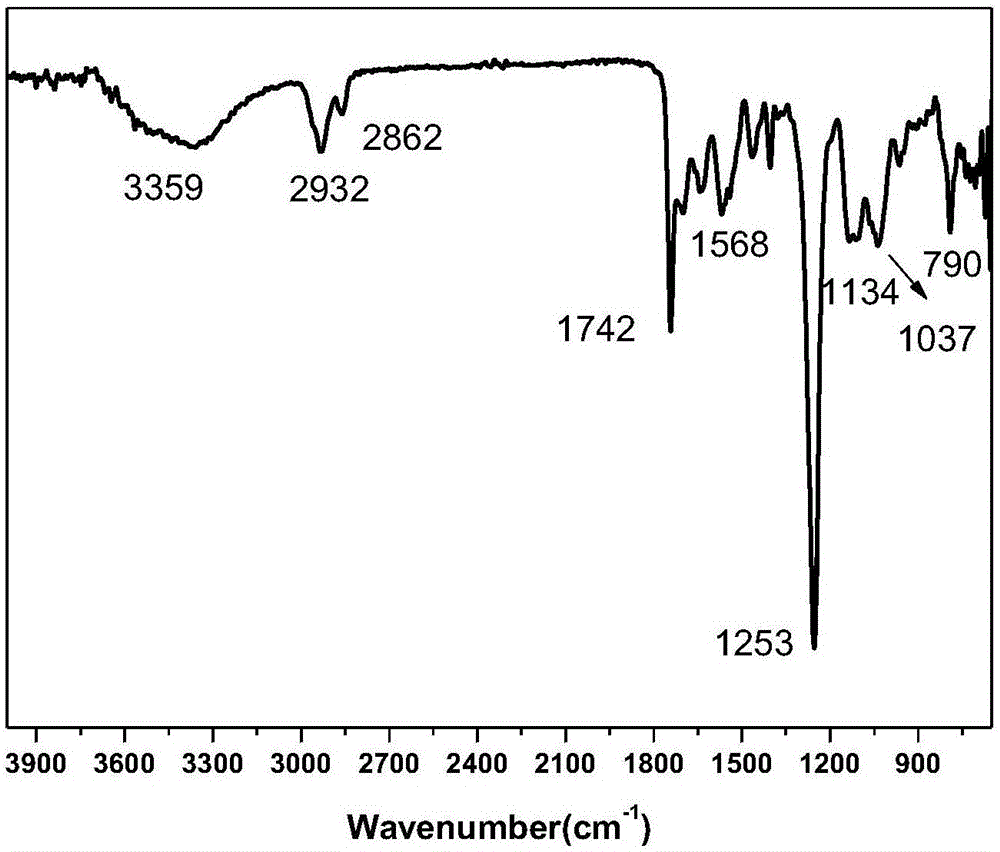

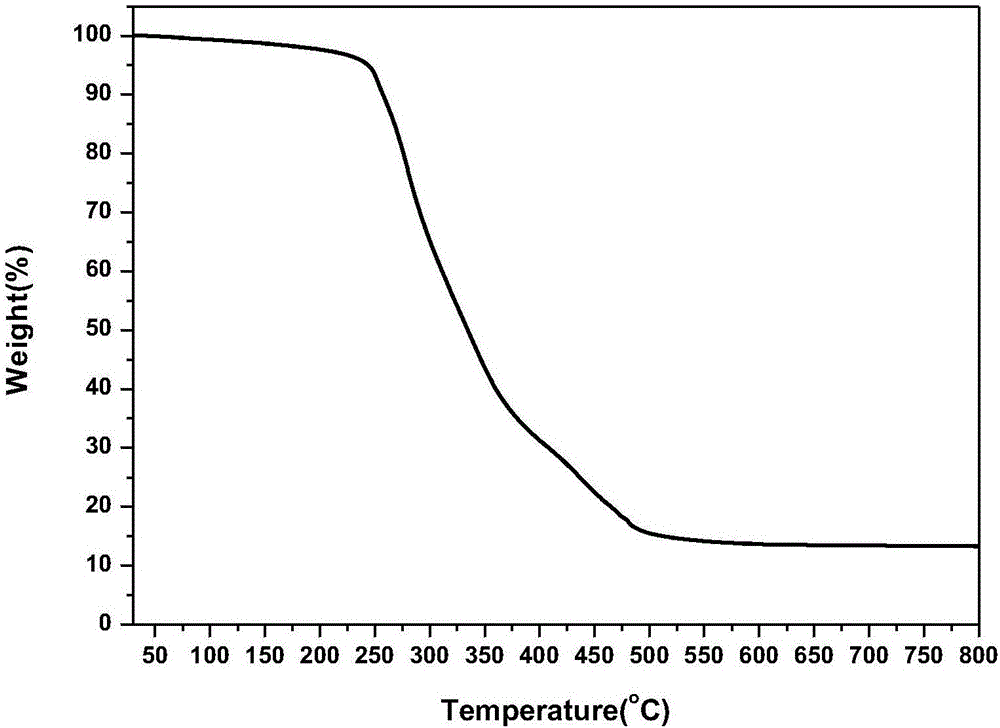

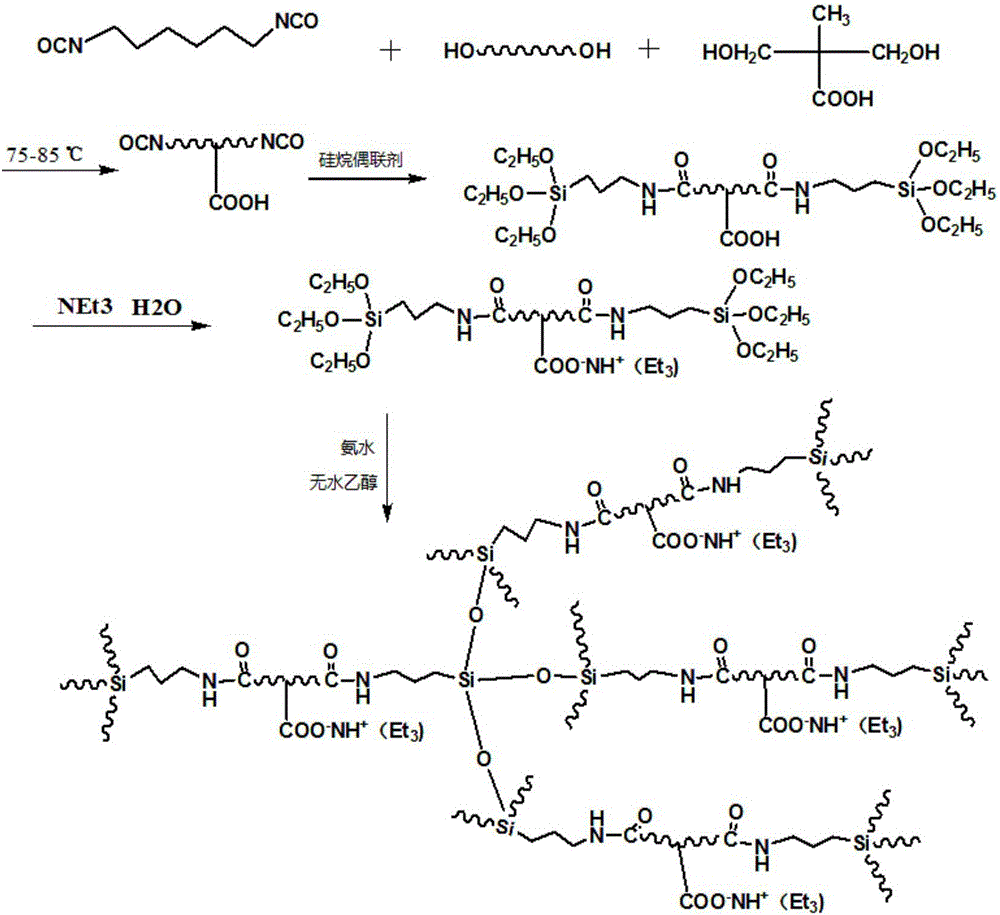

[0020] A silicon modified hyperbranched polyurethane, its preparation method is as follows:

[0021] In a 250mL four-necked flask, add 0.006mol (6g) of polycarbonate diol (PCDL-1000, indicating a molecular weight of 1000), 0.004mol (0.5365g) of dimethylolpropionic acid (DMPA), 10mL of N-formaldehyde pyrrolidone (NMP) and 50mL of acetone, then raise the temperature to 80°C and under the protection of nitrogen, add 0.015mol (2.0183g) hexamethylene diisocyanate (HDI), and add 0.0008mol (0.5g) of catalyst di Dibutyltin laurate (DBTDL), under these conditions, react for 3 hours to generate a linear polyurethane with isocyanate as the terminal group, then add 0.1mol (2.2137g) KH-550, and continue the reaction for 3 hours to obtain To linear polyurethane with terminal group, add 0.004mol (0.4046g) triethylamine and 100mL deionized water, and remove acetone by rotary evaporation at room temperature and vacuum degree of -0.095MPa to obtain a siloxane group as terminal group Finally, a...

Embodiment 2

[0023] A silicon modified hyperbranched polyurethane, its preparation method is as follows:

[0024] In a 250mL four-neck flask, add 0.0052mol (10.4g) of polycarbonate diol (PCDL-2000), 0.004mol (0.5365g) of dimethylolpropionic acid (DMPA), 10mL of N-methylpyrrolidone (NMP ) and 40mL of acetone, then raise the temperature to 75°C and under nitrogen protection, add 0.012mol (1.6146g) hexamethylene diisocyanate (HDI), and add 0.0007mol (0.4375g) of catalyst dibutyltin dilaurate (DBTDL), under this condition, react for 3 hours to generate a linear polyurethane with isocyanate as the terminal group, then add 0.008mol (1.7710g) KH-550, and continue the reaction for 3 hours to obtain a siloxane group as the terminal group. For linear polyurethane, add 0.004mol (0.4046g) triethylamine and 150mL deionized water, and at room temperature and vacuum degree of -0.095MPa, remove acetone by rotary evaporation to obtain linear polyurethane with siloxane groups as end groups. Finally, 125mL ...

Embodiment 3

[0026] A silicon modified hyperbranched polyurethane, its preparation method is as follows:

[0027] In a 250mL four-neck flask, add 0.0064mol (3.2g) of polycarbonate diol (PCDL-500), 0.004mol (0.5365g) of dimethylolpropionic acid (DMPA), 10mL of N-methylpyrrolidone (NMP ) and 30mL of acetone, then raise the temperature to 85°C and under nitrogen protection, add 0.020mol (2.6911g) of hexamethylene diisocyanate (HDI), and add 0.0008mol (0.5g) of catalyst dibutyltin dilaurate (DBTDL), under this condition, react for 3 hours to generate a linear polyurethane with isocyanate as the terminal group, then add 0.012mol (2.1515g) KH-551, and continue the reaction for 3 hours to obtain a siloxane group as the terminal group. For linear polyurethane, add 0.004mol (0.4046g) triethylamine and 200mL deionized water, and at room temperature and vacuum degree of -0.095MPa, remove acetone by rotary evaporation to obtain linear polyurethane with siloxane groups as end groups. Finally, add 150m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com